- Propose a final project masterpiece that integrates the range of units covered.

What will it do?

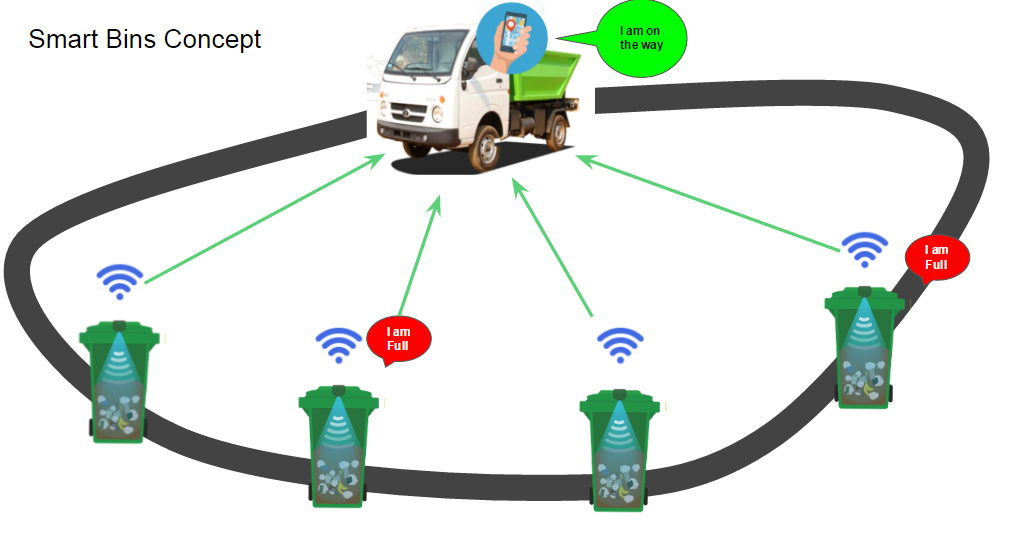

Sensor Based Waste Collection Bins is used to identify status of waste bins to check if it is empty or filled , so as to customize the waste collection schedule accordingly and also save the cost. it is done by checking the WasteBin fill level by using our Sensor Module .

Who's done what beforehand ?

There are so many companies are working on the Waste management systems and I didn't see any fab project under this domain. I got this idea during a hardware hackathon held in Kerala.

What will you design?

Here I am designing a Sensor module powered by the Internet of things by utilizing esp8266 SoC, and we have two major components one is hardware for Sensor Module and visualizing Display unit and another one is Monitoring Software that hosted in a web server.and my project will incorporate 2D and 3D design,also additive fabrication 3D printing processes,and i also handling the Website User Interface and Backend . here i' try to reduce using any pre-build module and i build most of the 99% parts my self in fab .

What materials and components will be used?

| Sl.No | Components | Qty(Nos) | Cost per Item ₹ (INR) | Total Price |

|---|---|---|---|---|

| 1 | ESP8266-12E | 1 | 150 | 150 |

| 2 | HCSR04- Ultrasonic Sensor | 1 | 90 | 90 |

| 3 | NCP1117 3.3v - SOT223 | 1 | 20 | 20 |

| 4 | LED RED - 1206 SMD | 1 | 5 | 5 |

| 5 | Push Button - 3112P SMD | 2 | 10 | 20 |

| 6 | Slide Switch - SDPT SMD | 1 | 1 | 25 |

| 7 | Capacitor 10uf - 1206 SMD | 2 | 4 | 8 |

| 8 | Capacitor 0.1uf - 1206 SMD | 1 | 4 | 4 |

| 9 | Resistor 10k - 1206 SMD | 5 | 1 | 5 |

| 10 | Resistor 0k - 1206 SMD | 1 | 1 | 1 |

| 11 | FTDI Male Header - SMD | 1 | 10 | 10 |

| 12 | Female Pinhead 1x4 | 1 | 5 | 5 |

| 13 | Terminal 2 Pos - SMD | 1 | 10 | 10 |

| 14 | Battery 9V | 1 | 30 | 30 |

| Total Cost Of componenets in ₹ (INR) | ₹ 383 or $ 5.62 | |||

What parts and systems will be made ?

Almost most of the parts for this project will be made by myself ,and building my own esp8266 board.we are developing a Sensor module that can monitor the waste level , and we are developing the complete solution here , the hardware as the sensor module and beackend and Web/Mobile Application.

What processes will be used ?

- 3D modeling :For Making Sensor Module and Disply Unit Casing.

- PCB designing : For making ESP8266 radio Module and Ultrasonic Sensing part PCB.

- PCB production : For making Sensor Module PCB.

- Laser cutting : For building Disply unit enclosure

- Vinyl Cutter : For making stickers and enclosure art works to looks great.

- 3D printing : For 3D Print Sensor Module enclosure.

What questions need to be answered ?

- How to measure the waste level accurately..?

- How we are Creating/routing the Waste Collection Map..?

- How last the Battery...?

Ans: Here we are using HC-SR04 Ultrasoic sensor Distance sensor it can monitor accurate waste level by measuring the distnce between waste and sensor module. .

Ans : Here we are using customized google map and combination of Dijkstra's, travelling salesman algorithm and aslo integrating with Google Routes for custom route map.

Ans : We are not keep on the sensor module 24x7 we are only keep the device on when they need to send the data . other time it will goes to Sleep or Deep Sleep state , so it can save more power , and in first prototype i used 9v battery and second i used Li-Ion and now am planning to use Solar cell in third prototype.so we don't botherd about it's juice.

How will it be evaluated ?

- Internet of Things Intergration to stop overflowing of wastebins along roadsides and localities as smartbins are managed at real time.

- Send optimized routes directly to drivers based on the realtime data and analytics

- Mobile and Web Application Interface for Customer and admins