What does it do?

- My final project will Extrude/make filament for 3D printers from pellets fed into it. It will be a desktop filament maker which would act as an aid to your 3D printer.

Who’s done what beforehand?

So, people have made these types of extruder machines before as a DIY project and as a Product too.

All of those machines were pretty expensive whether homemade or a final product. I wanted to try my hand on the project and see if I could make it uses low cost material which could be feasible for the Indian market.

Some of the sources from which the project is inspired from from are :

What did you design?

- Mechanical components :

- Barrel

- Hopper

- Housing

- Motor Shaft Coupling

- Electronics components :

- Input / Output Board

- Input / Output Board

What materials and components were used ?

- Mechanical Components :

- Mild Steel Stock

- Aluminium Stock

- 16mm Auger bit

- 12V 10RPM geared Motor.

- Brass end Cap

- Brass flange

- Lots of Nuts and Bolts.

- Electronics Components :

- NTC 100k Thermistor

- 12V 40W Heat Catridge

- Mosfet IF540

- Voltage Regulator 7805

- Atmega 328p

- Resistors, capacitor & LEDs.

Where did they come from?

Purchased Material :

- 16mm Auger bit

- 12V 10RPM geared Motor.

- Brass end Cap

- Brass flange

- NTC 100k Thermistor

- 12V 40W Heat Cartridge

Material from Lab :

- Mosfet IF540

- Voltage Regulator 7805

- Atmega 328p

- Resistors, capacitor & LEDs.

- Mild Steel Stock

- Aluminium Stock

- Lots of Nuts and Bolts.

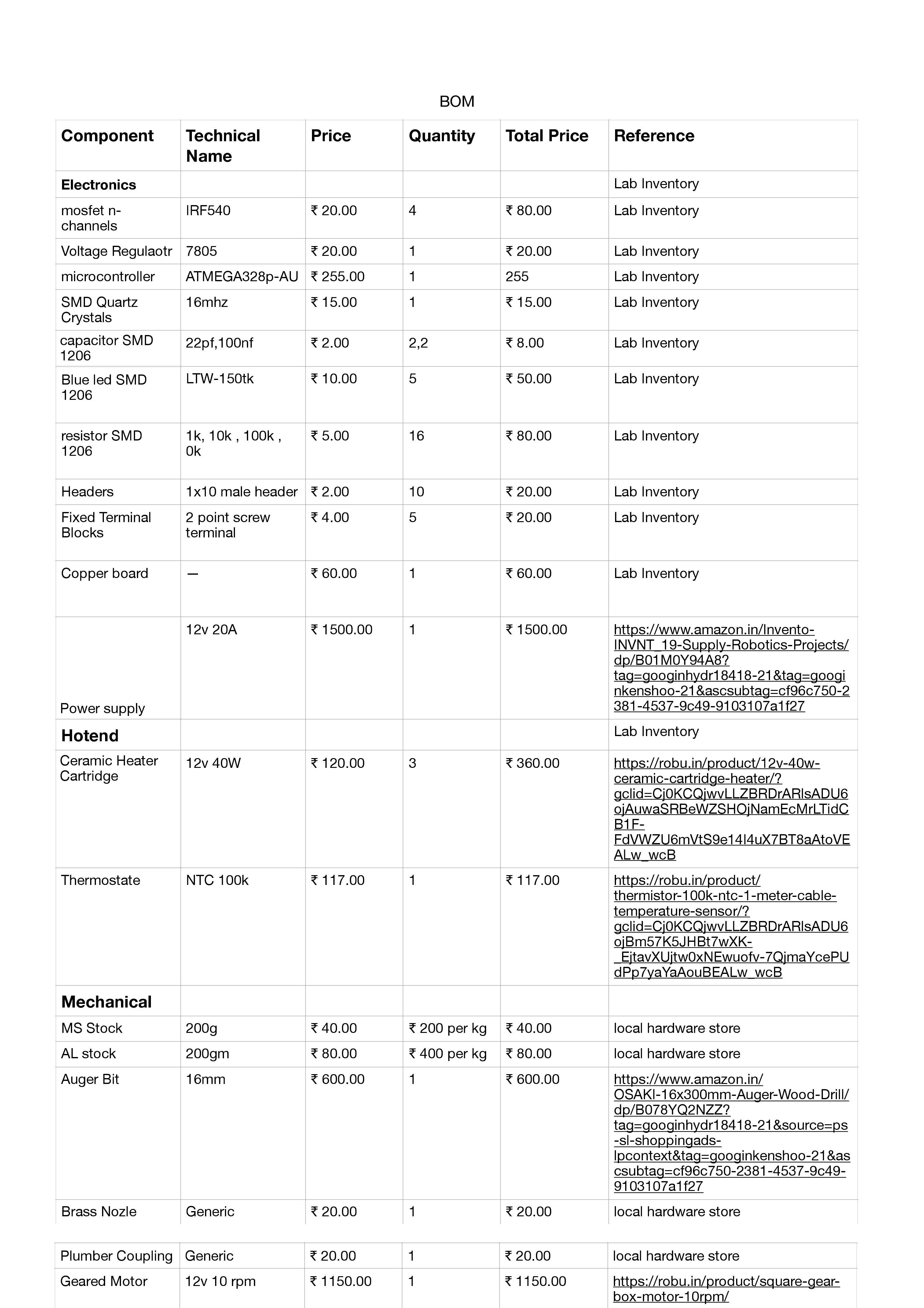

###How much did they cost?

- Bill Of Material

To view the image Kindly open it in a new tab .

To view the image Kindly open it in a new tab .

Find the BOM here.

What parts and systems were made?

- Barrel

- Hopper

- Base

- Coupling

- Electronic Board

What processes were used?

- 3D printing

- Turning

- Drilling & Tapping

- Milling

what tasks have been completed, and what tasks remain?

- Everything I aimed for has been completed.

- All the manufacturing work is done, assembly is done. Filament has been extruded.

- Some minor things need to be added like a 16x4 LCD and a outer case.

- PID control for the temperature remains.

What has worked? what hasn’t?

- Almost all the goals I set were accomplished.

- I tried writing a PID code for my board but could’t get it to work. I plan to debug the code further in order to have perfect temp control.

- Also I had to shift the heating cartridges to the front of heat end in order to prevent the heat from travelling to the 3D printed base. I plan to extend the barrel length to counter the problem.

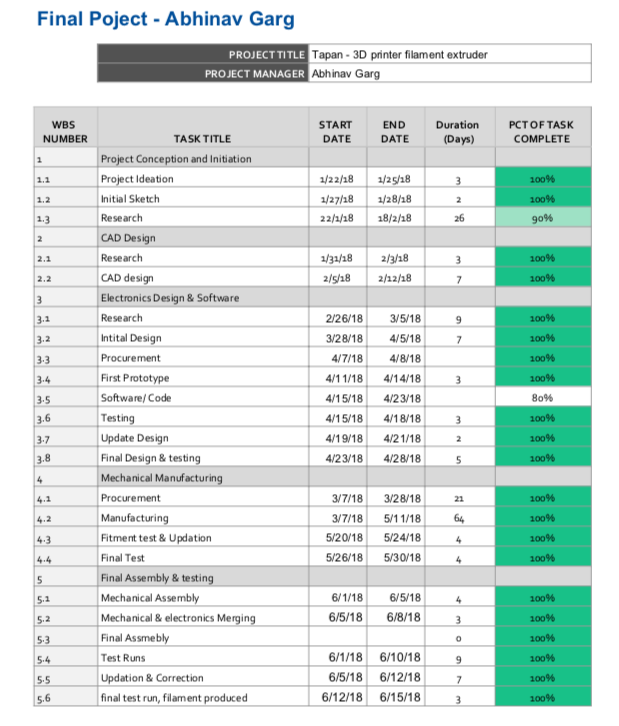

What will happen when?

- my project plan :

What have you learned?

- The learnings from the project have been enormous, been a Mechanical engineer I was always focussed and confined to the mechanical aspects of things.

- But in my final project everthing from mechanical , electronics and software was included.

- I got to learn so much about the electronics stuff, It’s such a proud moment when you get your board to work.

- I had previously worked on laser cutter but was’t aware of the press fit, and the flexures. Amazing.