Week - 8 Computer controlled Machining

About CNC Router Machine

Machine with a tool-holding head whose movements are controlled by a computer. Laser cutters, water jets, and CNC routers are all CNC machines

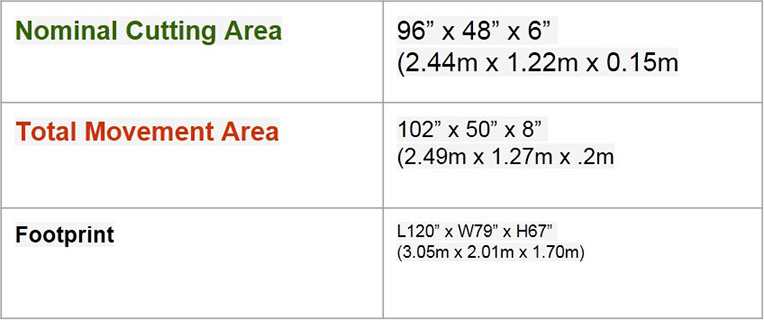

The ShopBot PRS Alpha 96,48 inchis a CNC machine that allows users to cut, drill, carve and machine

24,000 RPM, 3 horsepower Colombo spindle.

wood, plastic, MDF , Plastic and other materials along 3 axes, X, Y, & Z

Shopbot PRSalpha

Software Used

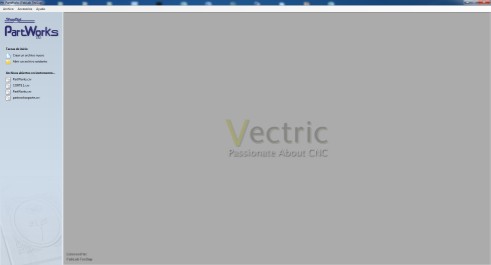

- Partworks 2d and 3d

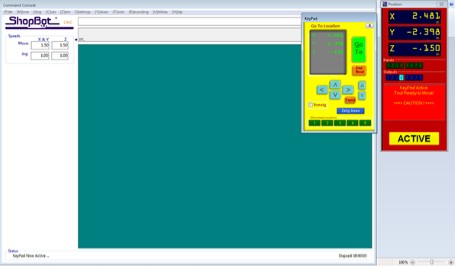

2. ShopBot

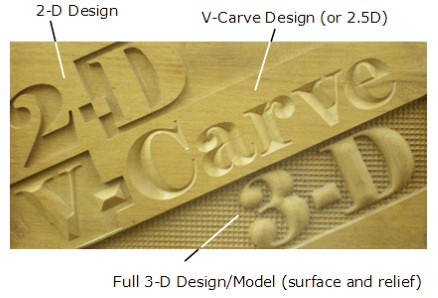

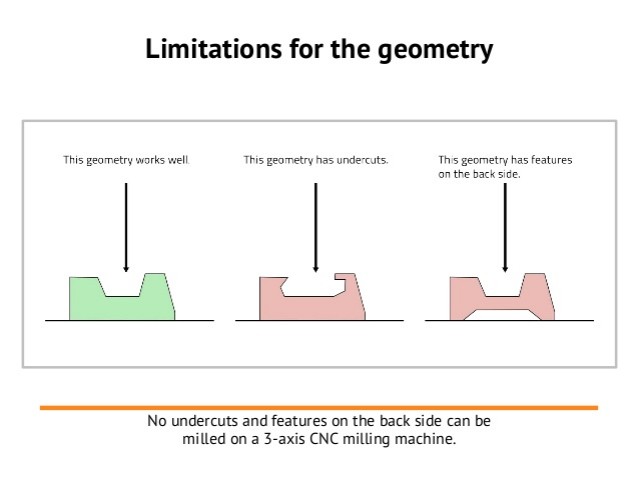

Difference between 2D , 2.5D and 3D CNC

when the Z axis of some CNCs moved only when X and Y were not moving, or only had a single up and down position. These earlier CNCs were thus not capable of 3D carving and were referred to as 2 or 2.5D tools

What is 2d CNC

If all we have is a flat outline of something we want to cut out, that would be considered 2D

What is 2.5d CNC

If we then added straight up and down movements of the cutter into and out of the material, we might now consider the project as 2.5D,cut features like grooves or flat pockets,where you are pocketing areas (e.g. around letters in a sign)All such cutting can be done in one or more different cutting planes after plunging to a cutting dept, V-carving as a 2.5D design process.

What is 3d CNC

this capability is technically described as 3-axis interpolation, which means that moves are made smoothly in 3D space using diagonals and curves. In 3D, your CNC cutter tip follows paths at 3D angles or in 3D curves in order to mill or carve complex shapes into the material

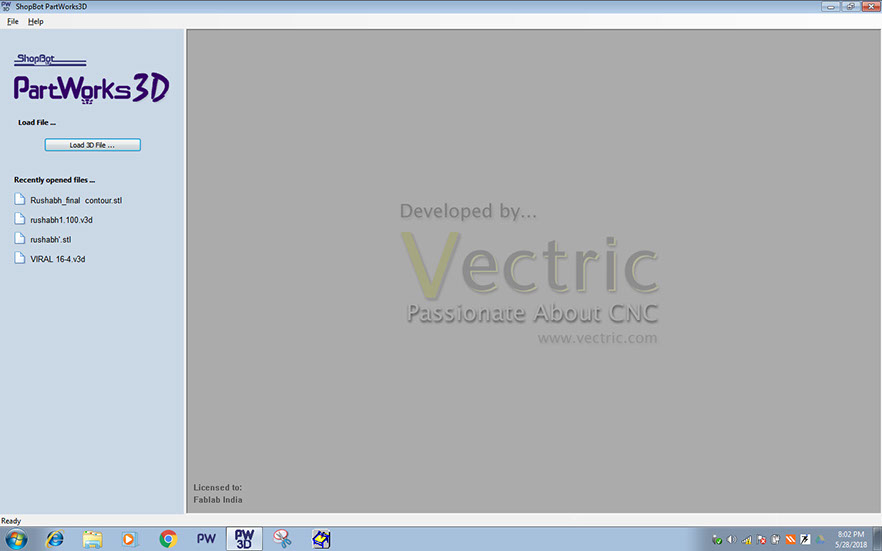

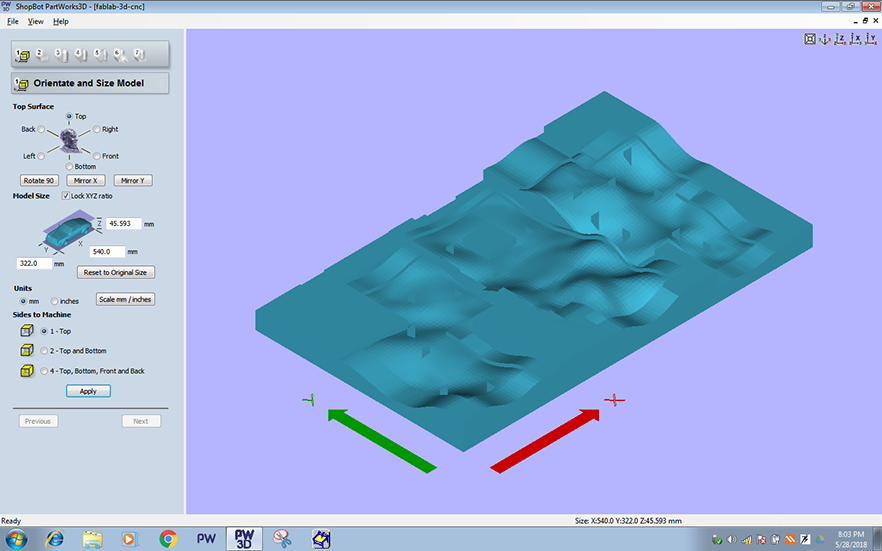

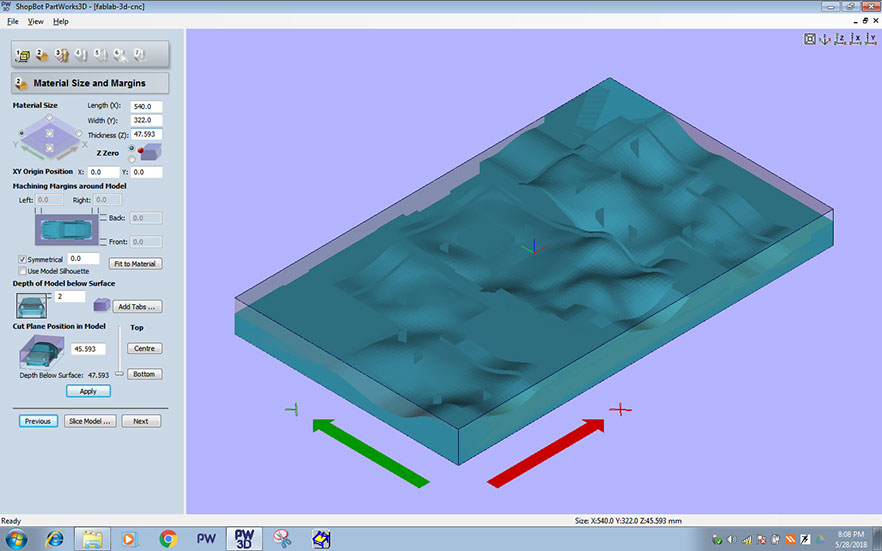

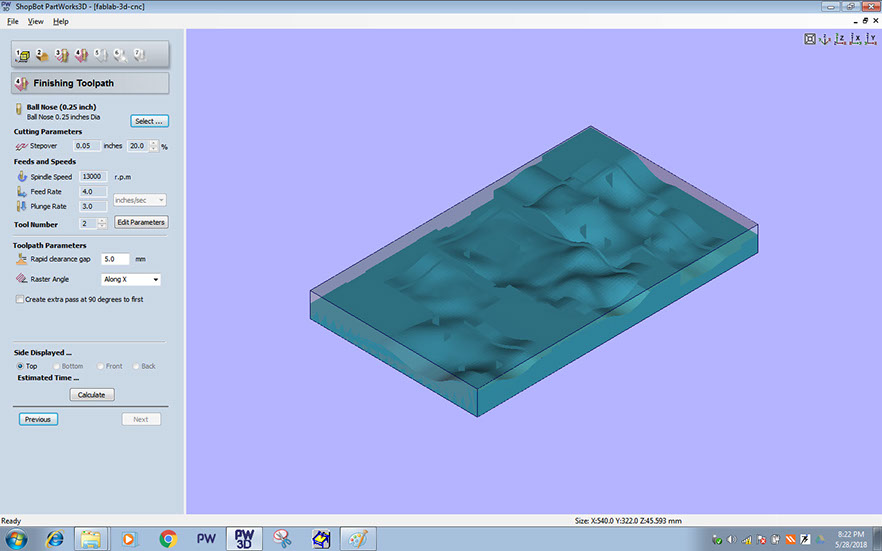

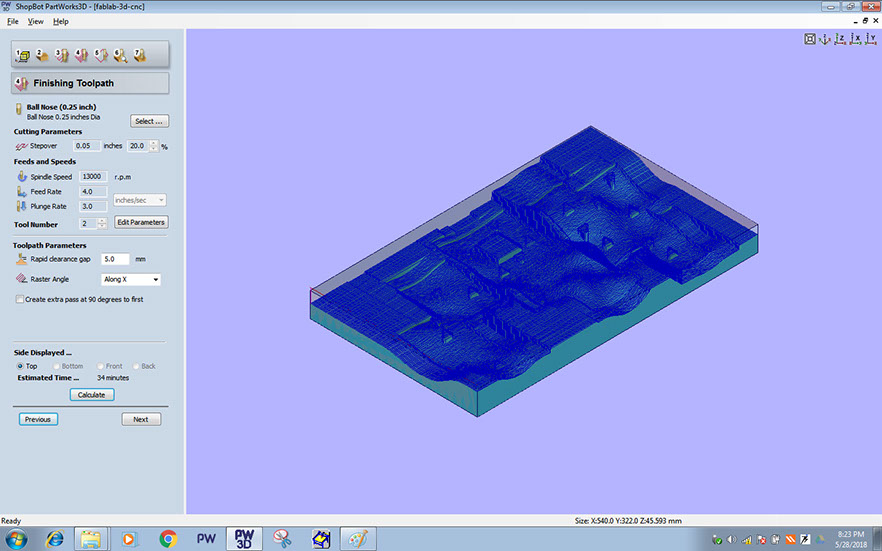

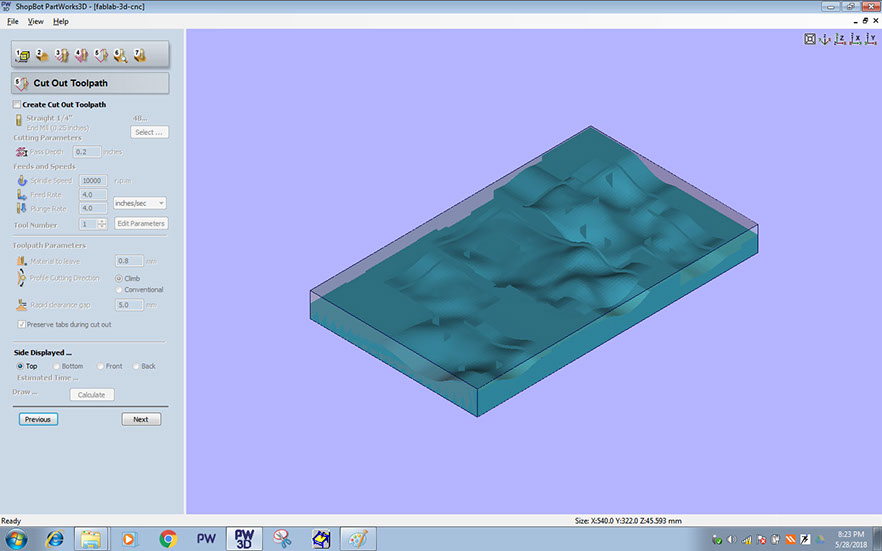

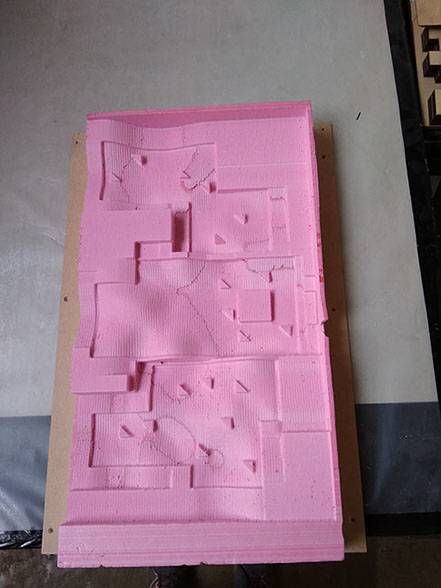

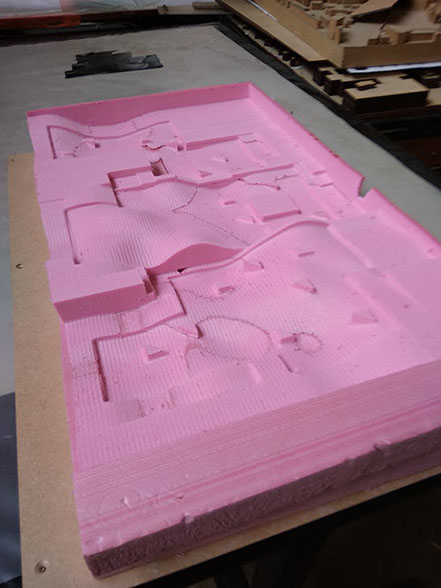

3D CNC -Working on Partworks 3d software:

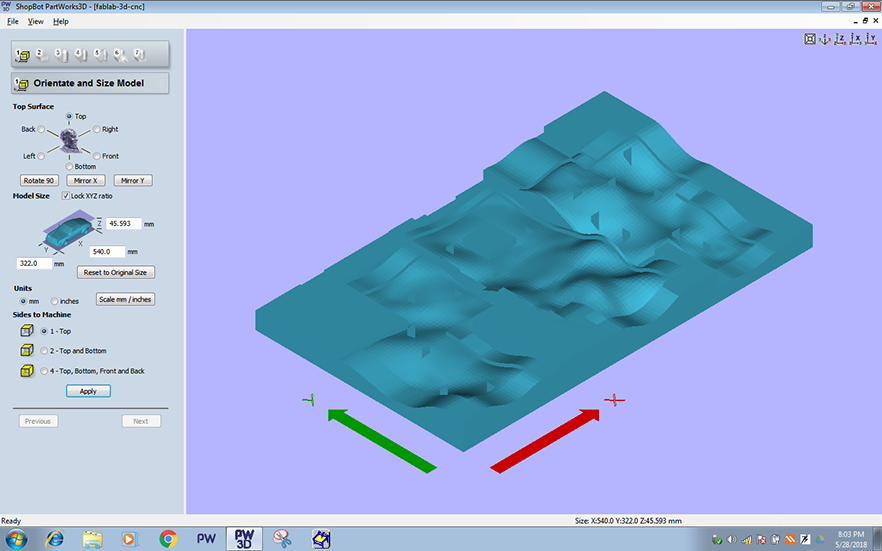

Load 3d file in PartWorks 3d software

Orientation and size model

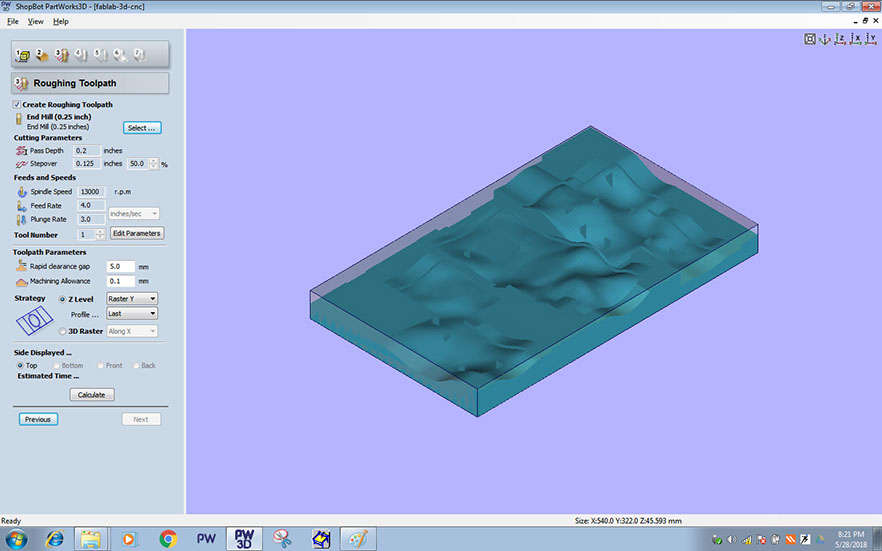

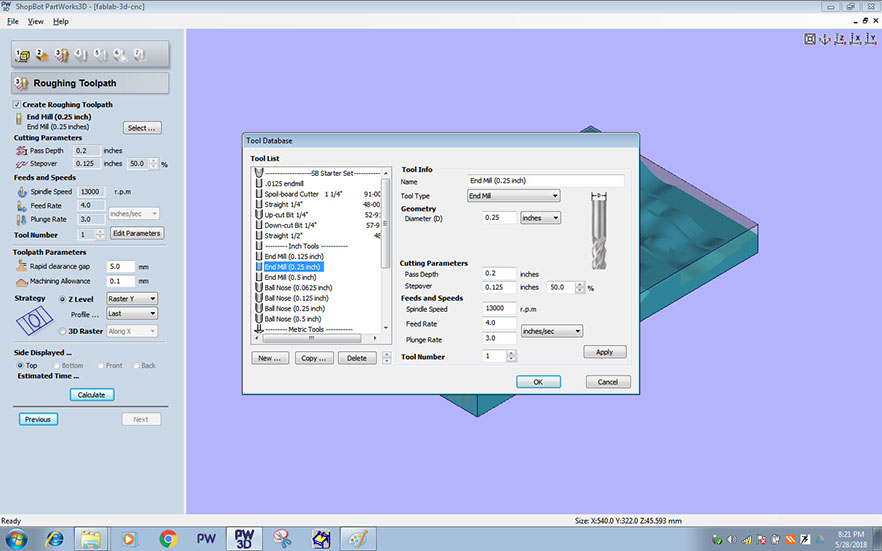

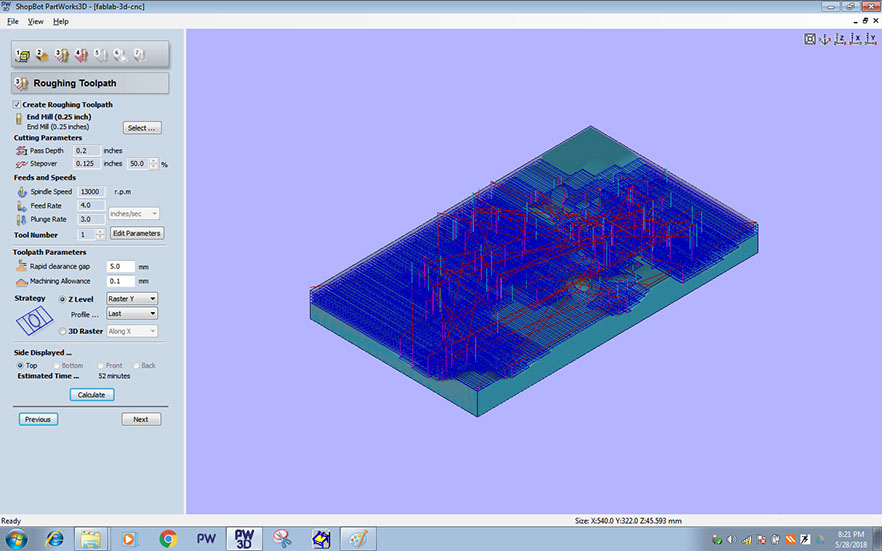

Roughing toolpath

Material size and margin

Finishing toolpath

Cut toolpath

Preview machining

Post processor

Working on Shopbot CNC machine guideline:

Step 1 Mounting material and tool on machine:

- Check your material is straight and stiff

- Make sure your material don't have any nail/screw/bolt or any metal object. This will break the tool and damage the machine.

- Mount the material on machine bed by screwing it from sides and corners

- Make sure material is straight and tightly fitted with sacrificial board

- Mount the tool by removing collect nut and dust collector sleeve

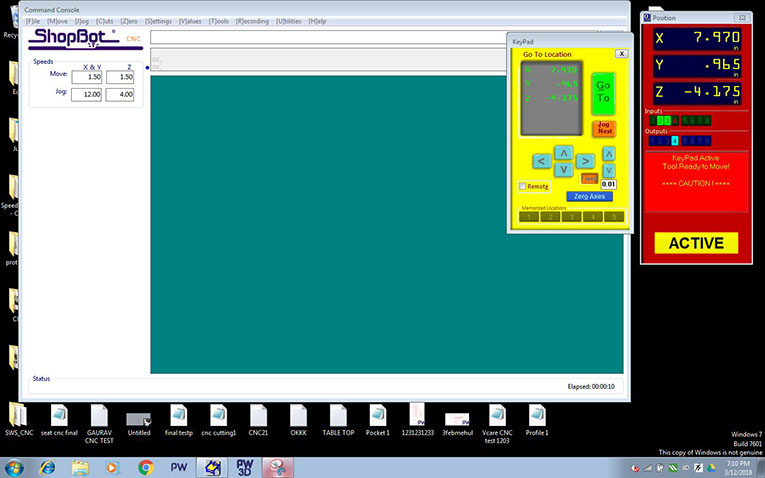

Step 2 Getting started with machine

- Turn ON main power switch

- Make sure computer is connected with CNC machine

- Turn ON the red switch near control box

- Insert the Key and turn it on

- Press reset button (Green) on Dongle box

- Turn on Shopbot 3 software

- Warm Up spindle routine toolpath and wait for 9 minutes

Zeroing the table:

- Use Keypad dialog box on Shopbot 3 software to navigate and move spindle at origin

- Set X, Y and Z zero by moving tool at material origin point

- Move spindle up once Z zero gets completed

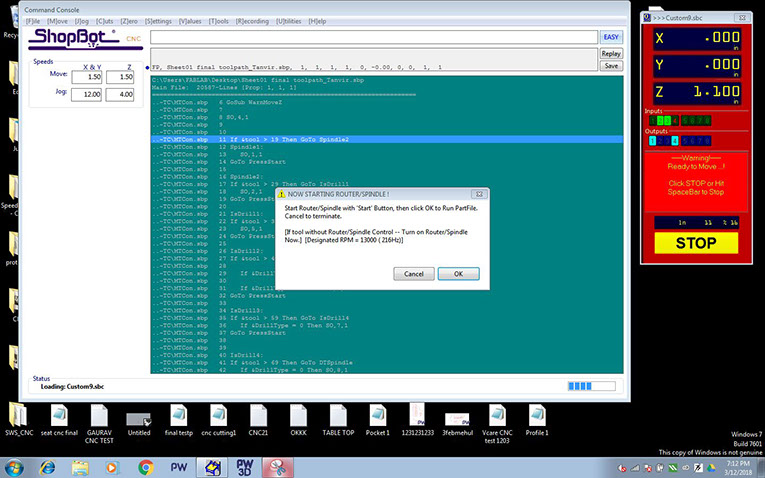

Starting a job:

- Import .sbp toolpath file in Shopbot 3

- Hit green Start tab

- Read dialog box carefully and follow instructions

- Turn on spindle

- Click Ok to start cutting

Emergency stop:

There are three emergency stop buttons that one can use,

- You can press space bar on the keyboard to pause operations

- Hit red stop button from yellow dongle which is on your hand

- Hit Emergency switch located on machine left side

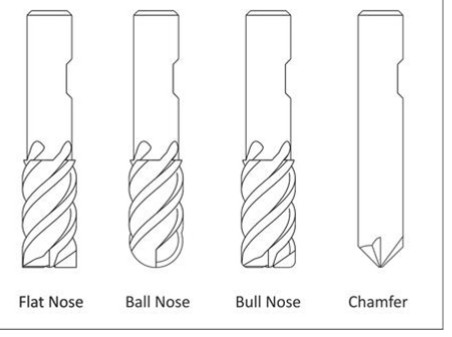

For more detail refer

http://mindworks.shoutwiki.com/wiki/Cutter_Types_(Mill)

Material use with Shopbot CNC

They are capable of cutting 2D and 3D shapes in wood, foam, plastic, some non-ferrous metals, and a variety of other materials

Allowed

1 MDF

2 Plywood

3 foam

4 cardboard

NOT Allowed

1 Metal

Safety Measures

•always wear safety glasses when closely observing cutting tools

•always wear safety glasses and hearing protection when operating CNC machines.

•always wear safety boots or other suitable footwear.

•always keep long hair covered when operating CNC machines.

•always keep hands clear of moving parts during machining operations.

•always avoid contact with cutting edges when handling tools or changing tools by hand.

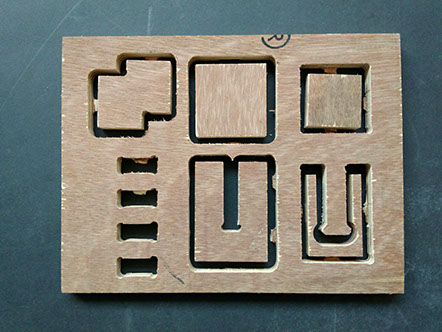

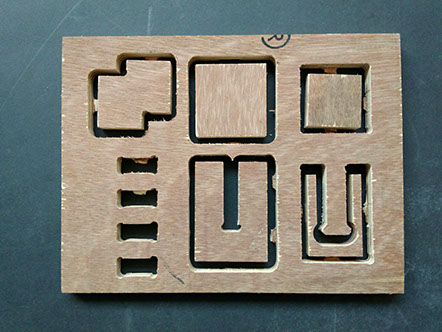

Exploring 2d CNC

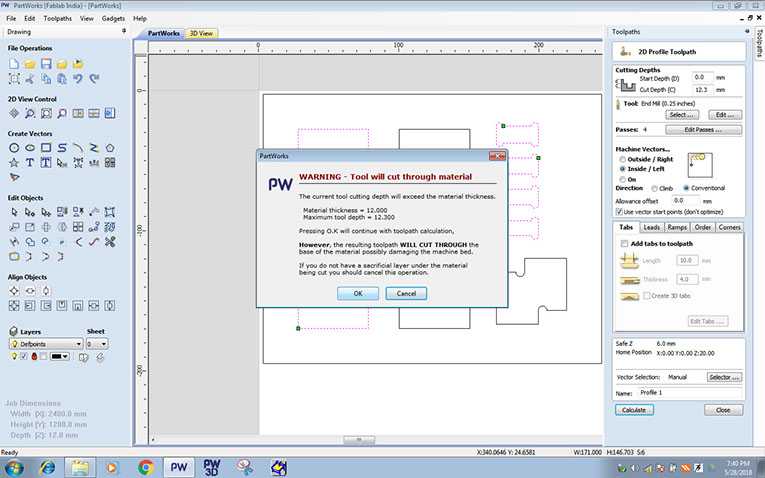

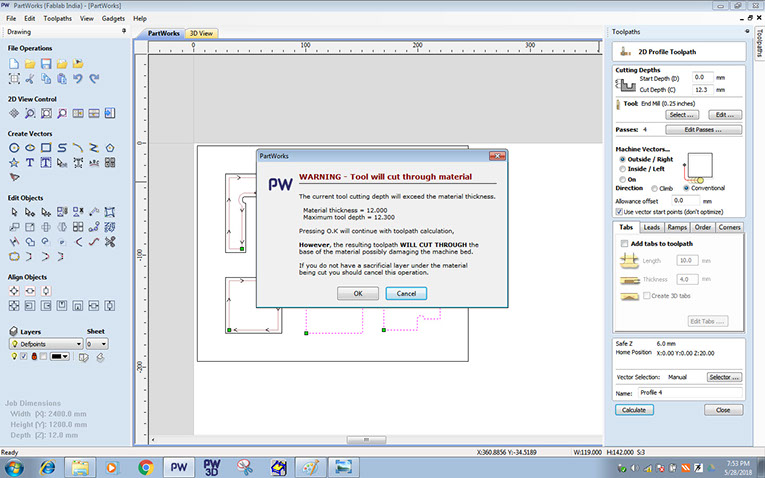

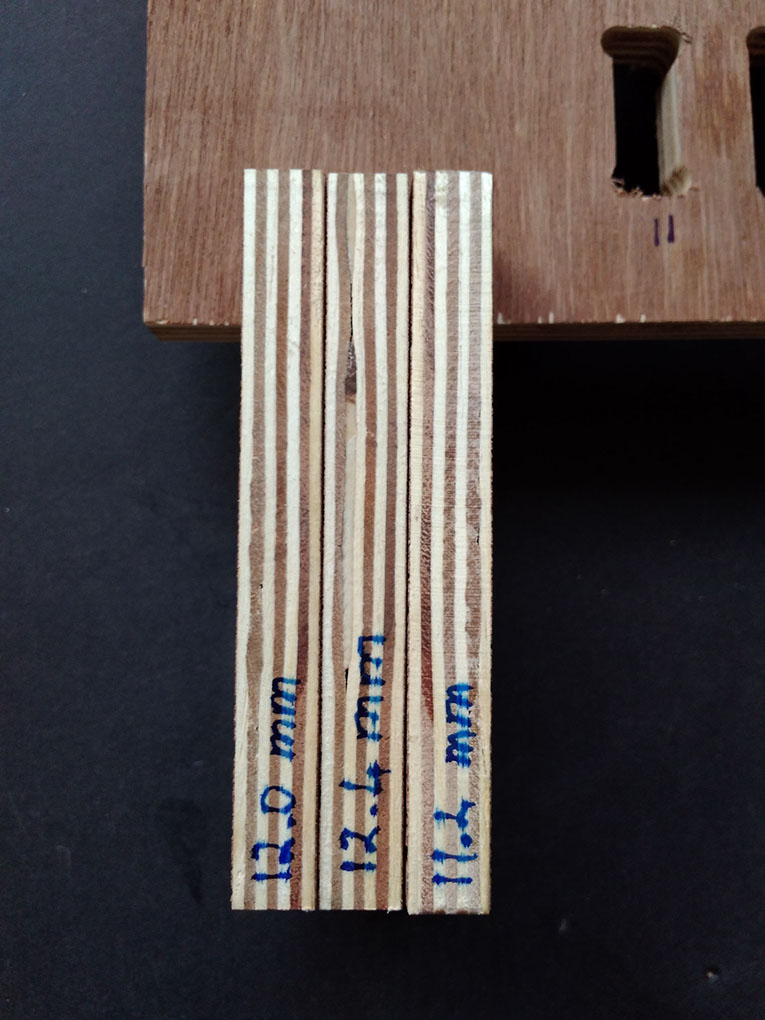

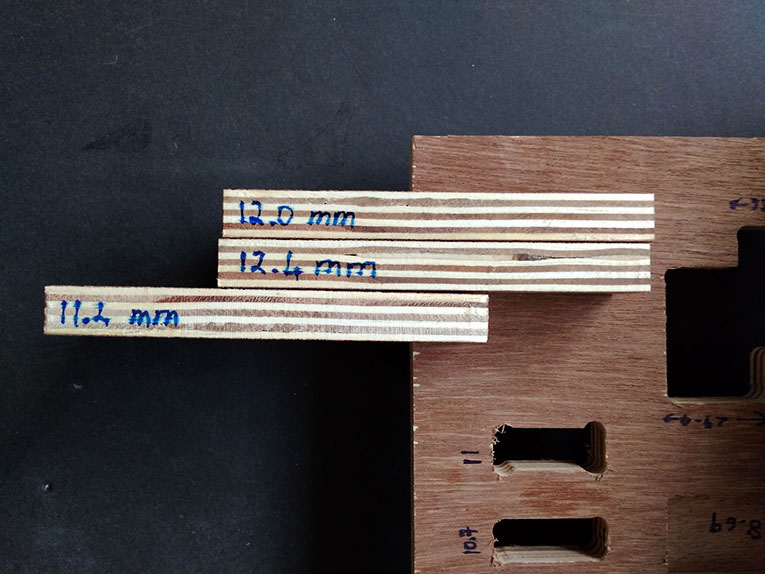

We plan a exercise for Testing The T- bone, outside and inside cutting , we are doing this test on 12 mm plywood

Steps for this

A. Design the fine in autocad

B. Tool path generation in part-works

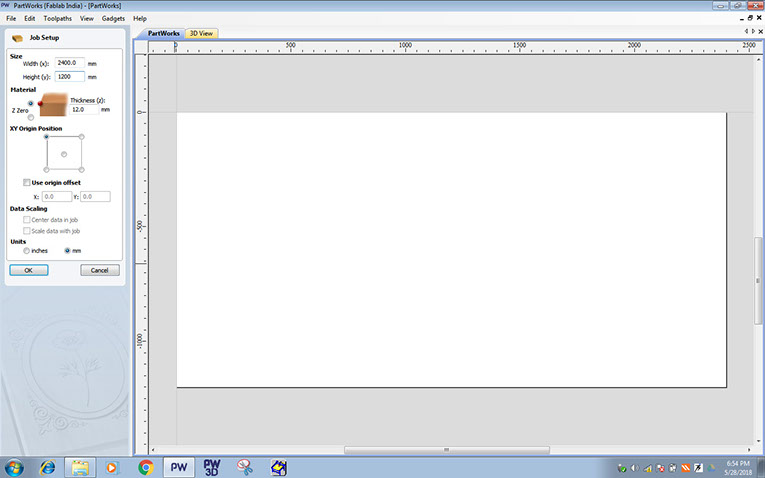

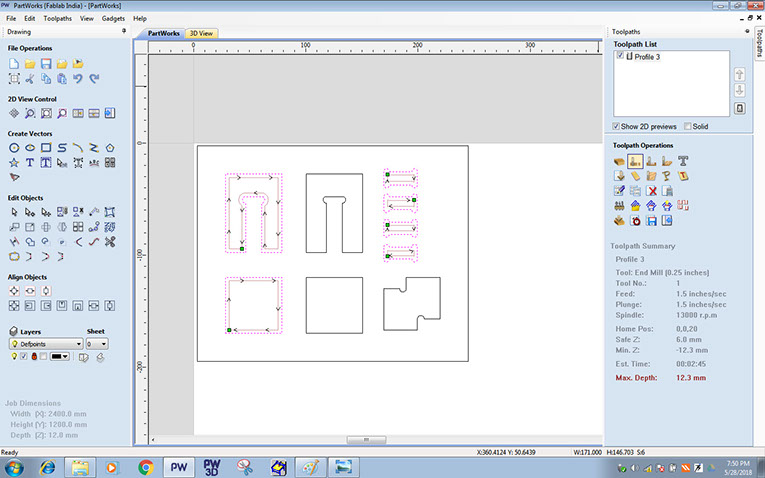

- Opening the part-works software g1

- Assign the dimension of your sheet , here we keep the bed size of 2400*1200 mm and selecting top point as origin

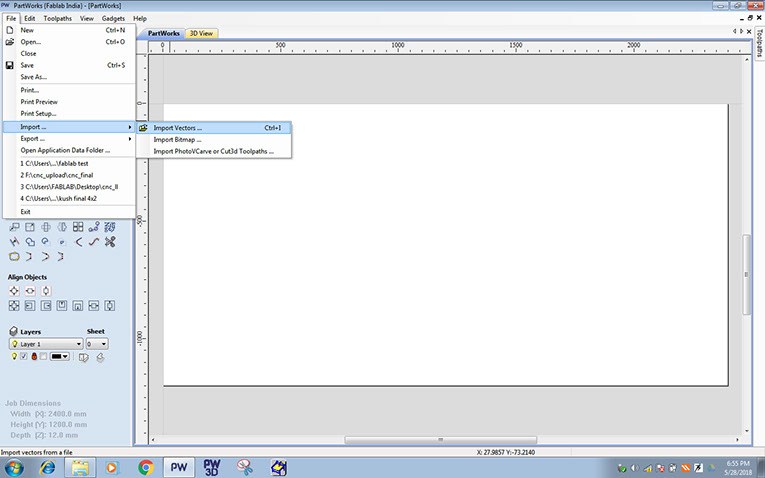

3 importing that file in partworks

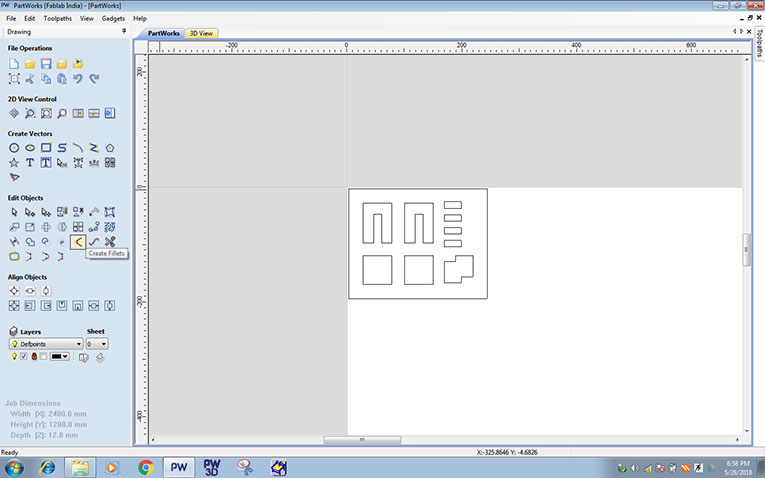

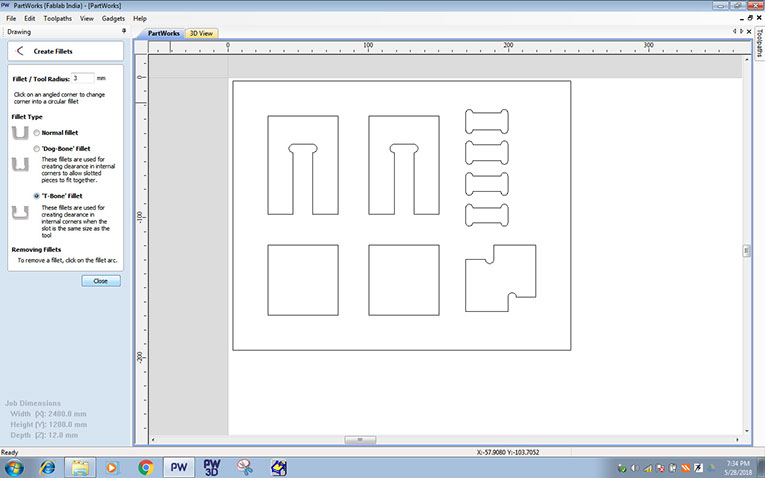

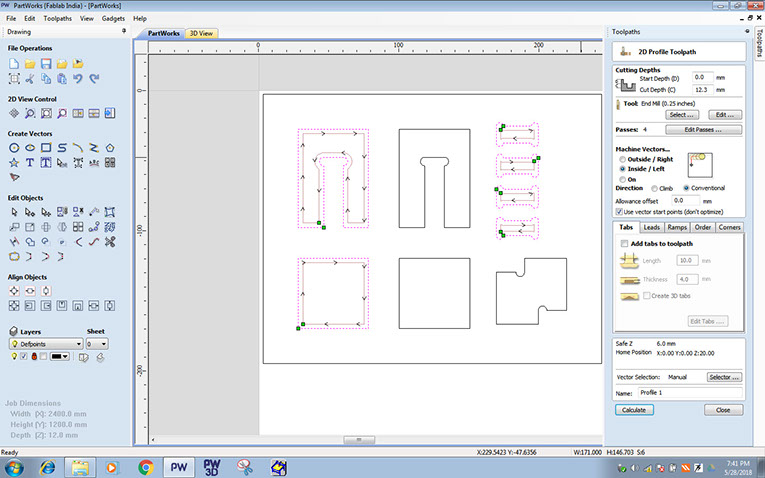

4. Selecting the profile and creating the fillets

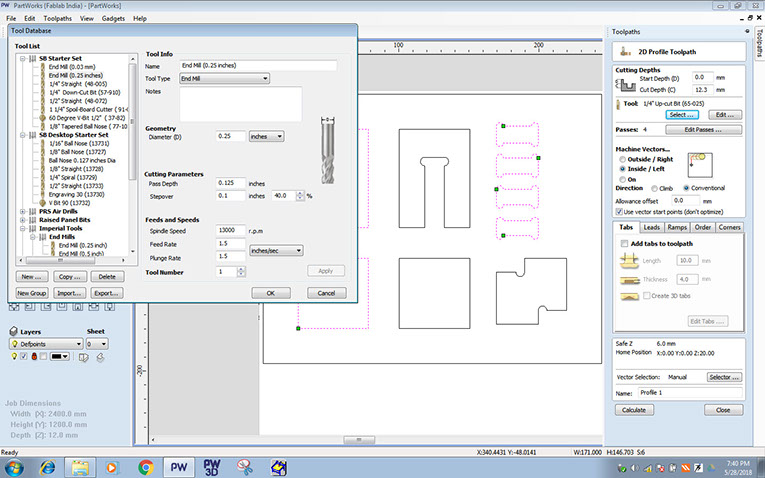

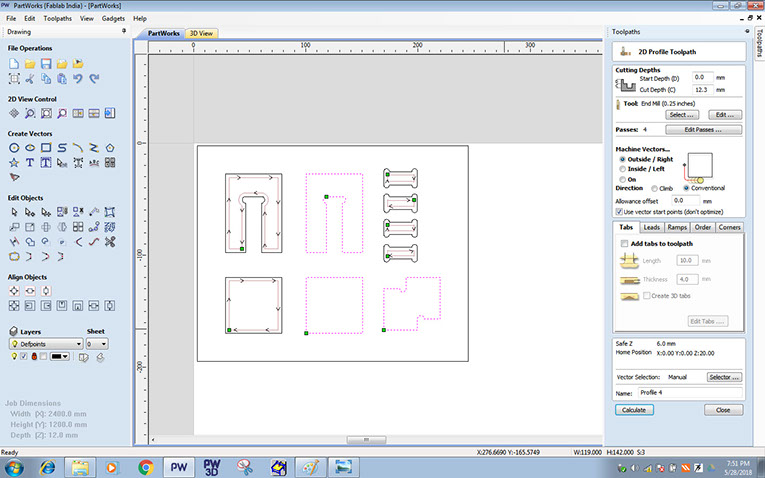

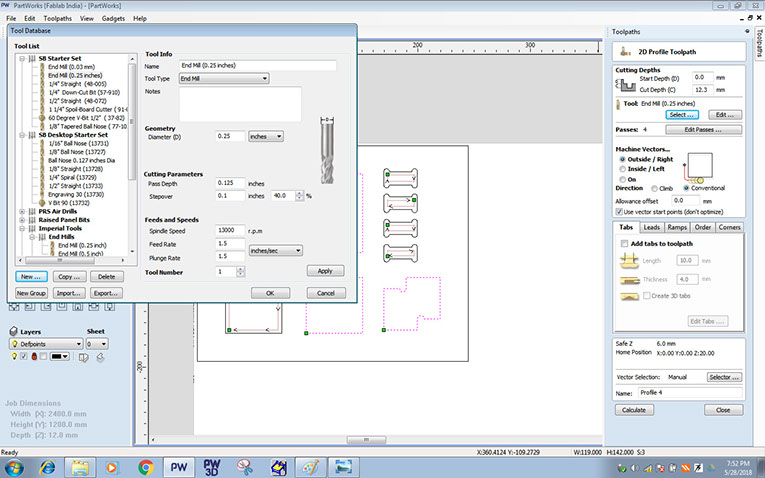

5. Creating the inside tool path selecting the tool for milling the tool selection is based on material and its thickness also on the size of your cut

6. Once you set all this parameters you are done with tool path now just select the calculate to generate the tool path

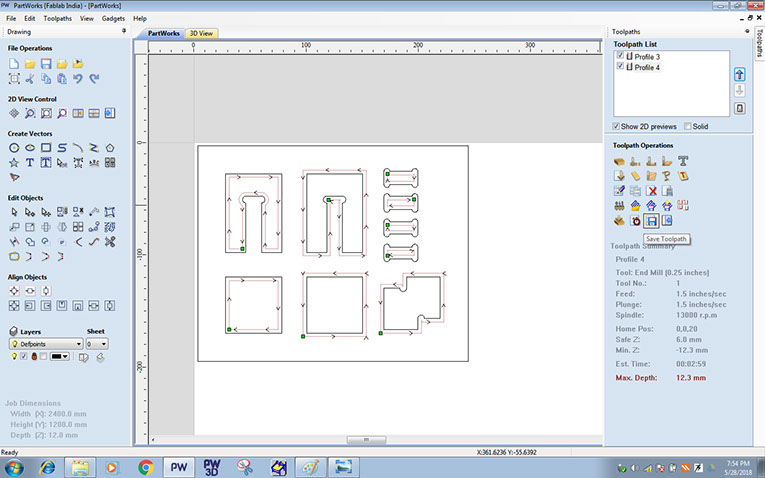

7. Creating the outside tool path similarly as inside tool-path

8. Save tool path

C using shop-bot software for operating machine

Setting the origin and give spindle warm-up which is From c5 command and load file for cut path before

Images of final outcome

Conclusion

- For designing the press fit t bone fillet is good option

- On measuring the outside and inside diameter of parts after cutting we get to know that there is different tolerance of cutting for both inside and outside cut this is depend upon your tool diameter

- If you want inside part of exact dimension than give it under outside boundary selection in tool path generation as tool will move outside so you get exact dimension

- If you want outside part of exact dimension to cut than give it under inside boundary selection in tool path generation as tool will move inside so you get exact dimension

Original Files

- All the original design files can be downloaded from here