About Me

The Present

I am originally from the North Shore area of Boston, Massachusetts, my hometown being Lynnfield. I presently reside in Hinckley, Ohio, which is famous for the annual migration of buzzards. The house I live in is an antique (prior to 1820) timberframe built by the grandson of Roger Conant, founder of Salem, Massachusetts. This is where I have a 135 acre farm, orchard and vineyard.

I'm presently enjoying growing fruit, making wine, and volunteering at a public K-8 charter school for gifted learners, leading “Tech Club.” I am in the process of "rescuing" an antique barn from the early 1800's and making part of it a makerspace for the farm. In the process of rescuing old timberframes, I learned how to use Chief Architect CAD, timberframing, jointing timbers, and sawmilling. I have also learned how to slate a roof. I did all the work myself, with the help of two part time laborers, including the rigging.

I operate a farmer's market and winery on the property. We are well known for our Asian Pears. I have developed a system for growing them here in Northeast Ohio, which is close in latitude to the best asian pear growing areas in Korea and Japan. We receive visitors from many different states. We have many customers from China, Japan and Korea who make a special trip to see us. We love our customers. We also employ many disabled citizens from Medina County through a work program called Windfall Industries. I work shoulder to shoulder with these great workers and provide meaningful employment for these people with challenges.

I still keep a home in Weston, Massachusetts, root for the Boston Red Sox as well as the Cleveland Indians, and I travel back to New England frequently.

When I was an adolescent, I enjoyed "Erector" sets, model airplanes, Radio Shack electronic experiments, chemistry sets, science fairs. In 1973, as a young teenager, I was fortunate enough to have access to a Digital Equipment Corporation PDP-8 minicomputer which was donated by the Tuck family to my high school. The minicomputer was previously at Dartmouth College, and it had a very very early implementation of the BASIC programming language. The machine had to be booted using rocker switches and was pretty impractical, but very interesting. After I learned to drive, I would take the family car out to Maynard, Massachusetts and visit the lobby of Digital Equipment Corp, where they had some CRT terminals that you could try. One day I walked through the facility, looking at all the engineers and technicians pushing empty racks and components around the large warehouse, not paying any mind to me being there. They were so engulfed in fabricating and making the next generation of minicomputer, the DEC PDP/11. Things were very different then.

College: The Academy

Right after high school, I entered the US Merchant Marine Academy where I studied Marine Engineering. I spent a year out at sea learning all about machinery, boilers, turbines, generators, refrigeration, and diesel engines.

While at the Academy, I was introduced to DTSS - Dartmouth Time Sharing System, which we accessed via teletype. This was the first viable commercial network system of it's time. DTSS, along with BASIC, was renouned at the time for the democratization of computing. Prior to having any CS courses, I managed to gain access to the mainframe system at Dartmouth, a Honeywell system and started exploring it's assembler code, GMAC. So, two months into the Academy, during the fall of 1976, I decided I would see how many programs a time sharing system could run at the same time. I wrote a program called GERM which basically replicated itself like a virus. Each copy was supposed to print on the terminal what copy it was. I ran the program at 7:45 am before morning colors. By 11:00 I was escorted down to the Admiral's office, where I was introduced to some attorneys representing the Trustees of Dartmouth College, who promptly interrogated me as to why I was maliciously tampering with DTSS during midterms. Long story made short, I was forgiven for writing what Ibelieve was the first virus on a commercial system.

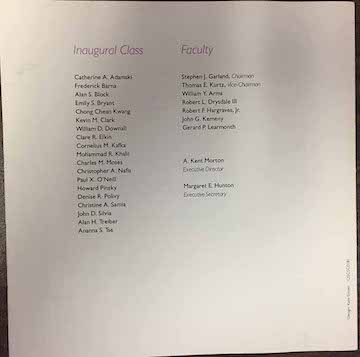

Dartmouth College CIS: Paul O'Neill, along with Jerry Learmonth, Blake Ives, William Arms, Thomas Kurtz, and Stephen Garland.

By the time I graduated the Academy, the folks up at Dartmouth got to know me pretty well. I was invited to attend the Inaugural Class of the Masters Program in Computer & Information Science at Dartmouth College, the first IT program of it's kind, founded by Drs. John Kemeny and Thomas Kurtz, and directed by Dr. Stephen J. Garland. Dr. Kemeny was the President of Dartmouth and Dr. Kurtz was the co-inventor of BASIC and time-sharing. Dr. Kenemy happened to be Albert Einstein's mathemetician. Stephen Garland later became one of the principal faculty at MIT's CSAIL program. William Arms later became head of Computer Science at Cornell University. Scott (Robert) Drysdale later became head of computer science at Dartmouth College. Both Kenemy and Kurtz are IEEE Hall of Fame members and very impressive people. In fact, everyone in the program, faculty and students alike, were very impressive in their own ways.

One month after graduating from Dartmouth CIS, I had the misfortune of being a passenger in a car which was struck by a drunk driver. I was a multiple-trauma victim, with multiple compound fractures of the pelvis, right forearm, as well as a pseudo-traumatic thoracic aortic aneurysm. Mortality rate for the pelvic fracture alone, at the time, was 85%. My doctors, Dr. John Collins, and Dr. Gilbert Mudge, both of Harvard Medical School and Brigham & Women's Hospital, never seen anyone survive this type of aneurysm, but they devised a way to repair me. I worked hard at recovering and was grateful that I received great care and support from my doctors, nurses, family and friends. While still in traction, I went to work in IT for the first time, working for the Computer Corporation of America, at the time in Kendall Square in Cambridge, Massachusetts, on their COMET email system. I would travel with a platform crutch and manage to get it out of the vehicle by hopping on my one good leg. Fortunately at the time, handicap parking became available in Cambridge, which is a very progressive community. Otherwise, I would never been able to get to work. I adapted with what mobility I had at the time so I could get to work. I was what the medic al profession calls a hemiplegic. I frightened a few people along the way because I looked a little unusual with screws and bars coming out of my right forearm. I was frequently grimacing with pain, but I was determined and preservered. I would apologize for my appearance and try to put them at ease with a big smile while I was grimacing. I avoided handshakes because it was very painful to do so. Being handicapped is a very humbling and humiliating experience. At this point in time,I am mildly disabled, but I hide it well.

Getting

Back, Giving Back

I recovered nicely, working hard to get back to doing nearly everything I used to do before I was injured. I was fortunate to recover as well as I did. In 1990, I started volunteering as an adaptive ski instructor at a ski area called Waterville Valley. I was oneof the first volunteers, working with the director, Kathy Chandler, and Bev Davis. I used my tinkering skills to make equipment and adaptations for people with disabilities to learn how to ski. I continued to teach for about 10 years after that.

Presently, I work with Windfall Industries of Rittman, Ohio, providing a paid workplace where disabled citizens of Medina County can come to work. Every Monday, a crew of 3 plus supervisor come to their paid job and perform tasks whichg match their abilities. At lunchtime, we usually have a pizza party which is very popular.

Making Stuff, Big, Big Stuff

My

professional career after that involved computers, engineering,

fabrication and real estate. At one point, I was the owner of a

shipyard (APEC - Hingham Shipyard) where I was operating a large

metal fabrication and machining business. One of the more interesting

projects I designed and built was a special 5-axis CNC machines for

Electric Boat Division of General Dynamics. I had CNC horizontal

boring mills, CNC bridge mills, robotic welders, ASME code stamps. I

would also build special machines for Massachusetts Institute of

Technology, Harvard University, Smithsonian Astrophysical Observatory

(SAO), Brookhaven National Laboratory and Amtrak to name a few. Click here for a video of a CNC Wind Turbine Blade Milling and Drilling Machine designed and manufactured by me for John Walton/TPI Composites, Bristol, RI.

My

professional career after that involved computers, engineering,

fabrication and real estate. At one point, I was the owner of a

shipyard (APEC - Hingham Shipyard) where I was operating a large

metal fabrication and machining business. One of the more interesting

projects I designed and built was a special 5-axis CNC machines for

Electric Boat Division of General Dynamics. I had CNC horizontal

boring mills, CNC bridge mills, robotic welders, ASME code stamps. I

would also build special machines for Massachusetts Institute of

Technology, Harvard University, Smithsonian Astrophysical Observatory

(SAO), Brookhaven National Laboratory and Amtrak to name a few. Click here for a video of a CNC Wind Turbine Blade Milling and Drilling Machine designed and manufactured by me for John Walton/TPI Composites, Bristol, RI.

I also fabricated much work for the nuclear engineers and the nuclear research reactor at MIT. My primary contacts were Mr. Yakov Ostrovsky and Dr. Otto Harling, PhD, Professor of Nuclear Engineering at MIT. My fabrication work, and relationship with MIT grew, when during the mid-1990's, MIT leased a 160,000 square feet portion of my shipyard for constructing of a large international physics project, adjacent to my machine shop.

(File, MIT Library documentation of Boron Neutron Capture Therapy device: 45593978-MIT.pdf)

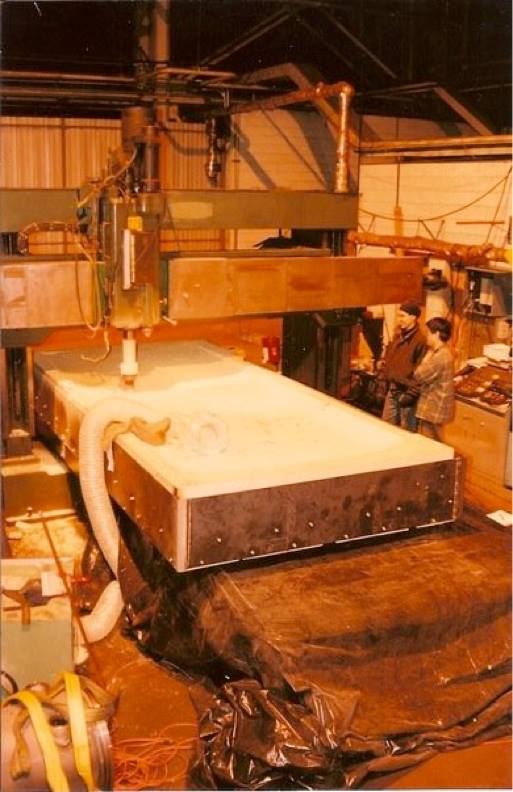

Teaching MIT SEVT How to Make the Manta GT Body - Digitally

One day, on a cold winter day during 1996, one of my engineers came up to my office and told me there were 15 students from MIT who would like to speak with me. While I was doing all this nuclear work for MIT, I went out to greet them. They explained to me their plight. Honda was sponsoring a competing solar electric race car team, and that Honda funded all the CNC machining. MIT did not have a makerspace at the time, and they wanted to see if I would sponsor them, and perhaps CNC machine their body. How could I say no? I said yes, on the condition that they learn how to do the work themselves, and I would teach them how. I ended up being listed on the MIT website as the lead faculty member for the

1996-1997 MIT Solar Electric Vehicle Team (Jorge Barrera, Ivano Gregoratto, Masa Ishigami). This student group used a large CNC Bridge Mill in my

shipyard for

developing and constructing the Manta GT. This was the first time this

team used CNC technology to mill the body mold. I taught

them concepts and methods of CNC milling and mold making, tooling and clamping, and how to

convert a 3-D model into G-Code and communicate it with Mastercam into a machine

tool. We all worked incessantly together for 6 months on the project.

For my effort, this group awarded me an honorary PhD, which I did not

expect. I am still friends with some of the team members today.

Fast forward to today. I am now married to a girl from Ohio, and we have a 14 year old girl who loves making and fablabs, Invention Convention, entomology, and creative writing. I have an orchard and vineyard in Hinckley, OH where I mostly grow Asian Pears, and make wine. I am learning every day about viticulture and enology, which I feel is the next big area for digital applications. Please contact me at paulxoneill@gmail.com