- For this week we had to Propose or discuss about out final project and answer a few questions related to it.

For my final project page & documentaion , click here.

- My final project is a 3D printer filament maker.

Questions to be answered.

What will it do? Whos done what beforehand? What will you design? What materials and components will be used? Where will come from? How much will they cost? What parts and systems will be made? What processes will be used? What questions need to be answered? How will it be evaluated?

Also it was mentioned that the project should incorporate 2D and 3Ddesign, additive and subtractive fabrication processes, electronics design and production, microcontroller interfacing and programming, system integration and packaging

What will it do?

- My final project will Extrude/make filament for 3D printers from pellets fed into it. It will be a desktop filament maker which would act as an aid to your 3D printer.

- Initially I planned to make filament from PET bottle strips but do to time constrained i’ve now chosen the more conventional path.

- To extrude we need to heat up the barrel/hotend to a certain degree which is closed (more &less)to the melting point of the material to be extruded. The heat from shear is more important than the heat from the heatin lelements or barrel. The material being pushed forward makes contact with the walls of the barreland the shear forces with frictions helps tomelt the material.

- The middle section of the barrel should have slightly more temp than the end section near the nozzle. the section near the nozzle should have temp equal to the melting point of the material.

- It should be able to produce filaments form raw Pelletes or failed 3d prints which are broken into small granules.

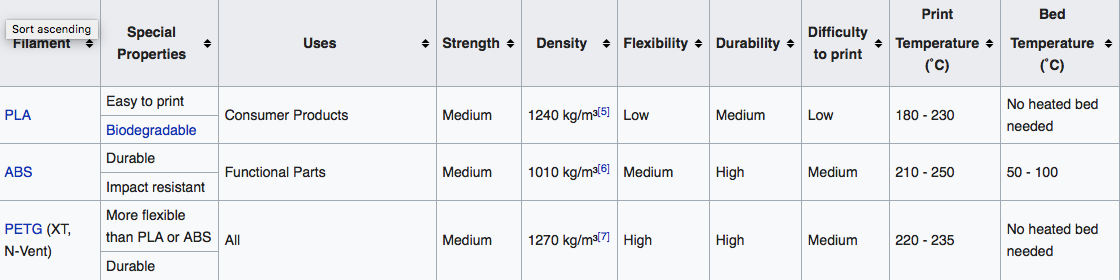

- There are genrelly three types of filaments used in 3D printing.

- ABS - Acrylonitrile butadiene styrene (ABS) (chemical formula (C8H8)x·(C4H6)y·(C3H3N)z) is a common thermoplastic polymer. Its glass transition temperature is approximately 105 °C (221 °F). ABS is amorphous and therefore has no true melting point.

The most important mechanical properties of ABS are impact resistance and toughness. A variety of modifications can be made to improve impact resistance, toughness, and heat resistance. The impact resistance can be amplified by increasing the proportions of polybutadiene in relation to styrene and also acrylonitrile, although this causes changes in other properties. Impact resistance does not fall off rapidly at lower temperatures. Stability under load is excellent with limited loads. source - PLA - Poly(lactic acid) or polylactic acid or polylactide (PLA) is a biodegradable and bioactive thermoplastic aliphatic polyester derived from renewable resources, such as corn starch (in the United States and Canada), cassava roots, chips or starch (mostly in Asia), or sugarcane (in the rest of the world). In 2010, PLA had the second highest consumption volume of any bioplastic of the world.

The name “polylactic acid” does not comply with IUPAC standard nomenclature, and is potentially ambiguous or confusing, because PLA is not a polyacid (polyelectrolyte), but rather a polyester. source - PETG -Polyethylene terephthalate (sometimes written poly(ethylene terephthalate)), commonly abbreviated PET, PETE, or the obsolete PETP or PET-P, is the most common thermoplastic polymer resin of the polyester family and is used in fibres for clothing, containers for liquids and foods, thermoforming for manufacturing, and in combination with glass fibre for engineering resins. source

Who’s done what beforehand?

So, people have made these types of extruder machines before as a DIY project and as a Product too.

All of those machines were pretty expensive whether homemade or a final product. I wanted to try my hand on the project and see if I could make it uses low cost material which could be feasible for the Indian market.

Some of the sources from which the project is inspiorange from are :

What will you design?

Mechanical - I’ve already design the component of my project.The base has been designed and 3D printed, the Hopper is laser cut. The heating block and motor coupling is left to be mnaufactured.

Electronics - I’ll designt he circuit board to control the temperature of the heating block.

What materials and components will be used?

Materials :

- PLA Filament

- MS solid pipe

- Aluminium solid pipe

- Acrylic Sheet

- MDF Block

- Mechanical Components :

- Mild Steel Stock

- Aluminium Stock

- 16mm Auger bit

- 12V 10RPM Geaorange Motor.

- Brass end Cap

- Brass flange

- Lots of Nuts and Bolts.

- Electronics Components :

- NTC 100k Thermistor

- 12V 40W Heat Catridge

- Mosfet IF540

- Voltage Regulator 7805

- Atmega 328p

- Resistors, capacaitor & LEDs.

Where will come from?

Purchased Material :

- 16mm Auger bit - Link to buy

- 12V 10RPM Geared Motor. - Link to buy

- Brass end Cap - Purchased from a local hardware store

- Brass flange - Purchased from a local hardware store

- NTC 100k Thermistor - Link to buy

- 12V 40W Heat Catridge - Link to buy

Material from Lab :

- Mosfet IF540

- Voltage Regulator 7805

- Atmega 328p

- Resistors, capacaitor & LEDs.

- Mild Steel Stock

- Aluminium Stock

- Lots of Nuts and Bolts.

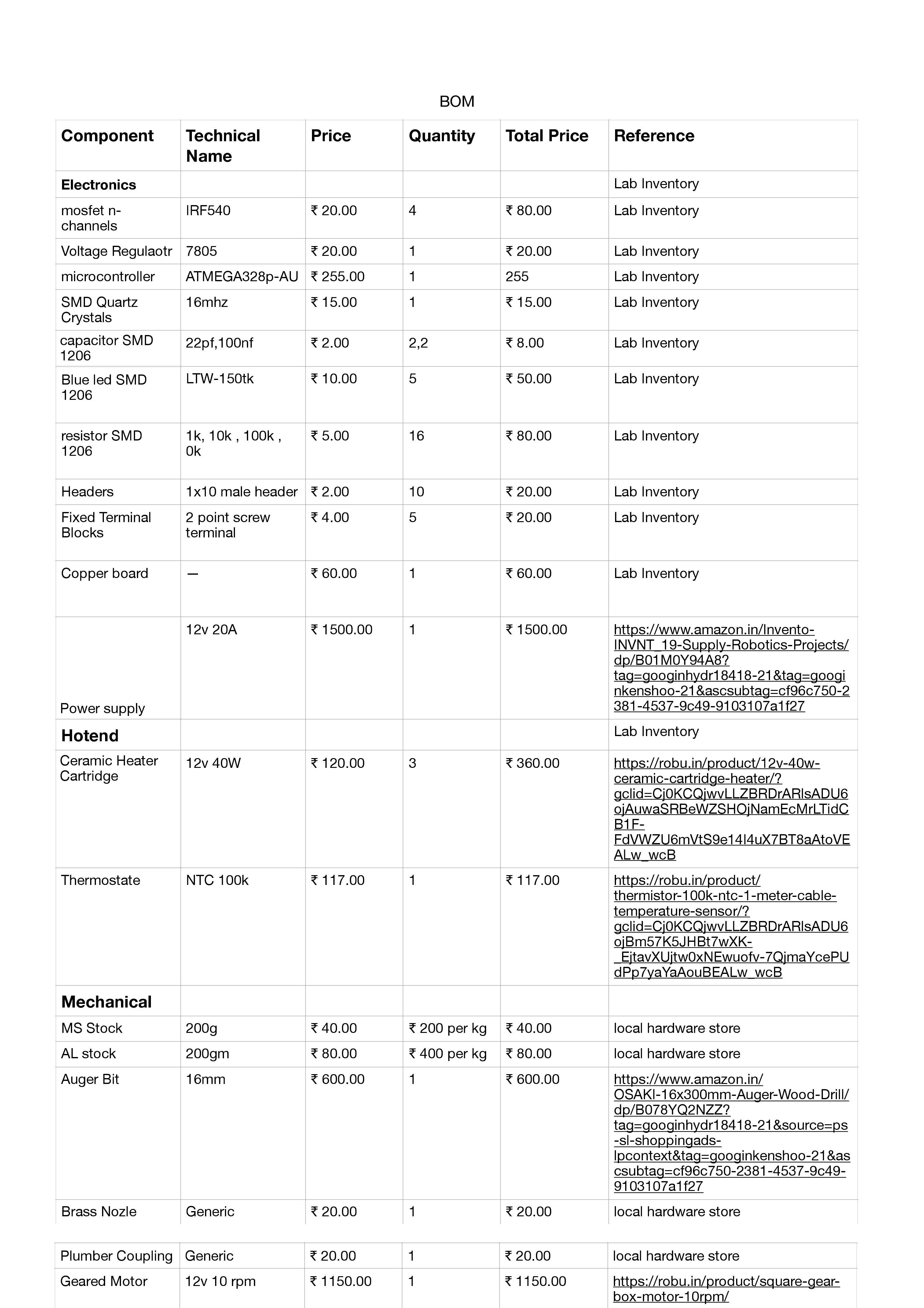

How much will they cost?

To view the image Kindly open it in a new tab .

To view the image Kindly open it in a new tab .

Find the BOM here.

What parts and systems will be made?

- Base - 3D Printed

- Heat block - Milled

- Motor Coupling - Lathe

- Hopper - Laser Cut

- MDF Insulation - Milled

- Electronics Control Board

What processes will be used?

- 3D Printing

- Laser cutter

- Subtractive Manufacturing : Mill and Lathe

- Electronics Design and Production

- Vinyl Cutting.

What questions need to be answered?

- PID controller working - I need to make a PID code for the MCU.

- 16x2 LCD Interface - I’m also planning o add a LCD which will show the required information.

- Extruded material diameter - Since my arrangement will not include a puller motor and a winder, I’m skeptical about the consistenct of the diamter of the extruded material, also the roundness of the material shall aso be checked.

How will it be evaluated?

- At this stage of the product , it should be evaluated on the basis of whether it is able to extrude filament/plastic.

- Later on the machine can be tuned and a puller motor could also be added to produce perfect filament.