3D Scanning and Printing

- Group project: test the design rules for your printer(s)

- design and 3D print an object (small, few cm) that could not be made subtractively

- 3D scan an object (and optionally print it) (extra credit: make your own scanner)

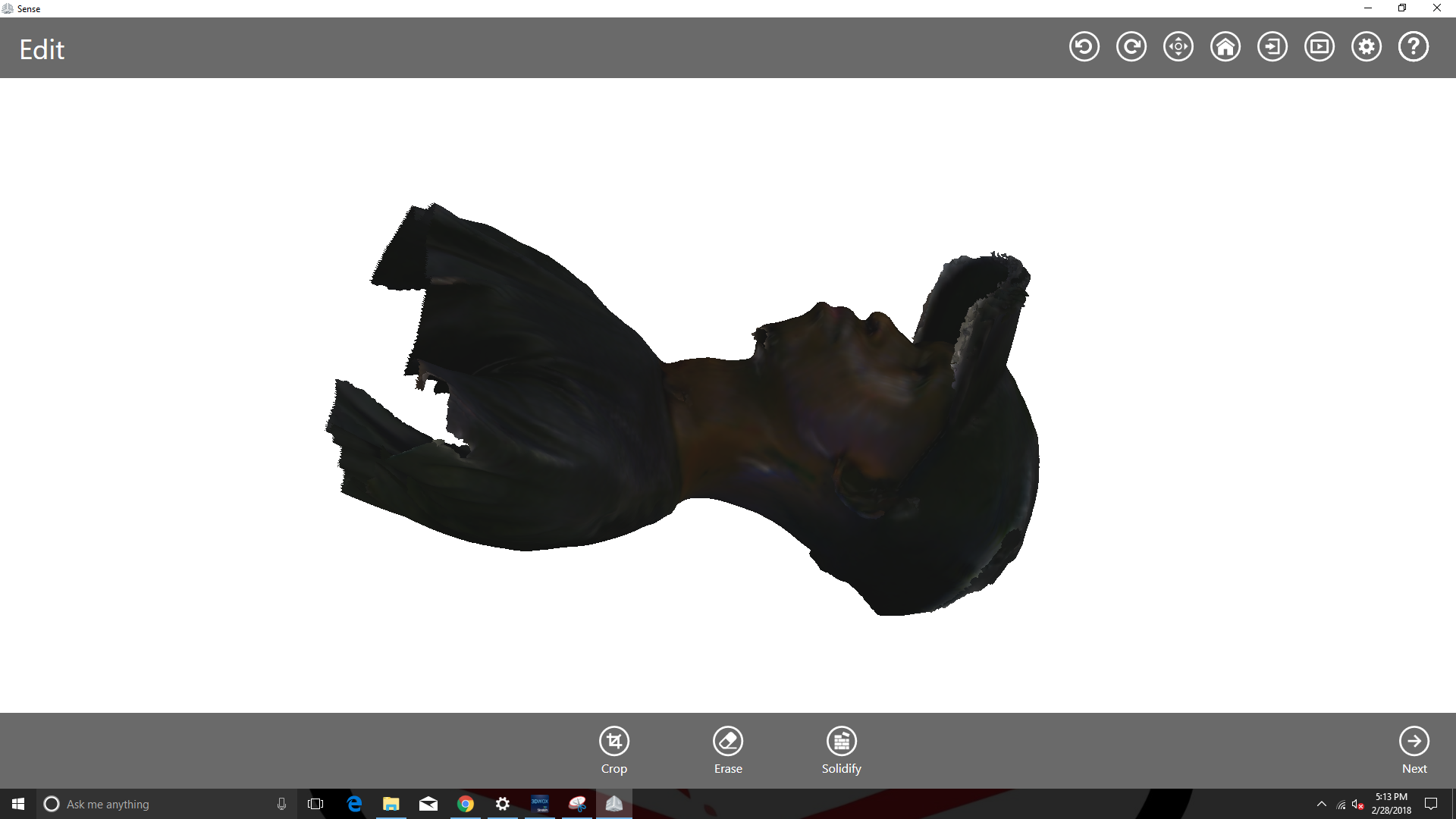

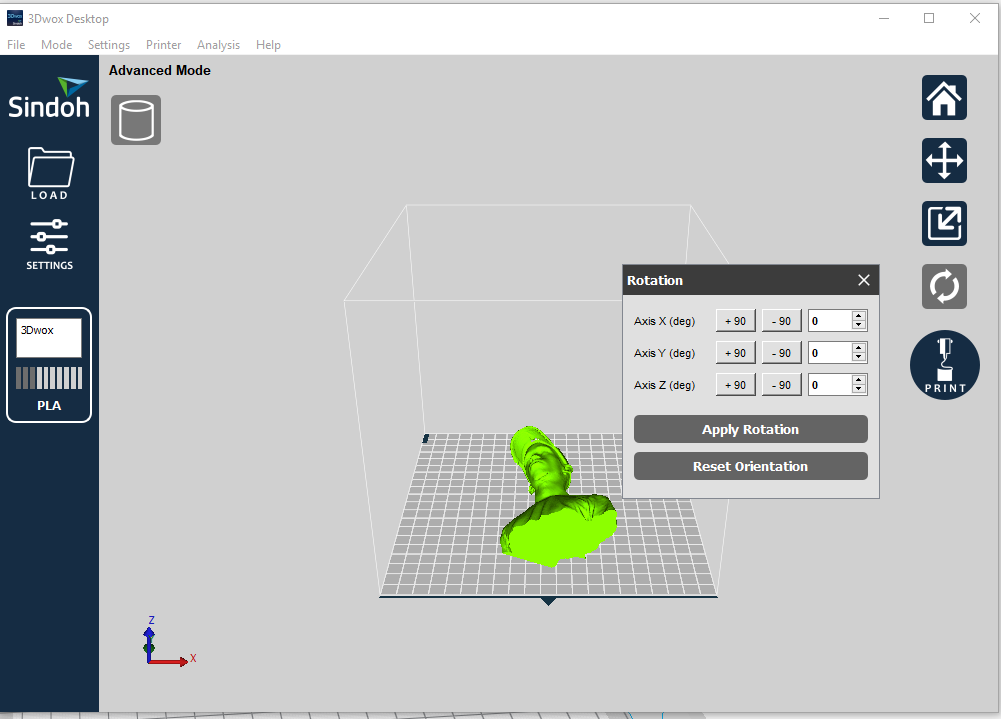

I first went for 3d scanning and I used a 3d sense scanner within the 3D Scanner I used 3D sense scanner to scan my classmate

FredStages to go through while scanning

Comparing the two printers I personally prefered 3Dwox,because it prints smoother surfaces and needs no memory cards to print and has various ways to connect with the computer either by Wifi,USB Drive and

Printing an object that could not be made substractively

I started by designing an object (small, few cm) that could not be made subtractively meaning it can't be made separately because it has no joints

The substractively model I printed did not come out as expected as the inpart was supported and the support couldn't be extracted easily so maybe I am going to try out it out without support and see how it comes out

Printer Testing

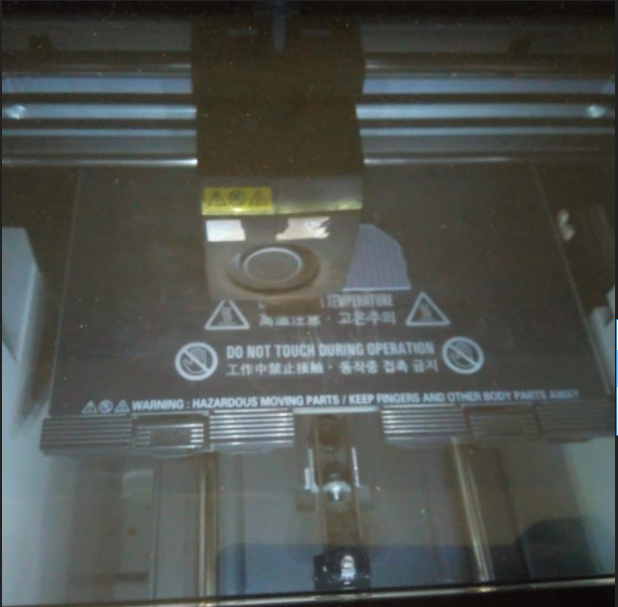

I downloaded a model on ThingIverse for an ALL in One 3D Printer Test that tests the overhanging,Angle printing and high temperature and low speed to have a really good quality as when you use a low speed then you have the ighest quality of skin surface

Conclusion is that our 3DPrinter can perfectly print angles and overhanged structures with a pretty smooth surface

Limitations

3D scanning's limitations are that when scanning you can easily lose the object's focus and it becomes hard to refind it

In 3D printing sometimes i'd leave an object to be printed for many hours and the electricity would be cutoff and it would stop printing because the UPS is damaged.

Another limitation is the one of supports that ruin the smooth surface of the printed object we might solve it by variating the temperature and speed There is this problem of not really smooth surfaces when printing probably caused by the supports that can not be gently removed.

Each material requires its own setting.

What have I learnt?

I've learnt that I can scan an object and replicate it

I've learnt the importance of 3D printing mostly on objects that cannot be made unsubtractively