1.INTRODUCTION

In this week we are going to make somthing BIG using the MILLING CNC Shop Bot, its a 3 axis cnc for wood and it has 3 stepper motors with maximum spindle speed of 20000 rpm after we talked about the machine now we will talk about the CAM softwres, Along with the ShopBot Control Software needed to run your ShopBot CNC, there are two powerful software programs to create CNC projects, and the softwares are FUSION 360 and V CARVE PRO.

To operate any milling cnc you have to use the right values of feeds and speeds, for your good luck I am a cnc expert and now I'm going to explain im my decomintation how to calculate the speeds for any material even metals :D, lets start.

1.Speed and Feed

1. Spindle speed

The cutting speed is determined at the outside diameter of a milling cutter. This can be converted to spindle rotation speed using a formula that should now be familiar:

V: is the recommended peripheral velocity for the tool being used

D: is the diameter of the tool in inches (British) imperial

N: is the rotational velocity of the tool R.P.M

Now the only thing that we want to know about is (V) as we said it is the recommended peripheral velocity for the tool being used and it unit is SFM serface feet ber minuit and it is based upon the cutting tool material and the matereial that we want to cut (work piece) so there are diffrent types of material of cutting tools like HSS which mean high speed steel and SOLID CRBIDE.

So if you searched in google by typing the recommended SFM for HSS you will fined a lot of tabels for diffrent materials of work piece.

2. drilling feed Z axis

Where f = calculated linear feed rate of the drill [in/min]

N = spindle speed [rpm]

fr = feed per revolution of the drill [in/rev]

Now the only thing that we want to know about is (fr) which is the recommended average feed rate for the cutting tool, as we said there are many types of bits like HSS and CRBIDE .....etc there are tools with one cutting edge, 2 flutes, 3 flutes and 4 flutes, in wood cutting we will use Solid Carbide bit with 2 FLUTES and 1/2" diameter.

3. Cutting Feed Rate (X and Y axis)

where f = linear feed rate of the end mill / cutter [in/min]

N = spindle speed [rpm]

ft = feed per tooth of the end mill / cutter [in/tooth]

m = number of teeth or flutes on end mill / cutter [integer

Now the only thing that we want to know about is (ft) ft depends on the diameter and the material of the tool and work piece.

I made this file by details and examples to calculate the cutting variables cnc milling doc

Now lets calculate the cutting variables in my case, first we have to decide what tool we will use and the material we wand to cut, in my case I have :

1.The cutting tool has the diameter of 1/2", the material is solid carbide and the number of flutes is 2.

2.The material that I want to cut is MDF this is the data of MDF.s

And this is the data for several types of wood.

2.DESIGN

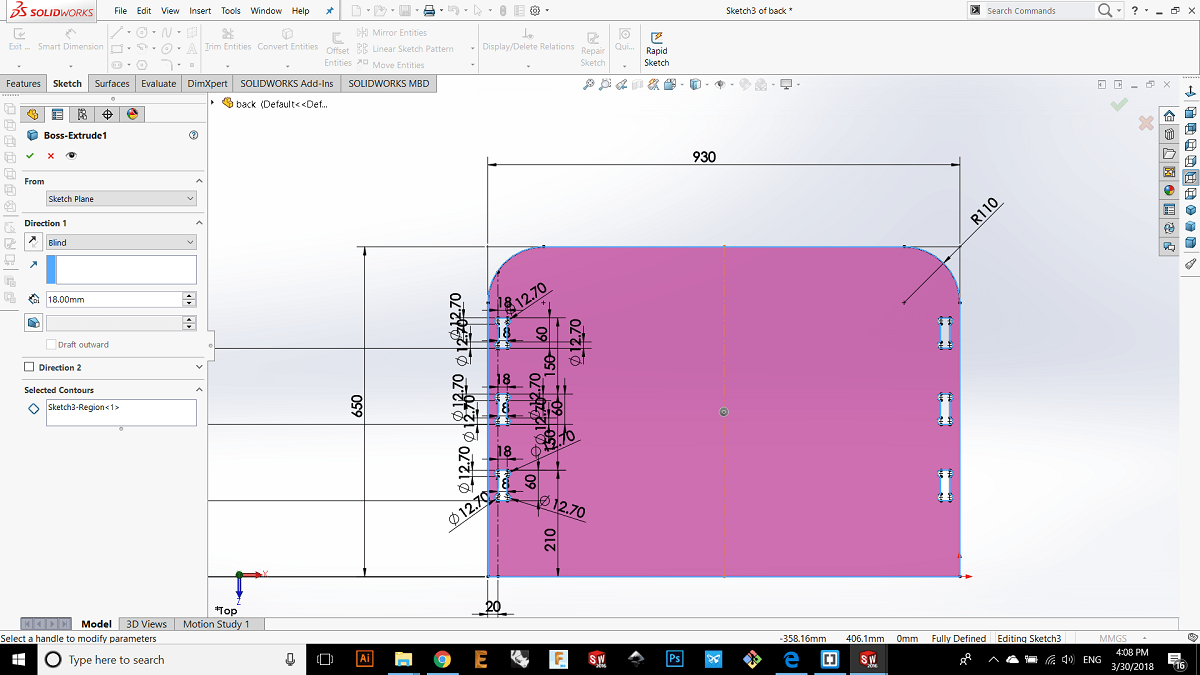

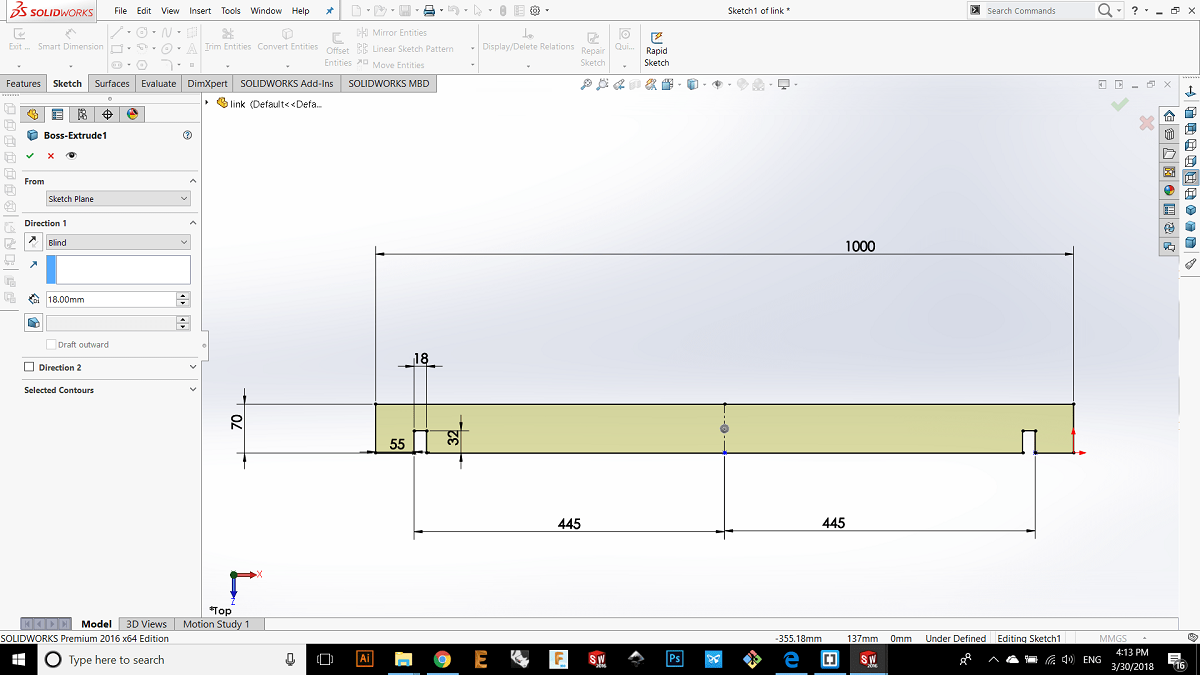

I decided to make a bed and the CAD software that I used is Solidworks with considering the thickness of the MDF wood plate of 18mm.

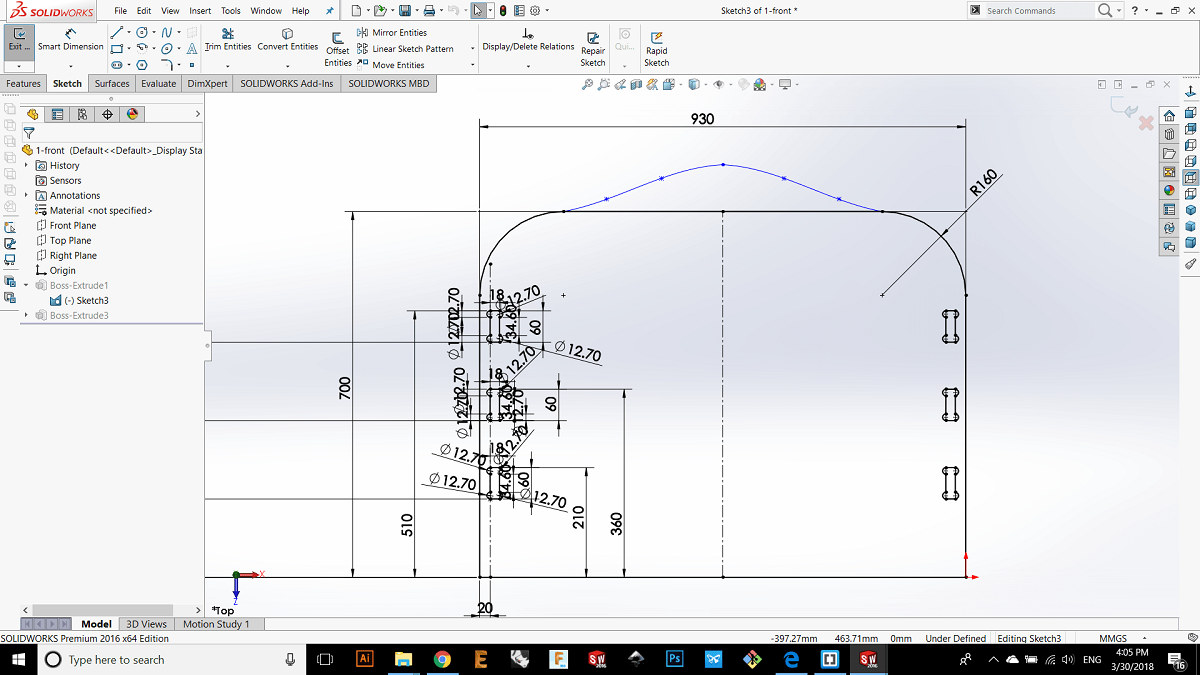

I started with 2D sketch to design the front part of the bed .

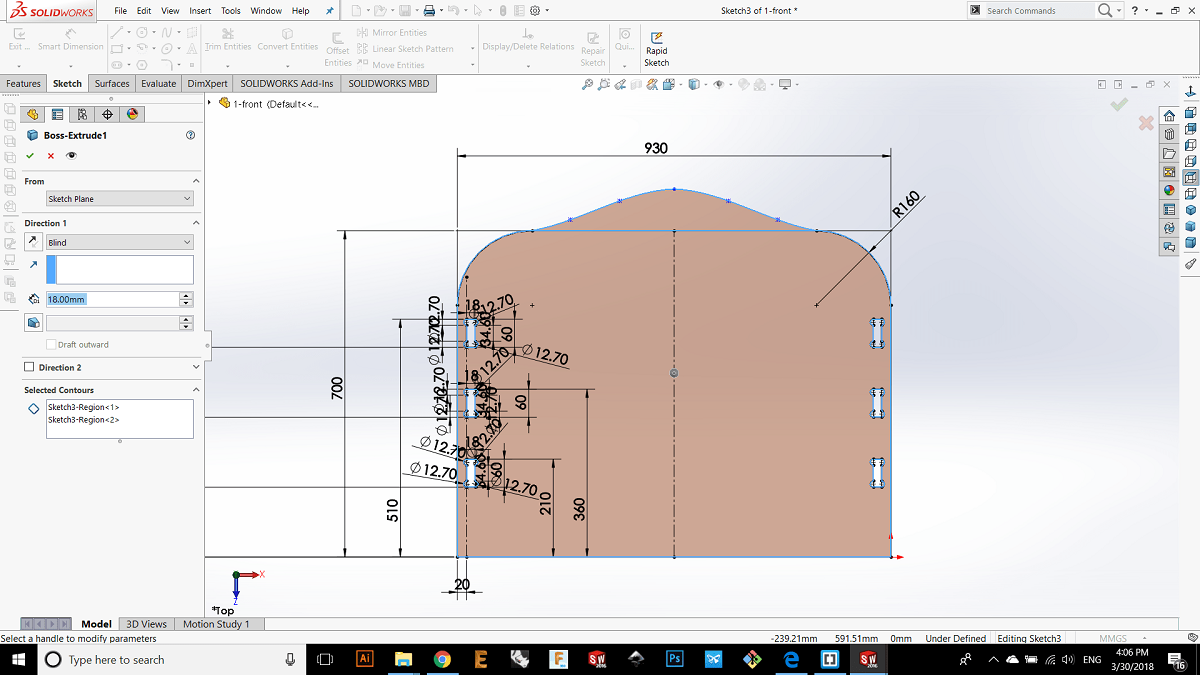

I made extrude the the sketch 18mm as the same thickness of the wood plate.

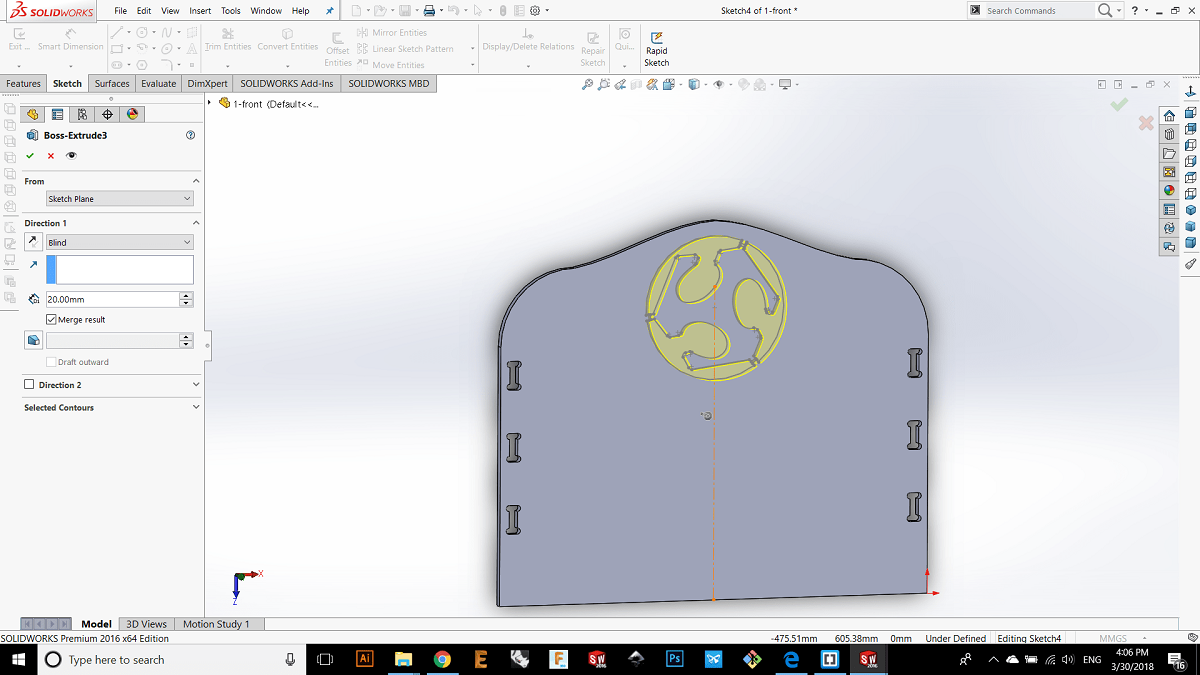

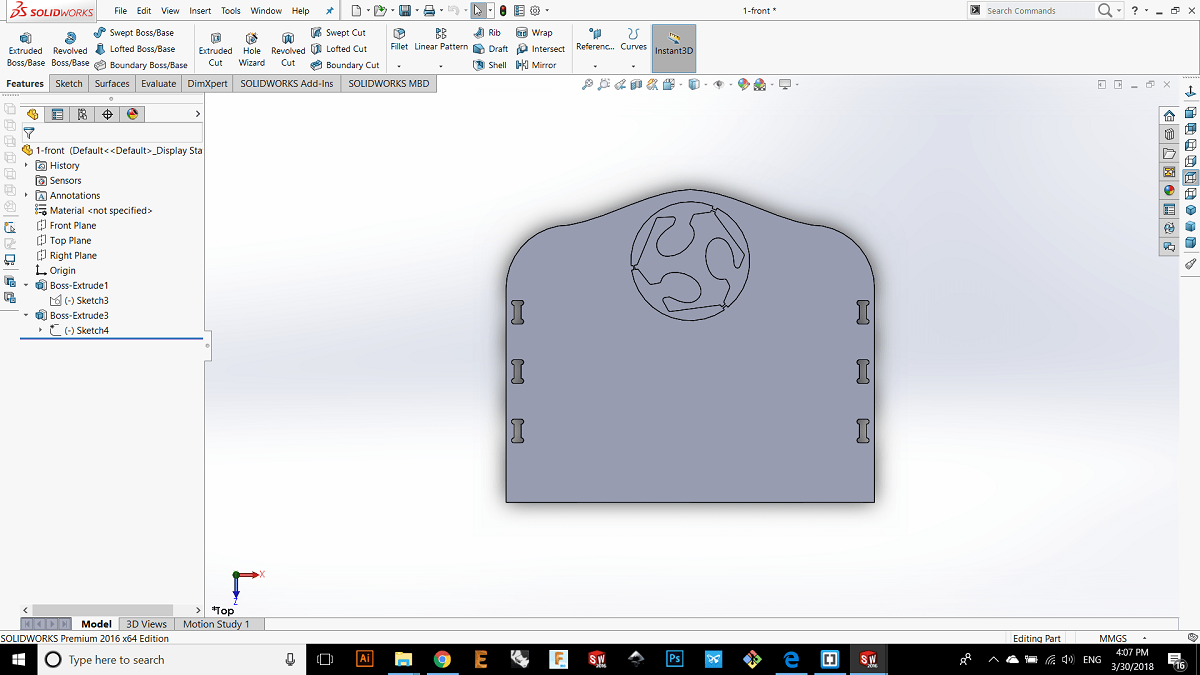

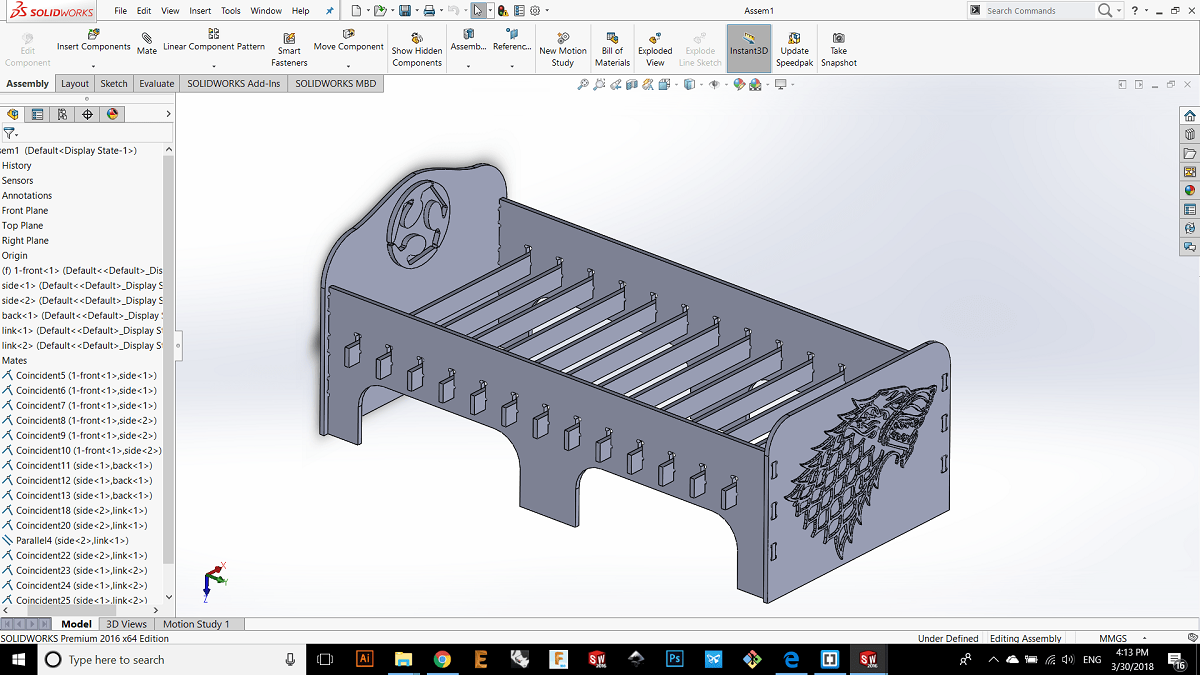

Then I made the fab academy logo.

Then I designed the opposite part.

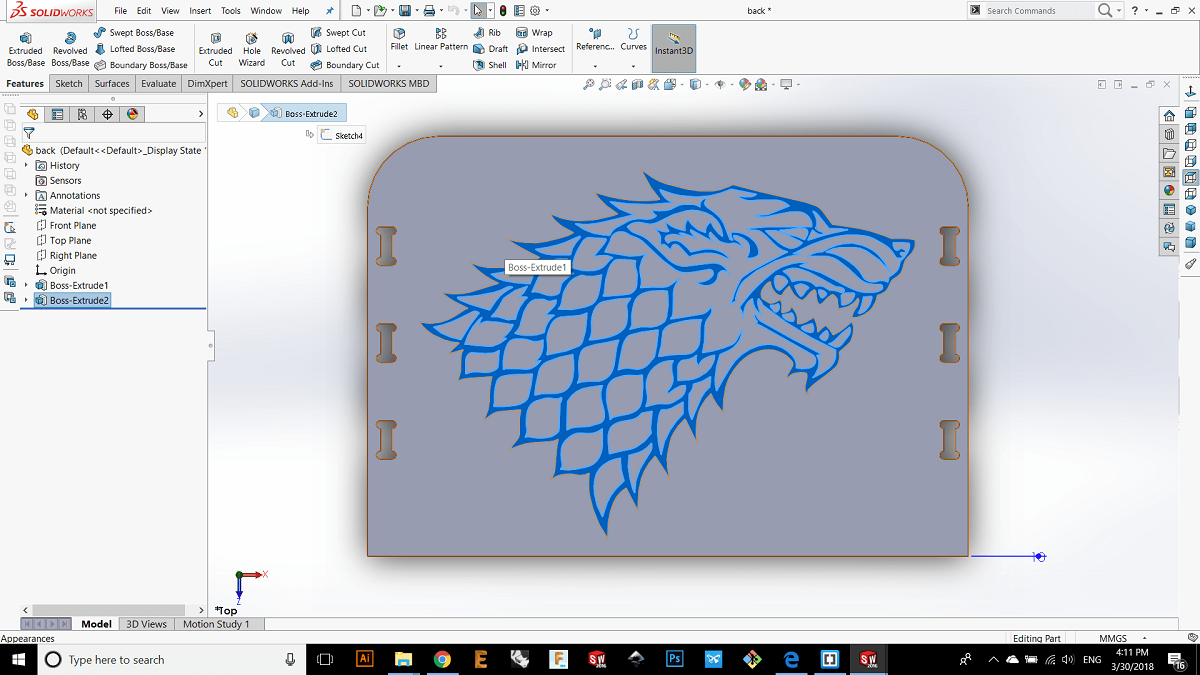

Then I made convert entities to a ready design of GAME OF THRONES logo and I made make block from tools then insert block to the logo in my design.

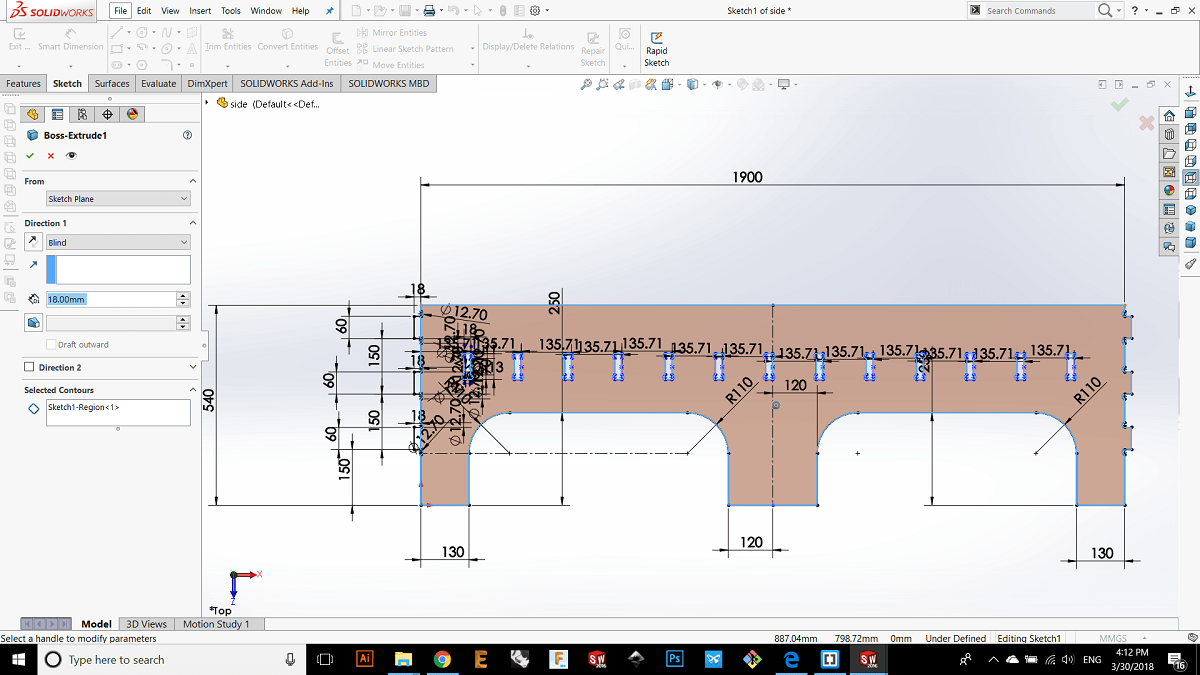

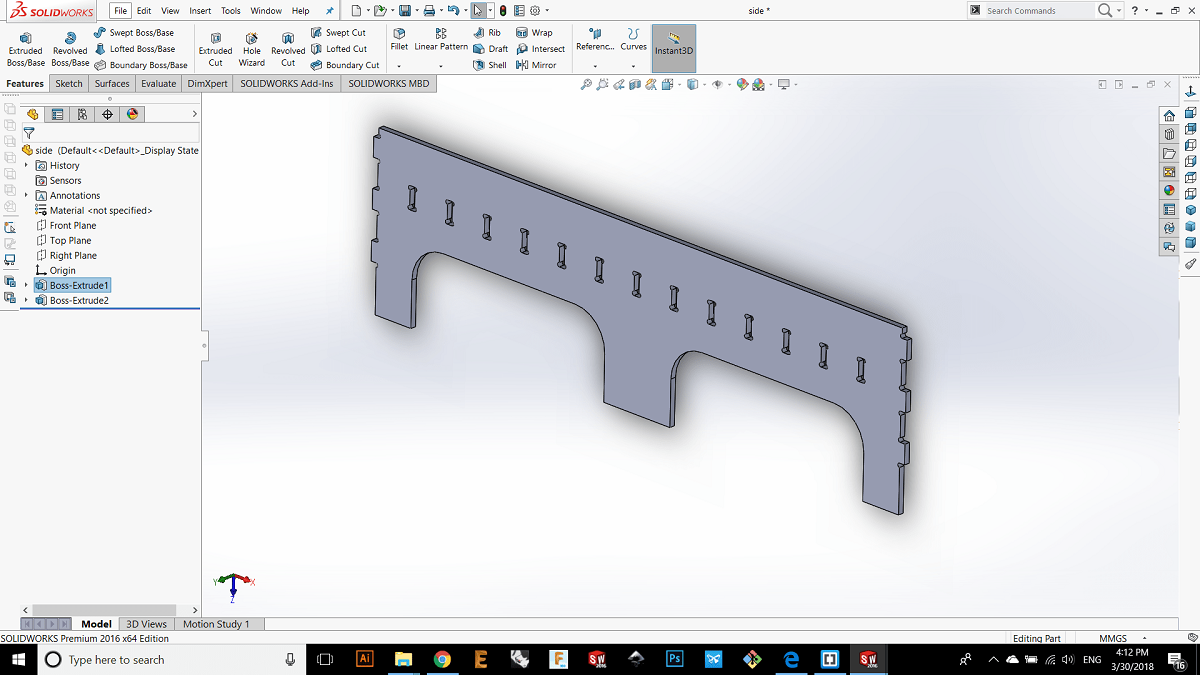

I designed the side part of my bed.

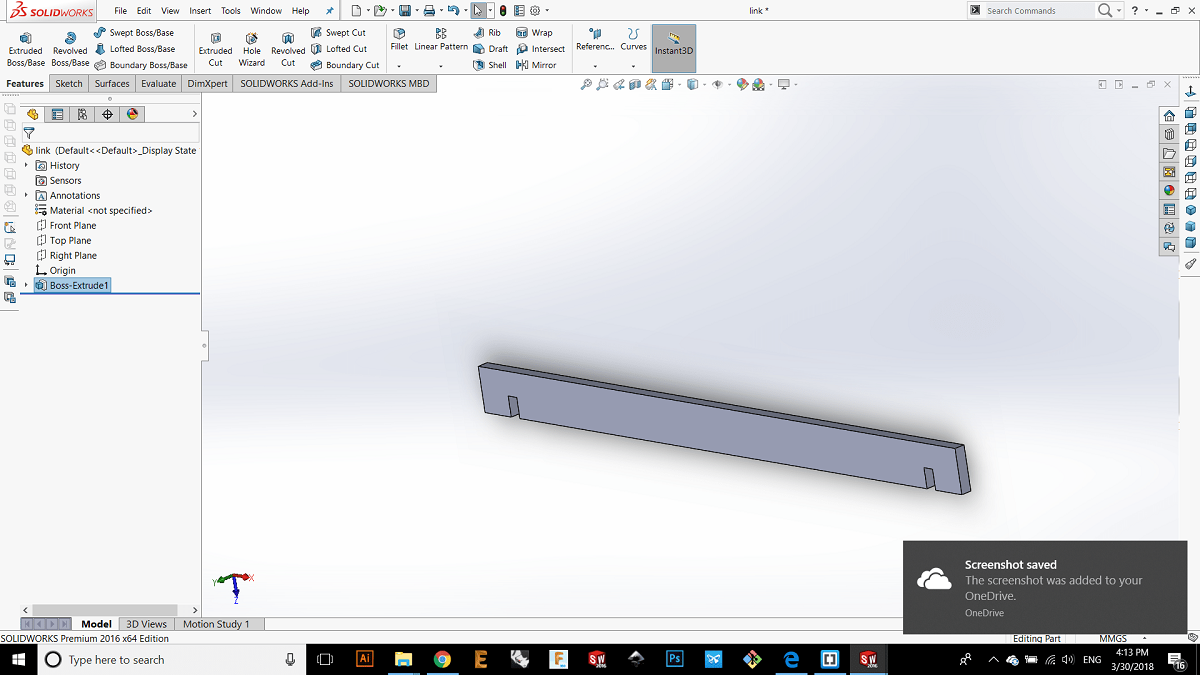

I designed the links between the sides of my bed.

Then I made assemply to the parts.

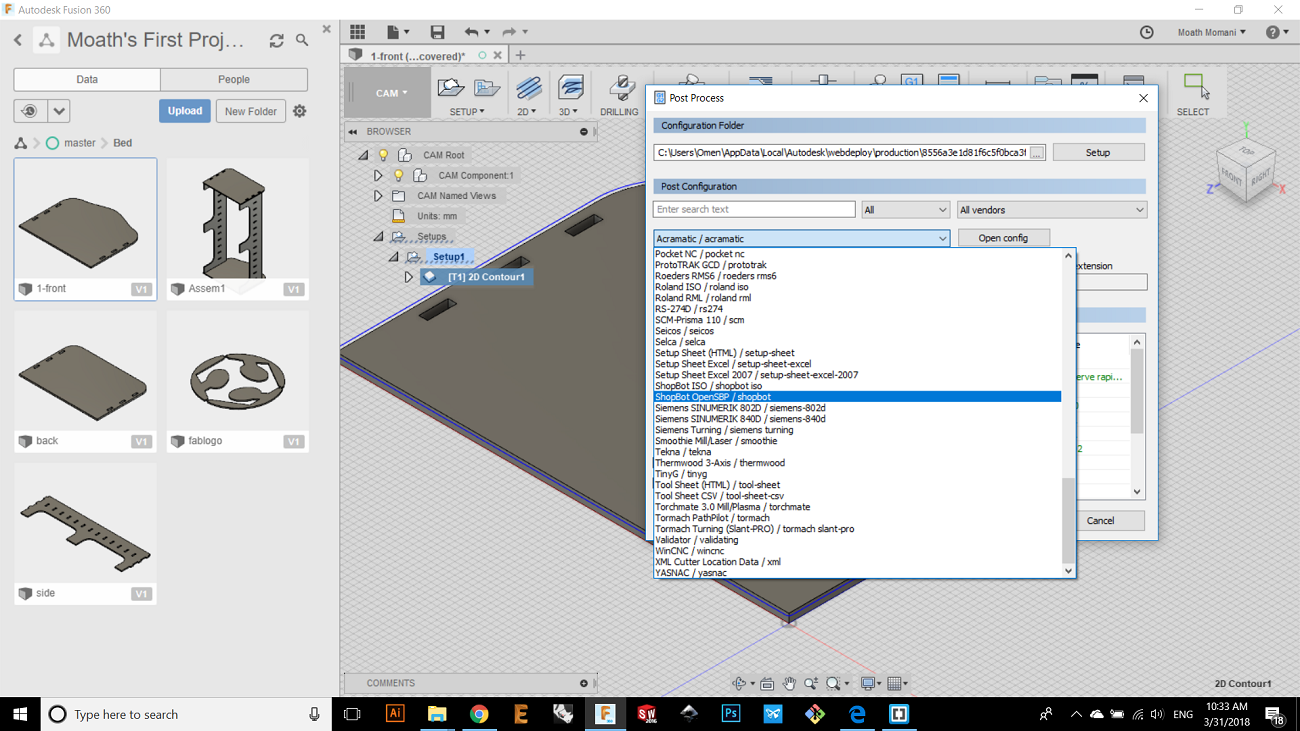

3.CAM

You can use here fusion 360 or v carve pro, the important thing in the cam software is the post process so you can choose the machine that you want to operate.

in v carve its already save as the shop bot extension but in fusion you can operate many machines so from post process you choose shop bot sbp if yoou are working on it.

The software that I used is v carve.

When I opened V carve I chose new from file and then I put the variables such like the units in mm and the dimension of the wood plate as shown.

Then I imported my DXF design, after that I did something important and what I did is to click on the join open vector.

After that from the tool path I chose to make Engraving and the bit that I used is v bit to engrave the logo on the wood.

After calculating the tool path

The cutting variables are:

1. rpm =20000

2. feed =2 inches/s

3.depth of cut =2mm.

after I finished engraving I chose 2D tool path to make a 2D cut for the outside contour with 1/2" solid carbide end mill

the yellow points are tapes, the work as fixtures for the part

Operations

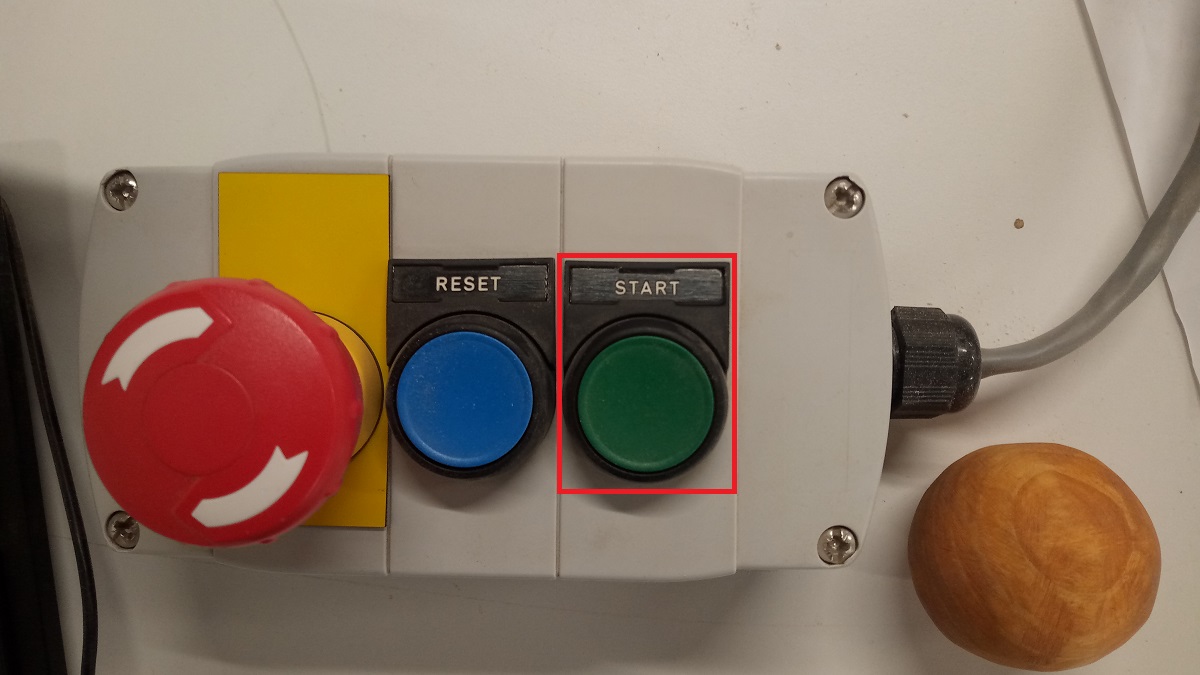

To operate any machine you have to commit the safty rules to avoid injury, in cutting mdf wood using the cnc shopbot you have to wear the safty staffs like mask to protect you from the dust, glasess to protect your eyes its very important because eyes cant be healed any more and hold the E stop button as shown in the picture.

And you have to be around the machine untill the job finished, someone of fab academy 2018 students cause a fire burned his fab lab in this week because i am sure he left the machine while it was working.

4.My bed

5.Problems

Actually in this week I had no problems :D whay? because in our fab lab we have also milling cnc for metal and I am the supervisor of the wood shop and metal shop and I have been working in fab lab IRBID 1year and a half so after many problems that i passed thruogh I hard to make the same mistake again, one of the prblems that I did two time is to forget the tongs and plate connected with the spinde, and then I pressed spindle on :P so I spend halfe hore to find the tongs 6 meters away from the machine and the wire became small pieces everywhere.

The second problem that happend with me is to forget the spindle start putton

It is important to say that the spinde does not working automatically if you lunch the job, for example in the most milling machines if you lunch the job then the spindle will start rotation and then the machine will start moving X,Y and Z, but in this machine the spindle wont start untill you press the start button. You can get my design as solidwork part and this is the links:

1.FRONT PART

2.BACK PART

3.FAB ACADEMY LOGO

4.LINK PART

5.SIDE PART

6.ASSEMPLY