Computer-Controlled Cutting

Group members

Technology Used

- FreeCad

- Inkscape

- Laser Cutting Machine

- MDF 3mm

- Acrylic 3mm

Challenges

- We made lots of effort and time on generating different files with different kerfs and importing them to Inkscape and adjusting the width and lenght of the shapes in Inkscape and then laser cutting them with 2 materials: MDF and acrylic. But having the results in hand, surprisingly we noticed that the size of all of the pieces is the same although we defined and designed them with different sizes. So digging more in what we have done, we learned that the moment that we import our design to Inkscape, we should not change the size of our design becuase it affects the size of the kerf as well. Therefore, we did all the process again and this time we did all the adjustments in CadFree and we did not touch anything except the border width in Inkscape :-D

Results

- Kerf: 0.08mm for MDF 3mm using EPILOG Laser Fusion 75 WATT

- We could not find a proper kerf for acrylic 3mm. But we were quite close to find a good number. Maybe we continue our experiment later on.

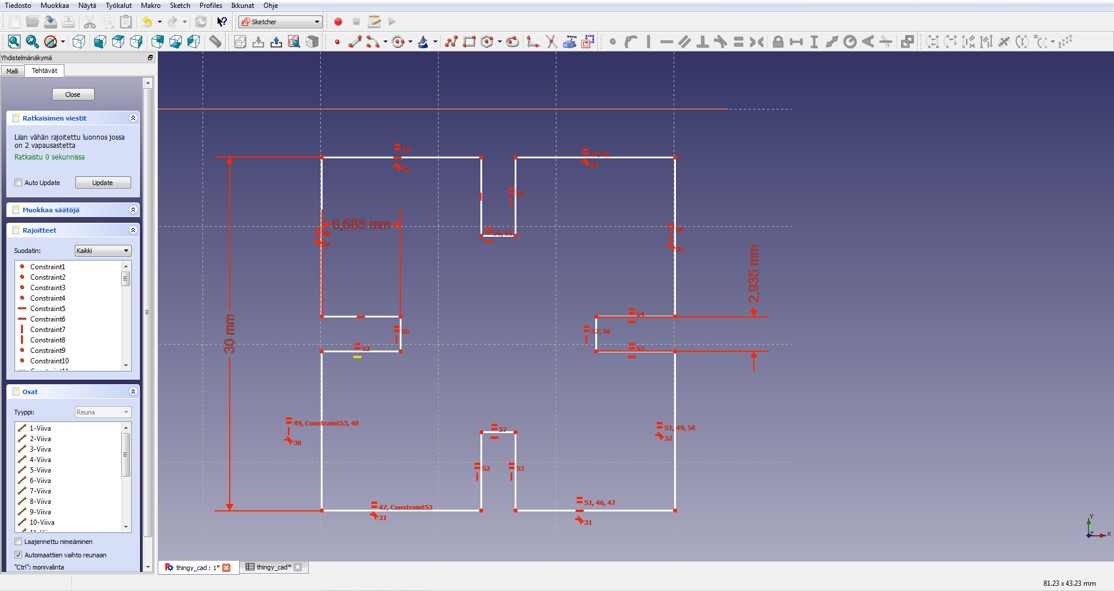

- First we designed our shape using FreeCad.

- Then we considered different measures for the kerf.

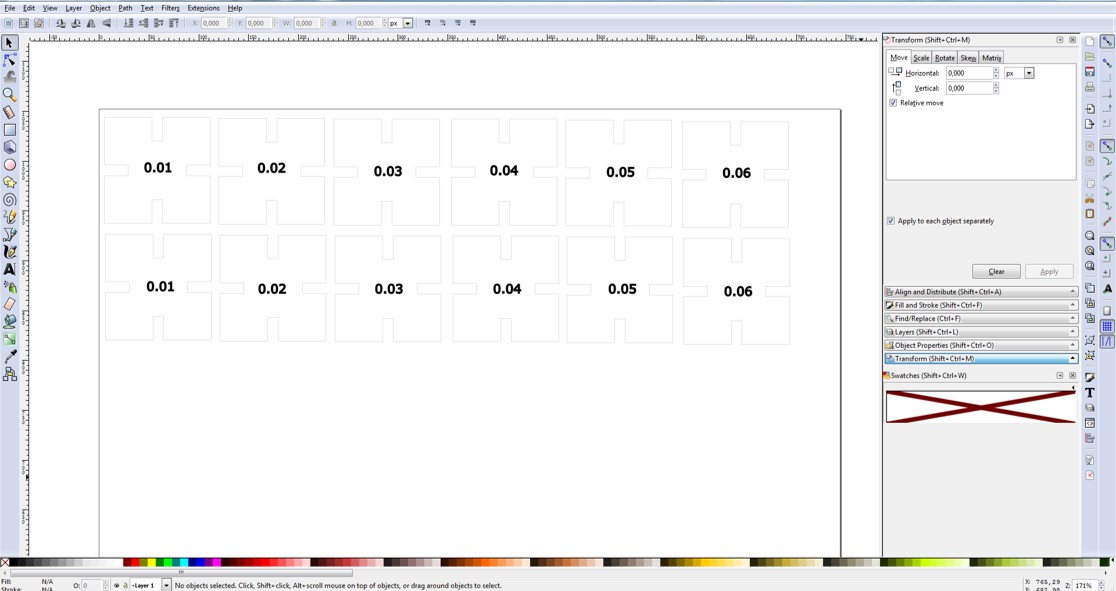

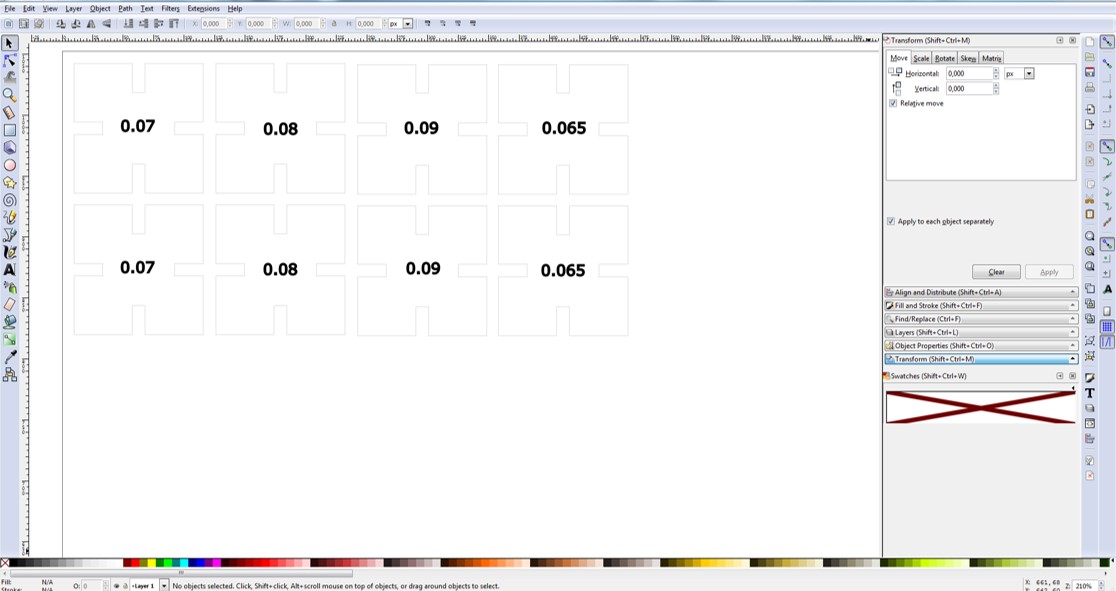

- We imported our design to Inkscape and wrote its kerf on it.

- We were not satisfied with the results so we considered some new numbers.

- Consequently, we were happy with 0.08mm kerf for MDF 3mm.

Testing Laser settings

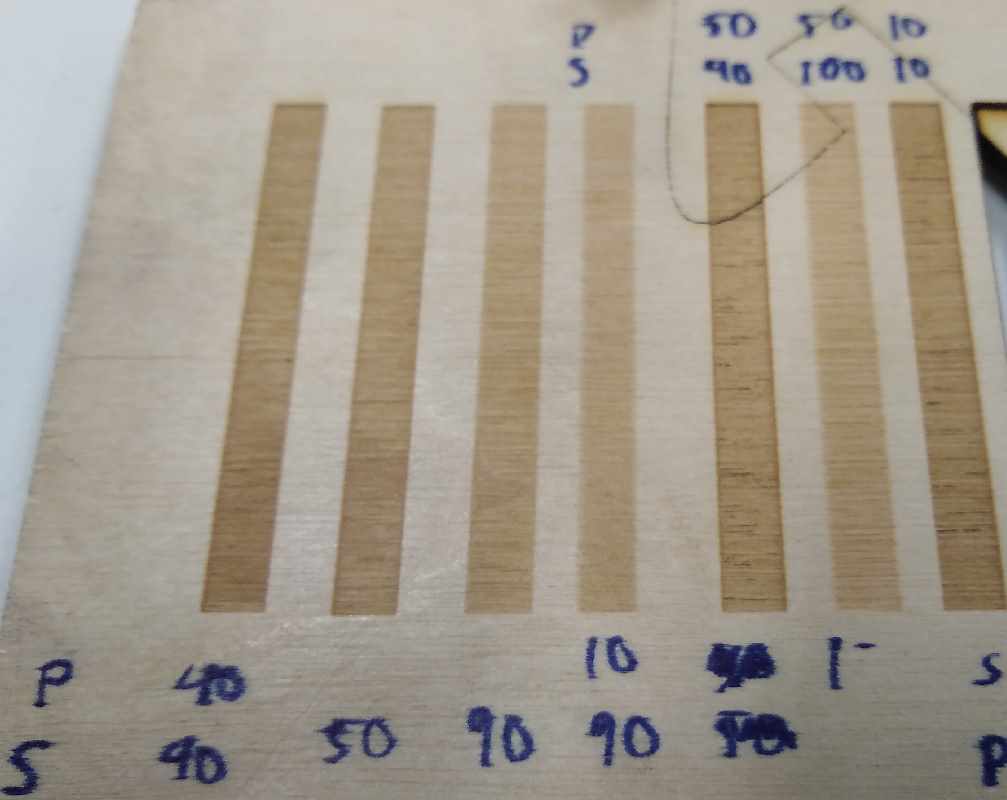

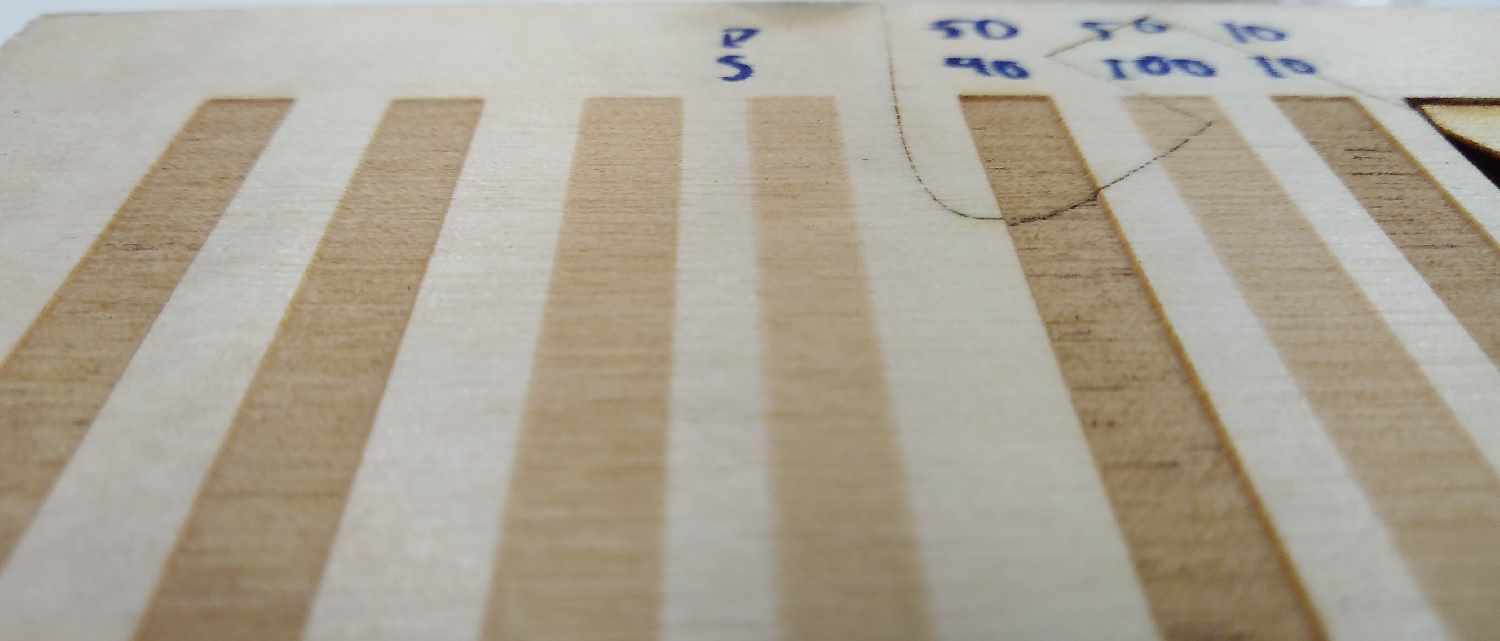

- Testing rastering with different values. Started with saved default setting for 4mm plywood, 40 speed and 40 power.

- From above images we can see that power has higher impact than speed.

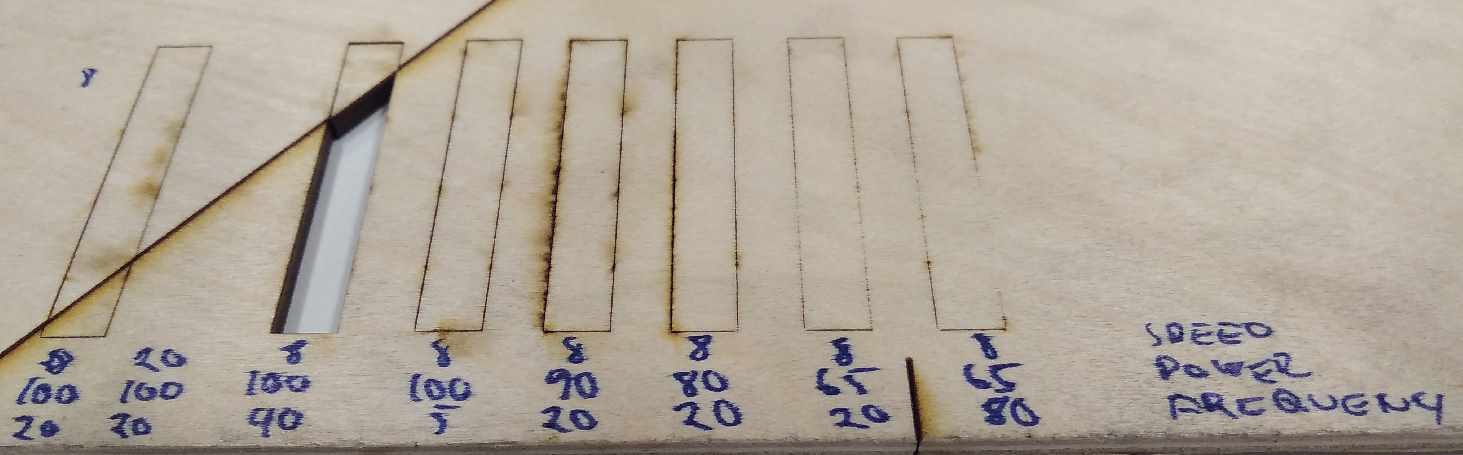

- Testing vector(cutting), with default setting for 4mm plywood: 8 speed, 100 power, 20 frequency.

| Settings | 1 | 2 | 3 | 4 | 5 | 6 | 7 |

|---|---|---|---|---|---|---|---|

| Power | 40 | 40 | 40 | 10 | 50 | 50 | 10 |

| Speed | 40 | 50 | 90 | 90 | 40 | 100 | 10 |

| Settings | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 |

|---|---|---|---|---|---|---|---|---|

| Speed | 8 | 20 | 8 | 8 | 8 | 8 | 8 | 8 |

| Power | 100 | 100 | 100 | 100 | 90 | 80 | 65 | 65 |

| Frequency | 20 | 20 | 40 | 5 | 20 | 20 | 20 | 80 |

From this we can see that Power is the main adjustor, and speed is next in the line. Frequency is the final, fine tuning adjustment.