Week 6

3D printing and 3D scanning

This is 3D printing and 3D scanning week.I already learned a 3 D design software rhino and this week I learned fusion 360.

3D printing

3D printing is any of various processes in which material is joined or solidified under computer control to create a three-dimensional object,[1] with material being added together (such as liquid molecules or powder grains are fused together). 3D printing is used in both rapid prototyping and additive manufacturing (AM).The term "3D printing" originally referred to a process that deposits a binder material onto a powder bed with inkjet printer heads layer by layer. More recently, the term is being used in popular vernacular to encompass a wider variety of additive manufacturing techniques.3D printing is an innovative technology that lets you create a physical object from a digital model. It started in the 80’s under the name ‘rapid prototyping’ because this was the purpose of the technology: to prototype faster and cheaper. A lot’s changed since then, and today 3D printers offer amazing results and let you create anything you can imagine.

In Our lab we have two 3D printers.for experiment I take 3D print of very small size. and then I made a small box which I needed for my project.First i made the design in rhino and then take the print.

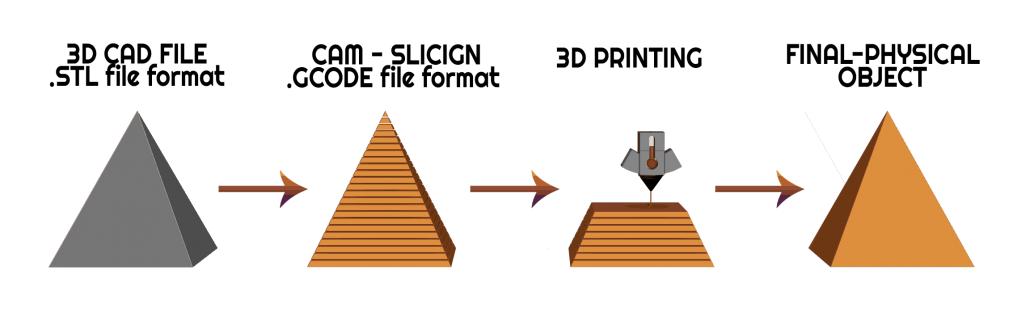

how does the 3d print work

In order to print something, first you’ll need a 3D model of the object you want to create, which you can design in a 3D modeling program (CAD - Computer Aided Design), or use a 3D scanner to scan the object you want to print. There are also more simple options, like searching online on Youmagine.com for 3D models that have been created and shared by other people. Once your design’s ready, all you need to do is import it into Cura, our open source print software. Cura will then turn your design into a gcode file ready to be printed as a physical object. Simply save your file to the supplied USB stick and insert it into your Ultimaker and press print.

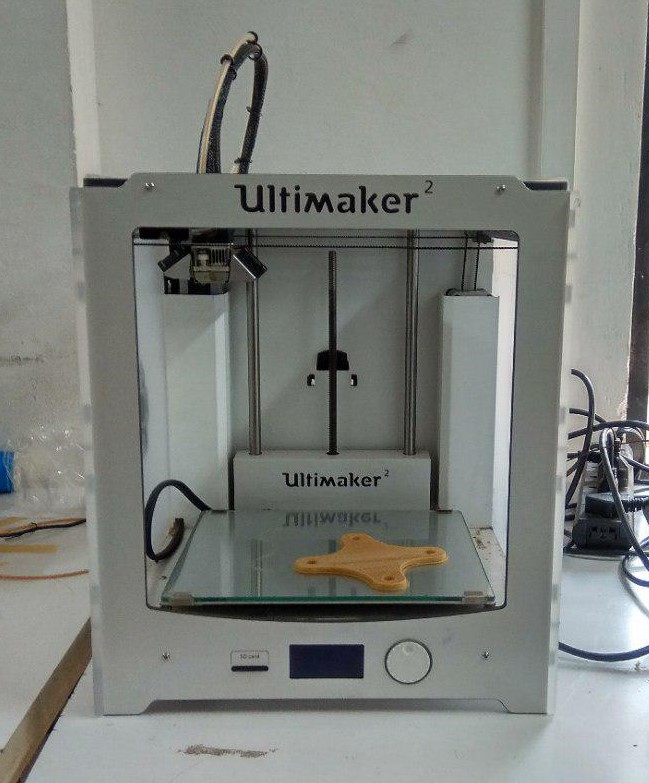

details of ultimaker

Ultimaker is a 3D printer manufacturer. Their product line includes the Ultimaker 3 family, Ultimaker 2 family and the Ultimaker Original. The company started out as an open-source printer company.Ultimaker 2 is the successor to the Ultimaker Original and was released in September 2013. MAKE magazine classified the Ultimaker 2 as the "best open-architecture 3D printer of 2014" and named it runner-up in the category "Prosumer FFF".

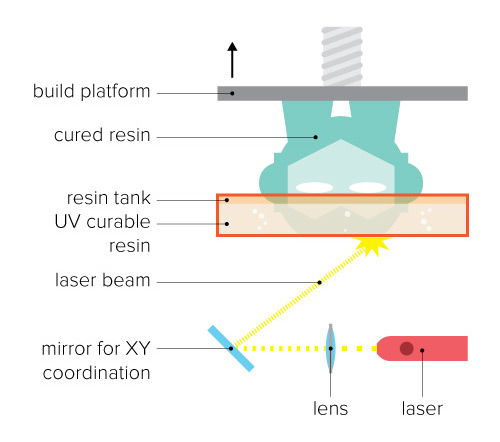

Stereolithography(SLA)

This process that converts liquid plastic into solid objects.

These 3D printing technologies are also available in desktop 3D printers. Materials are limited to resins, but new varieties have appeared recently providing strength or flexibility to the final objects.SLA and DLP 3D printers produce highly accurate parts with smooth surface finishes and are commonly used for highly detailed sculptures, jewelry molds, and prototypes. Because of their relatively small size, they are not recommended for printing large objects.(Source :- https://www.3dhubs.com)

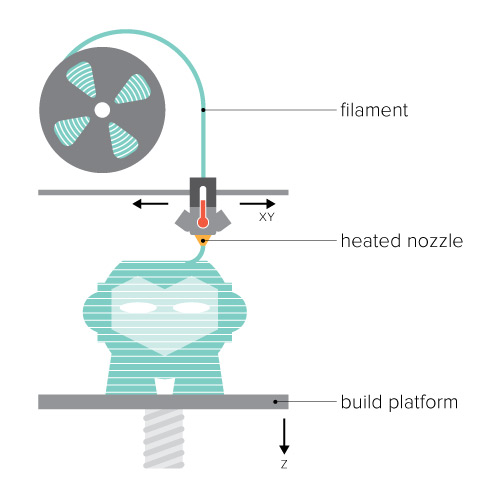

Fused-deposition molding (FDM)

The FDM printing process starts with a string of solid material called the filament. This line of filament is guided from a reel attached to the 3D printer to a heated nozzle inside of the 3D printer that melts the material. Once in a melted state, the material can be extruded on a specific and predetermined path created by the software on the computer. As the material is extruded as a layer of the object on this path, it instantly cools down and solidifies – providing the foundation for the next layer of material until the entire object is manufactured.

As the cheapest 3D printing technology on the market, FDM also offers a wide variety of plastic-based materials in a rainbow of colors including ABS, PLA, nylon and even more exotic material blends including carbon, bronze or wood.(Source :- https://www.3dhubs.com)

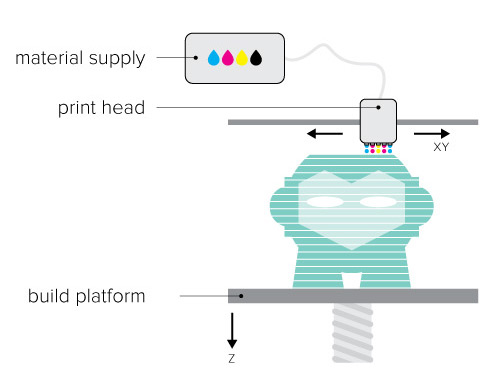

Material Jetting (PolyJet and MultiJet Modeling)

Material Jetting (Stratasys PolyJet and 3D Systems MultiJet Modeling) technologies are similar to inkjet printing, but instead of jetting drops of ink onto paper, these 3D printers jet layers of liquid photopolymer onto a build tray and cure them instantly using UV light.

(Source :- https://www.3dhubs.com)

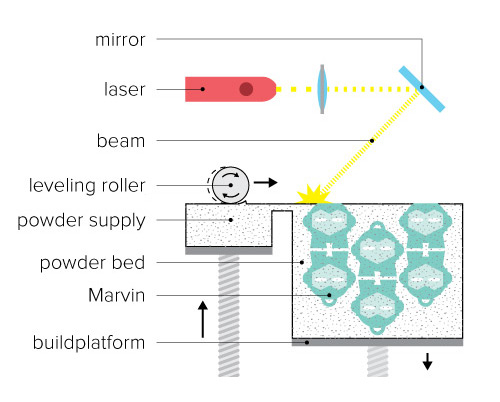

Selective Laser Sintering (SLS)

Selective Laser Sintering (SLS) uses a laser to melt and solidify layers of powdered material into finished objects.

steps for 3d printing

1.First I designed the object in rhino

2.Then I export it to stl and open in cure.

3.Convert it to G code and save in pendrive.

4.Open the G code in 3Dprinter and start printing.

the design of my 3d printing object

opening the file in cura before printing

the printed object

I like drones.So I already designed drone's frame in the designing week and I tried to print the design in this week

the design of my drone

design in cura

final output

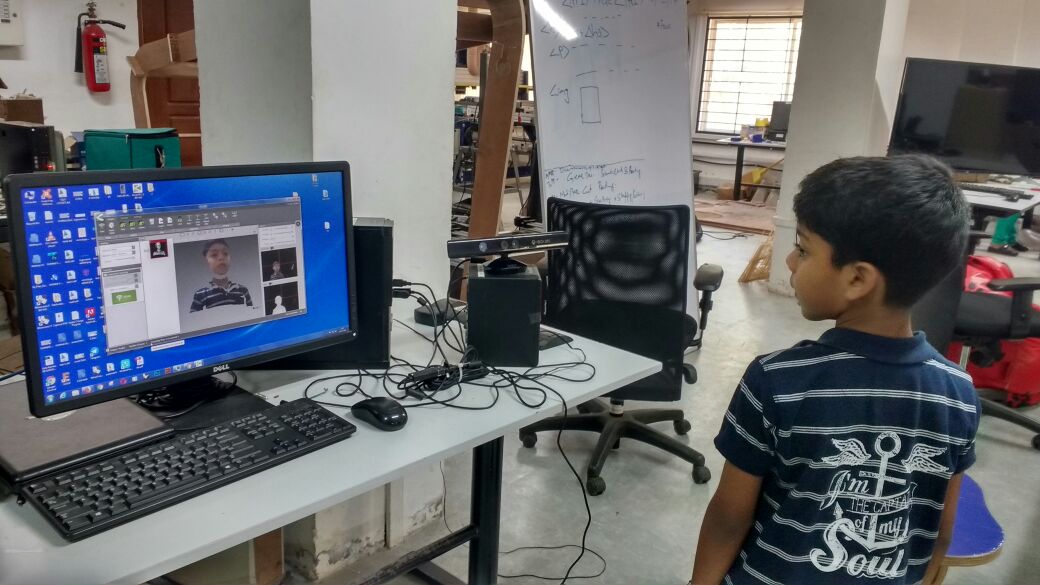

3d scanning

3D Scanning is a process to convert Real 3D object to computer File.Today there somany 3D Scanner's avilable, Depthsensor like Micorsoft Kinect and Intel Real-Sense is a good Example. In this week am using two method to scan a 3D object , using Modela and Microsoft Xbox Kinect.I started 3D scanning. I 3D scanned myself with the help of software called K scan and also used the kinect XBOX 360.First we need to align the scanning area for caliberating the sensor and software.My instructors helped in all my way for scanning my image.so many scanned images take.and combined options used to combine all the images.Then finalize option is used for finishing the image.The image was not that much good.so i dont like to print it.The image is then export to.Stl format.

microsoft xbox kinect

Kinect (codenamed Project Natal during development) is a line of motion sensing input devices that was produced by Microsoft for Xbox 360 and Xbox One video game consoles and Microsoft Windows PCs. Based around a webcam-style add-on peripheral, it enables users to control and interact with their console/computer without the need for a game controller, through a natural user interface using gestures and spoken commands.

I used KScan 3D Software to scan the object

I totally captured 40 images.

Then I pressed combine for combining all the images.

Then I exported to STL file and loaded it in cura.