Assignment

group assignment:

- test the design rules for your 3D printer(s)

Test printers

To characterize our 3D printers, we picked test model from Thingivers.

Test data : All In One 3D Printer test by majda107

The set of filament material and printer we tested :

- PLA with Makerbot Replicator 2X

- ABS with Afinia H480

In our lab setting, we usually use Replicator for printing big stuff (larger than approx. 100mm square), and Afinia for small stuff that requires accuracy.

Although ABS has high degree of flexibility and accuracy, it often curves as it cools down (we tackle this problem by adding raft or pre-heating the platform), and this curve gets worse if the model size gets bigger. That is the reason why using ABS for only small things, and Afinia Studio and the slicer setting on Afinia is optimized to the use of ABS. Its build volume is smaller than Replicator too.

In contrast, Replicator has big build volume (24.6 L X 15.2 W X 15.5 H cm) so we are using it for printing large things with PLA. PLA filament has less deformation after printing (it is also less flexible and difficult to do after processing)

Results

Makerbot Replicator 2X

Filament : PLA (bonsailab/white/1.75mm)

Attempt #1

| Parameter | Value |

|---|---|

| extruder temp | 210 |

| build plate temp | 60 |

| infill | 20% |

| raft | yes |

| support | no |

| layer height | 0.3mm |

| print speed | 10m/s(raft), 30m/s(model) |

| cooling fan speed | 50%(raft),50%(model) |

| filament diameter | 1.77mm |

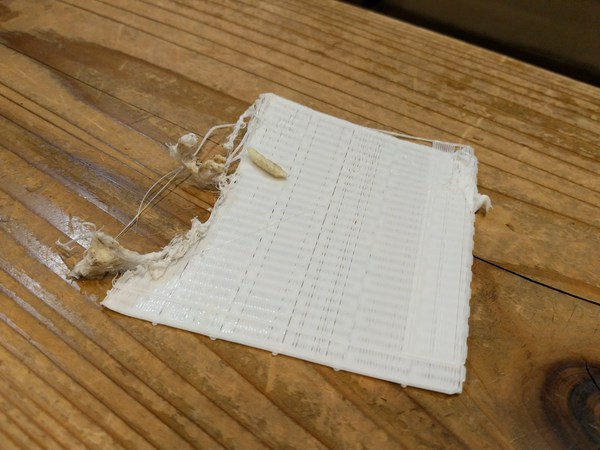

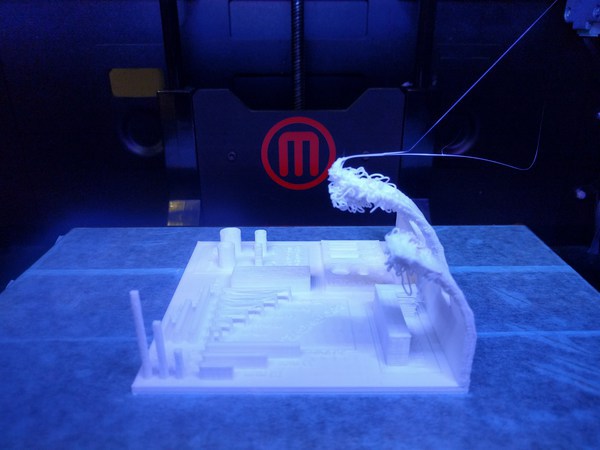

Resulted in failure

- In the first time, model

- raft pealed off

Attempt #2

| Parameter | Value |

|---|---|

| extruder temp | 220 |

| build plate temp | 60 |

| infill | 20% |

| raft | no |

| support | no |

| layer height | 0.3mm |

| print speed | 10m/s(raft), 30m/s(model) |

| cooling fan speed | 50%(raft),50%(model) |

| filament diameter | 1.75mm |

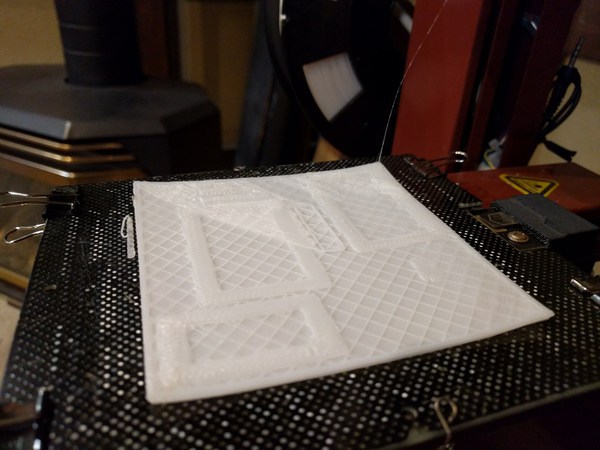

Success!!!

findings

Afinia H480

Filament : ABS (Afinia genuine)

| Parameter | Value |

|---|---|

| extruder temp | 270 |

| build plate temp | 90 |

| infill | 20% |

| raft | no |

| support | no |

| layer height | 0.3mm |

| print speed | n/a |

| cooling fan speed | n/a |

| filament diameter | n/a |

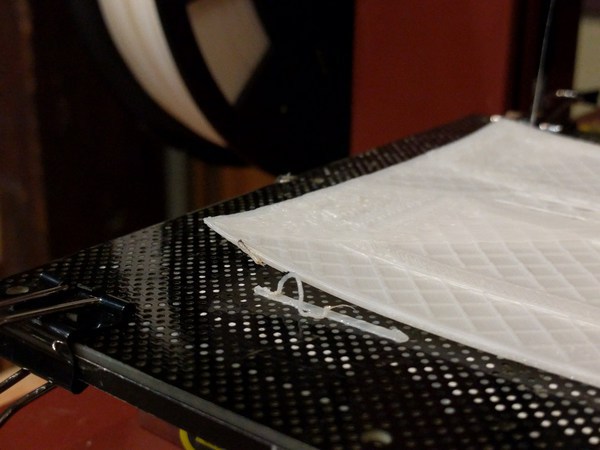

Failed due to the distortion. I also tired printing out with raft, and with higher build plate temperature, but could not fixed the problem.

Filament material characteristic

| PLA | ABS | |

|---|---|---|

| Printing temp | 200-210˚C | 210-240˚C |

| Print bed temp | 20-60˚C (optional) | 80-110˚C (mandatory) |

| Strength | Decent Strength | Above Average Strength |

| Flexibility | Brittle | Moderately Flexible |

| Heat Resistant | no | yes |

| Biodegradable | yes | no |

| Acetone Treatment | Not Possible | Possible |