An electric guitar from scrap materials.

Idea

My main objective in choosing a project here was to draw on as many of the lessons as possible within FabAcademy,

it must be doable regarding my skillset, able to be completed within the alloted timeframe and a project that would also be relevant and perhaps interesting to high school aged children.

The project I have decided upon is to make an electric guitar from scap materials. The inspiration for this is the Recycled Orchestra of Asuncion, Paraguay

To do list

This project will encompass multipe areas of digital fabrication.

1. Design and cut wooden neck and body - CNC router

2. Design an cut fretboard - Laser cutter

3. Design or obtain 3D model of machineheads and print - 3D Printer

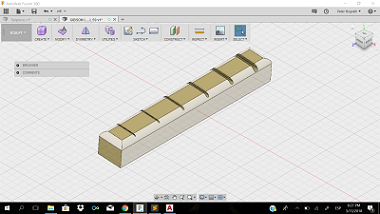

4. Design a pickup winding machine and make pickup - Electronics design, input devices

5.Design guitar body electronics and output jack - Electronis design and output devices

6. Design and make small box to house speaker and amplifier - Pressfit construction

7. Design small 3W+3W audio amp using PAM8403 amp module.

8. 3D print bridge and then cast this in metal.

Day1

Collected a range of offcut material of various Panamanian woods and cut and glued these by hand to make the neck and body blank for this guitar. I had previously consulted the Guitar Templates Archive (see below) and decided on a LesPaul style shape and dimensions.

The wood pieces were bonded with epoxy glue, clamped and left to dry overnight.

I had previously obtained a 3D CAD drawing of a guitar machinehead from Grabcad(see below) and I wanted to print this out on the makerbot2 to determine sizes and whether ther material would be strong enough to withstand the tensile forces of a tight guitar string. The result of this print is shown below. The print is not particularly pleasing, but the dimensions are correct and I will be able to test the tensile strength of this piece.

Day2

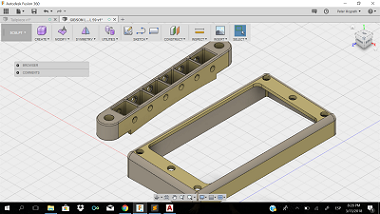

I had hoped to get a whole bunch of different parts printed off both as prototypes and as models for later casting. The 3D model of the bridge that I had downloaded from grabcad turned out to be made of 90 separate pieces which did not want to join to make a single component in Fusion360. After many attempts I finally managed to get the part printed in black PLA. Although the part appears very strong it will not be able to withstand the force of 6 metal strings pulling on it. This part will eventually be cast in metal (once I have learnt how to cast metal)

The other pieces I still need to print, with the option of later casting, are the nut, pickup covers and tuning knobs.

References

Building a cigar-box guitar.Grabcad

Guitar templates archive

Pick up winder for guitar