Assigment:

Group assignment:

-Review the safety data sheets for each of your molding and casting materials, then make and compare test casts with each of them.

Individual assignment:

-Design a 3D mold around the stock and tooling that you'll be using, machine it, and use it to cast parts.

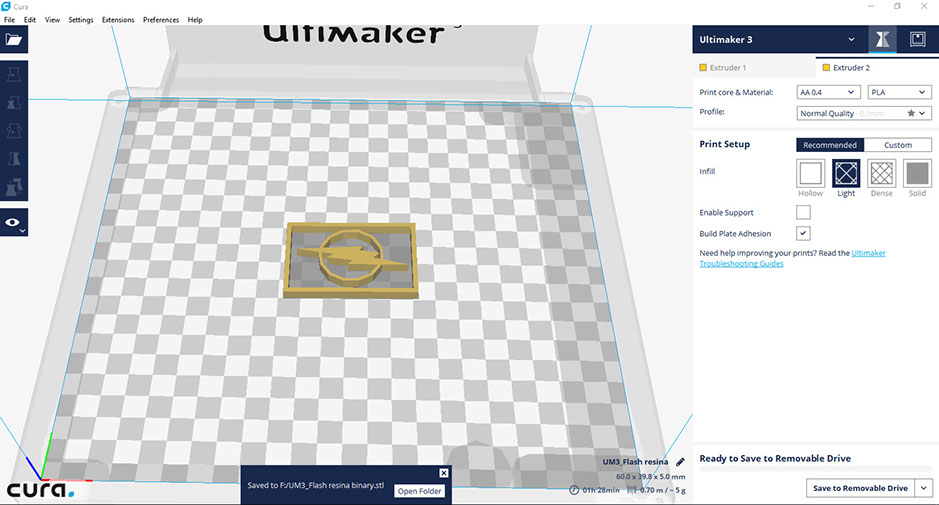

stl binary file

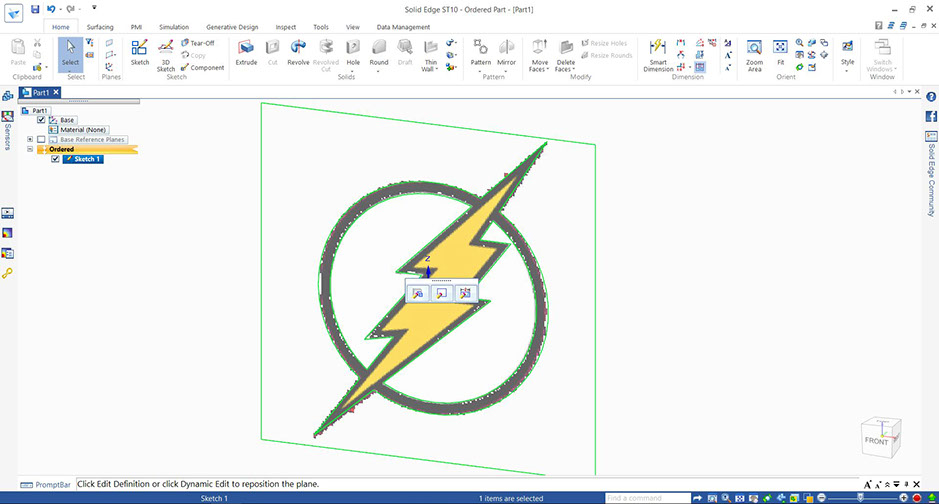

First I downloaded the image I want to make its mold, I choosed the flash logo because it is one of my favorite superheroes.

I uploaded to Solid Edge to calc the image and convert it to vector and after this extrude the logo. I also made a frame outside the logo and extrude it too, I made a mistake not extruding the frame more than the logo.

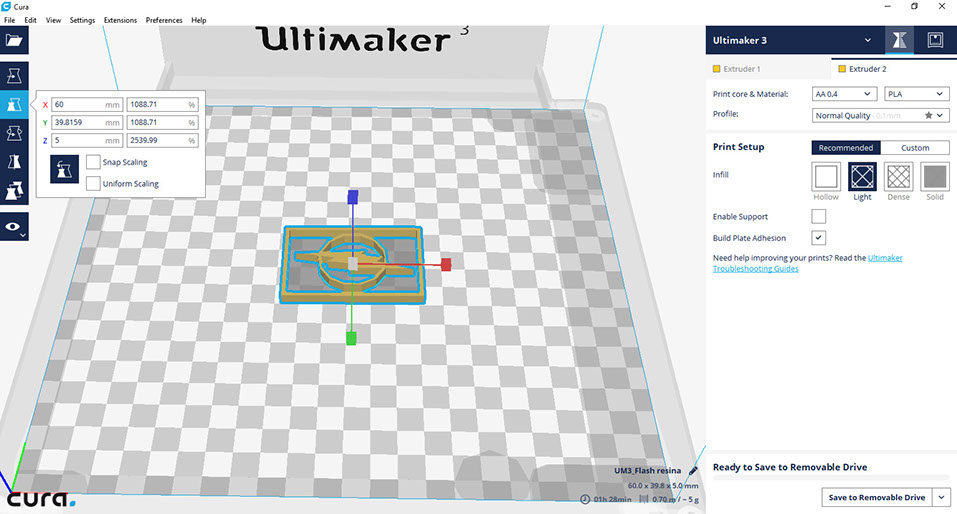

I loaded my stl file to cura to make the slt binary and check the dimensions to fit it my wax.

When I loaded my original stl file to cura this software changed the circle to another kind of circle.

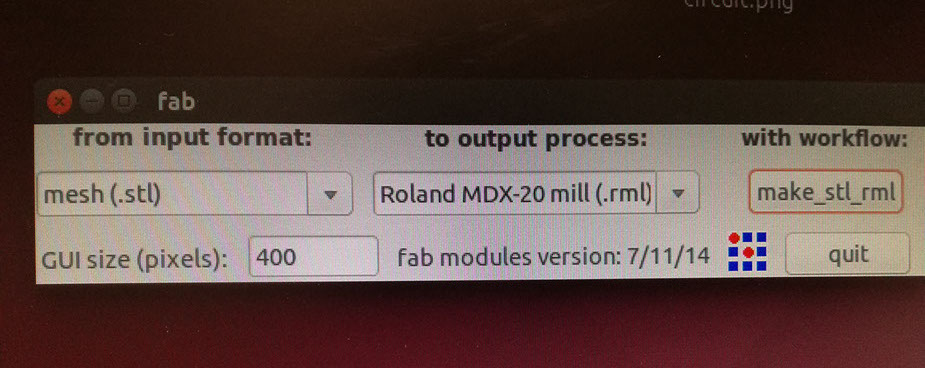

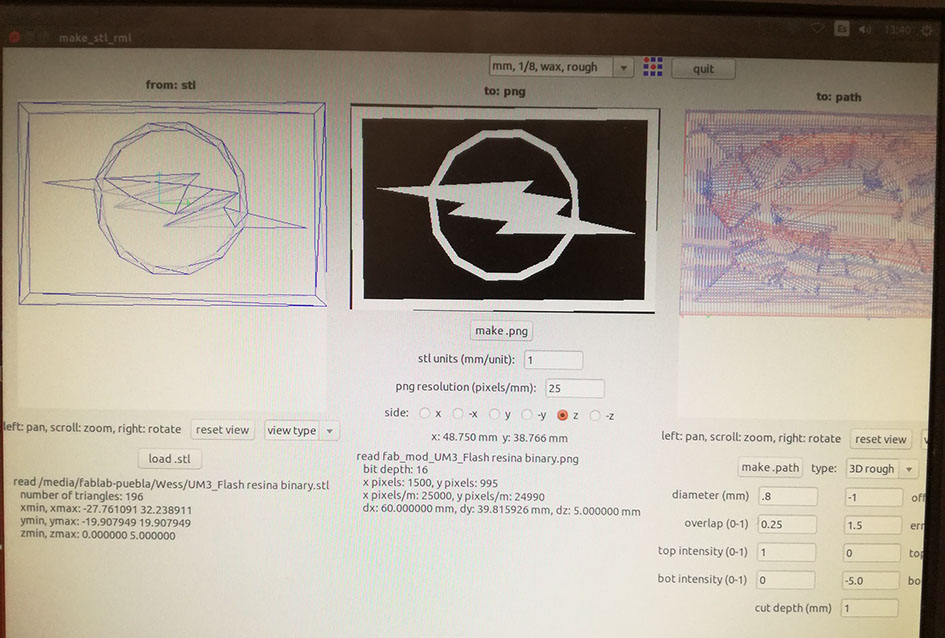

I opened fabmodules to import the binary stl file.

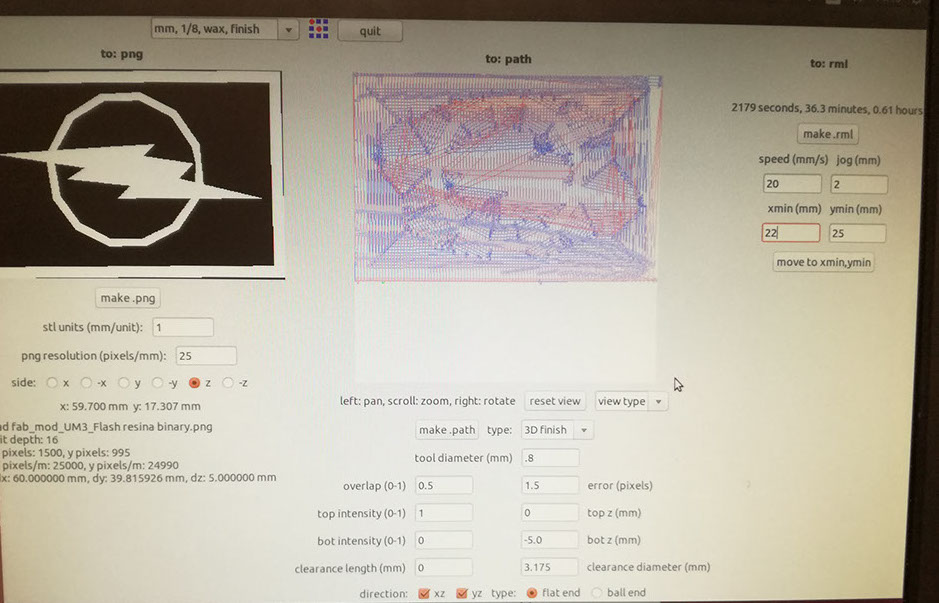

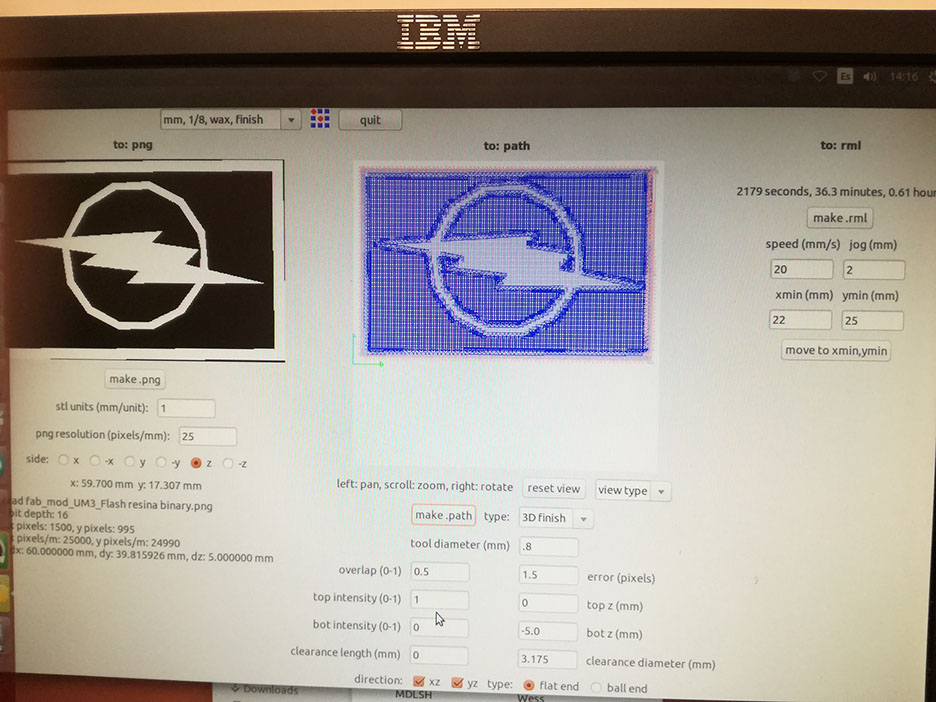

I loaded my file and choosed this parameters

Click on make path, put xmin and ymin, click on make .rml and send it. when this step have been finished change the option from rough to finish and again the steps above.

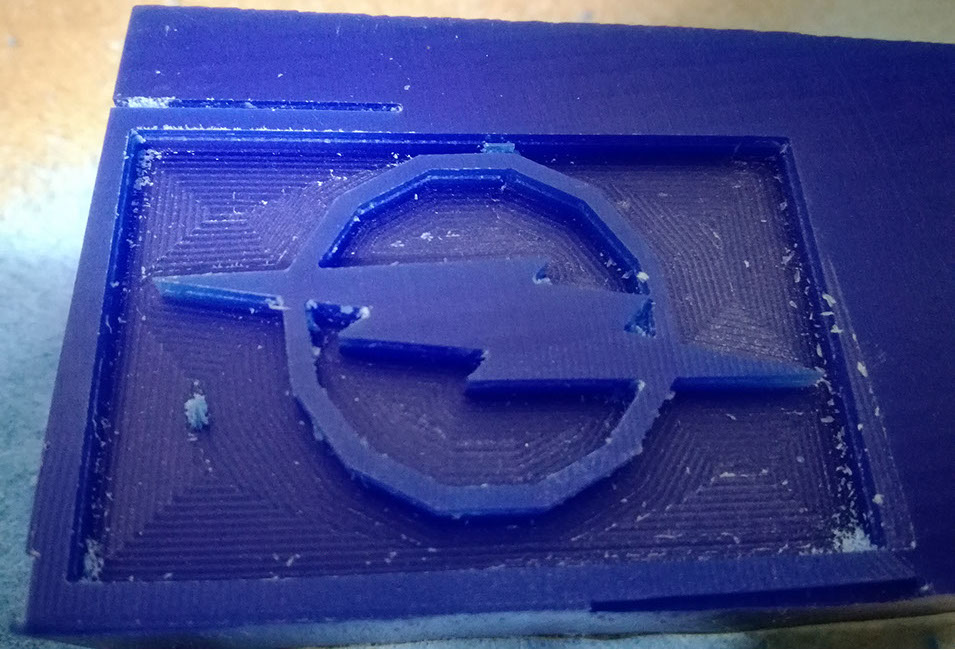

This was the result to milliing the wax

I made a mistake not aligning my file when I saved from cura and I broken a milll during the milling. after this I mixed the silicone whith the diluyent, this need to be the 30% from the total of your silicone, and at the end, I pour the catalizer to my mix and this need tom be the 2% from the total of the mix.

I hit the wax against the table to take out the bubbles in the silicone, but to the next try I going to use a vacuum chamber to make sure to take out all the bubbles and this was the result of the negative mold.

As you can see I can not take out all the bubbles from my mold. after this I use gel coat to make a piece on this mold. I mixed the gel coat with the catalyzer, this nedd to be the 2% from the total of your gel coat.

This was the result of the final piece. this have many imperfections because the silicone mold had bubbles. and I do not take out the bubbles when I poured the gel coat into the mold. in the next try I will use the vacuum chamber to take out the bubbles in the silicone mold and when I pour the mix to the mold.

Materials that I used it:

Gel coat

Silicone

Diluyent

Catalyzer for silicone