Electronics production

Characterization of the Modela MDX-20

| Specifications | |

|---|---|

| Software resolution | 0.025 mm/step (0.000984 in./step) |

| Mechanical resolution | 0.00625 mm/step (0.000246 in./step) |

| Revolution speed | 6500 rpm |

| Feed rate | 0.1 to 15 mm/sec. (0.00393 to 9/16 in./sec.) |

For this week's group assignment we tried milling PCBs with two different tools: the 1/64 endmill and the 20º 0.1 mm V-shaped Engraving Bit.

A. 1/64 endmill:

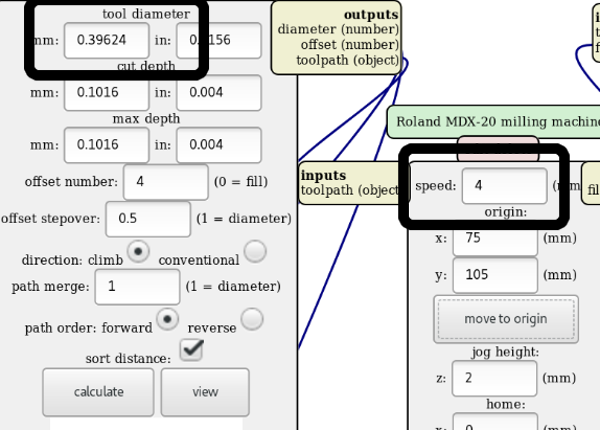

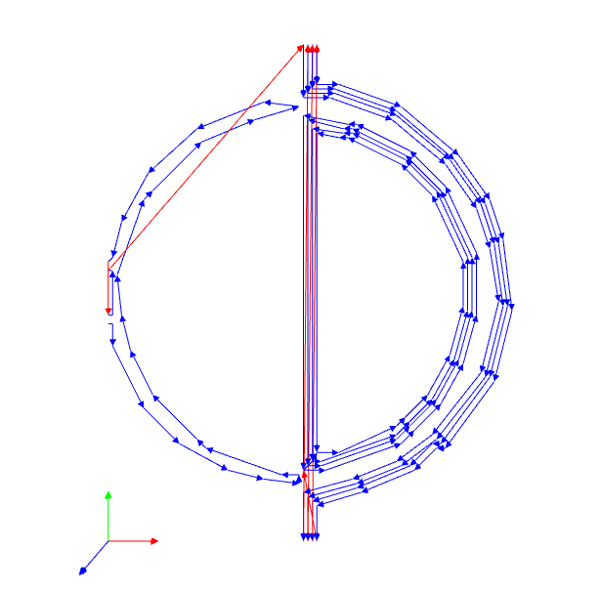

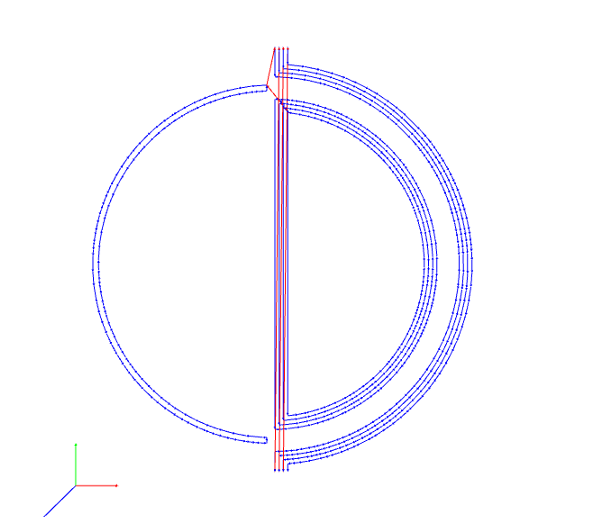

We downloaded the line test image to test the different widths that can be given to the traces using mods to mill with the Modella MDX 20. The process of using mods for PCB production is explained later on. For this tool the parameters are already by default in moods when selecting 1/64. The tool diameter is 0.39624 and the speed 4 mm/s.

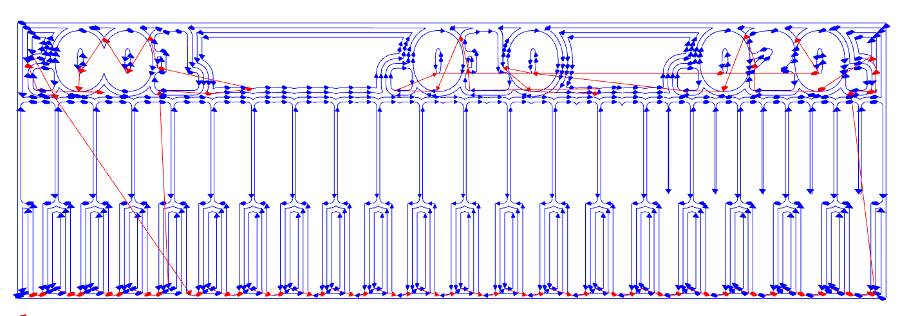

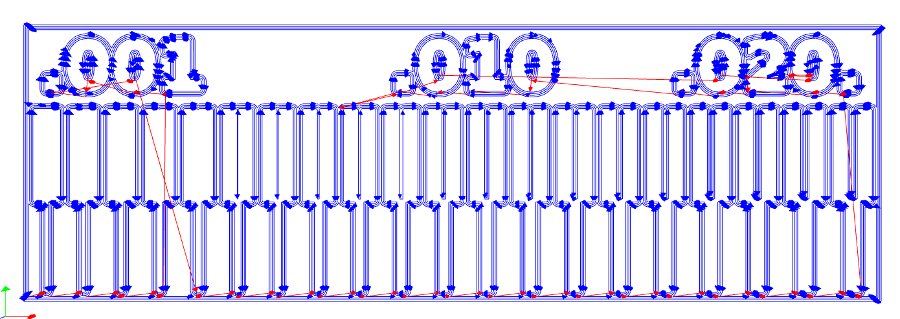

It can be observed on the 2D raster that after .015 the division between the traces disappears. What we want to see also is if the thinner traces remain when being milled.

20º 0.1 mm V-shaped Engraving Bit

The second tool that we tried was the V-shaped engraving bit.

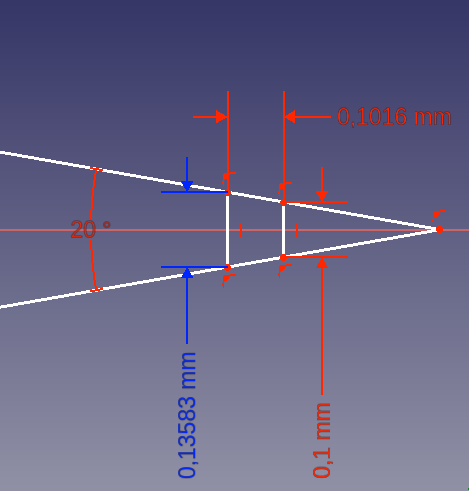

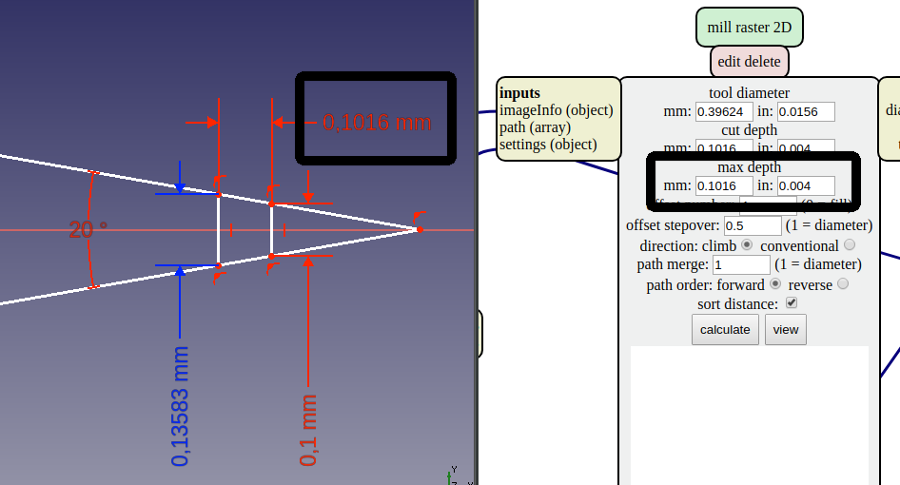

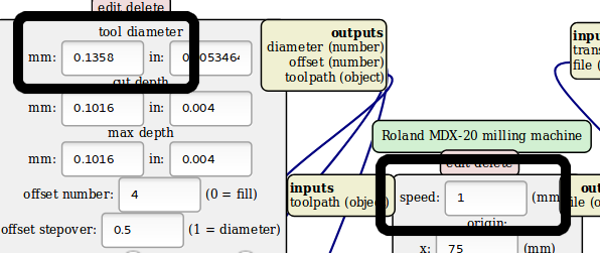

In this case the tool diameter and the speed are not giving by default. They need to be calculated. For doing so we drew the shape of the tool giving it the 20º angle that it has. What we need to consider is the max depth that we need to reach to mill the copper which is 0.1016 mm. Giving that measurement we look in the drawing to what diameter corresponds that depth: 0.1358. That is the tool diameter that we are looking for.

So we set those parameters in mods and we calculate the 2D raster. In this case it can be observed that the separation between traces will be milled properlly until 0.005 approximately as this tool has a thiner dimater.

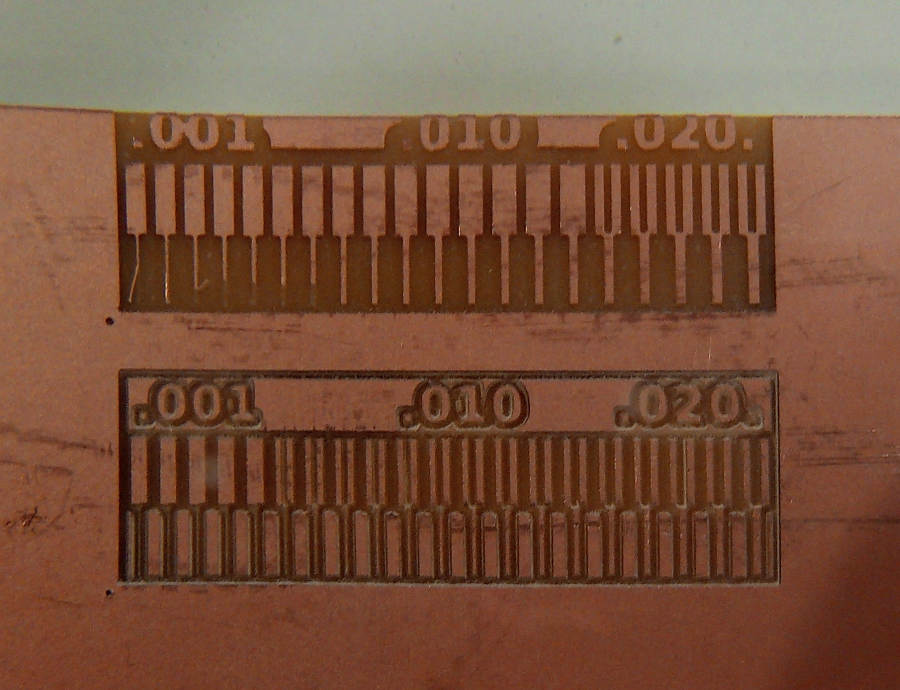

Result of the milling PCB tests

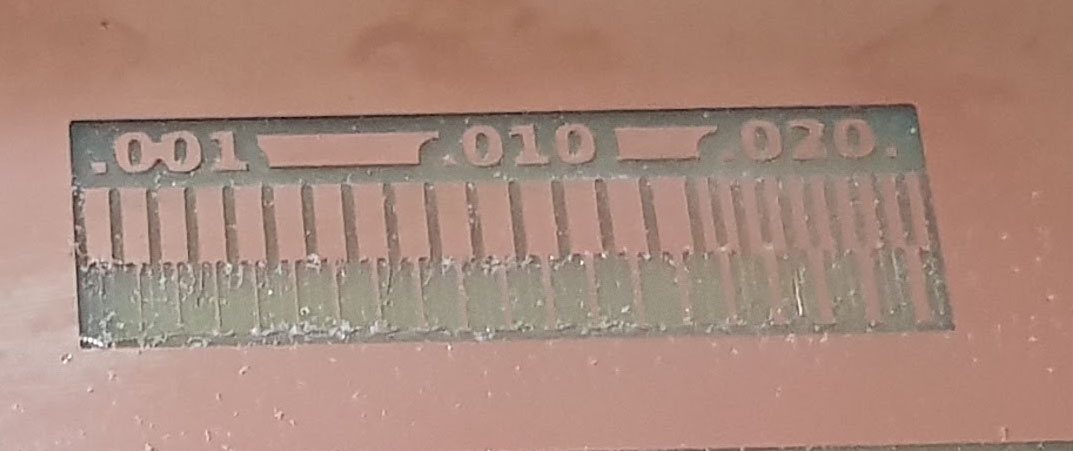

The next pictures show the results of the different tests. The two top pictures have been milled with the 1/64 tool whereas the bottom one was milled with the v-shapped tool. The differences between these two is that with the 1/64 as it has a bigger radius you can't create small separated traces whereas with the v-tool you do. But on the other hand the traces that have been milled with the second one are not fixed as they should.

File resolution

Files

- modela/test01.png 72 dpi

- modela/test02.png 1500 dpi

- modela/linetest.png