Week 05: 3D Scanning and Printing

- Test the design rules for your printer(s) (group project)

- Design and 3D print an object (small, few cm) that could not be made subtractively

- 3D scan an object (and optionally print it)

Learning outcomes:

- Identify the advantages and limitations of 3D printing and scanning technology

- Apply design methods and production processes to show your understanding.

Have you:

- Described what you learned by testing the 3D printers

- Shown how you designed and made your object and explained why it could not be made subtractively

- Scanned an object

- Outlined problems and how you fixed them

- Included your design files and 'hero shot' photos of the scan and the final object

My Process

Background

I have a fair amount of experience with FDM 3d printers (especially the Ultimaker series), so I wanted to get my feet wet with SLA printing. 3D Scanning is new to me.

Testing 3D Printer

Our lab has a couple of Formlabs Form 2 SLA 3d printers that I wanted to try out. I started by grabbing a formlabs test file, akin to what Neil showed us in lecture. I found one that I liked here, among several others:

I downloaded the Form Lab Preform 3d slicing/printing software and loaded my STL file.

I used the "generate supports" tool, and then sent the file to the printer

I made sure the resin setting in Preform matched the resin that was loaded into the printer.

This is what the Form Lab Form2 SLA printer looks like.

It took about 3 hours to print, and so I left it to print over the weekend. When I came back Monday, someone had kindly removed my print from the printer and run it through the alcohol wash station.

Here's another view

I broke off the supports.

There was a small piece of debris that got caught between the layers. It may have been in the tank from the beginning or fallen from the build platform.

The print quality was not great. Any holes/deeply concave parts did not come out - instead they were just filled in. It looks like the resin just flowed into the crevices and bonded. It's possible it was left in the print tank too long after printing. Alternately there may be something else that needs adjusting on the printer. This would need more testing/callibration if I wanted to do parts with fine concave details.

3D Scanning

Our lab has a variety of scanners. At first I tried to setup the 3D Systems Sense scanner, but I found it has some pretty annoying usage restrictions - you can only setup the software if you register the device and get an activation key. I wanted to try the Sense because it is affordable and I thought it might be a good option for my Fab Lab to purchase one, but given these onerous DRM restrictions, I am not inclined to buy one now.

So, we moved on to a much higher end Creaform HandyScan 3d scanner. The Creaform scanner requires the use of "positioning targets" - small adhesive dots placed on the object (or in the background in fixed relationship to the object. I looked around for an interesting object, and picked a Canon DSLR camera we had in the lab.

Once the dots were in place, I began scanning it. The Creaform uses a grid of visible lasers to determine the shape of the object.

The scan was not perfect. The STL file generated had a lot of artifacts:

Highly reflective surfaces, like the lens or the LCD screen were not picked up by the scanner. Small details and highly concave sections were also missed.

Here's the STL of the raw scan data:

To fix and solidify the model, I brought it into Meshmixer, a free 3d modeling tool from Autodesk. Once in Meshmixer I used the Analysis > Inspector tool to Autofill all the holes in the mesh

After Autofilling the holes, I also used some of the sculpt tools to fix some of the shape by hand. Then I used the Edit > Cut plane tool to create a flat bottom for the camera so it could be 3d printed more successfully.

Here's the repaired, prepped STL file:

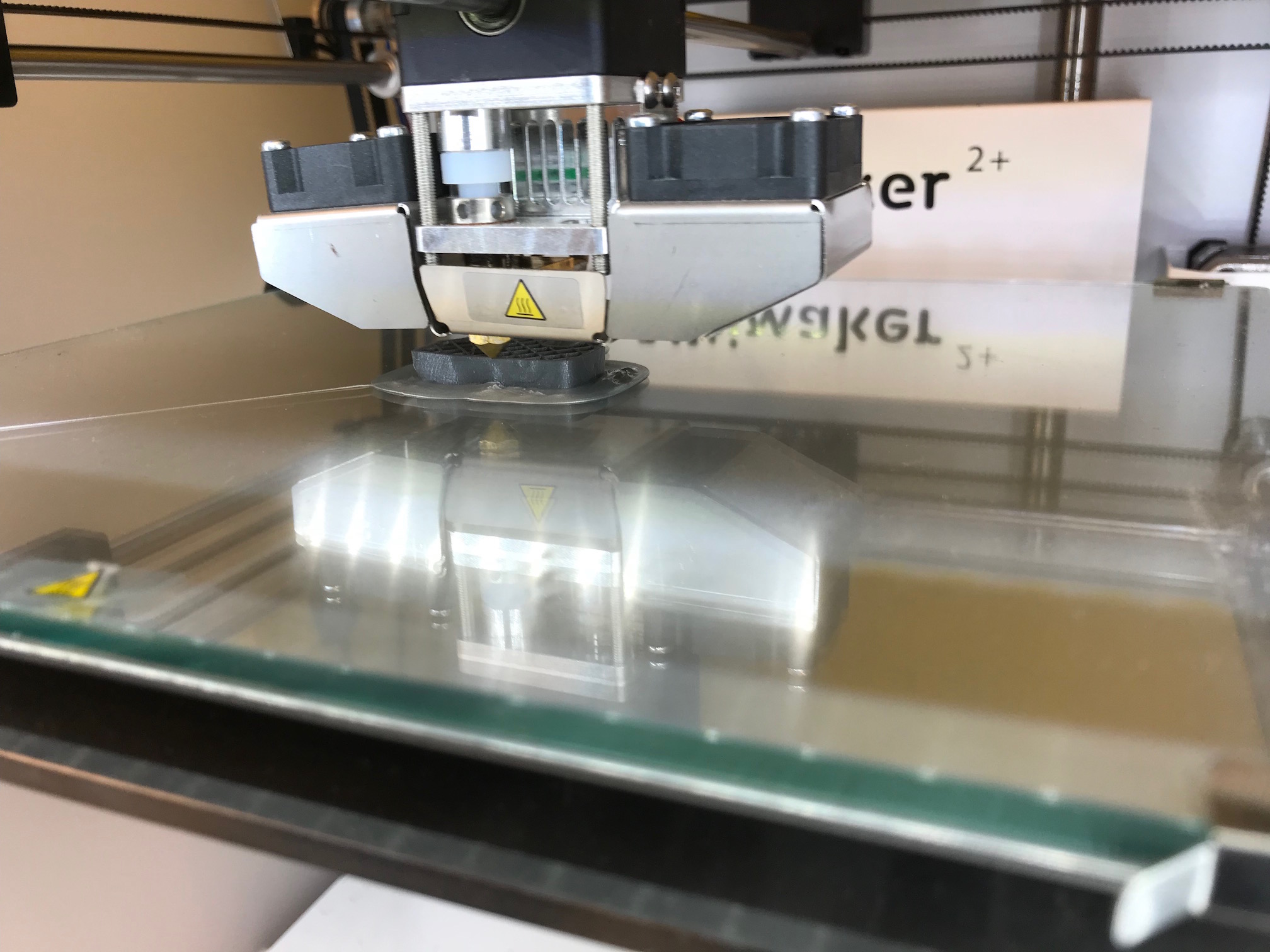

I decided to try to 3d Print this object. I brought it into Cura - the slicing tool for my Ultimaker 2+ printer.

I scaled it down quite a bit for a faster print and to save material.

3D Printing

To print something that can not be easily made by subtractive manufacturing, I wanted to play with organic, voronoi-ish designs. I went and found a Darth Vader bust that I had worked on some time ago and set to work.

I had modified the Darth Vader bust so that it could be printed in one piece with no supports. I can no longer find the source file I used on Thingiverse, but it was similar to this one (the one I used may have been removed for copyright infringement since I downloaded and remixed it). The modification I made entailed joining the helmet top to the helmet base (in the background in the picture below) and then cutting a plane through the bottom of the helmet to cutoff the shoulder and ensure that the "wings" of the helmet landed flat on the build plate.

I have successfully printed this modified bust several times in the past.

I brought this Darth Vader bust into Meshmixer, did a quick Analysis > Inspector to repair a couple of holes, and then I used the Edit > Patterns tool to make the voronoi-ish pattern.

I did another Analysis > Inspector pass to repair a couple holes that popped up, and then exported the STL to my slicer.

I was reasonably happy with the final product.

A quick movie shows the pattern a little better than the photos:

Design Files

Formlabs Test file (.STL file)

Canon Camera Raw Scan data (.STL file)

Canon Camera repaired scan data (.STL file)

Darth Vader Bust (.STL file)

Darth Vader Voronoi-ish Bust (.STL file)