FABACADEMY

Computer-Controlled Machining

Welcome to my week 8

Computer-Controlled Machining:

Learning Outcomes:

Brief

CNC router :-

A CNC router (Or Computer Numerical Control router) is a computer-controlled cutting machine related to the hand held router used for cutting various hard materials, such as wood, composites, aluminium, steel, plastics, and foams. CNC stands for computer numerical control. CNC routers can perform the tasks of many carpentry shop machines such as the panel saw, the spindle moulder, and the boring machine. They can also cut mortises and tenons.

A CNC router is very similar in concept to a CNC milling machine. Instead of routing by hand, tool paths are controlled via computer numerical control. The CNC router is one of many kinds of tools that have CNC variants.

A CNC router typically produces consistent and high-quality work and improves factory productivity. Unlike a jig router, the CNC router can produce a one-off as effectively as repeated identical production. Automation and precision are the key benefits of cnc router tables.

A CNC router can reduce waste, frequency of errors, and the time the finished product takes to get to market.

Group Assignment

For this week’s group assginment - visit here.

There are some basic operaitions you can perform on a CNC they are :

- Profile.

- Pocket.

- Drill.

- Engrave.

- Inlay.

- V-Carve.

- Texturing.

For more detailed information on operaitions click here.

Getting started with CNC Router.

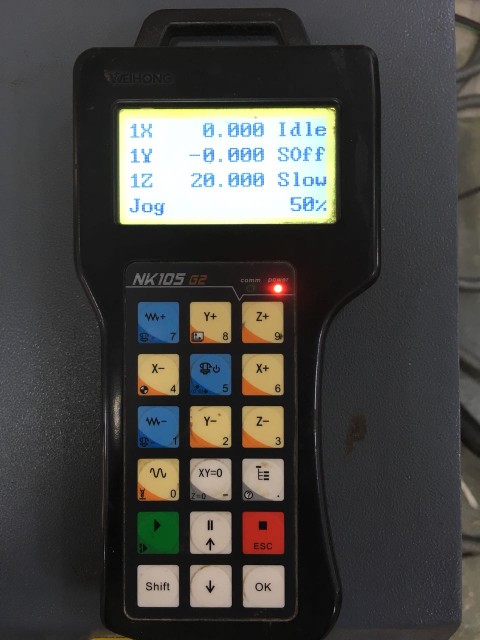

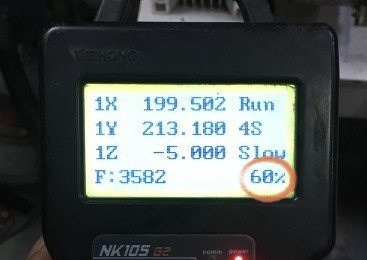

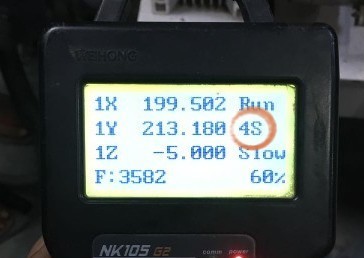

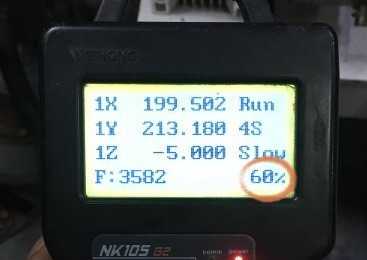

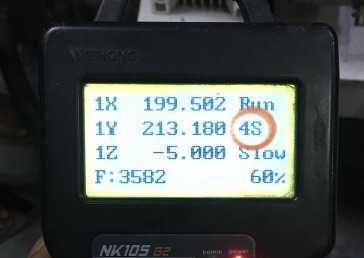

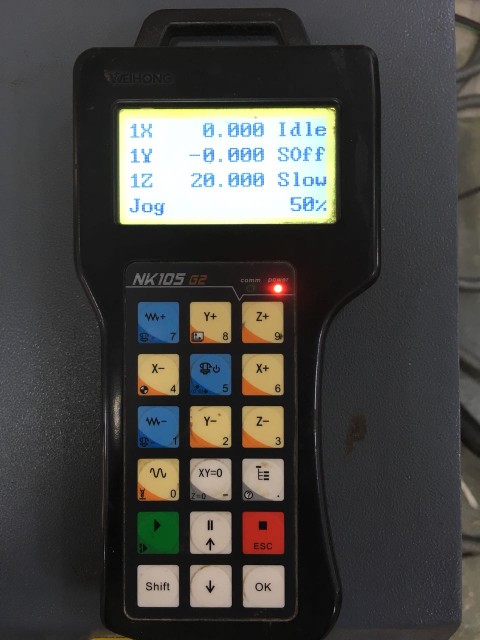

Teach Pendant :

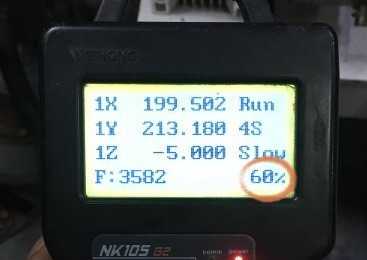

In our cnc the Feed Rate and the Spindle Speed ws controlled thorugh the Teach Pendant only rather then providing those values on the CAM software.

Feed Rate and Cutting Speed :

Cutting speed is defined as the speed (usually in feet per minute) of a tool when it is cutting the work.Feed rate is defined as toolís distance travelled during one spindle revolution.

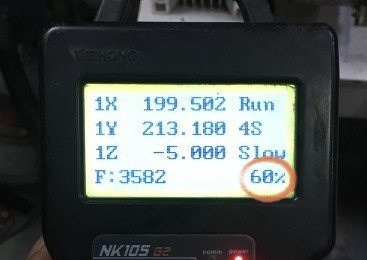

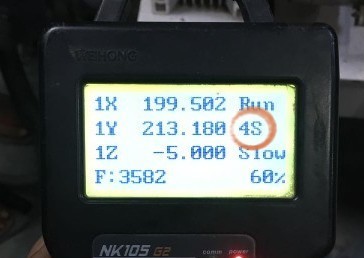

The cutting speed the CNC has is mentioned in terms of Percentage, we can have 10% to 100%, though itís not recommended of go beyond 70%.

Spindle Speeds :

The spindle speeds in the machine is denoted by a number followed by S. They are 4S, 5S, 6S, 7S. 4S being the slowest and 7S the fastest.Tha maximum spindled speed at 100% is 3200RPM.

My Assignment:-

Folding chair.........

I got inspried from internet so i watched a lot pics and then I mixed two designs in one design. so I designed this chair in solidworks.

I have designed in solid edge.

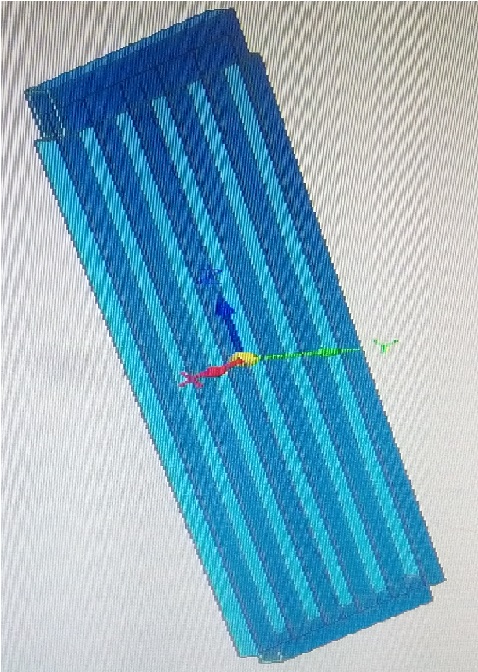

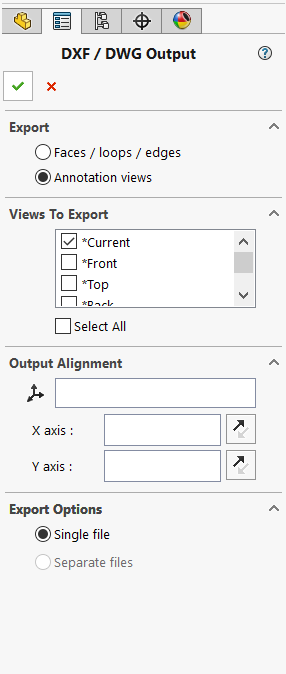

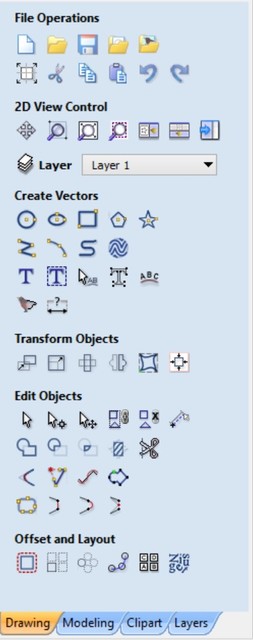

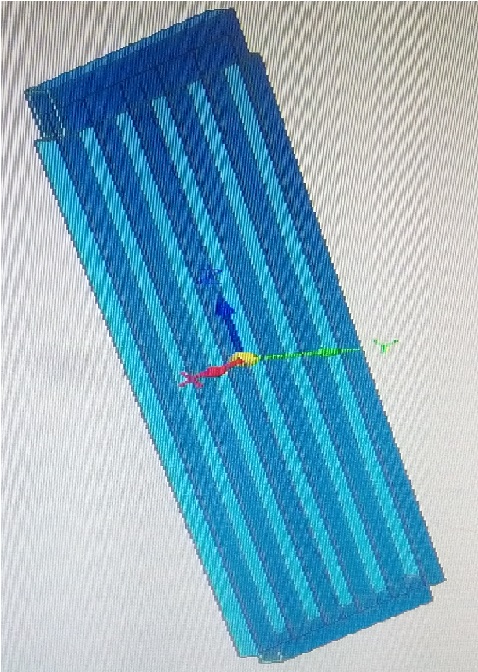

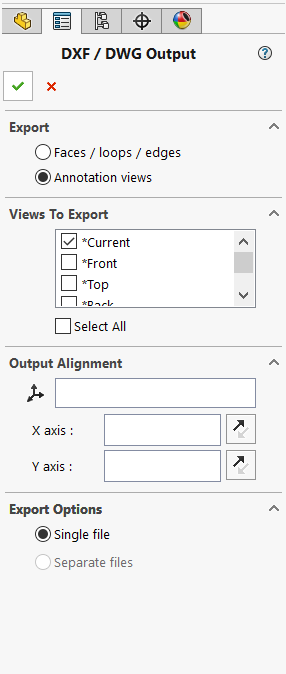

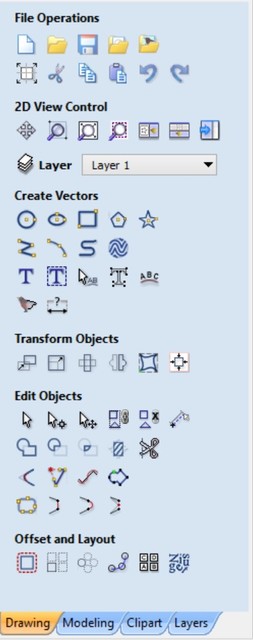

After My design is complected. I imported .dxf file in Aspire cam. Because for CNC wood router we use Aspire cam software for the settings we need.

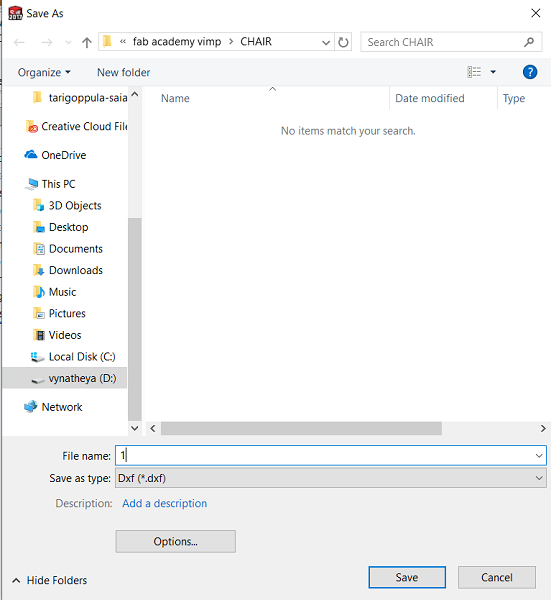

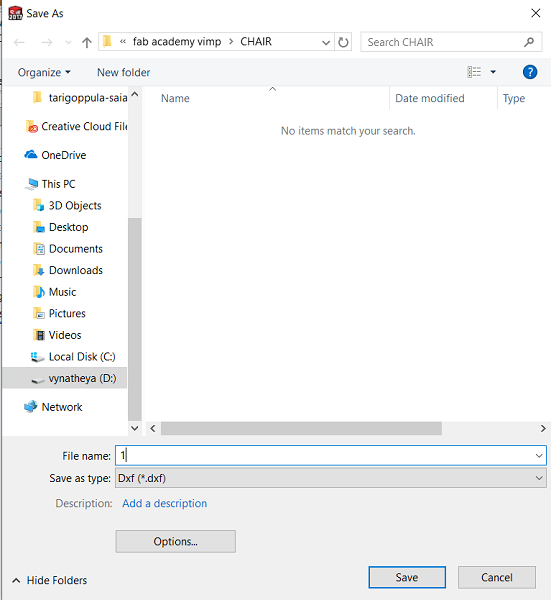

Steps to export .sld to .dxf

click on save as

click on save as type - .dxf

click on ok

so we can import in Aspire cam

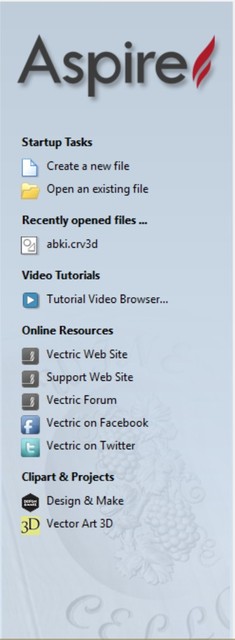

ASPIRE CAM

U can Download the software Here

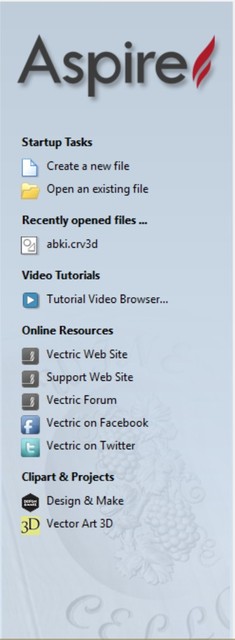

I used Aspire to generate toolpaths for my designs.I earlier planned to use Fusoin 360 for CAM but later end up using ASPIRE since fusion360 was not working properly on my PC. ASPIRE was recommended to us by our instructor, itís pretty easy to use and straight forward.

When You first open Aspire you are greeted with this screen :

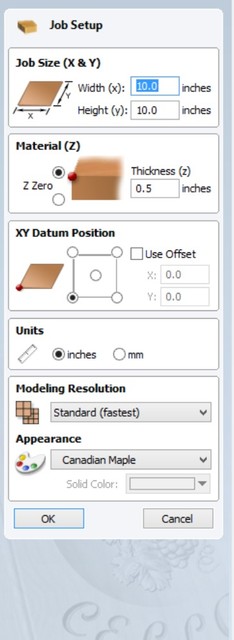

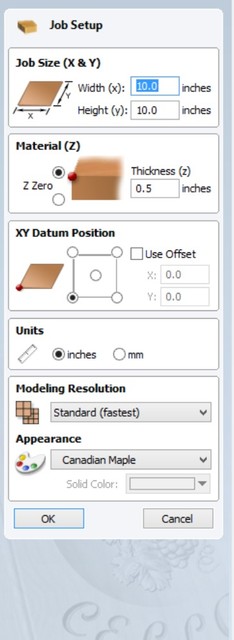

Enter the dimensions of the board youíll be cutting on :

You can also draw in aspire, which we did for test cuts :

If you have designed the files in a different softwares, save them as .dxf for 2D

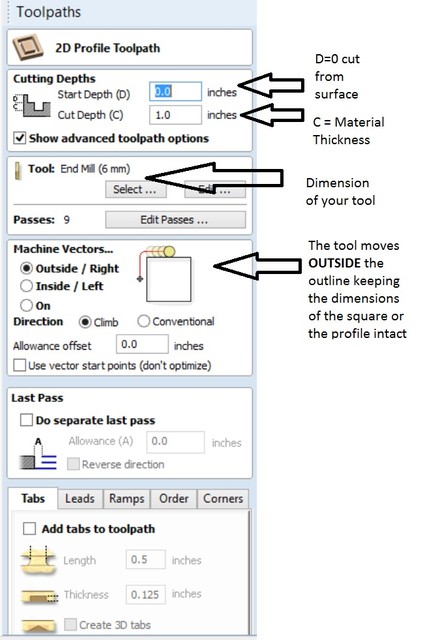

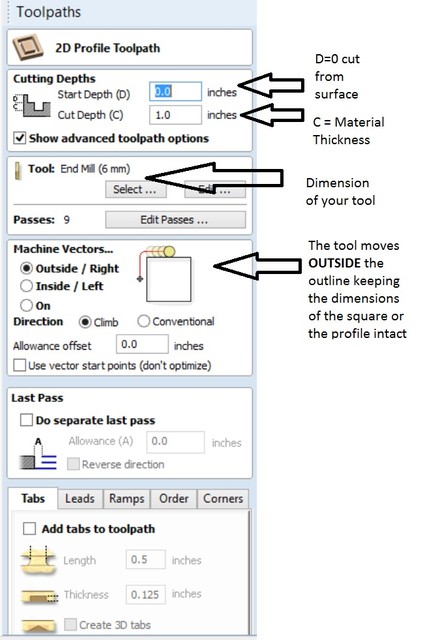

After loading your own file you create the toolpath :

After I created my fle I exported my file as .cnc and the I cutted my file in cnc wood router.

Cutting Speed and Feed i gave to my desigh

Cutting speed is defined as the speed (usually in feet per minute) of a tool when it is cutting the work.

The cutting speed in this machine is mentioned in percentage 10% to 100%, My instructor has asked me not to go beyond 70% due to safety reasons.

Feed rate is defined as toolís distance travelled during one spindle revolution.

The spindle speeds in the machine is denoted by a number followed by S. They are 4S, 5S, 6S, 7S. 4S being the slowest and 7S the fastest.Tha maximum spindled speed at 100% is 3200RPM.

This is my final product

Experiment Safely :-

Donít get too carried away with the numbers, use your common sense and trust your gut. Every bit is a little different and there is a wide range of densities in solid wood and different sheet goods. Also, always wear your safety glasses. It seems like an overly cautious measure many times, but consider the likely scenario of a small 1/8 inch carbide bit shattering. Itís not likely that wood dust will put you in the hospital, but a small shard of steel in your eye is something to reckon with.

Download .sld file here...

Go throught this safety instructions. Here

Group Assignment

For this week’s group assginment - visit here.

- Profile.

- Pocket.

- Drill.

- Engrave.

- Inlay.

- V-Carve.

- Texturing.

For more detailed information on operaitions click here.

Getting started with CNC Router.

U can Download the software Here

Cutting Speed and Feed i gave to my desigh

Cutting speed is defined as the speed (usually in feet per minute) of a tool when it is cutting the work.

The cutting speed in this machine is mentioned in percentage 10% to 100%, My instructor has asked me not to go beyond 70% due to safety reasons.

Feed rate is defined as toolís distance travelled during one spindle revolution.

The spindle speeds in the machine is denoted by a number followed by S. They are 4S, 5S, 6S, 7S. 4S being the slowest and 7S the fastest.Tha maximum spindled speed at 100% is 3200RPM.

Download .sld file here...