-

Fab Academy 2018

-

Design. Make. create.

-

Shape the Future

Our group work assignment is to test the design rules for your 3D printer.

Here at Fablab Irbid, we have 2 types of 3D Printing technology, which are the: Fused Deposition Molding (FDM) & Sterolithography (SLA).

The assignemnt's objective is to test how accurate the 3D Printed object is in comparison with the original design.

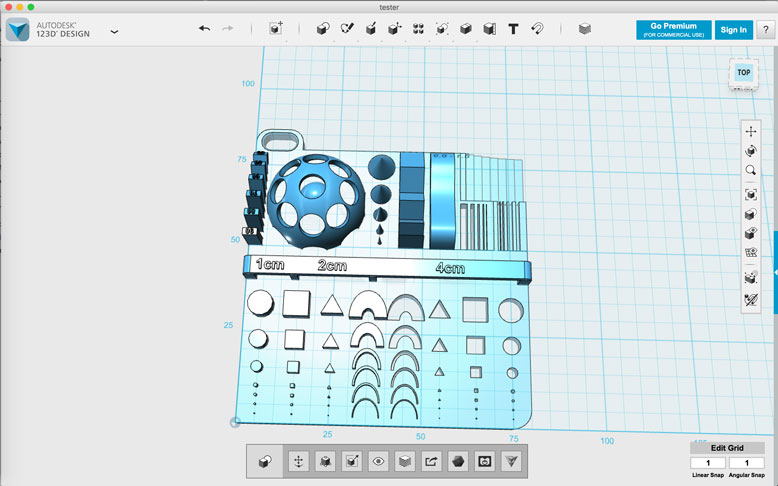

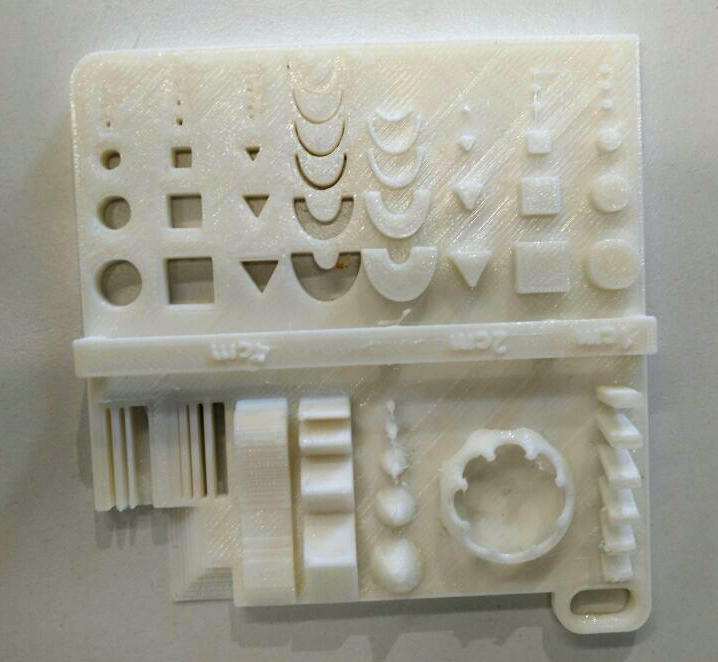

The object we decided to print, is borrowed from a fellow Fab Academy student Johnathan Yen.

His design had a lot of angles and arched parts that are ment to test the capabilities of a 3D Printer.

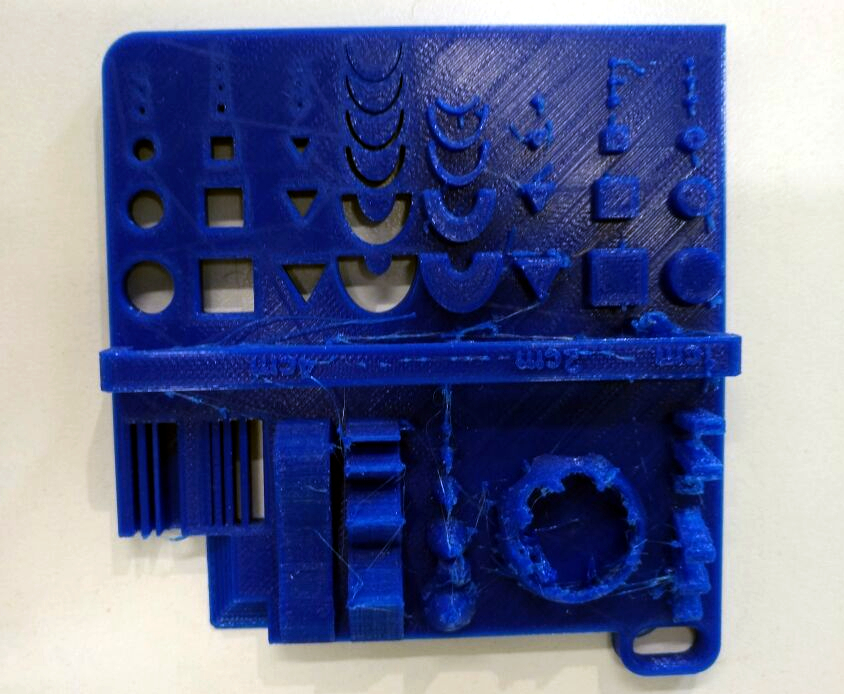

We first printed the design using the Ultimaker 2+, the settings we used were:

We left the design to print over night, and we were a bit shocked with the result as we expected it to be superb but it wasn't. We think that's because we didn' reduce the travel speed and left it at the default value 120mm/s.

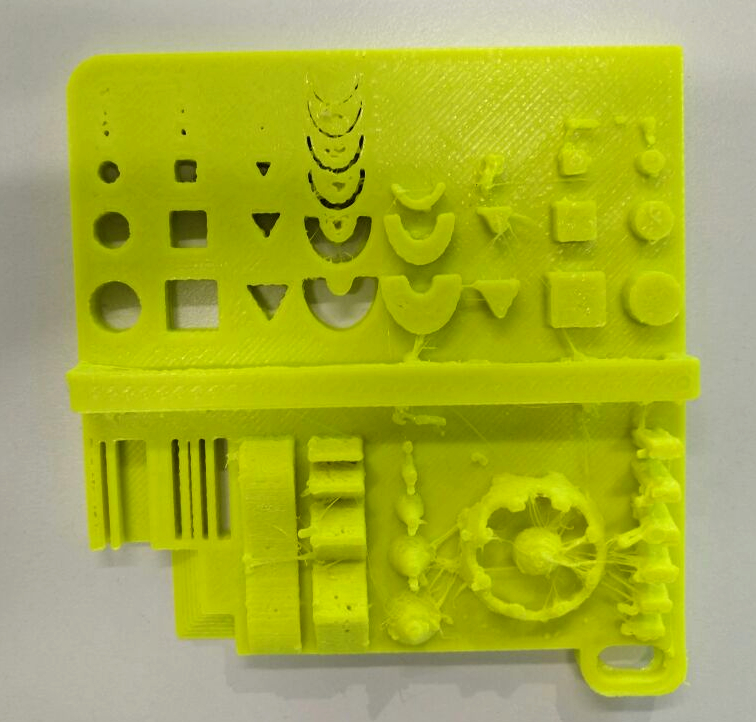

Then we printed on Ultimaker 3 Extended using the following settings:

Considering we used a 0.8mm nozzle, the result was definitely better than expected.

The last printer we tested with was the Witbox 2. We used the following settings:

Surprizingly, this print was the best of them all. Although witbox usually works better with flexible material but it did pretty good with PLA.

You can download the file we used here.