Ordering and recieving the parts that I needed went good without any delay.

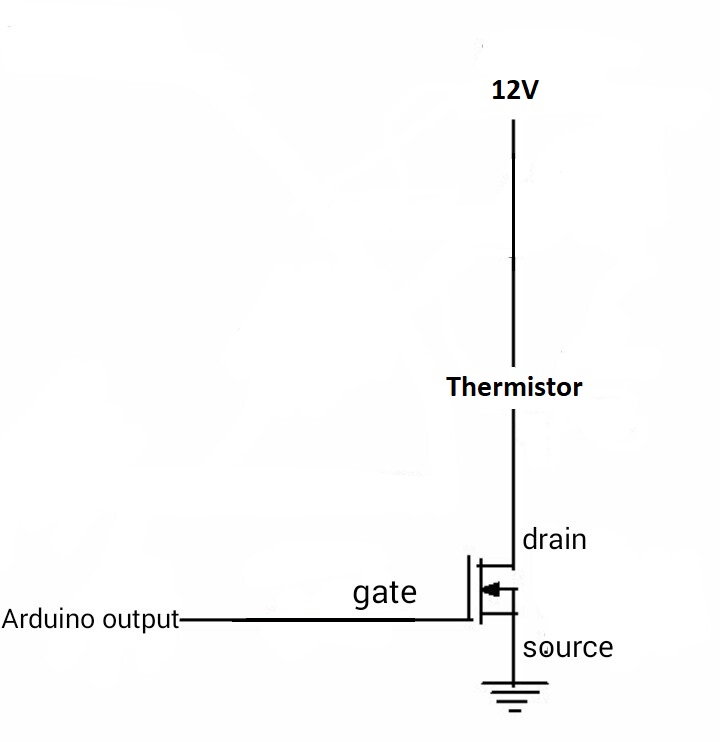

// which analog pin to connect

#define THERMISTORPIN A0

// resistance at 25 degrees C

#define THERMISTORNOMINAL 100000

// temp. for nominal resistance (almost always 25 C)

#define TEMPERATURENOMINAL 25

// how many samples to take and average, more takes longer

// but is more 'smooth'

#define NUMSAMPLES 5

// The beta coefficient of the thermistor (usually 3000-4000)

#define BCOEFFICIENT 4267

// the value of the 'other' resistor

#define SERIESRESISTOR 100000

#define rotPin A2

#define curPin A3

#define heatPin A4

float steinhart;

int rotVal = 0;

int curVal = 0;

int heatVal = 0;

uint16_t samples[NUMSAMPLES];

int tmp;

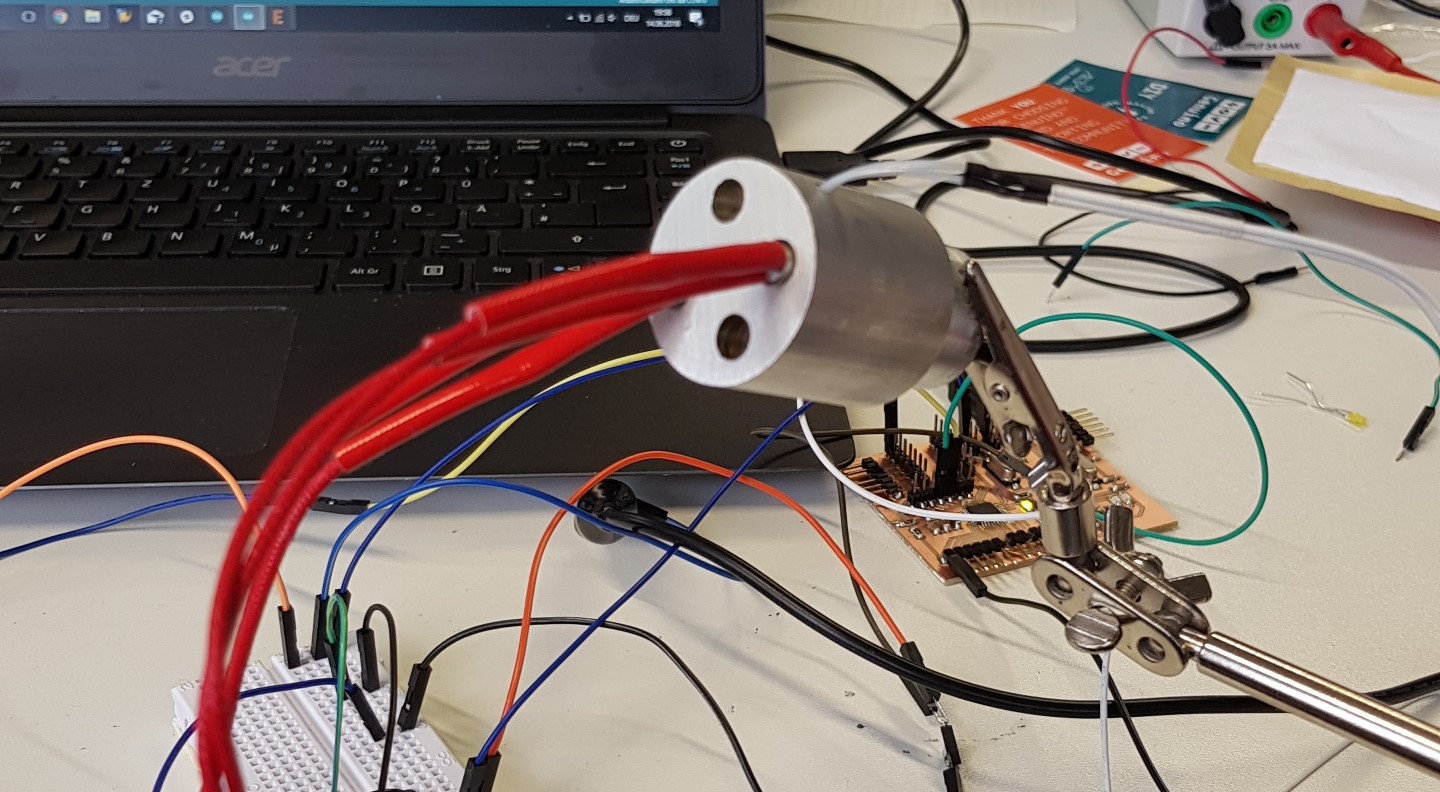

int stepPin1 = 4; // step pin

int dirPin1 = 7; // direction pin

int en = 8; // enable pin

int heaterPin0 = 6;

int heaterPin1 = 9;

int heaterPin2 = 10;

int heaterPin3 = 11;

void setup(void) {

pinMode(stepPin1,OUTPUT);

pinMode(dirPin1,OUTPUT);

pinMode(en,OUTPUT);

Serial.begin(19200);

pinMode(heaterPin0, OUTPUT);

pinMode(heaterPin1, OUTPUT); // sets the pin as output for Heaters

pinMode(heaterPin2, OUTPUT);

pinMode(heaterPin3, OUTPUT);

pinMode(rotPin, INPUT); // sets the pin as output for potentiometers

pinMode(curPin, INPUT);

pinMode(heatPin, INPUT);

delay(500);

}

void loop(void) {

rotVal = analogRead(rotPin); // read values for rotation spead

rotVal = map(rotVal, 0, 1023, 4000, 0); // map values for motor

curVal = analogRead(curPin);// read values for current

curVal = map(curVal, 0, 1023, 0, 255); // map values for current for analogWrite()

heatVal = analogRead(heatPin);// read values for Heaters

heatVal = map(heatVal, 0, 1023, 25, 250); //map values for Heaters

if(rotVal>3990){

digitalWrite(dirPin1,HIGH); // Enables the motor to move in a particular direction

digitalWrite(en,LOW); // send low singnal to EN in satstep

//one revolution

for(int x = 0; x < 200; x++) { // 200 steps/revol

digitalWrite(stepPin1,HIGH);

delayMicroseconds(rotVal); //here we manipulate the rotation speed

digitalWrite(stepPin1,LOW); //here we manipulate the rotation speed

delayMicroseconds(rotVal);

}

}

uint8_t i;

float average;

for (i=0; i < NUMSAMPLES; i++) {

samples[i] = analogRead(THERMISTORPIN);

}

// average all the samples out

average = 0;

for (i=0; i < NUMSAMPLES; i++) {

average += samples[i];

}

average /= NUMSAMPLES;

//Serial.print("Average analog reading ");

//Serial.println(average);

// convert the value to resistance

average = 1023 / average - 1;

average = SERIESRESISTOR / average;

//Serial.print("Thermistor resistance ");

//Serial.println(average);

float steinhart;

steinhart = average / THERMISTORNOMINAL; // (R/Ro)

steinhart = log(steinhart); // ln(R/Ro)

steinhart /= BCOEFFICIENT; // 1/B * ln(R/Ro)

steinhart += 1.0 / (TEMPERATURENOMINAL + 273.15); // + (1/To)

steinhart = 1.0 / steinhart; // Invert

steinhart -= 273.15; // convert to C

//Serial.print( analogRead(THERMISTORPIN));

//Serial.print("------------------\n");

//Serial.print("Temperature ");

if (steinhart < heatVal){

analogWrite(heaterPin0,curVal); //

analogWrite(heaterPin1,curVal); // analogRead values go from 0 to 1023, analogWrite values from 0 to 255

analogWrite(heaterPin2,curVal); //

analogWrite(heaterPin3,curVal);

}else if (steinhart > heatVal){

analogWrite(heaterPin0,0); // a

analogWrite(heaterPin1,0); // write 0 as soon as we arrived the desired heat

analogWrite(heaterPin2,0); //

analogWrite(heaterPin3,0);

}

//Serial.println(" *C");

// delay(1000);

}

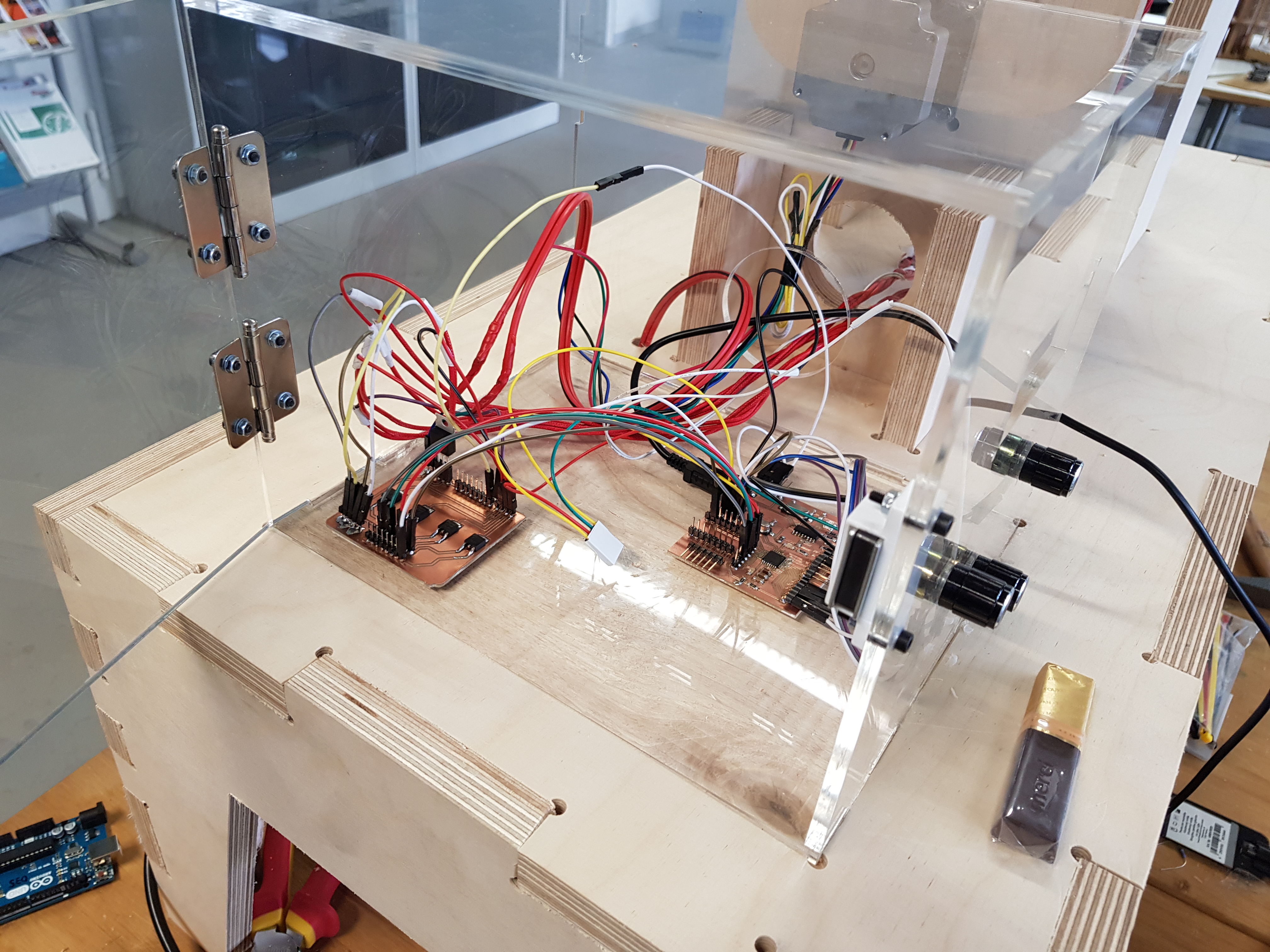

#include <LiquidCrystal.h>

#define rotPin A2

#define curPin A3

#define heatPin A4

float steinhart;

int rotVal = 0;

int curVal = 0;

int heatVal = 0;

//String input;

// Connections:

// LCD pin 3 for contrants to GND, good for beginners

// rs (LCD pin 4) to Arduino pin 12

// rw (LCD pin 5) to Arduino pin 11

// enable (LCD pin 6) to Arduino pin 10

// LCD pin 15 to Arduino pin 13

// LCD pins d4, d5, d6, d7 to Arduino pins 5, 4, 3, 2

LiquidCrystal lcd(9, 8, 7, 6, 4, 3, 2); //!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!! Changed the pins, so that we can upload the code without chaniging the wires from pins 12 to 10

void setup(){

pinMode(rotPin, INPUT);

pinMode(curPin, INPUT);

pinMode(heatPin, INPUT);

//Serial.begin(19200);

lcd.begin(16,2); // columns, rows. use 16,2 for a 16x2 LCD, etc.

lcd.clear(); // start with a blank screen

// if you have a 4 row LCD, uncomment these lines to write to the bottom rows

// and change the lcd.begin() statement above.

//lcd.setCursor(0,2); // set cursor to column 0, row 2

//lcd.print('Row 3');

//lcd.setCursor(0,3); // set cursor to column 0, row 3

//lcd.print('Row 4');

}

void writeLCD(){

lcd.clear(); // clear the LCD

/*

lcd.setCursor(0,0);

lcd.print("CT:"); // change this text to whatever you like. keep it clean.

lcd.setCursor(4,0); // set cursor to column 0, row 1

lcd.print(input);

*/

lcd.setCursor(8,0); // set cursor to column 8, row 1 (the first row)

lcd.print("ST:"); // change this text to whatever you like. keep it clean.

lcd.setCursor(12,0); // set cursor to column 12, row 1

lcd.print(heatVal);//print desire heat val in C

lcd.setCursor(0,1); // set cursor to column 0, row 1 (the first row)

lcd.print("RS:"); // change this text to whatever you like. keep it clean.

lcd.setCursor(4,1); // set cursor to column 4, row 1

lcd.print(rotVal);// print desire rotation speed in %

curVal = map(curVal, 0, 255, 0, 100); //map current values to %

lcd.setCursor(8,1); // set cursor to column 8, row 1 (the first row)

lcd.print("CR:"); // change this text to whatever you like. keep it clean.

lcd.setCursor(12,1); // set cursor to column 12, row 1

lcd.print(curVal); // print output for current change in analogWrite

}

void readPins(){

rotVal = analogRead(rotPin); // here we read the values from the potentiometer (analog pin A2)

rotVal = map(rotVal, 0, 1023, 0, 100); // here we map the value from the potentiometer to %

curVal = analogRead(curPin); // here we read the values from the potentiometer (analog pin A3)

curVal = map(curVal, 0, 1023, 0, 255,);// here we map the value from the potentiometer

heatVal = analogRead(heatPin); // here we read the values from the potentiometer (analog pin A4)

heatVal = map(heatVal, 0, 1023, 25, 250);// here we map the value from the potentiometer

}

void loop(){

readPins(); // call the readPins() function

writeLCD();// call the writeLCD() function

delay(100);

}

}