Week 16

Wildcard Week

assignment

Individual Assignment

1- Design and produce something with a digital fabrication process not covered in another assignment, documenting the requirements that your assignment meets and including everything necessary to reproduce it. Possibilities include (but are not limited to) composites, textiles, biotechnology, robotics and cooking.

I assembled the pieces into the two parts that interlocked to form a 3m cavity.

I put on the necessary safety equipment to proceed working with the resin, silicone gloves and either a well ventillated room or a chemical mask.

>

I sprayed the inside of the mold with a silicone release agent.

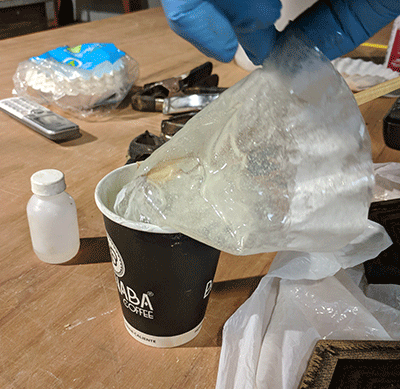

Next, I measured out the proper quantity of resin, using 0.03:100 of the part A and B catalyst. I added the part B catalyst to the resin and stirred the mixture for two minutes to allow the two parts to mix together.

I began dunking the coffee filters in the resin one by one and letting them absorb it.

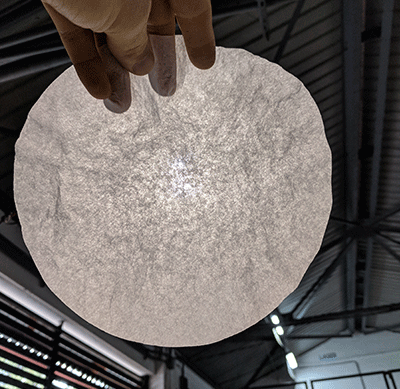

To my surprise the filters appeared to disappear in the resin.

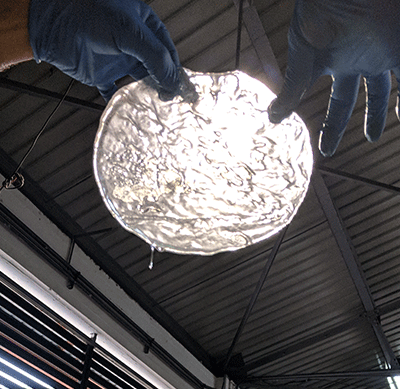

After 5 layers the resin began to coagulate so I quickly placed the mold together and clamped it.

My fingers had become covered in the resin so I was grateful to have used the latex gloves. Unfortunately I was unable to save them and had to throw them away. They made the job very easy to clean up and kept me safe from toxic chemicals.

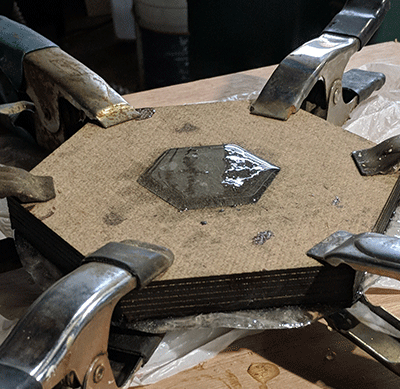

After 1 hour I checked on the mold, the resin had solidified and created the shape I wanted with the properties I was hoping to achieve!

I was happy that I could create a composite board that was both functional and had a geometric form. I would have to spend some more time doing some material testing to determine how long it would take the composite to decompose, how much of an insulator it was, how long it was able to withstand condensation and how long did you have to wait before it stopped smelling so strongly.

I was able to combine the resin with coffee filters to achieve results that were beyond what I expected. Most importantly, I learned more about the CNC milling machine which will be very useful for making 3D molds.

1- Design and produce something with a digital fabrication process not covered in another assignment, documenting the requirements that your assignment meets and including everything necessary to reproduce it. Possibilities include (but are not limited to) composites, textiles, biotechnology, robotics and cooking.

Files used:

Laser cut file .RDD DownloadWalkthrough

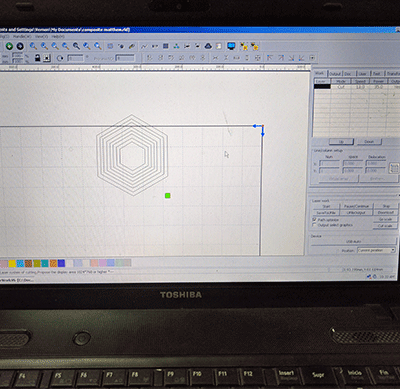

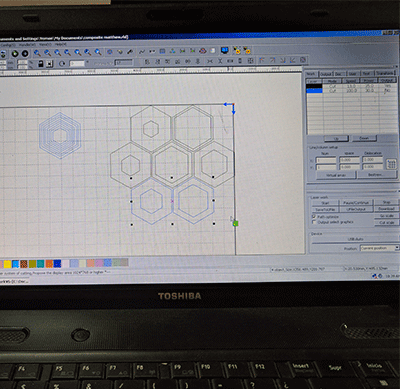

I designed a mold that would be able to fit together in two parts and create a sealed interior. Using the laser cutting software I copied a hexagon shape into individual pieces to form an interior void of 3mm.

|

|

I assembled the pieces into the two parts that interlocked to form a 3m cavity.

I put on the necessary safety equipment to proceed working with the resin, silicone gloves and either a well ventillated room or a chemical mask.

>

I sprayed the inside of the mold with a silicone release agent.

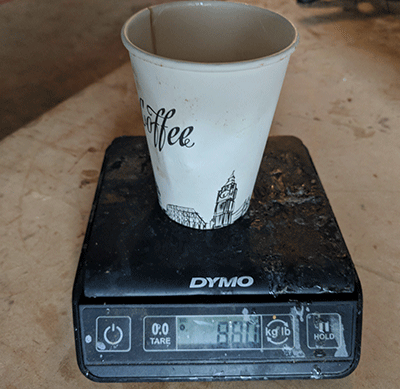

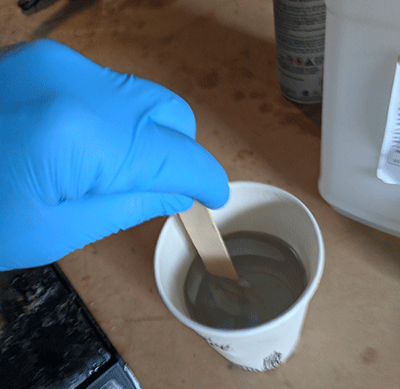

Next, I measured out the proper quantity of resin, using 0.03:100 of the part A and B catalyst. I added the part B catalyst to the resin and stirred the mixture for two minutes to allow the two parts to mix together.

|

|

I began dunking the coffee filters in the resin one by one and letting them absorb it.

|

|

|

|

To my surprise the filters appeared to disappear in the resin.

|

|

After 5 layers the resin began to coagulate so I quickly placed the mold together and clamped it.

|

|

My fingers had become covered in the resin so I was grateful to have used the latex gloves. Unfortunately I was unable to save them and had to throw them away. They made the job very easy to clean up and kept me safe from toxic chemicals.

|

|

After 1 hour I checked on the mold, the resin had solidified and created the shape I wanted with the properties I was hoping to achieve!

|

|

|

I was happy that I could create a composite board that was both functional and had a geometric form. I would have to spend some more time doing some material testing to determine how long it would take the composite to decompose, how much of an insulator it was, how long it was able to withstand condensation and how long did you have to wait before it stopped smelling so strongly.

Conclusion

This week I was interested in making a tile or panel that could fit into a slot between two other layers. It had to be thin but strong and also opaque. I had recently worked with a clear resin and so I thought about reinforcing it with a natural fiber in the same way that ply are laid to make plywood.I was able to combine the resin with coffee filters to achieve results that were beyond what I expected. Most importantly, I learned more about the CNC milling machine which will be very useful for making 3D molds.