Week 20

Final Project

Project

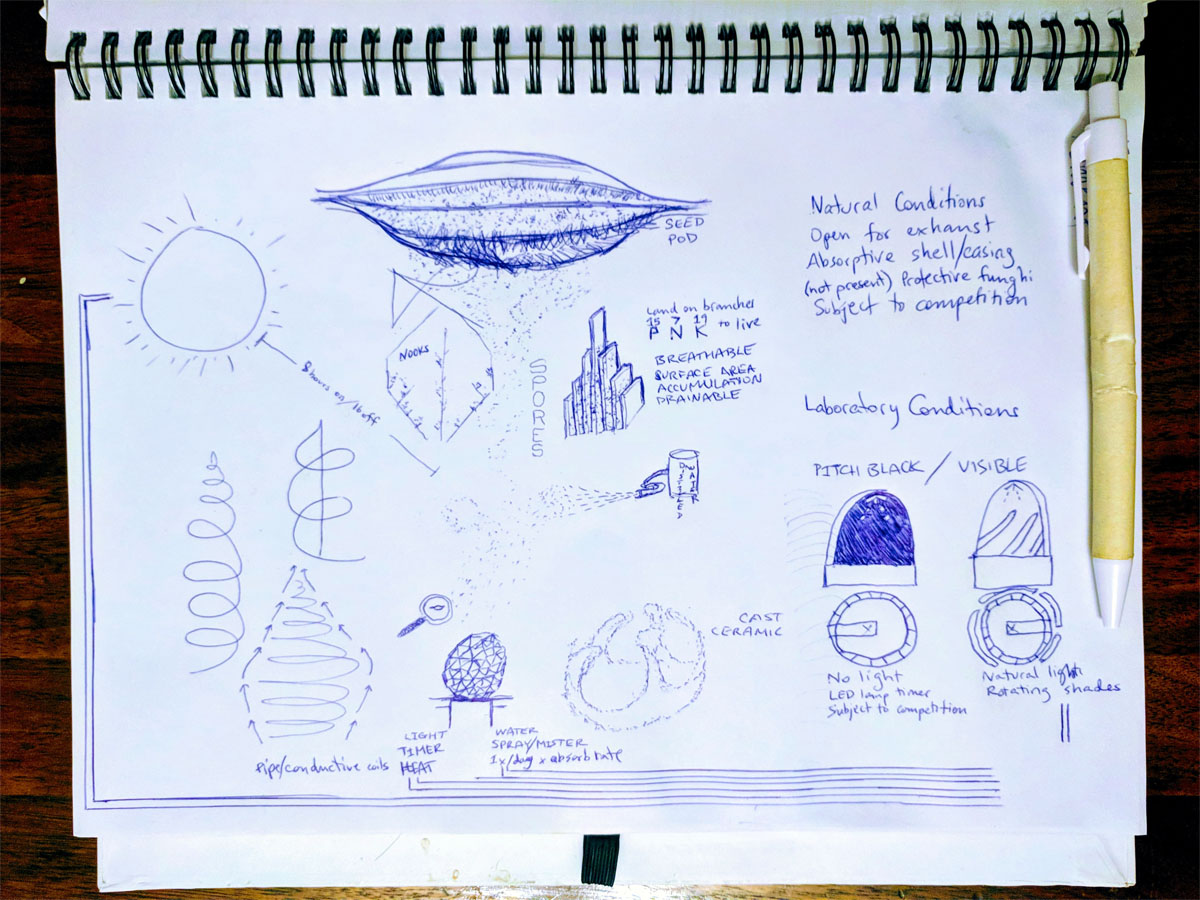

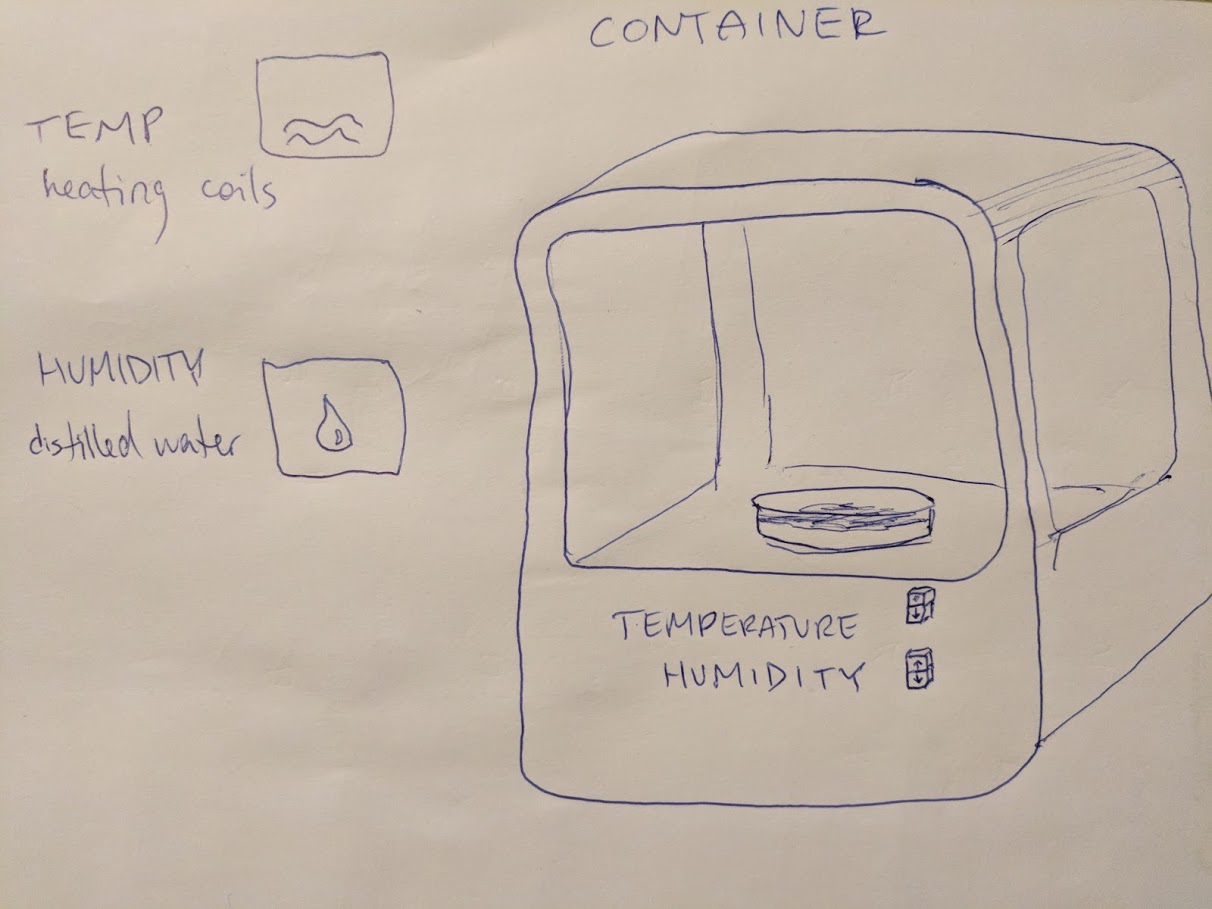

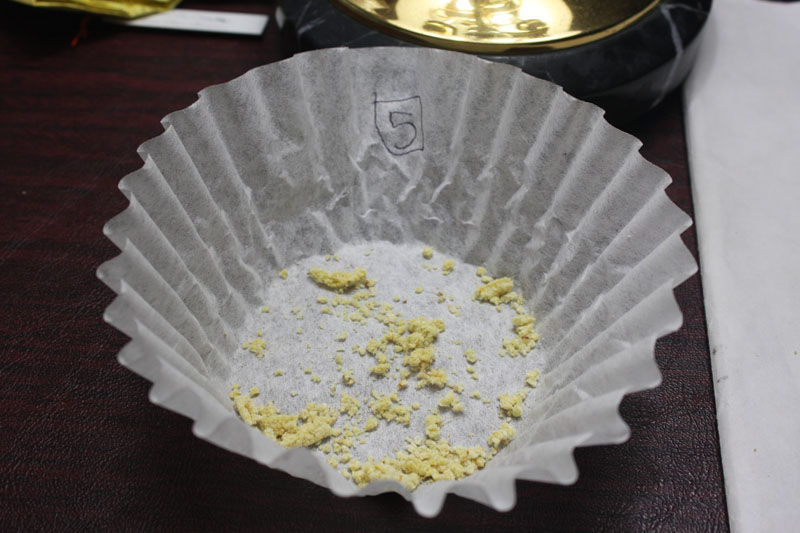

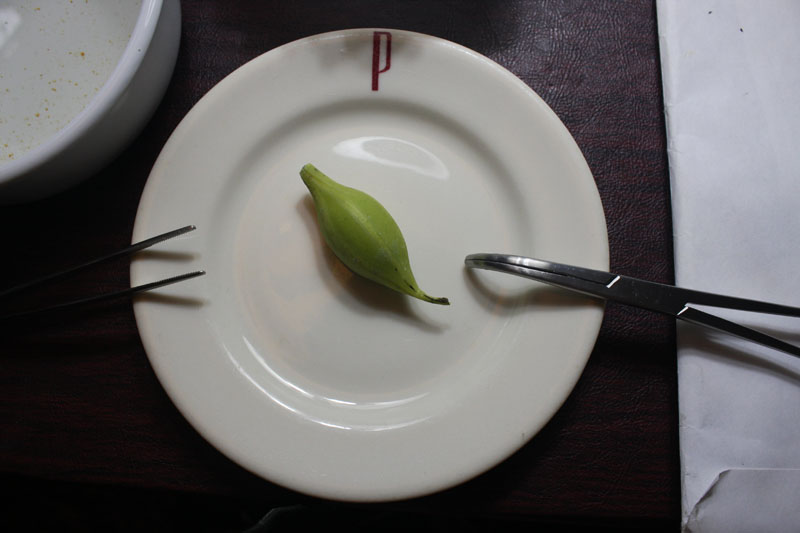

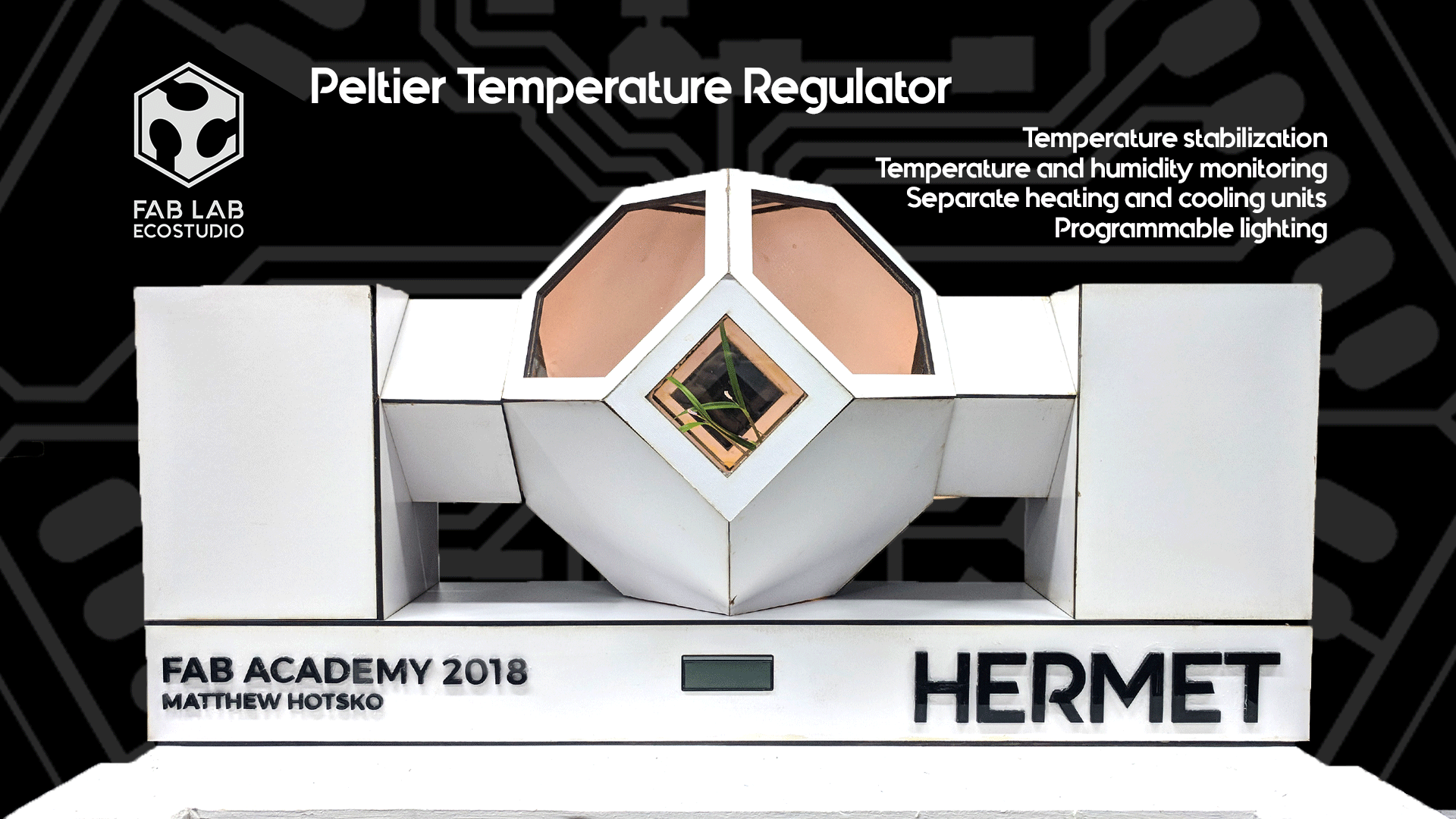

Design and prototype a chamber that can maintain the conditions needed to germinate microsopic seeds and spores in any climate.

Controls

Temperature - increase or decrease from 60-85 degerees

Light - artificial on a timer scheduled to simulate growth cycles

Hermeticity - initially 100% to isolate the fragile seeds, then reduce in increments of 10% to gradually expose the seeds to the outdoors

Puncturable - in case of emergency to drain or add ingredients or water

Humidity monitor - to more precisely test and measure growing environment

Introduction

The conditions required for orchids to grow in the wild exist because of symbiotic relationships with other organisms. In order to reproduce epiphytes in laboratory conditions, equipment such as autoclaves and laminar flow hoods are used to create sterile growing environments.My mentor suggested that I look into some of the equipment that is built for the Bio Academy to see if there were any relevant examples already in use. I checked out:

Open Culture Technology

I couldn't find a device that would fulfill the function I needed so I continued by searching past student projects. I found one project :

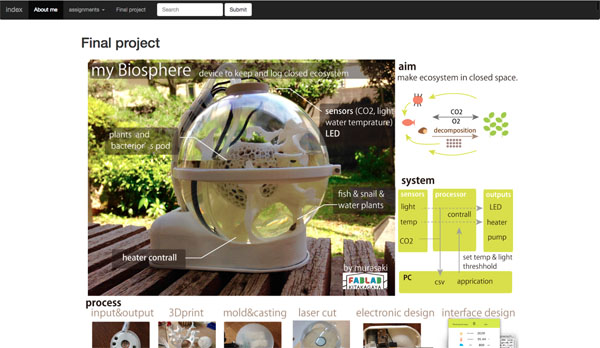

Biosphere - by murasaki at Fab Lab Kitakagaya

A device to keep and log a closed ecosystem

The project is a very good example of a chamber with similar controls. The main difference will be the hermetic control needed for epiphyte type plants to grow.