MECHANICAL DESIGN, MACHINE DESIGN

This week's assignment is to Design a machine (mechanism + actuation + automation), including the end effector, build the passive parts and operate it manually. And to Plan and make a machine.Document the group project and my individual contribution.

This project is a group project between me, Hassn Jaffar , and Ali Alsharakhat . We all worked together and pitched in in various parts of the project, but my main foucs was the electronics, motor control, gcode generation and the software side.

There are several parts of this projct. it is a group project done collaberativally between all Fab Lab Bahrain FabAcademy students that extends over the period of 2 weeks

This page details my individual contribution, the group page is linked and contains all the detials of the machine design. My main role was the electronics and programming part. the electronics part in the group project page is all my controbution.

This is a link to our common project page

Fab Lab Bahrain machine

link

link

And a link to the electronics page which I worked on and documented

Electronics section

link

link

Week 1 (Mechanical design)

During this week the goal is to make a machine, build the passive parts and operate it manually.

During this week my group and I have gone through a lot of time and effort to come up with a concept, design the machine, machine the parts, build it and operate it manually.

I will have to admit that I spent a lot of that time reaserching stepper motors, different software options and drivers to prepare for the upcoming week and the automated operation of the machine

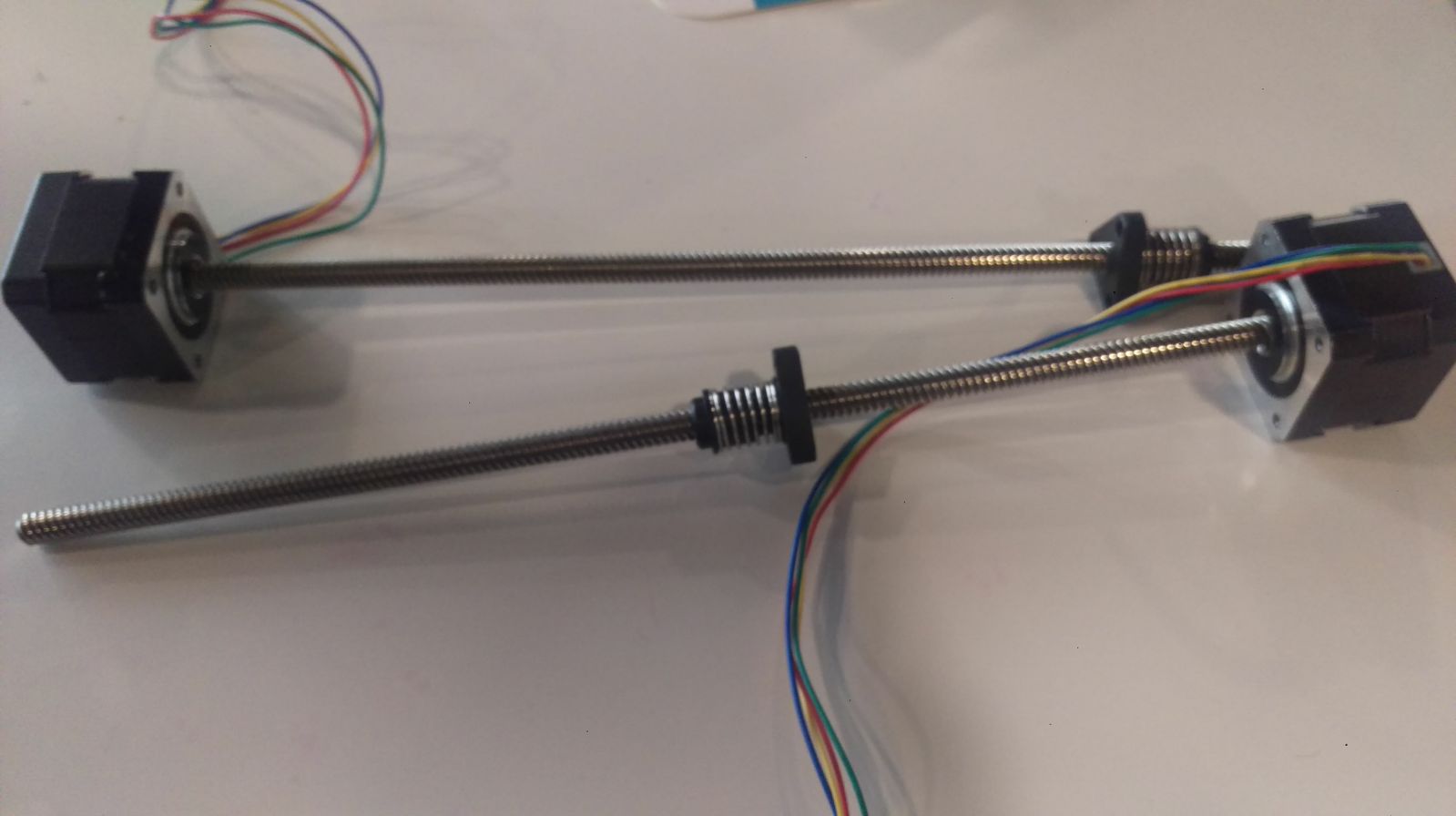

We had a lot of the elements already figured out at this point. We had the fab machine kit that involved a lot of the elements we will use in the machine so we did not have to think about that much. I did not have to select the components (The stepper motors) as those were already available. Which saved a lot of time to be honest.

Week 2 (Machine Design)

This is the week in which my role really comes in. The week in which the machine really becomes a machine! Can be operated via software to preform a spicific task, in this case, sketch a sketch through software.

The first really important step was to connect the stepper motors to the motor drivers now that they were mounted in the machine. I connected the stepper motors to the motor drivers twice in fact, once to the grblsheild motor driver and once to the geko stepper motor drivers (more details on that in the group electronics page)

I tried out alot of softwares until i found ones I liked. I tried spice, and pretty much every software on this page

Here until I found softwares that worked well, were not very buggy, didnt have connection issues and were avilable on mac. details on that is on the electronics page.

I conducted the testing of the machine using the different softwares, learned grbl commands, adjusted the grbl library to fit my needs and debuged the issues I had with the motors. everything is documented on the project electronics page.

The machine concept

The group decided to create a machine that would be useful and can help automate an operation that is currently done manually for the most part. We decided to create a cake decorating machine!

Cake decorating is done for the most part by hand and ius very time consuming and need experience. It is also difficult to prefect small details. Creating a machine that can automate that would solve a problem that exists in bakeries that have to decorate cake in large quanteties and for cake design that require precise details

The main function:

The machine would dispense icing in a spicific shape according a design selected by the user.

The design