Computer Controlled Cutting

Fabacademy week4 group assignment

Charactorize Fablab Kamakura’s laser cutting tool

Model : Trotec Speedy 100

Parameter

Power : 70

Speed : 1.0

Frequency : 1000Hz

Examine

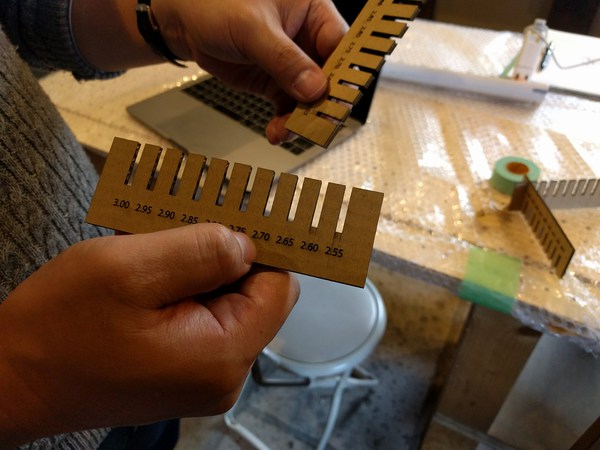

First of all, we made press-fit test kit to examine proper offset for our laser cutter when cutting 3mm thickness cardboard.

The gap width starts from 3.00mm and increases 0.05mm each to finally gets to 2.55mm.

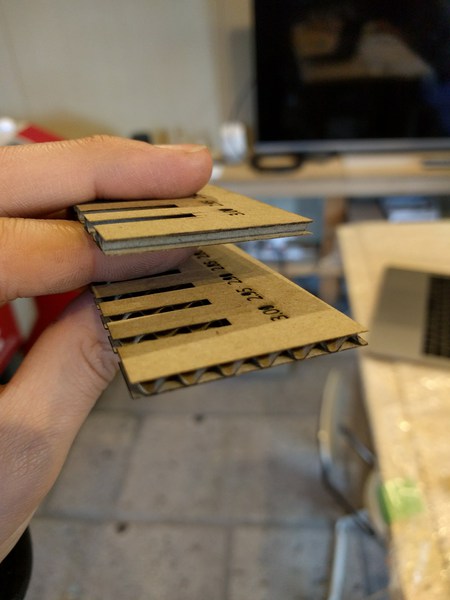

We thought that we need to pay attention to the direction of cardboard. Since it is quite hard to get hard cardboard that Neil mentioned in the lecture, we are using soft regular type of cardboard for making press-fit construction kit, and they some times collapse by their direction of joining.

Therefore, we made two types of test-kit: horizontal and vertical, as you can see in the following picture.

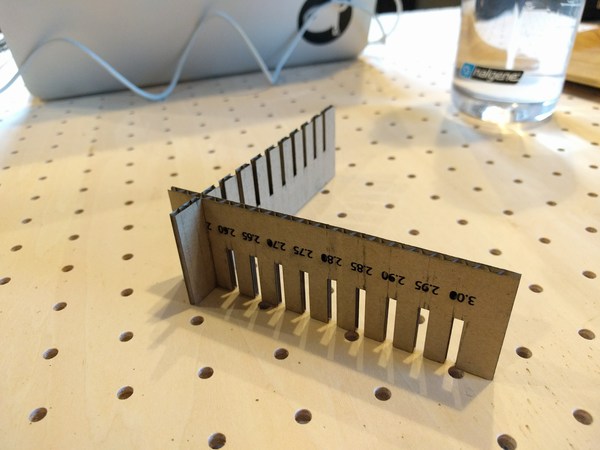

Result

2.60mm fitted the most, but we decided to set our offset value to 0.45mm (which means 2.55mm in thickness), because the joints get loose as you keep assemble and diassemble.

As we assumed, the direction mattered. Vertical gap worked better, but it makes the parts weaker that easily break while assembling.

Material : Cardboard

Material thickness : 3mm

Offset value : 0.45

Now cutting!

Please refer to individual page.