Computer-Contolled Maching

In this assignment we have to make something big on the CNC machine.

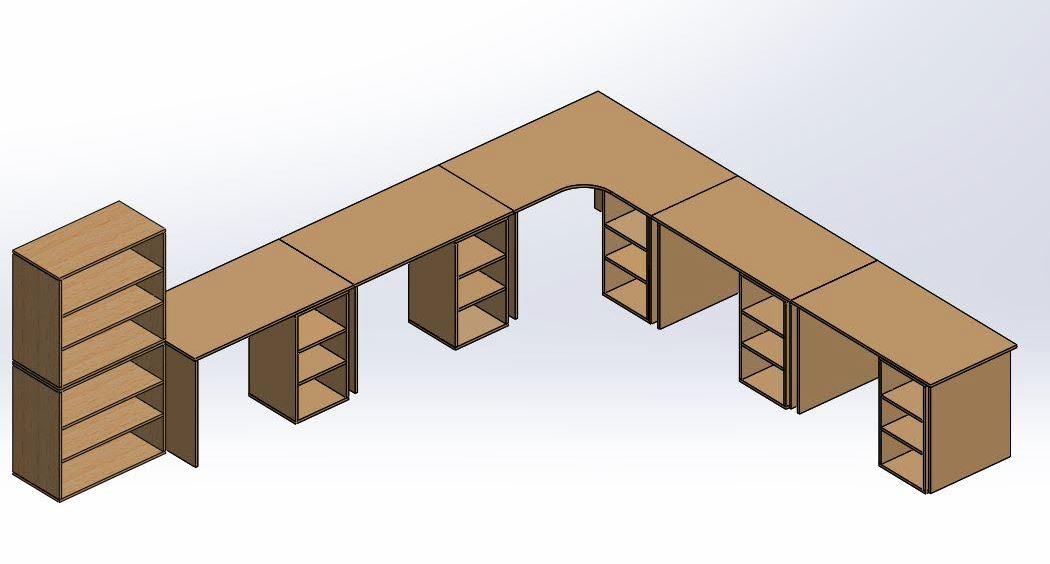

As for assignment of week 2 when we were choosing from 3D CAD software to use for the whole course, I designed a table while I was testing SolidWorks.

Img: table design

I designed this table in different parts which is a better practice for making furnitures.

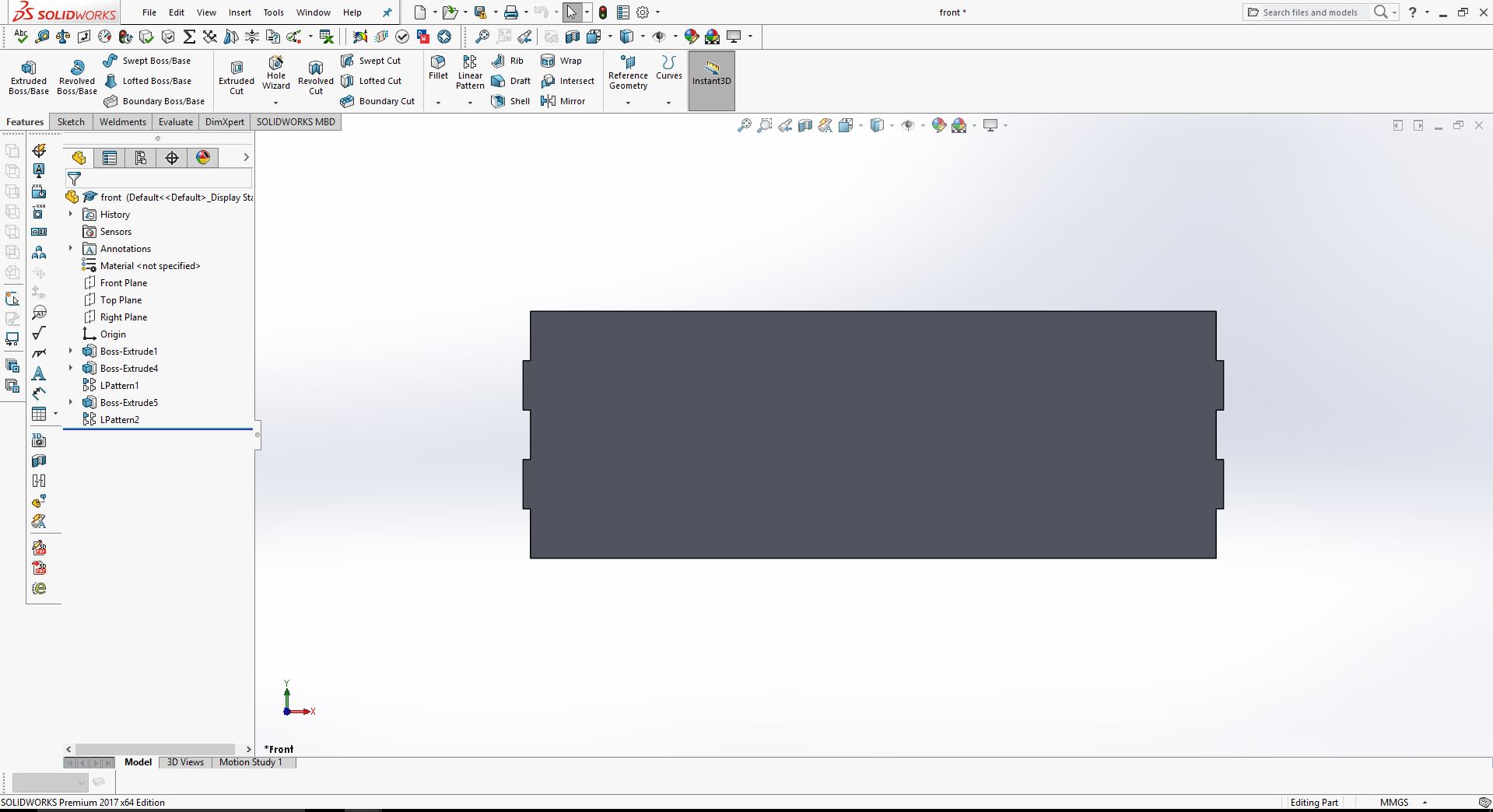

I designed the front part of the table.

Img: Front part

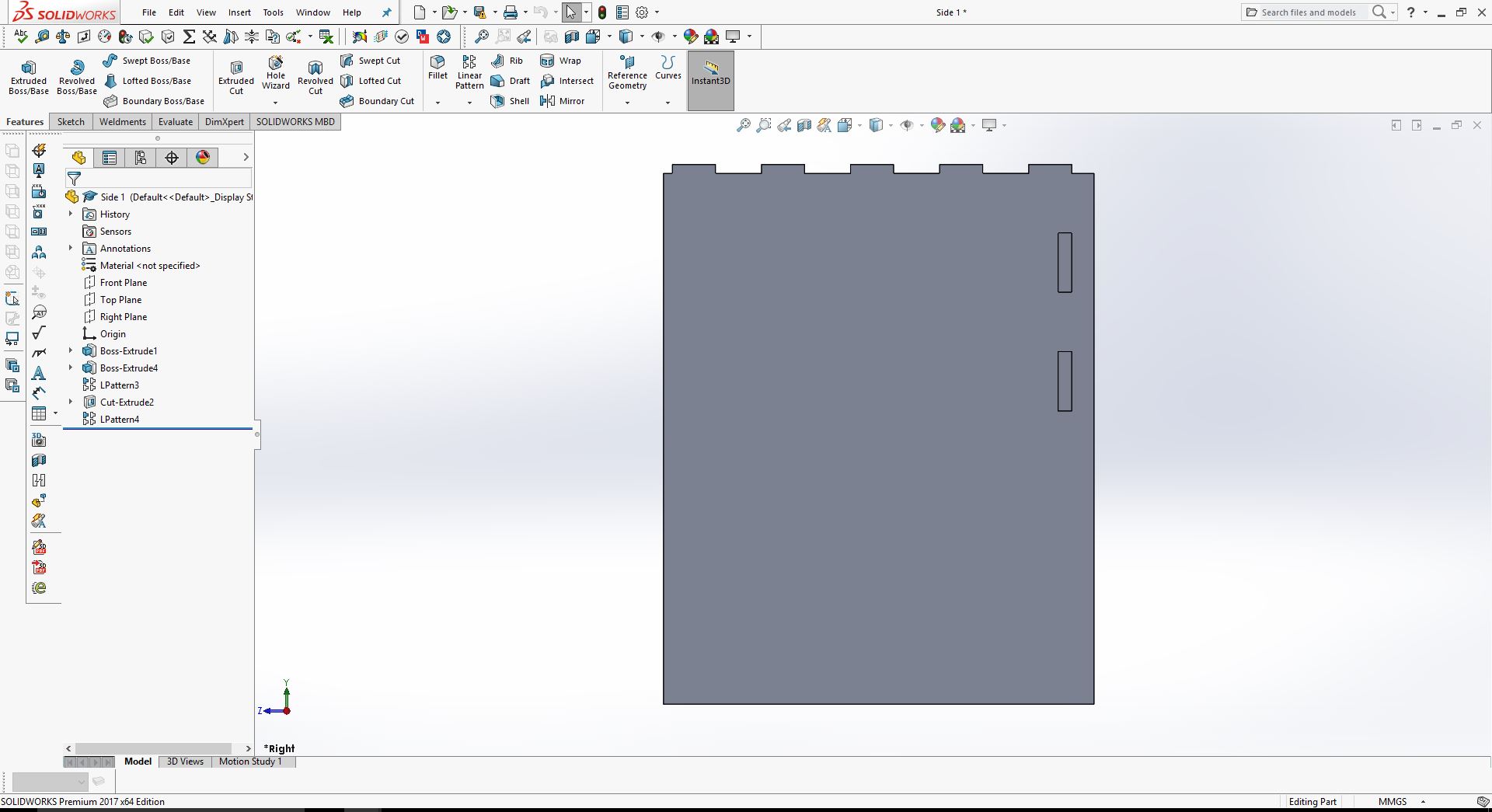

Also I designed a side part.

Img: Side part

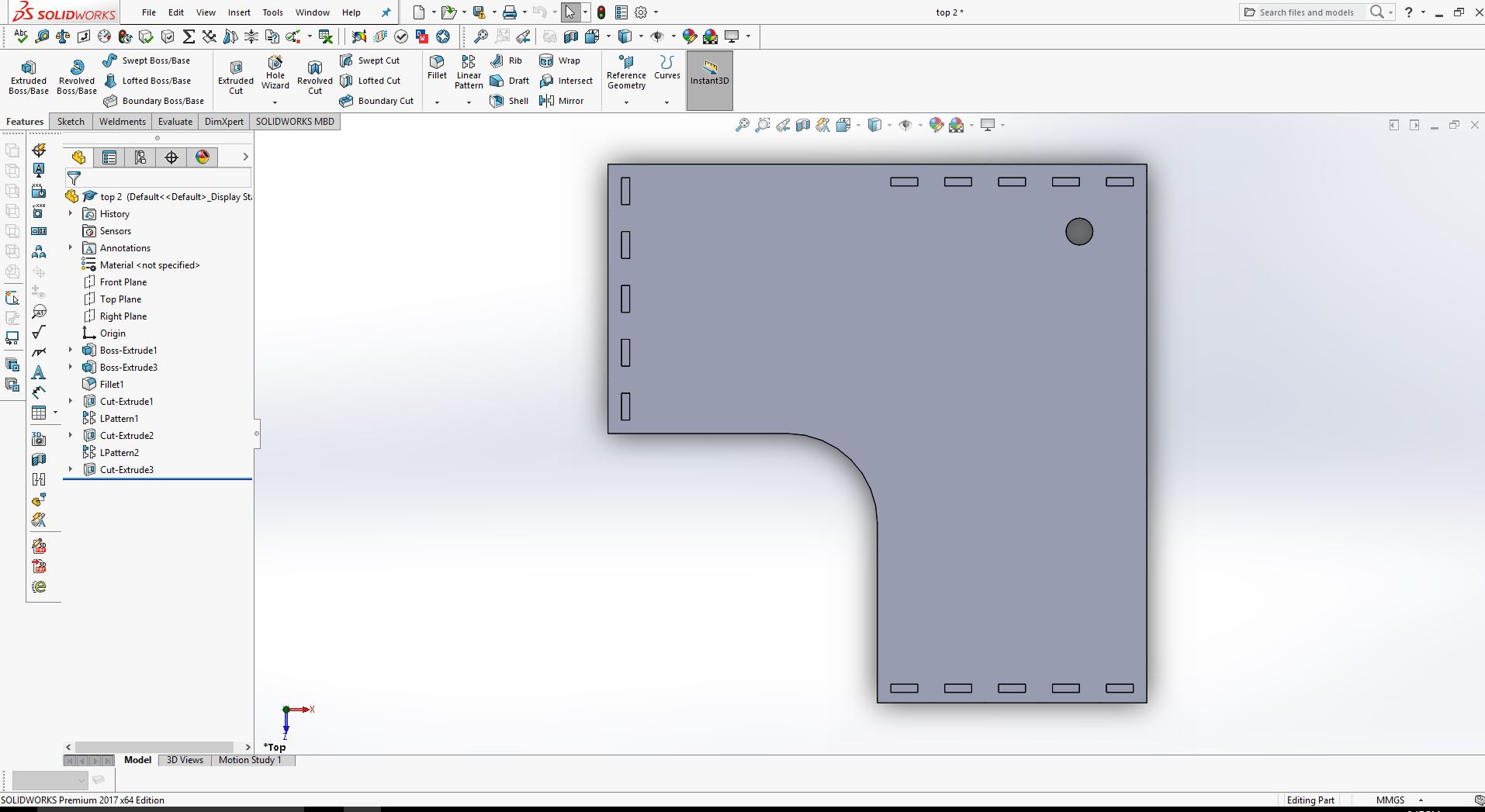

The below design is the top part of the corner of the table.

Img: Top corner part

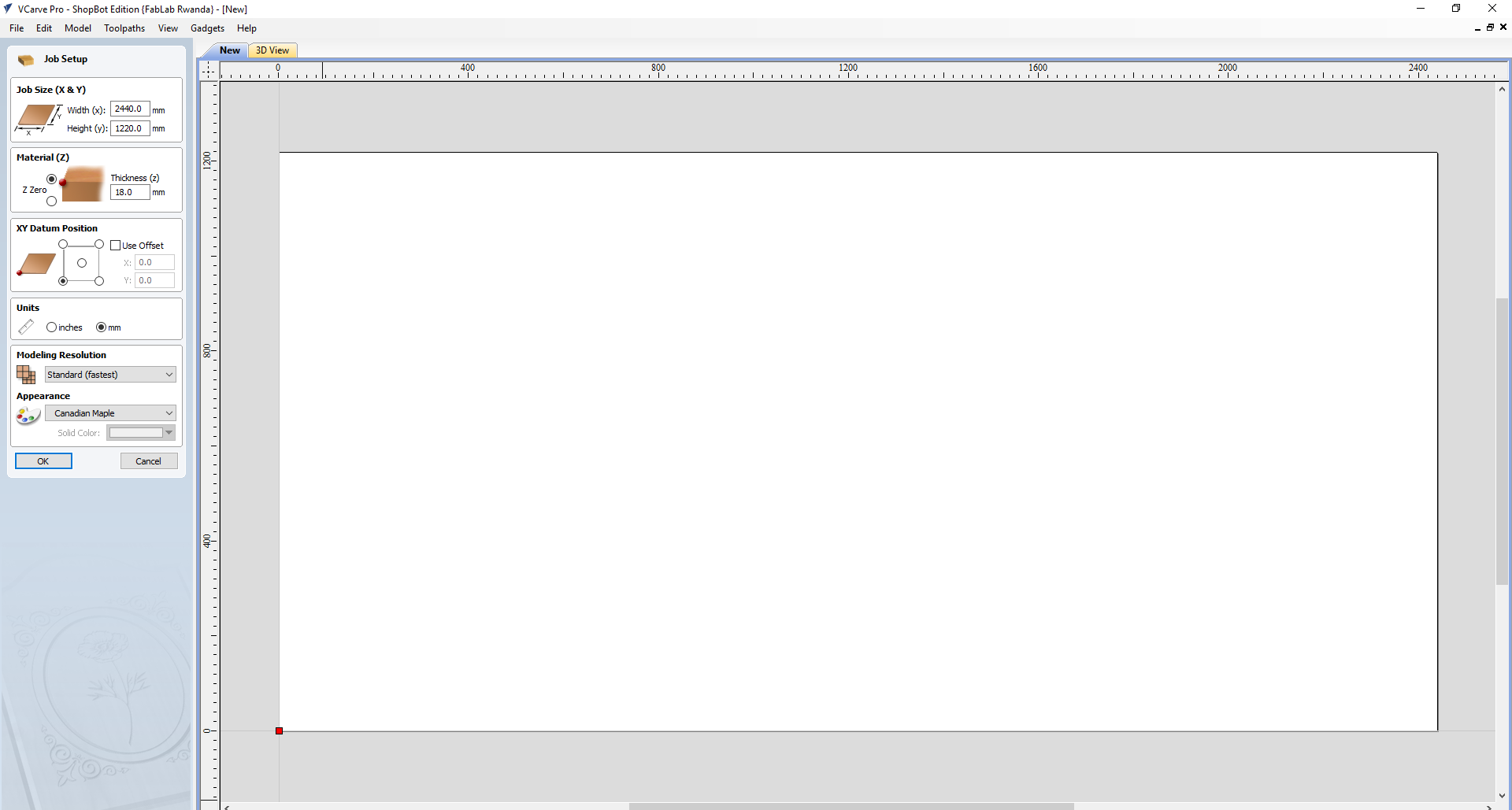

After designing all needed part, I exported my design in Vcarve software.

Vcarve is used to generate Gcode which I sent to shopbot to cut parts you want.

Img: Vcarve

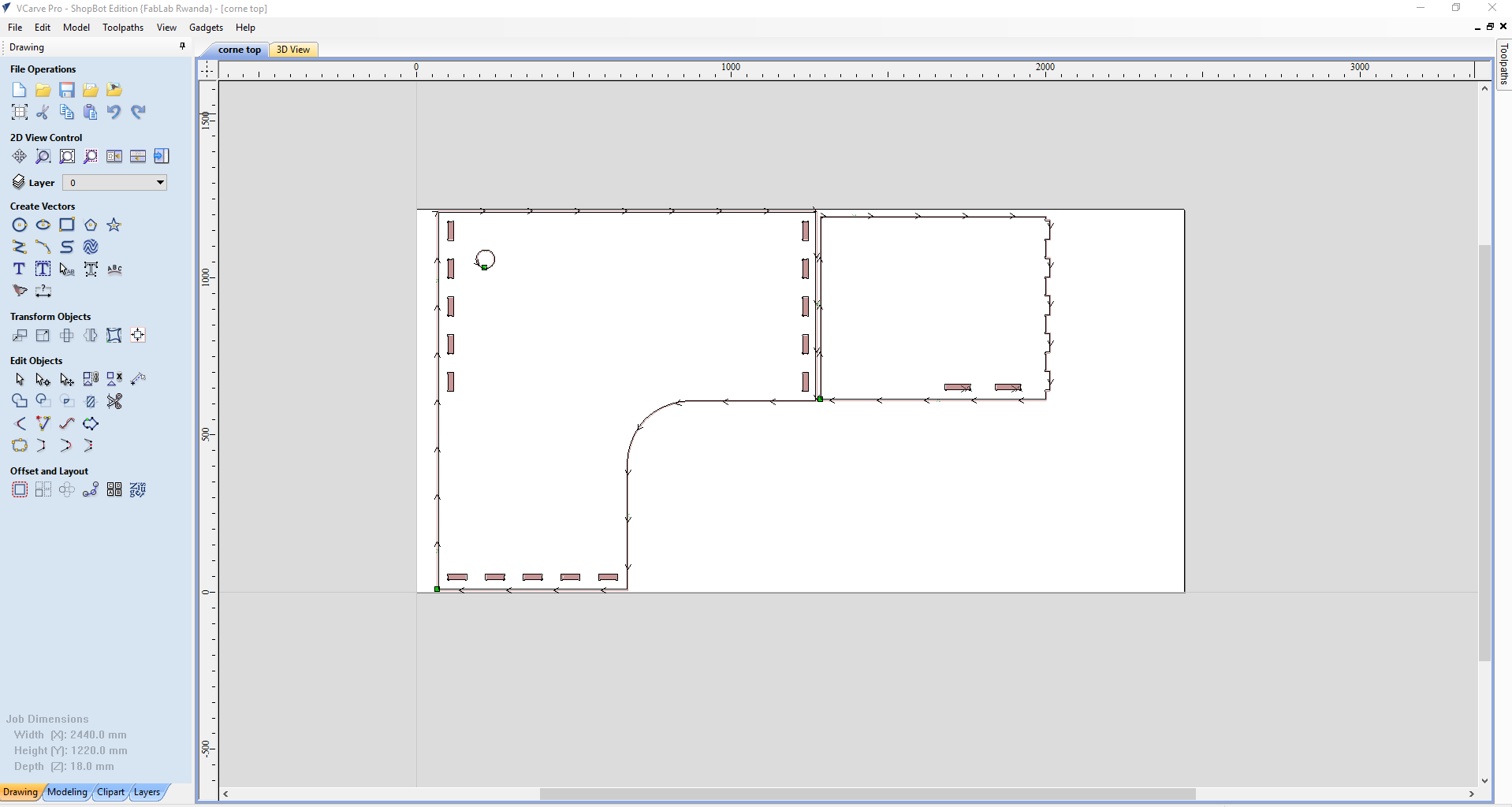

I layed table parts in vcarve a cording on how I want to make it.

Img: Vcarve laying part

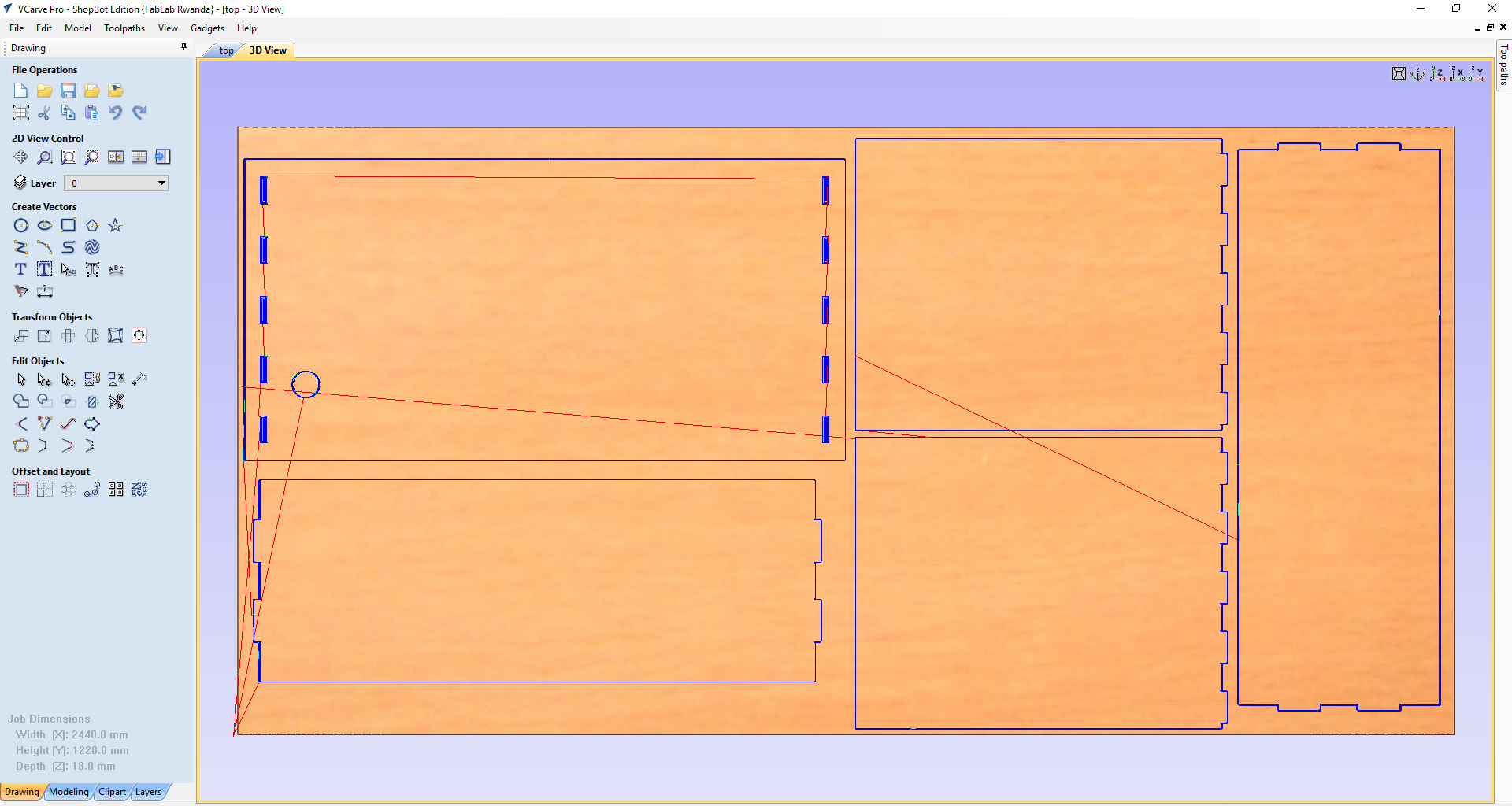

After laying parts I do configure how those parts must be cutted.

Img: Vcarve configuration

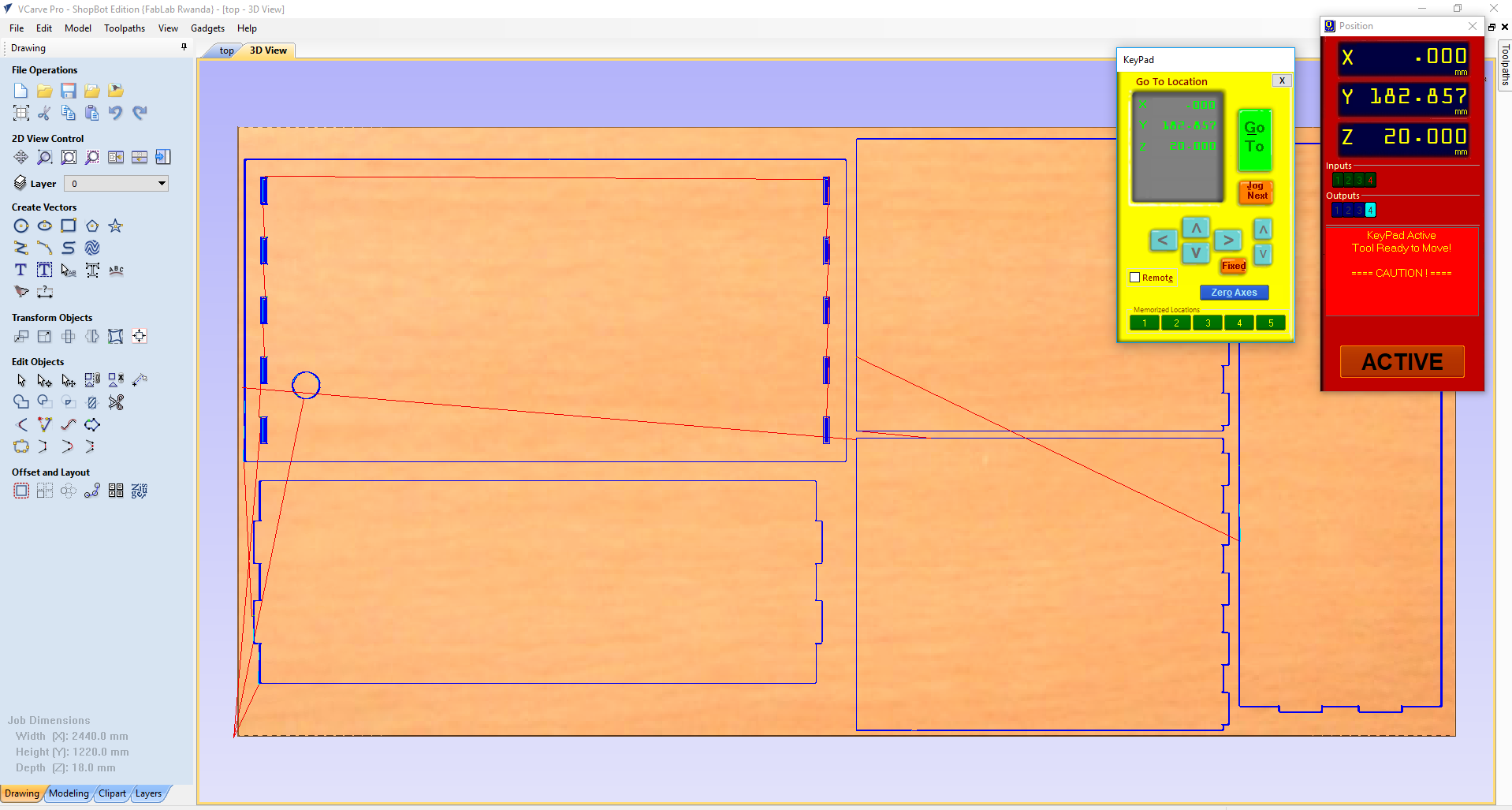

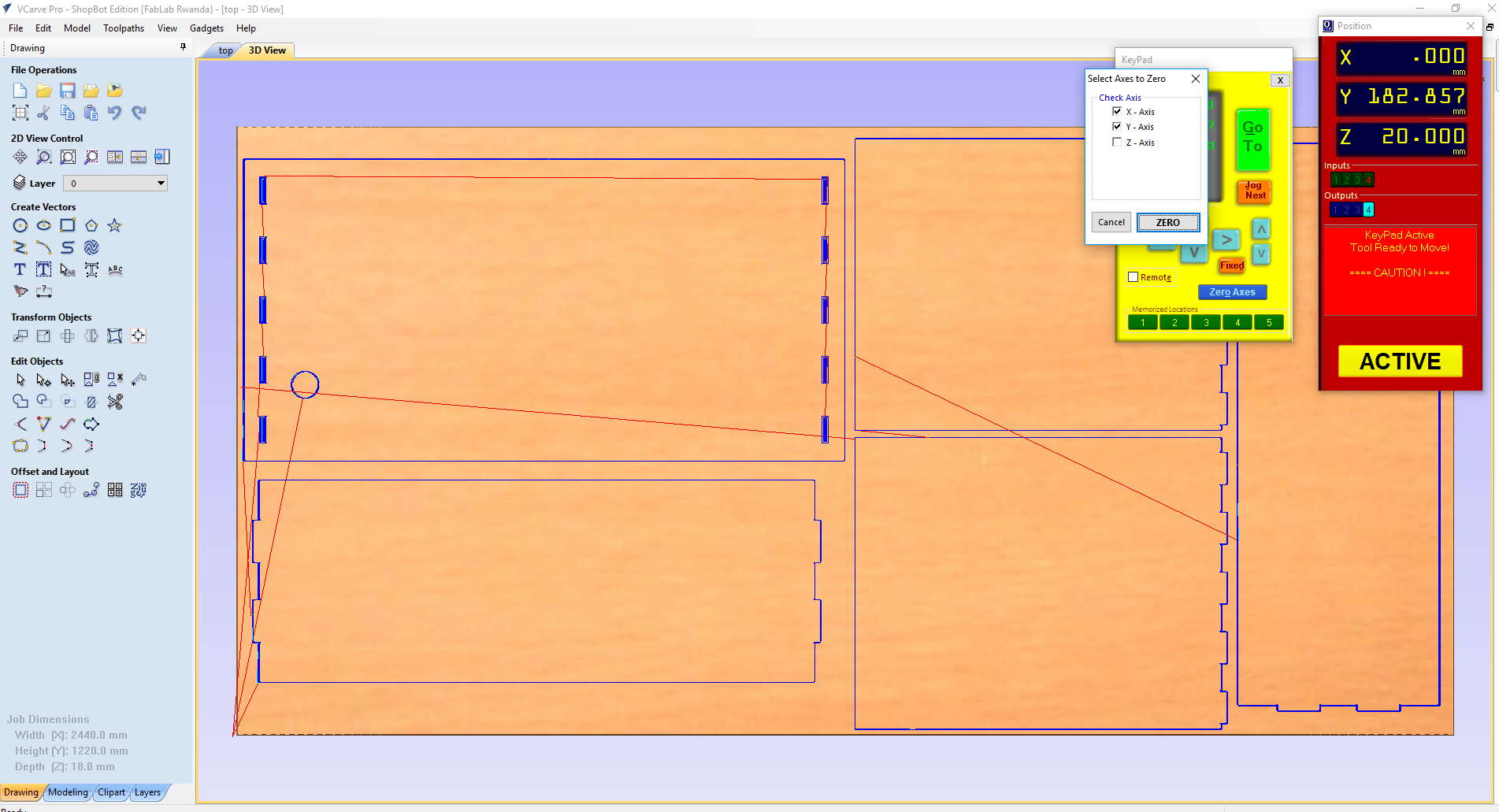

Before cutting parts I initialized coordinates of the shopbot in the software.

Img: shopbot coordinates

Img: shopbot coordinates 2

I used the appropriate plate to set coordinte of the shopbot.

Img: shopbot plate

Below are toos I used to installed wood sheet I was to work on.

Img: shopbot tools 1

Img: shopbot tools 2

Thi is my selfie while I was cutting table parts.

Img: shopbot selfie

After cutting all parts, I assembled them to make the table.

Img: table assembled

For files used can be downloaded Here.