Week 17

Wild Card Week

Introduction to Composites

When Should you use Composites ?

Weight reduction

Durability and maintenance

Added functionality

Design freedom

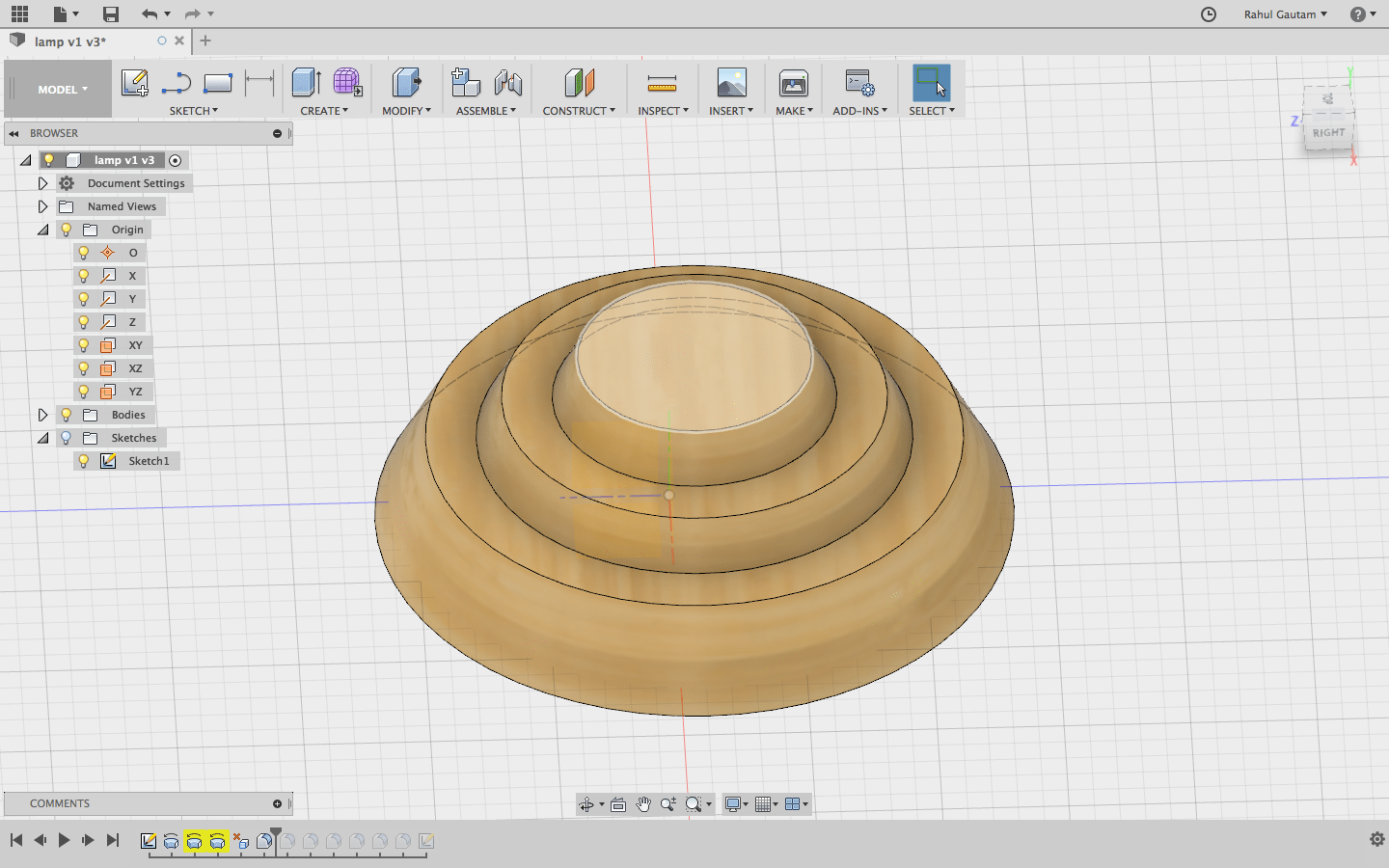

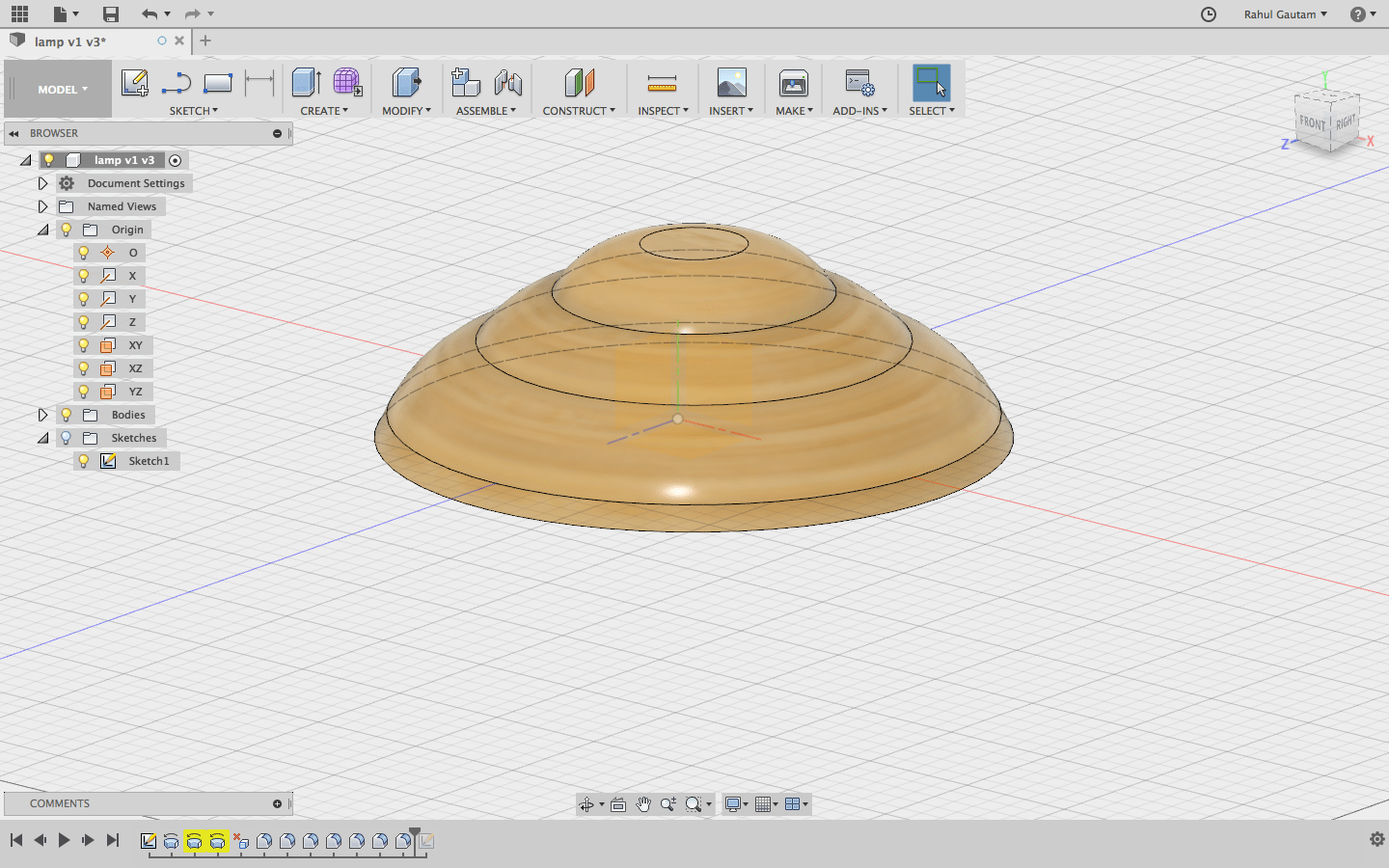

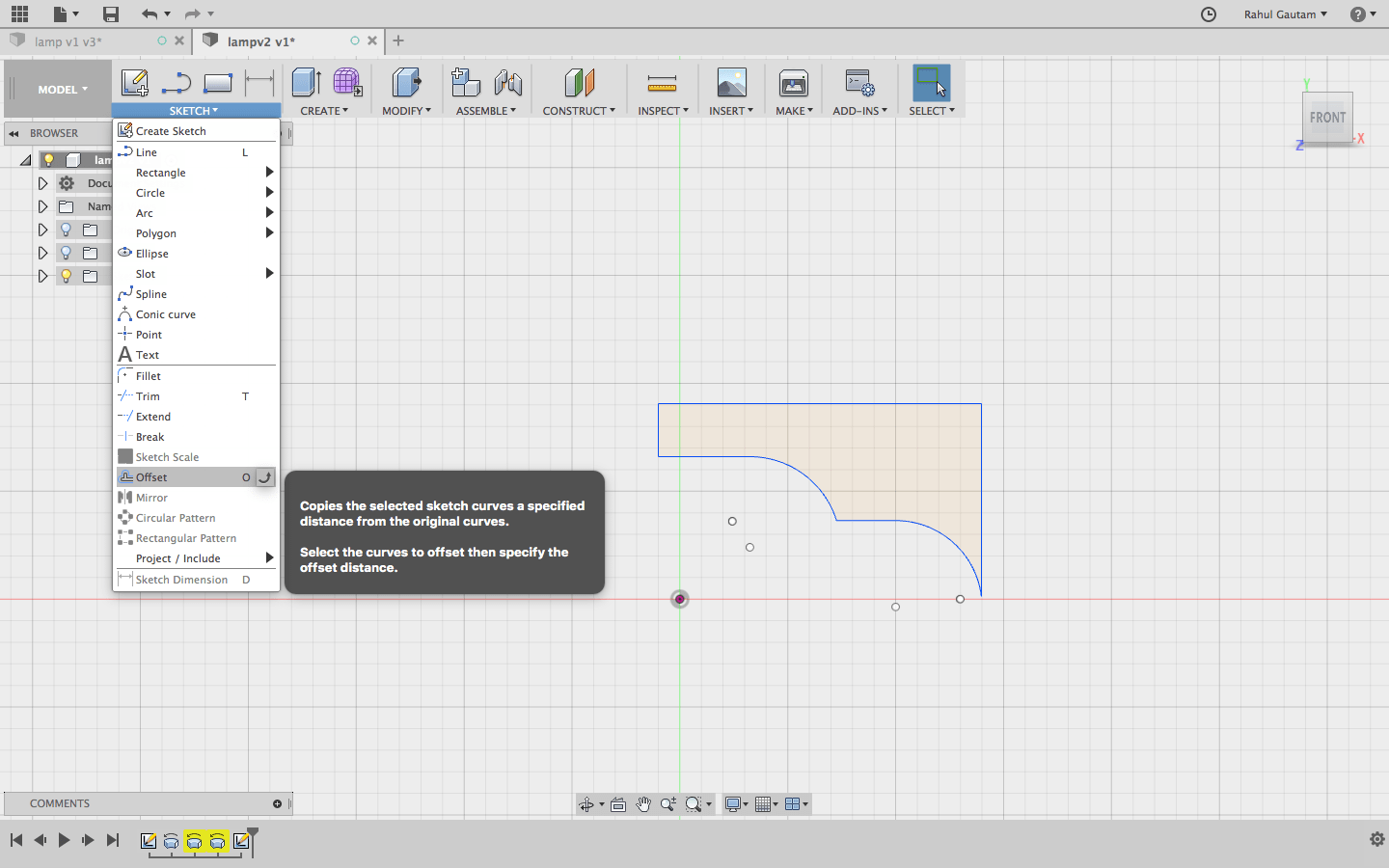

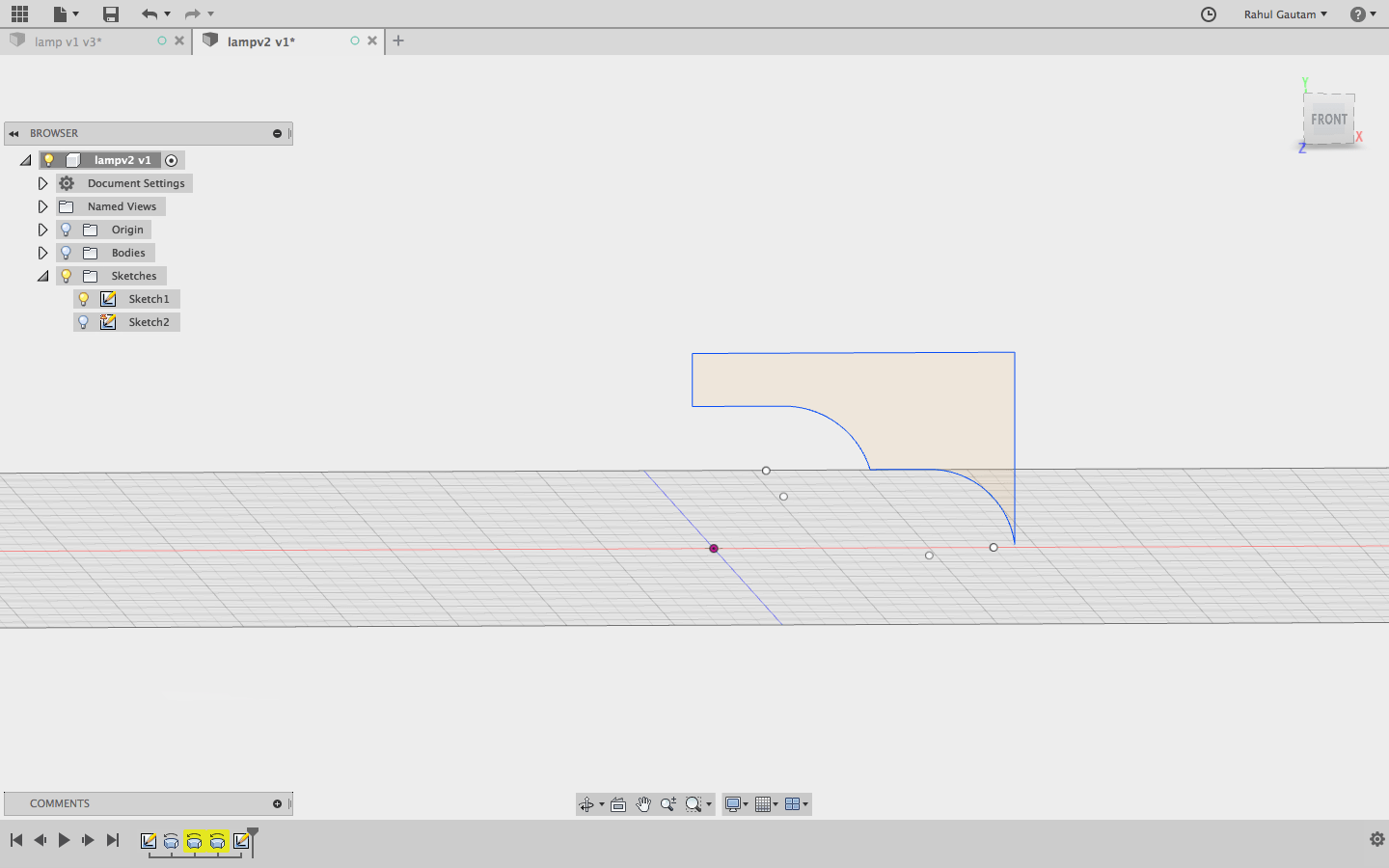

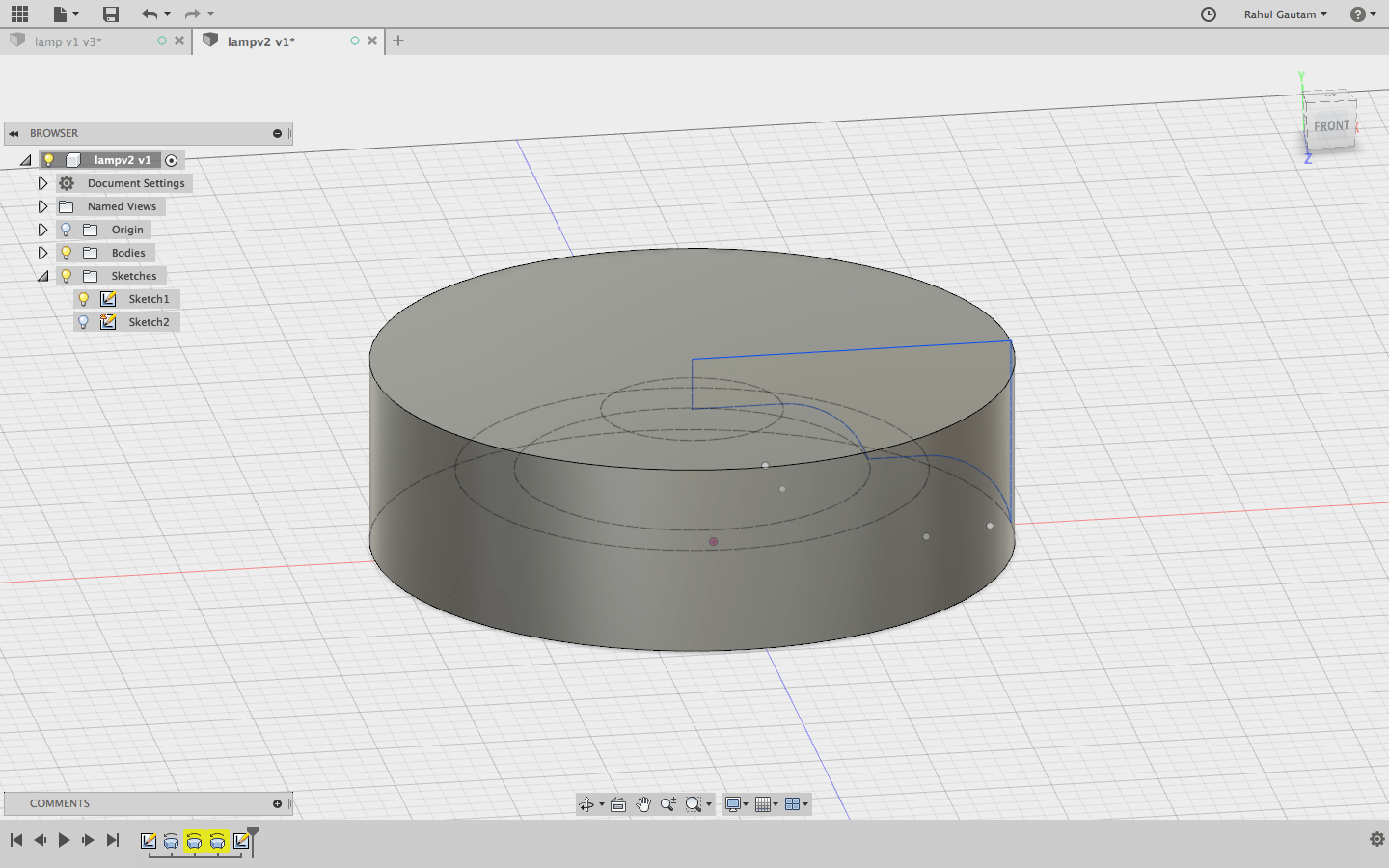

The Lamp

Download Fusion Files (Lamp Shade)

Download Fusion Files (Lamp Shade)

Problem with this design

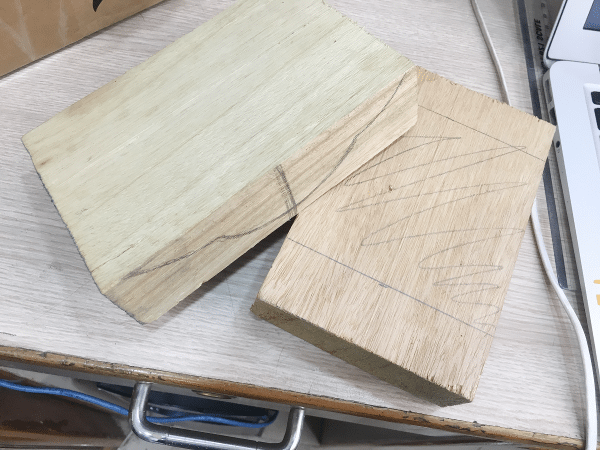

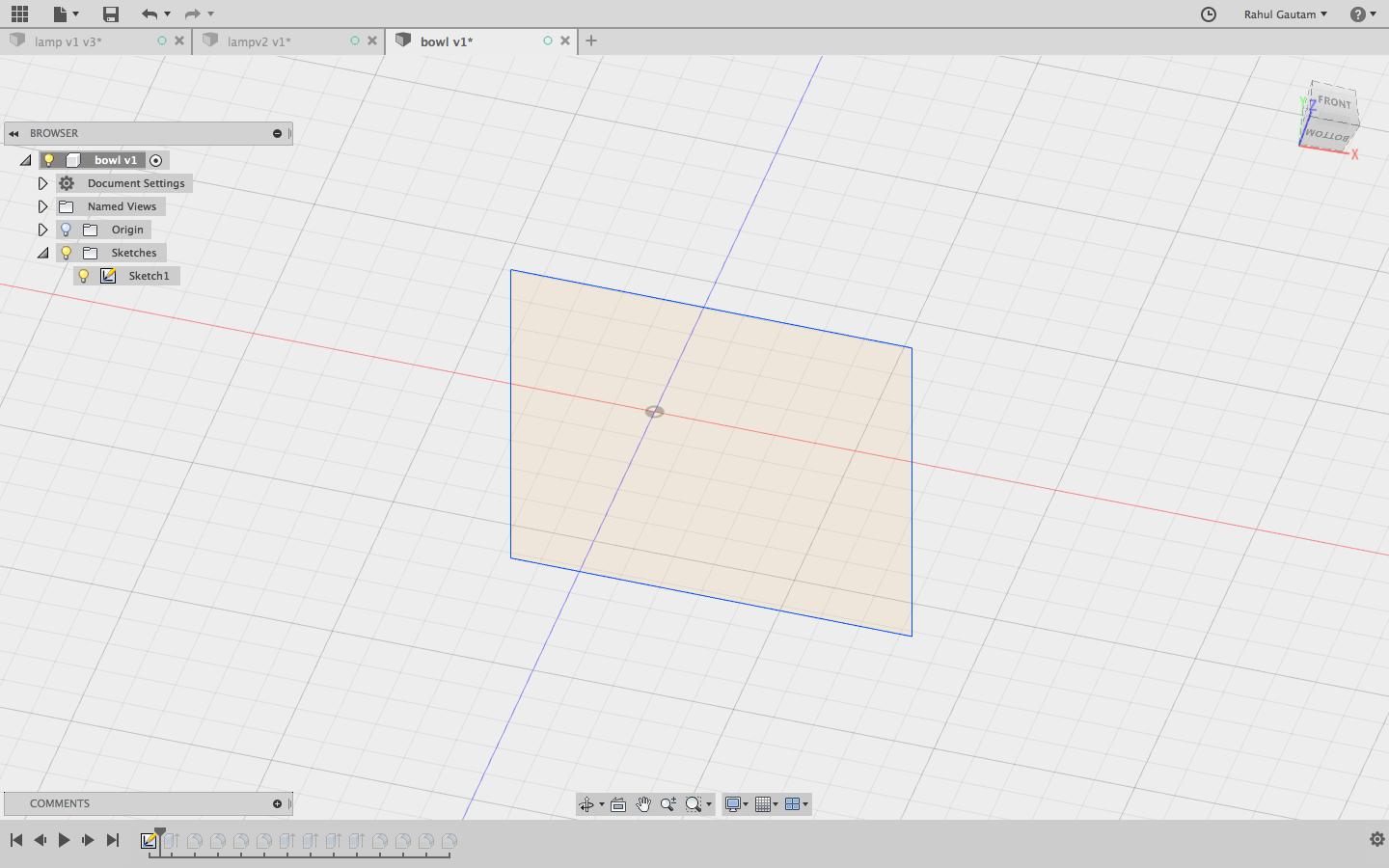

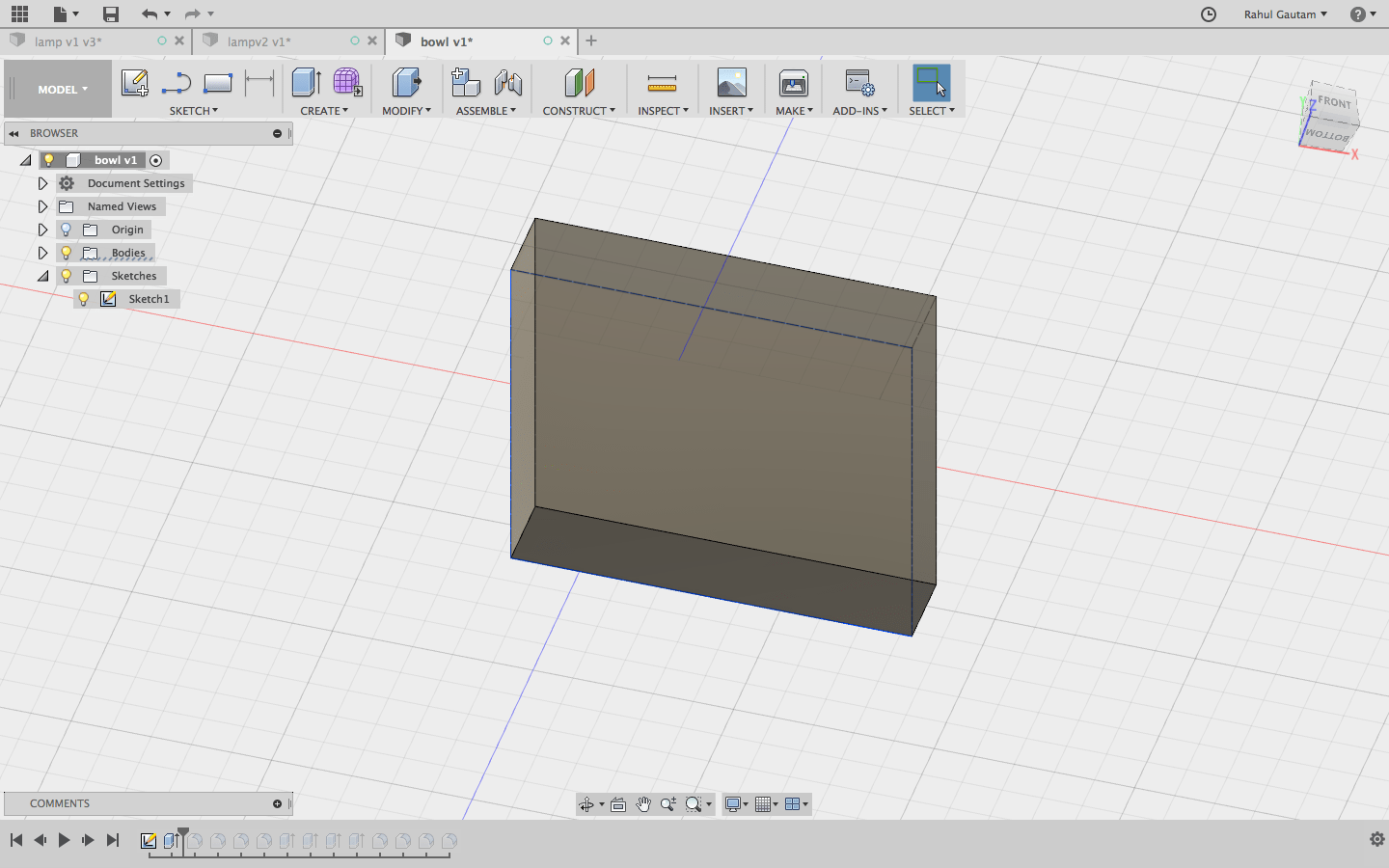

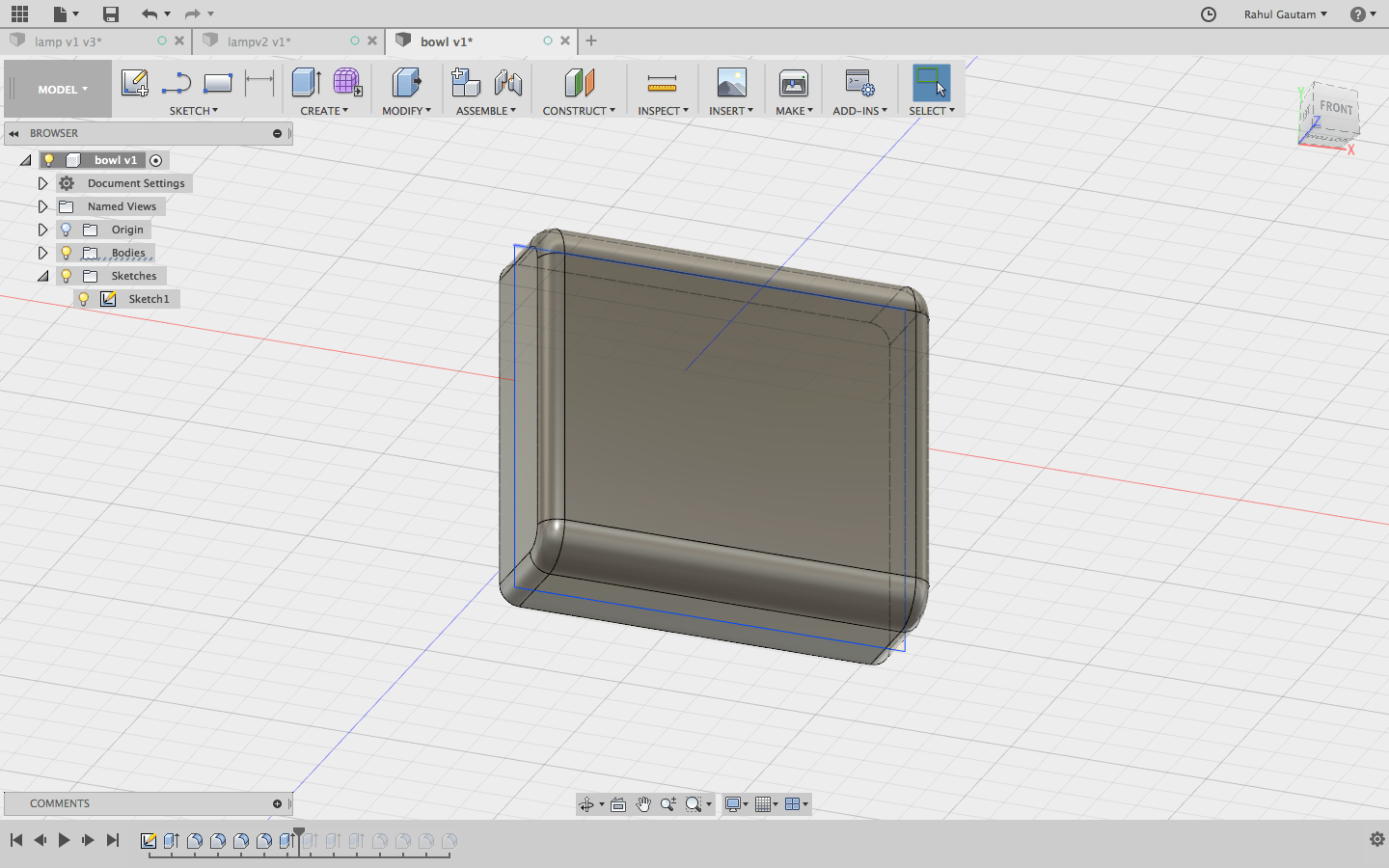

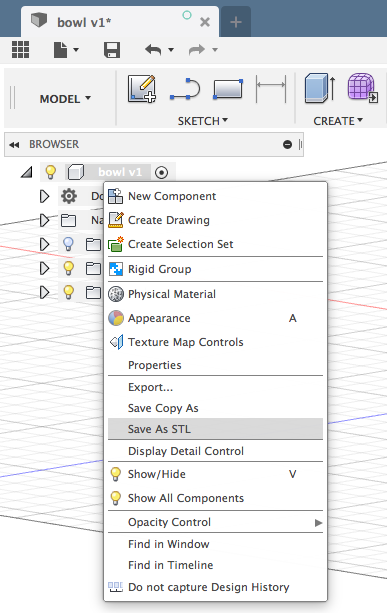

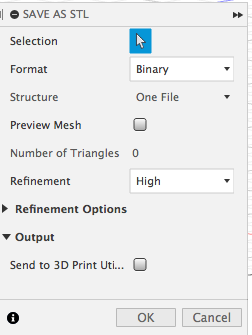

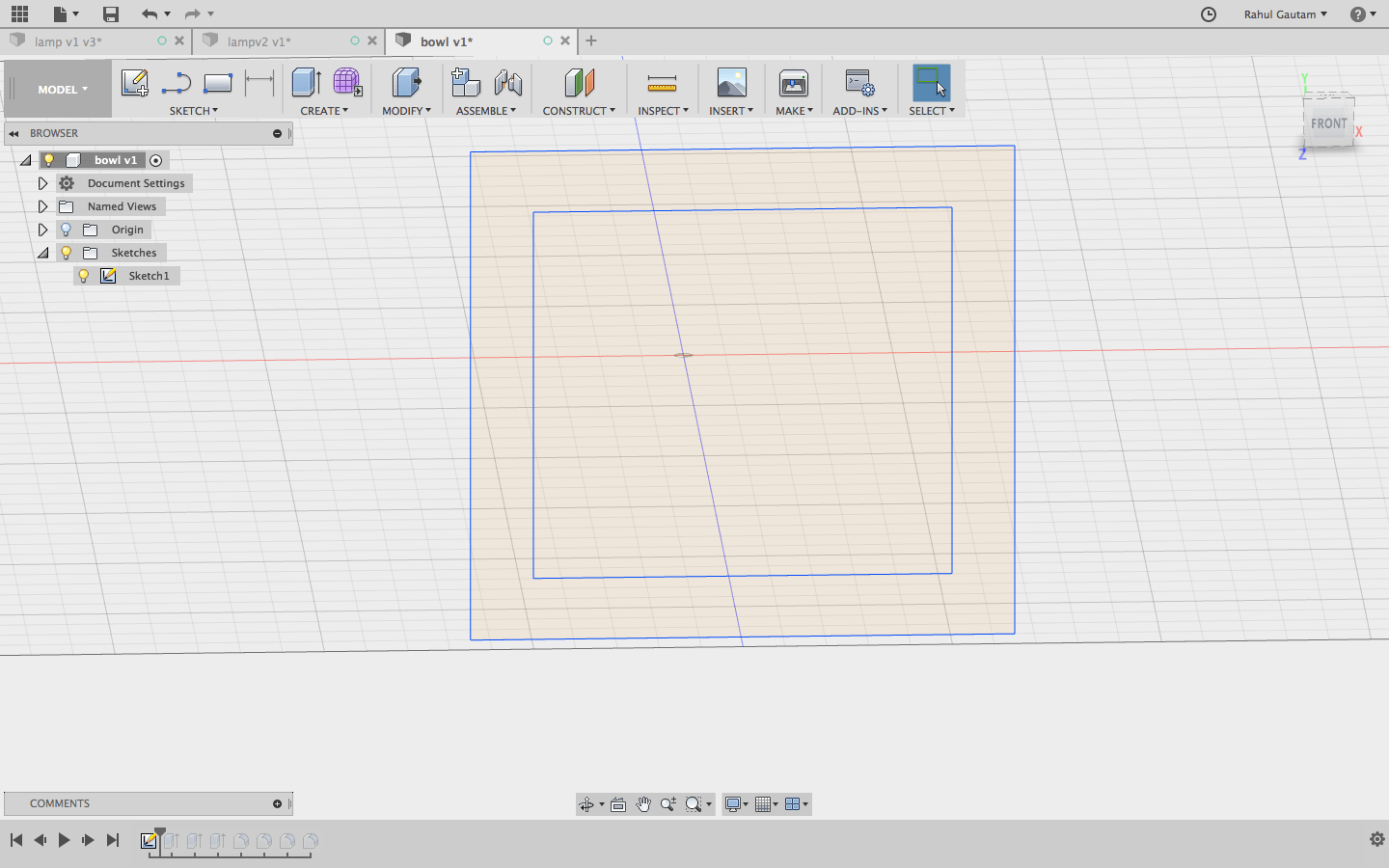

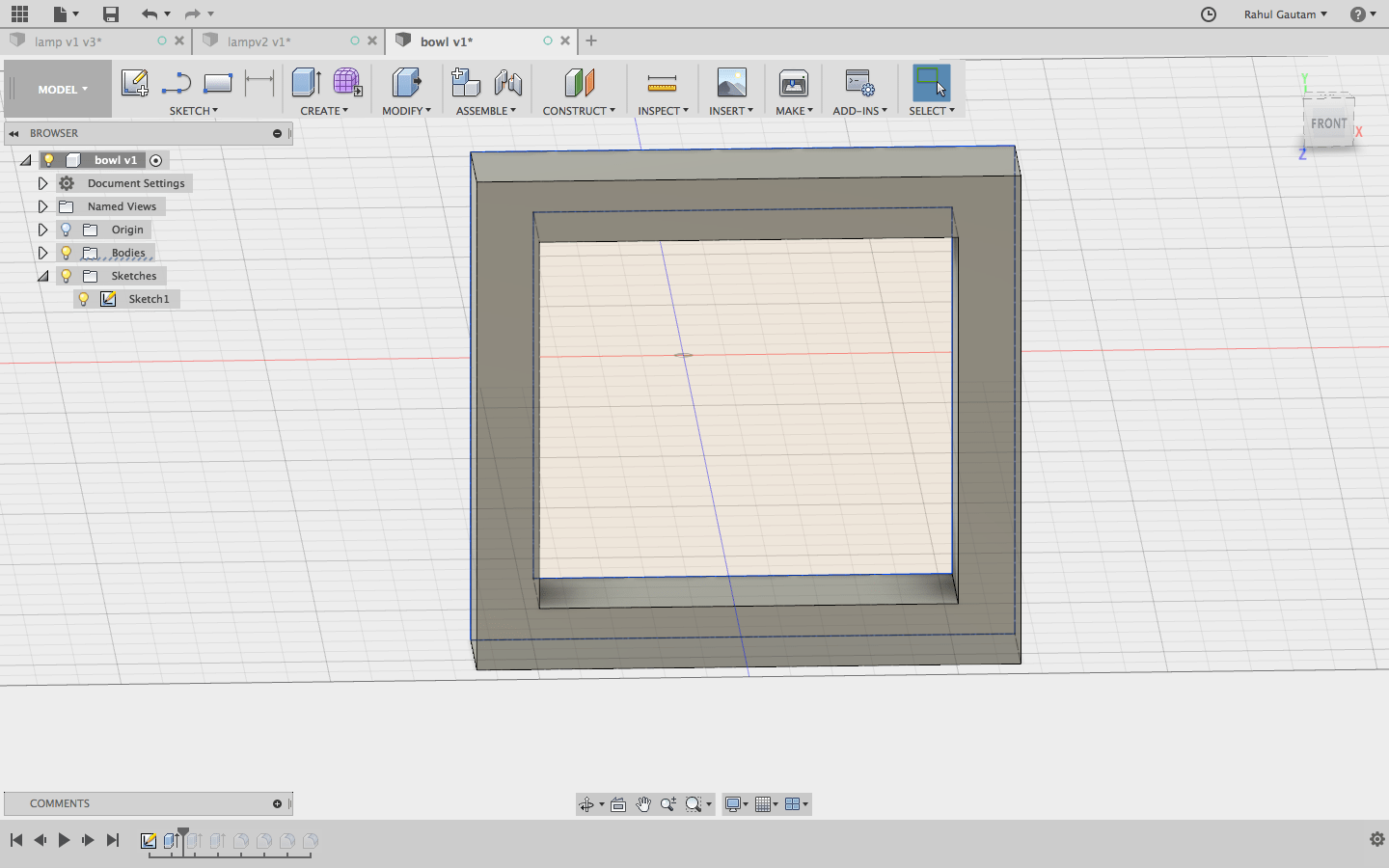

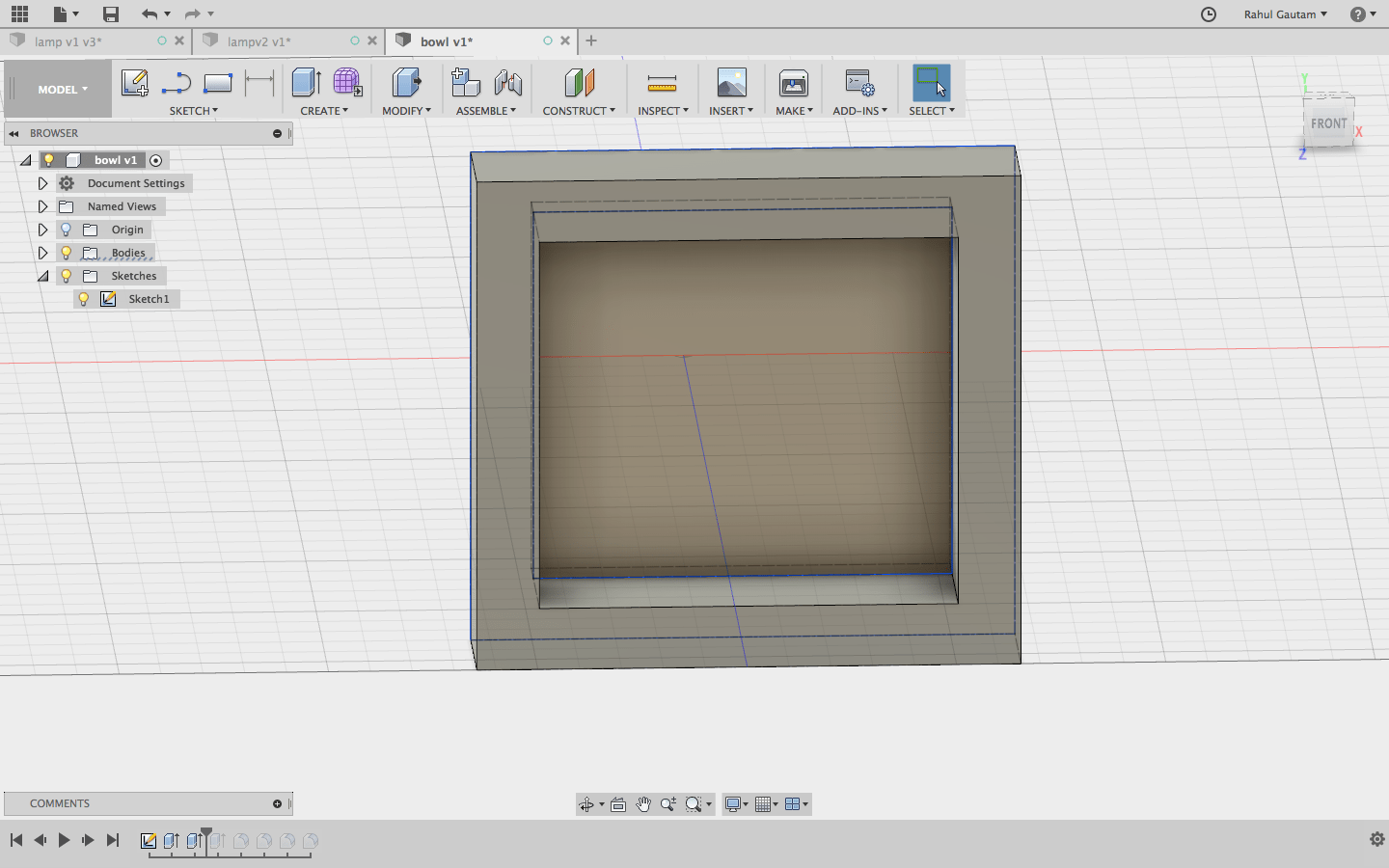

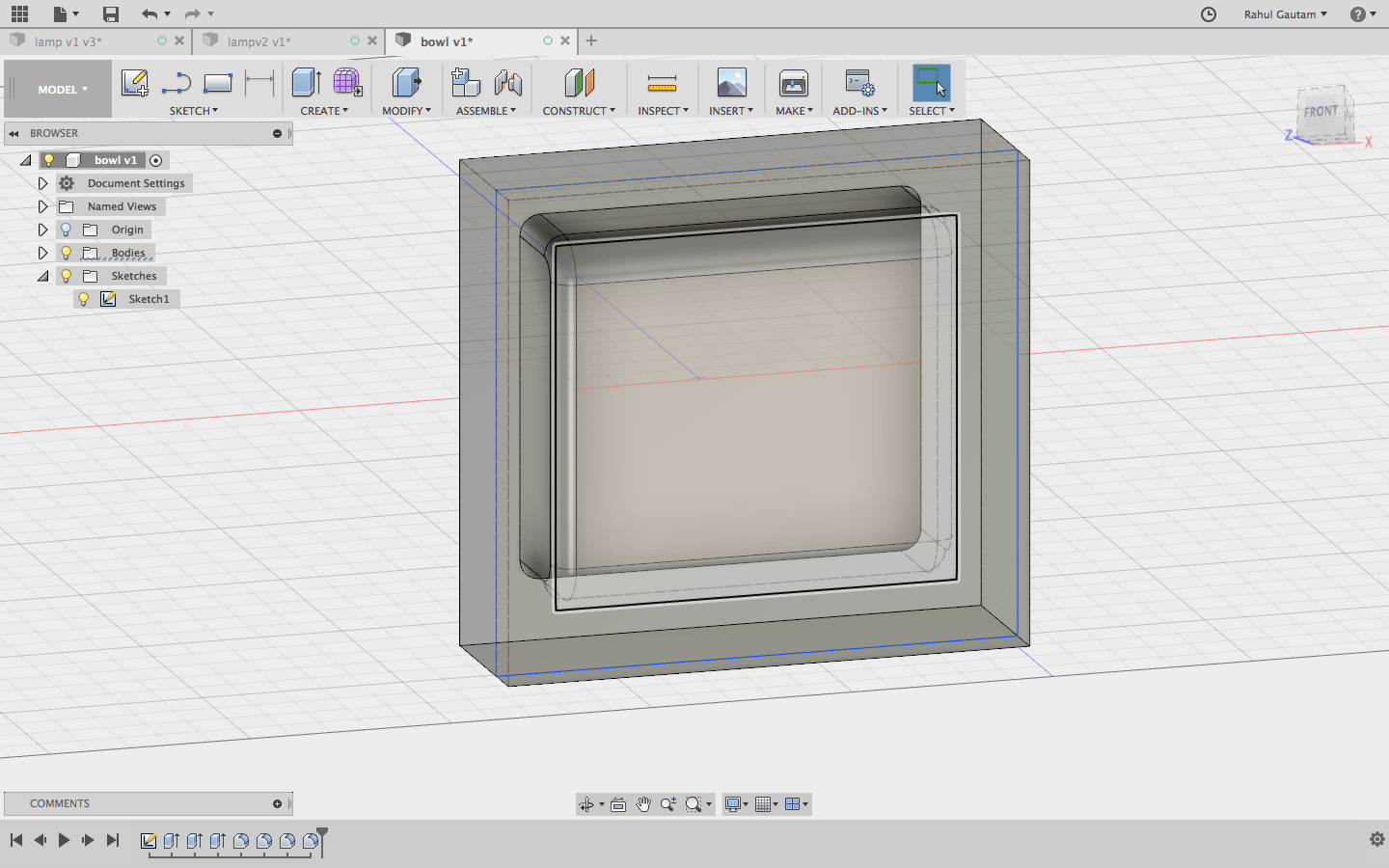

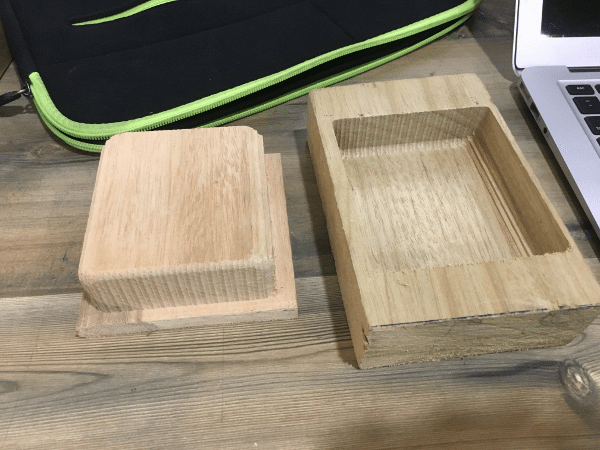

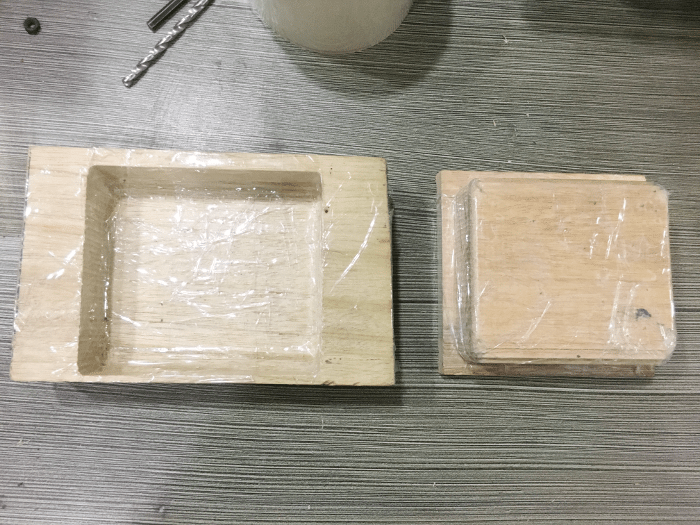

The Bowl

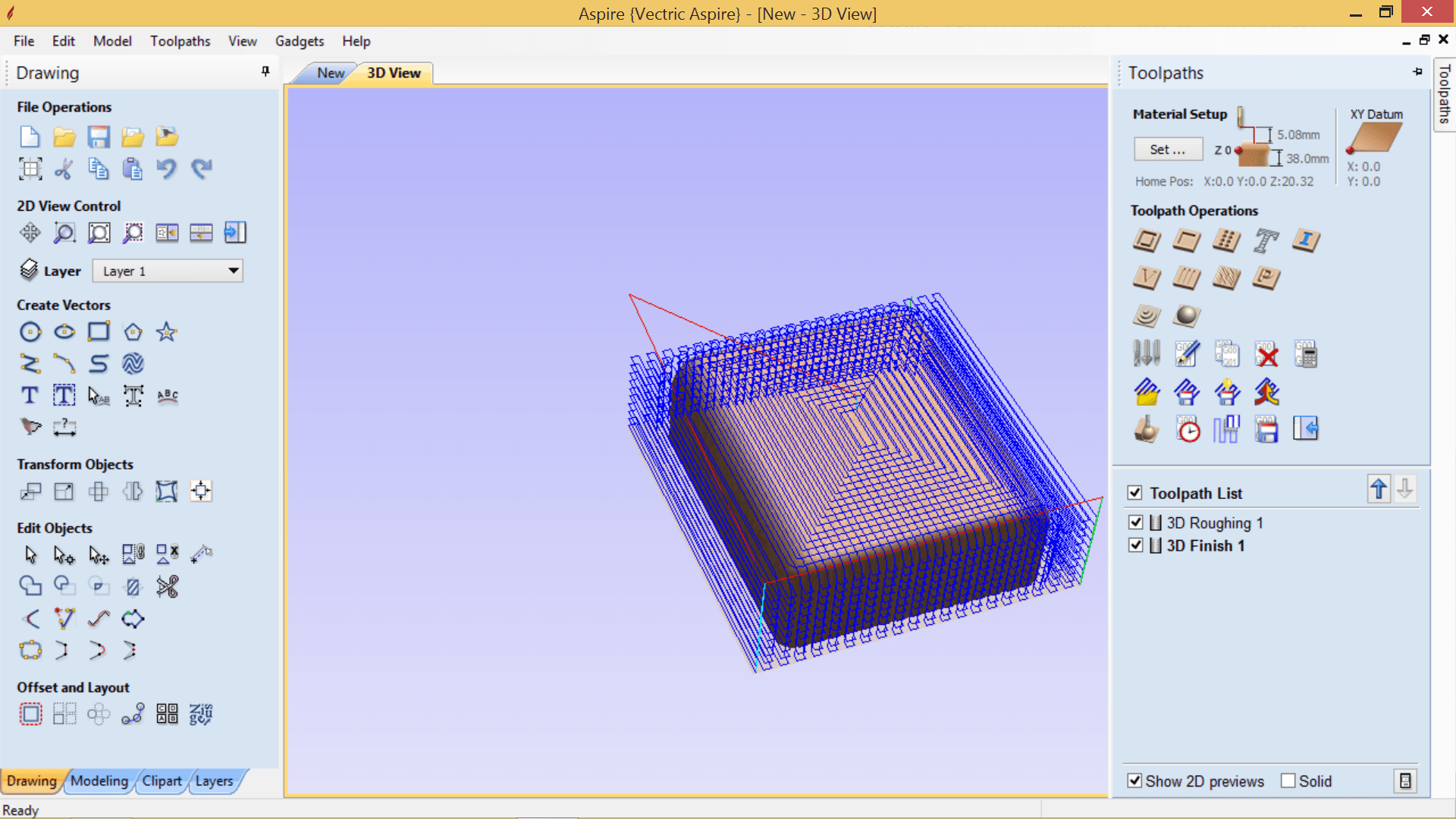

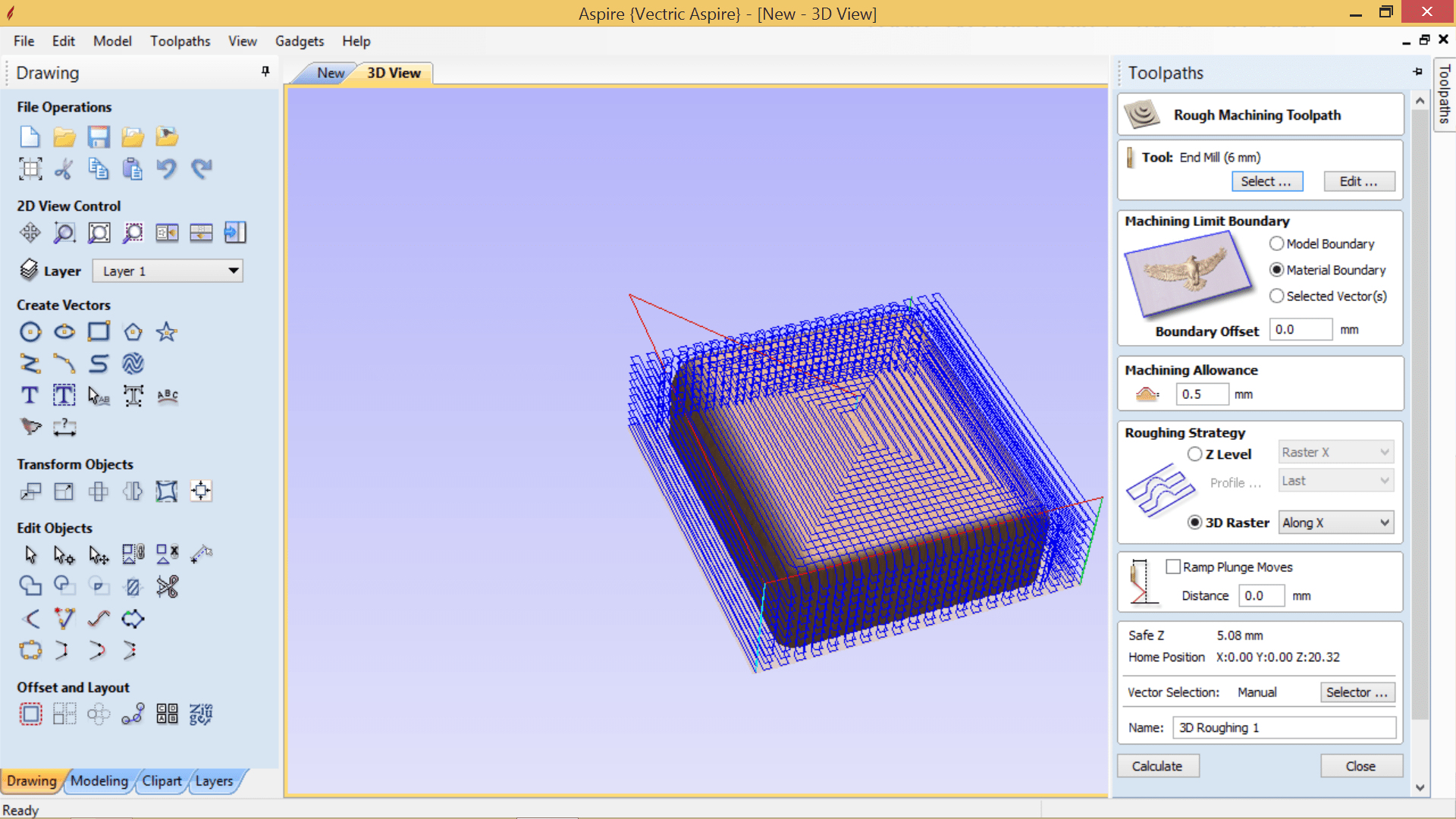

Tool Path

Download CNC Files (Bowl)

Download CNC Files (Bowl)

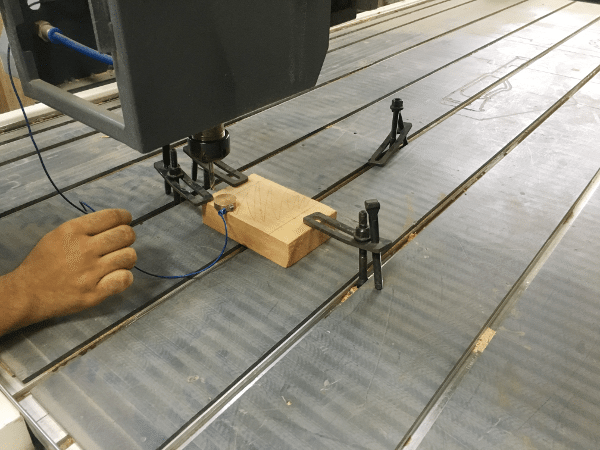

Milling

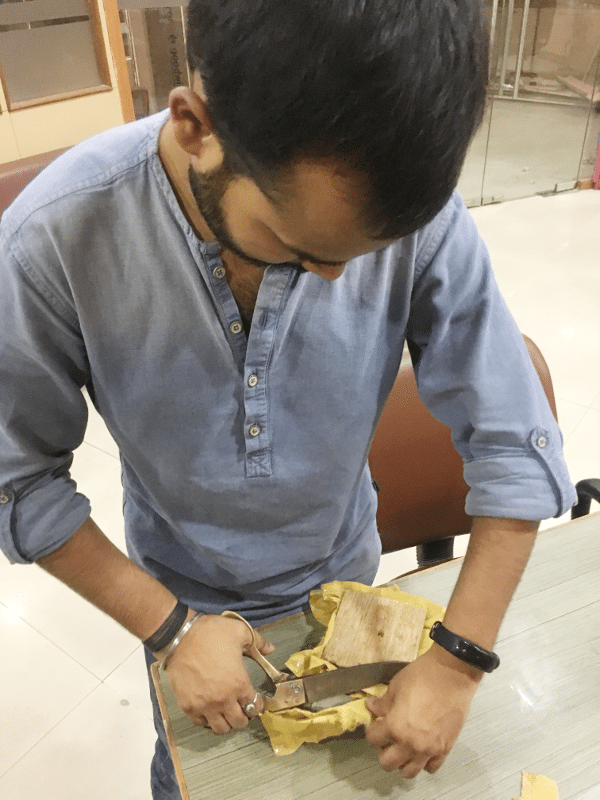

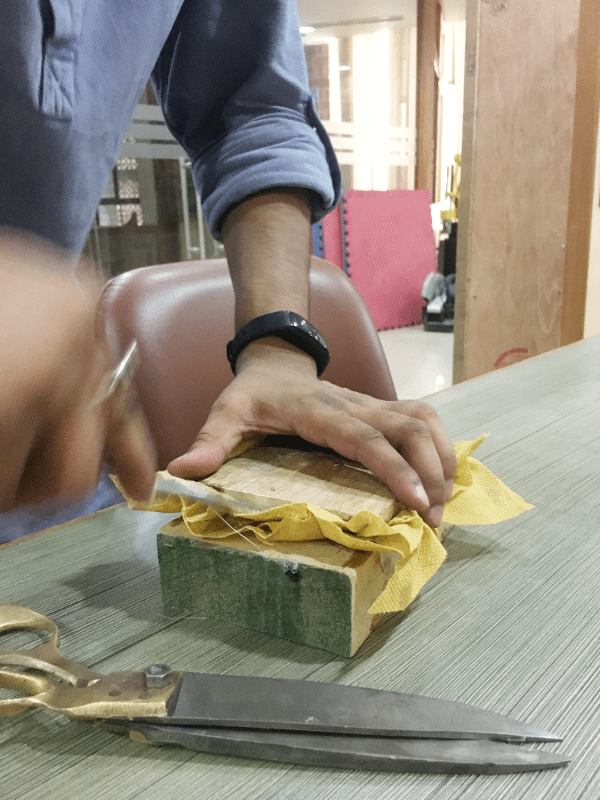

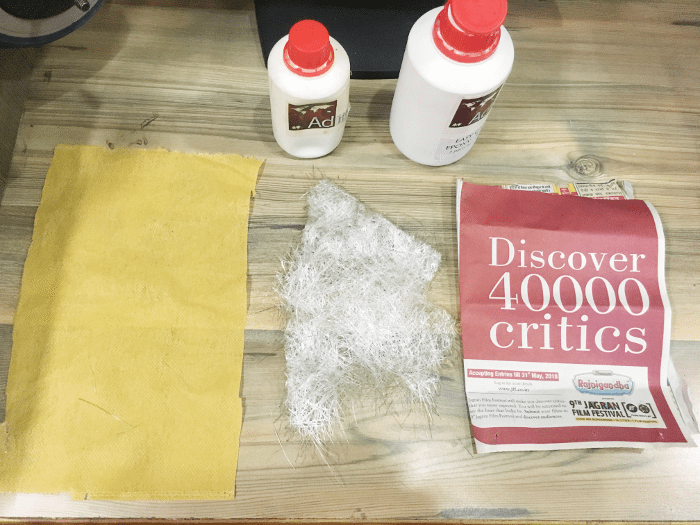

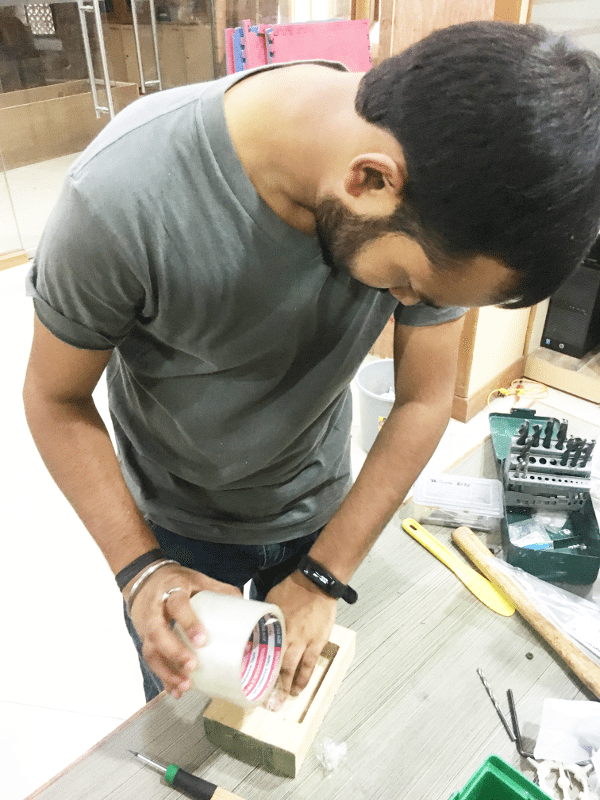

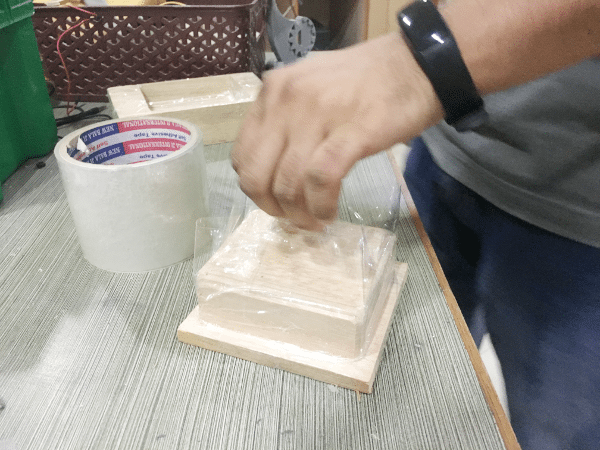

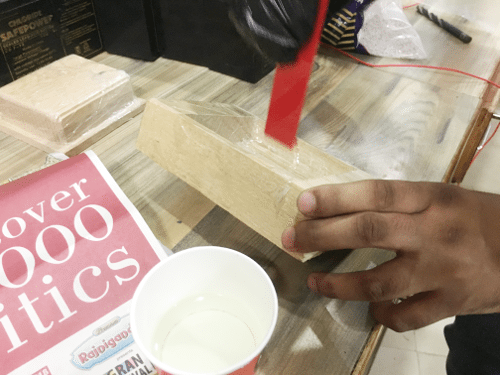

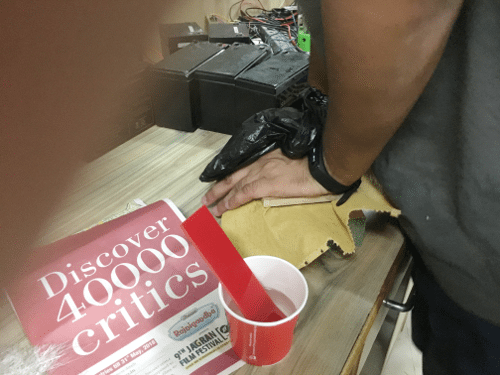

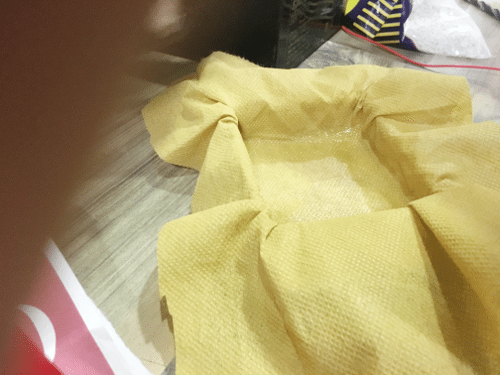

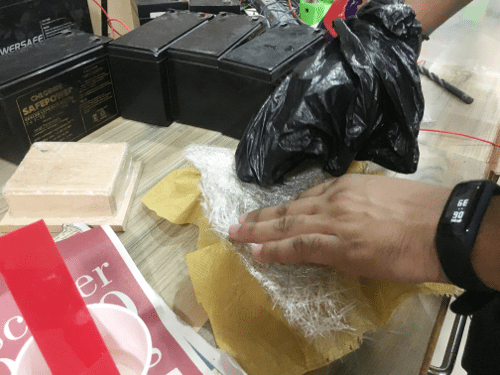

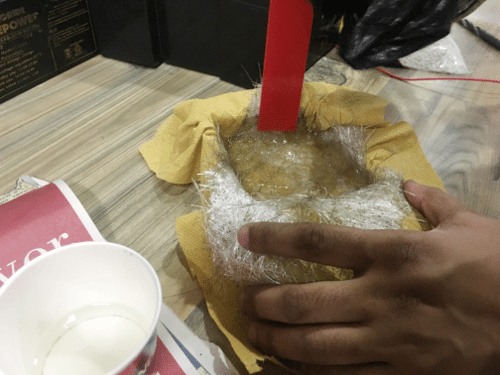

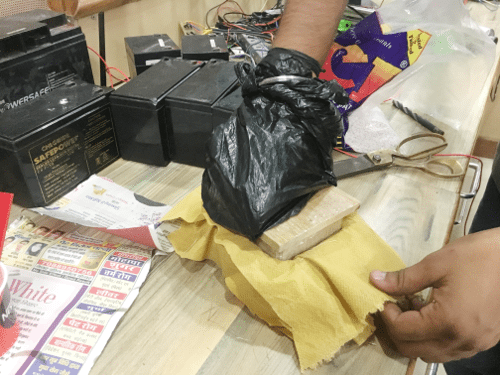

Composite

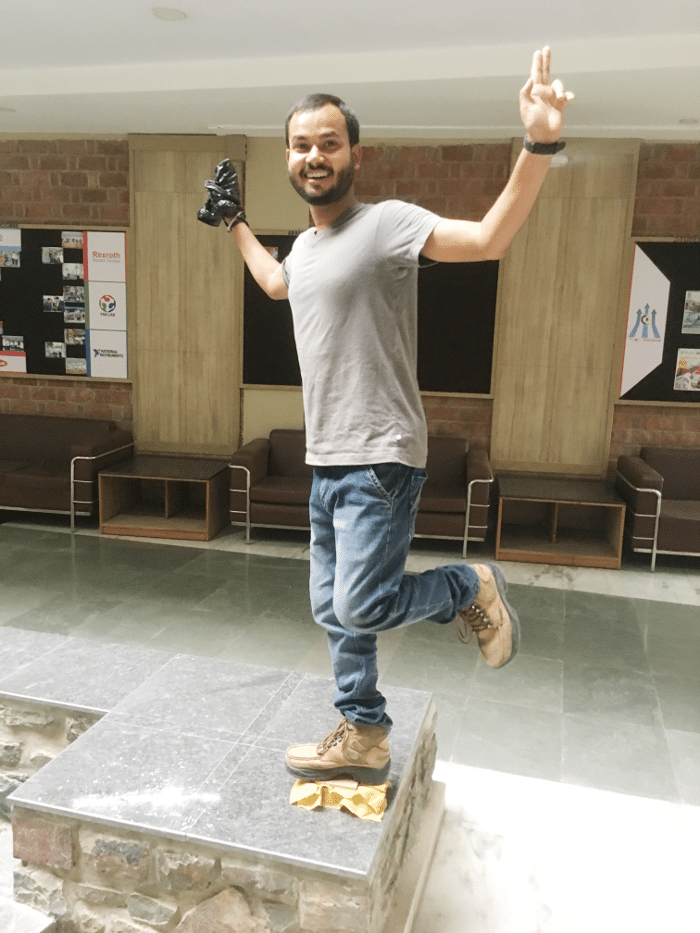

After 24 hrs