Applications and implications

I have to answer to these questions:

What will it do?

My final project it's called for now "Wanabee-Rockstar Helper Gyroswitch " or WRHG system.

It allows guitarist or else to triggered effects with rockstar movements.

The WRHG is composed by a transmitter fixed to the guitar neck with a clamp. This transmitter is equiped with a gyroscope and a radio transmitter.

It's transmitting gyro's data to one or several receivers. For FabAcademy I'll make one receiver acting like a footswitch.

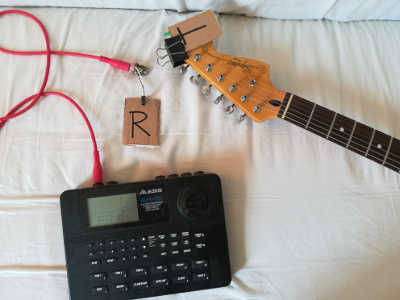

A footswitch is a simple button who's allow to triggered specific thing on a music device. For exemple, this rhythmbox can be triggered with a footswitch for stop/play rhythm and a another one to launch some break or change pattern:

So you just have to make a board to fool the machine who is sending some 3.3V into the machine:

But in the future I'll make some other receivers board to interact with computer for exemple like what I made for Interface and Application Programming week:

Who has done what beforehand?

Sang-won Leigh has made a "Programmable, portable, and remotely controllable guitar preamp/effector that plugs into a guitar."

The Input is an interface on a phone and the output is bluetooth board plugged between the guitar and the amp:

Vilhjalmur Magnusson made a theremin electric guitar:

Aaaaand the plastic guitar from the game Guitar Hero. To launch the special power you have to raise the guitar, there's a gyro in it.

And you have a lot of DIY electric guitar.

What materials and components will be required?

-

For the boards:

- Copper sheets

- 2 RF24

- 2 Attiny84

- 2 flat switch

- 2 10kO resistors

- 4 capacitors

- A lot of pinheads

- CR2032 battery holders

- PLA or resin for the enclosure

- I don't know yet for the clamp

For the product:

Where will they come from?

All electronic parts will come from the Waag.

PLA will come from my personal collection. It's It's Ice filaments

Resin will be Smooth-Cast 325 and Vytaflex from Smooth-On.

How much will it cost?

- Copper sheets -> 10€

- 2 RF24 -> 2€

- 2 Attiny84 -> 6€

- 2 flat switch

- 2 10kO resistors

- 4 capacitors

- A lot of pinheads

- CR2032 battery holders

- Jack audio ports

- PLA or resin for the enclosure

- I don't know yet for the clamp

What parts and systems will be made?

-Enclosures

-Clamp

-Boards

What processes will be used?

2d milling (for the enclosure), 3D printing or mold/cast (3d milling) for the clamp.

Electronic production

What tasks need to be completed?

-Design, mill and solder 2 boards.

-Design, print or cast the enclosure.

-Program the boards.

What questions need to be answered?

How to program RF24 radio with an Attiny84. If it doesn't work, it will be wired.

What is the schedule?

31/05 -> Designing and milling the board.

01/06 -> 07/06 Programming the boards.

08/06 Design the enclosure based on boards.

09/06 Making the enclosure.

10/06 Design the clamp.

11/06 Making the clamp.

12/06 -> 17/06 Time if there's problems.

17/06 -> 20/06: Making the doc, slides and other stuff.

How will it be evaluated?

The product is supposed to allow 3 types of movements. The biggest problems can be when you're using for exemple the z axis, it's also trigger the x axis because it's too sensible.

Another thing to avoid is latency between the movement and the output.

So it's will be good if the movement to trigger one thing is clear and if it's easy to do without any problem.