WEEK 5

Electronics Production

Equipment

- Hardware: Roland RM20

- Software: Fabmodules, VPanel, BashTerminal

- Material: Copper PCB board

Fab Modules

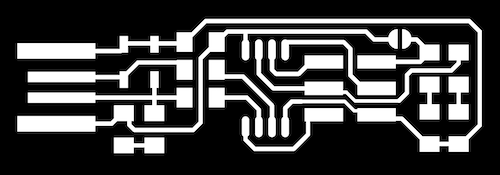

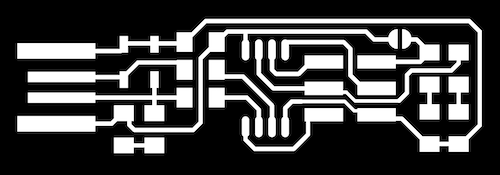

I used Brian's FabTinyISP design.

Download both trace & outline files.

Creating STL file using FabModules

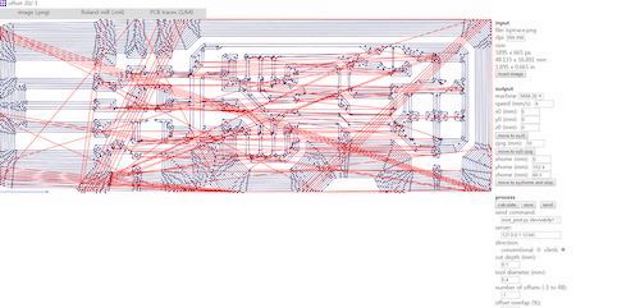

Go to Fab Modules

Trace Files

Input: Select png and find ISP traces file

Output: Roland mill (.rml)

Process: PCB trace (1/64)

Offset from origin

XO: 0

Y0: 0

Z0: 0

zjog (mm): 10

number of offsets: use minimum 4 or (-1 to fill)

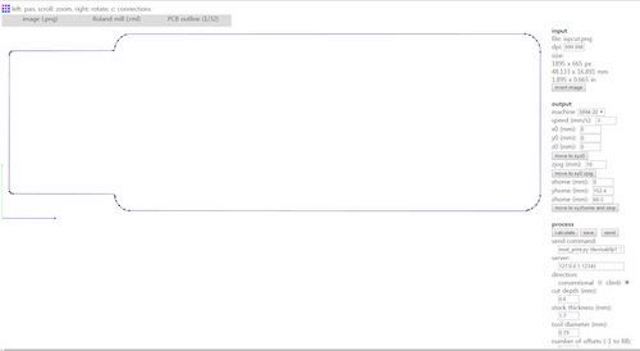

Outline File

reset Fab Modules

Input image(png) -> Outline file

Output -> Roland Mill (.rml)

Process- PCB outline (1/32)

Outline Speed- 0.5 ***

Put offset origin to 0,0,0.

zjog (mm):10

Offset: 1

Machine- SRM 20

RML Outline file

Note: When importing files, check that traces and outline files are the same size

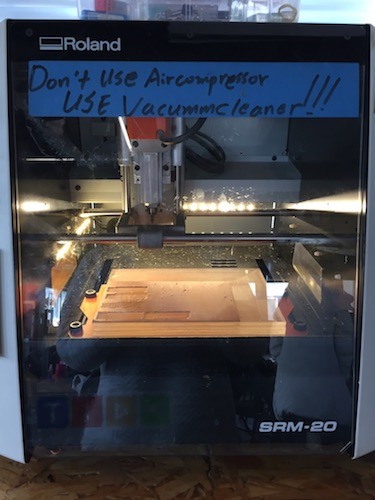

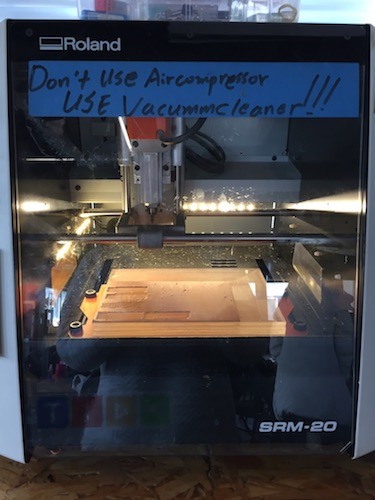

Milling Process

Roland SMR-20

1/64- Tracing Tool

.4 x .8 x 38L = .4 diameter x .8 cut depth x 38 length of tool

1/32- Outline Tool

.8 x 1.6 x 38L = .8 diameter x 1.6 cut depth x 38 length of tool

For Tracing, use the .4 tool.

Estimate your X/Y origin (bottom left). Lower the Z so that the tool tip is close to the surface. Use the wrench to loosen the tool to manually and gently lower so the tool tip just touches the copper. Set X/Y/Z origin. Use the machine to increase the Z to about 10-12 (Zjog).

Starting Position for Trace

Ready to Cut- Delete all previous files and find the tracing.rml file and when ready to mill -> Output.

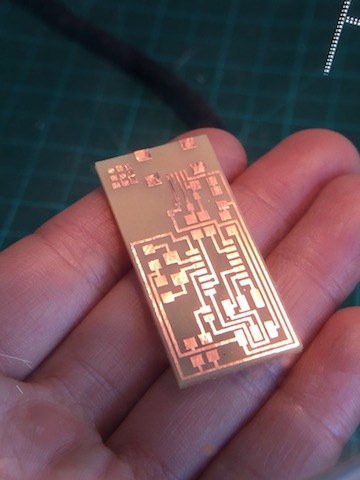

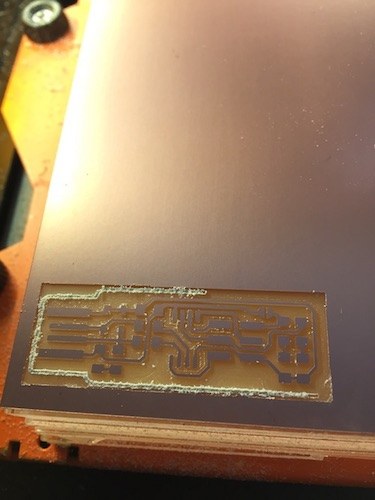

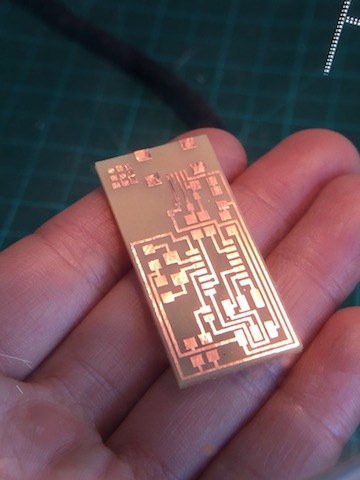

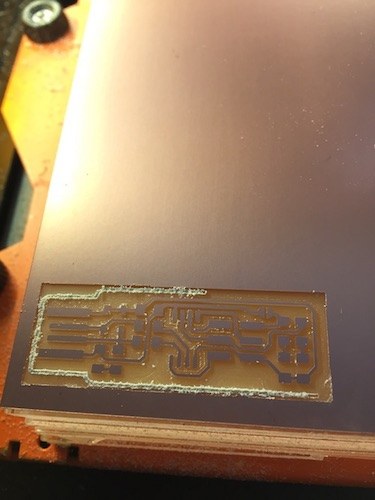

Finished Traces

Replace the milling tool to .8 head when running the outline cut.

Move the milling tool so the tip touches again the surface again and reset Z origin to 0. DO NOT CHANGE THE X/Y origin as it is relative to the tracing file.

Increase Z and GO TO X/Y origin.

Ready to cut- delete previous file and add outline.rml file -> Output

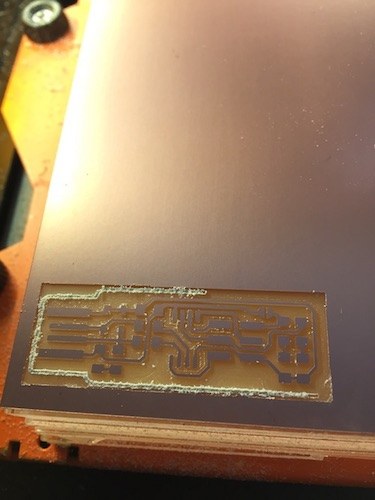

Milling Outlines

Finished Outline

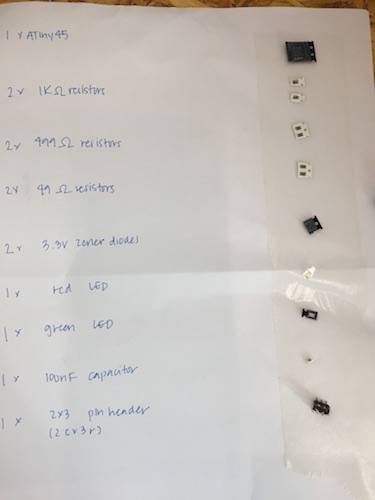

Soldering

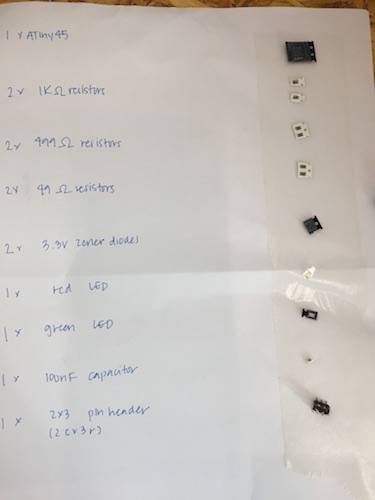

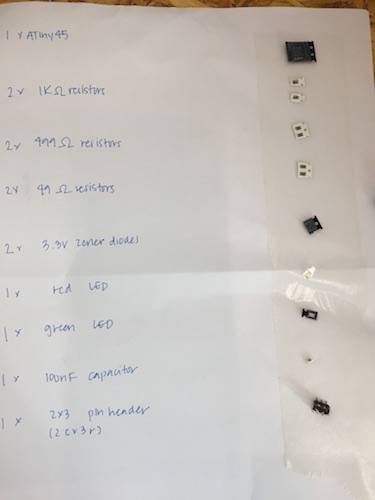

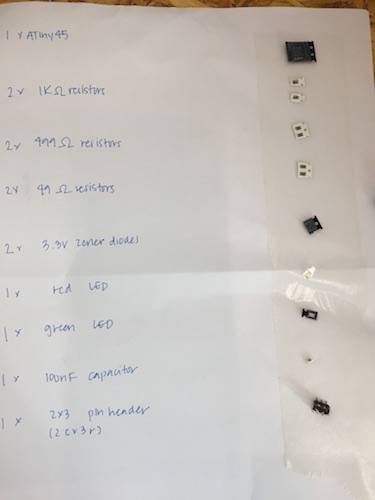

Components List

Diodes have positive and negative values so important to check the polarity.

LEDs too- color is on the positive side and negative (line) on the bottom

Resistors & Capicitors do not have polarity so orientation doesn't matter

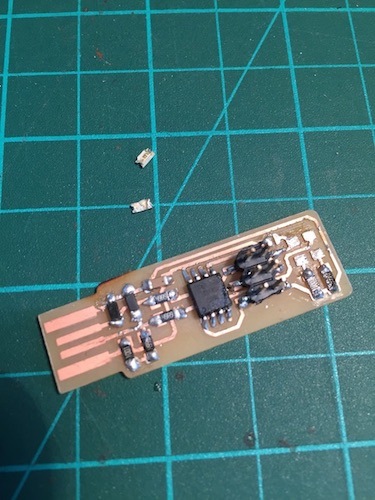

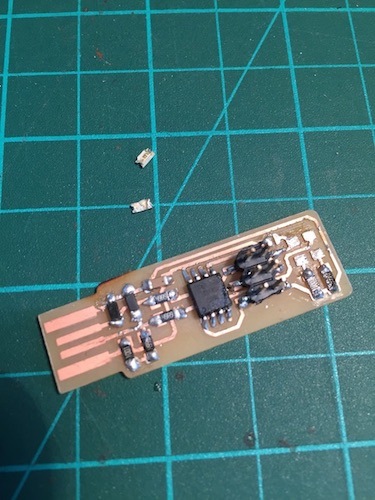

Resoldering LEDs

LEDs were attached incorrectly so they had to be desoldered and resoldered.

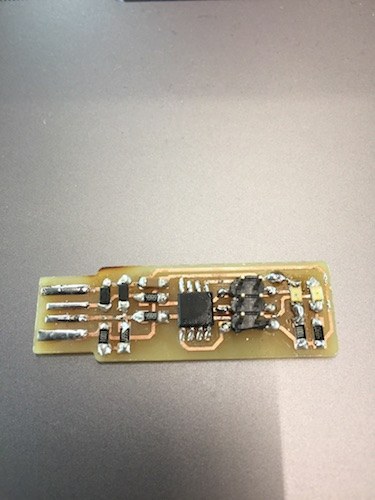

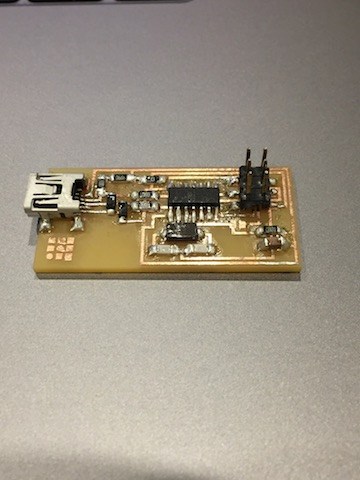

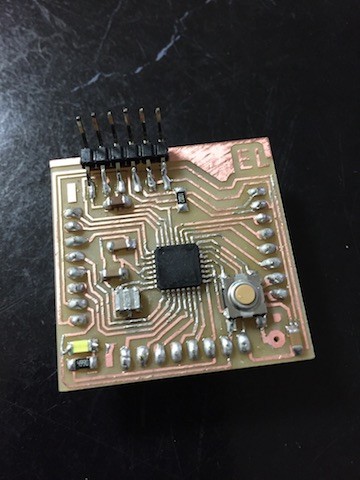

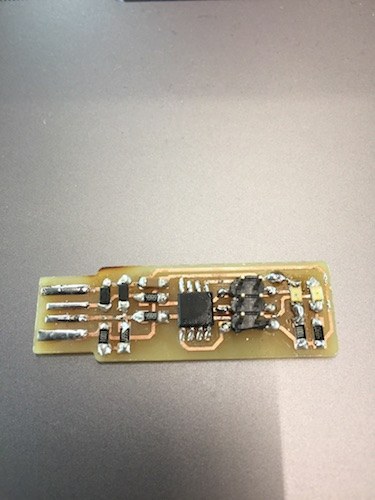

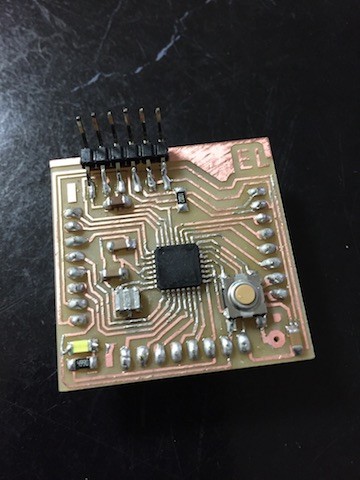

Soldered Board

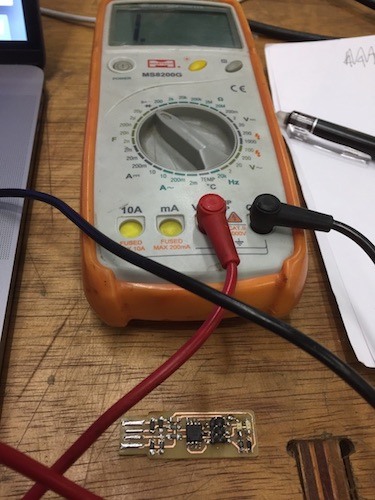

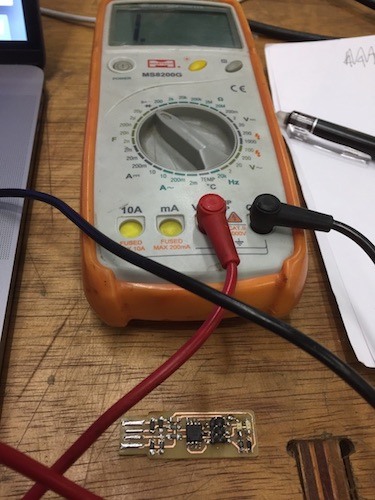

Check connections with Multimeter

Dial turned to arrow when checking Continuity

Checking resistors- Set dial to next higher scale

All connections seem to be fine and resistors working as they should

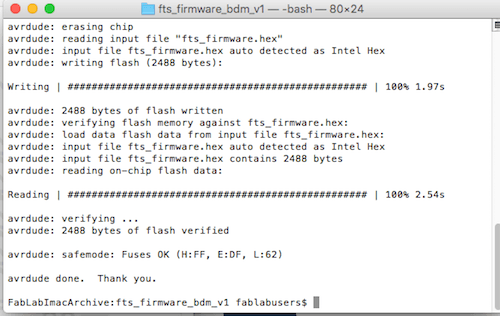

Programming

-

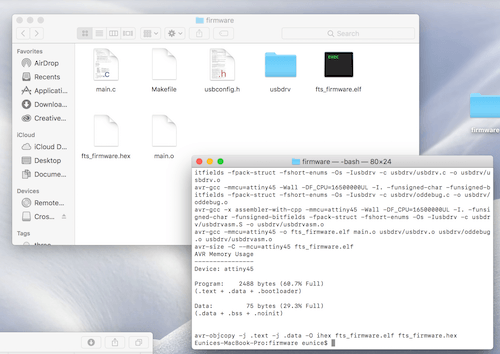

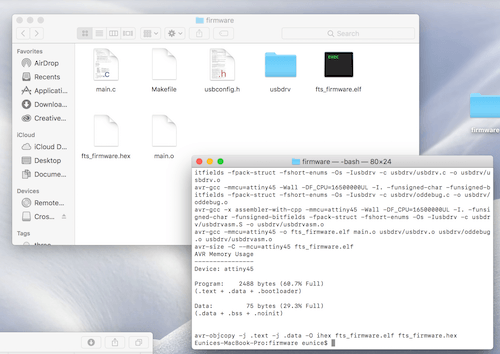

Run Make

-

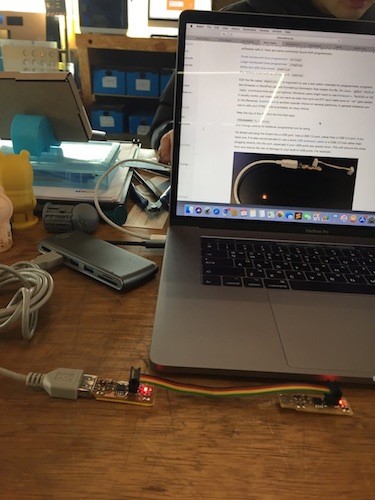

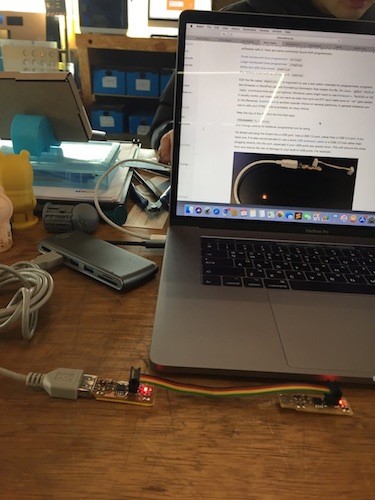

Connecting ISP to Programmer ISP

-

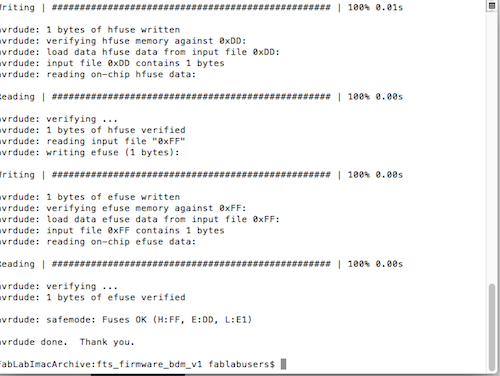

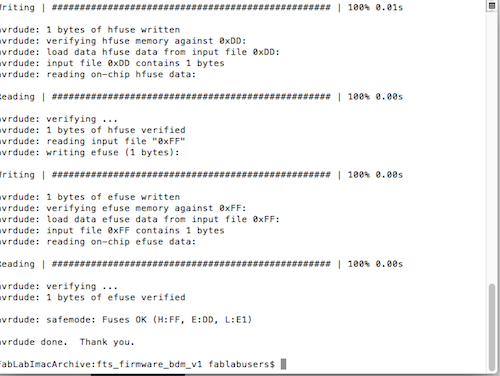

Run Make fuses

-

Check to see if ISP is recognized on device.

-

Run Make rstdisbl

-

Unsolder Jumpers

Making FabOptimus

I was having some trouble with my first board not being recognized by the USB Port on my computer.(See debugging below) I knew I needed a working programmer for future assignments, so I tried another ISP to get more practice and in the case that I wasn't able to program my first one, then I would have a backup. I used Ali's FabOptimus

from the Fab Academy website.

Everything worked on the first try with this board. Yay!

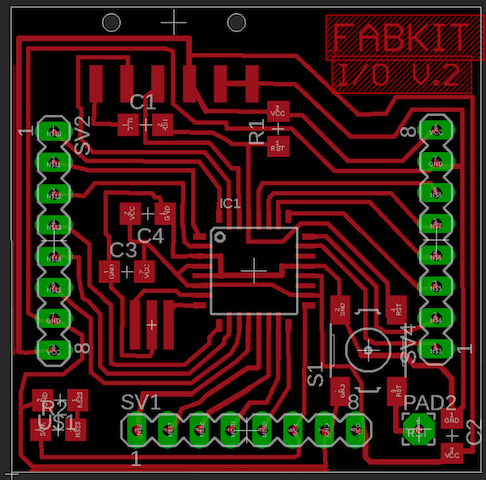

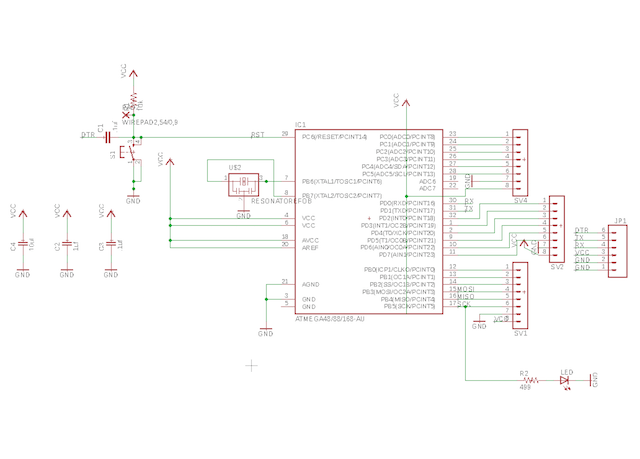

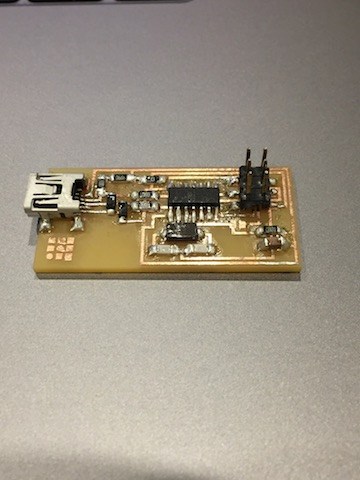

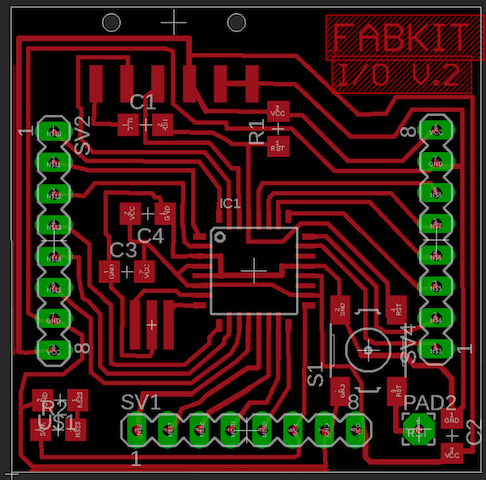

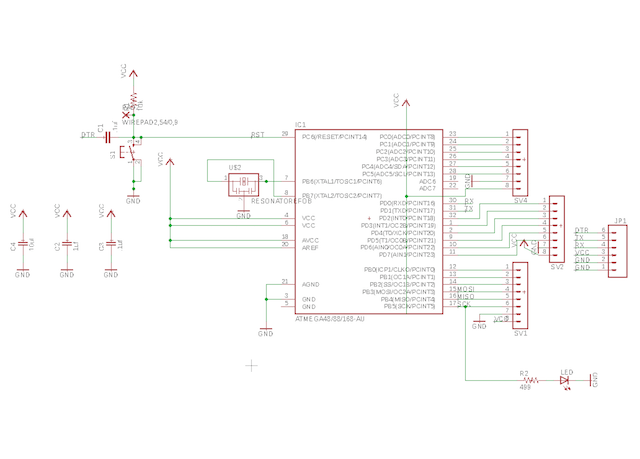

Building FabKit 2.0 Board

FabKit Board & Schematics

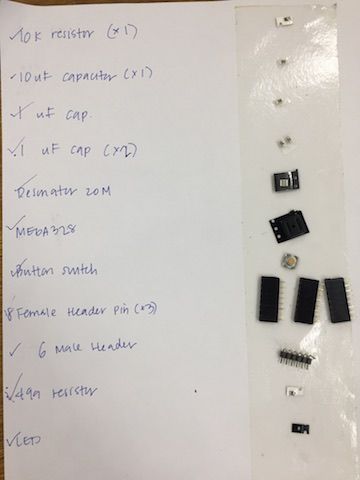

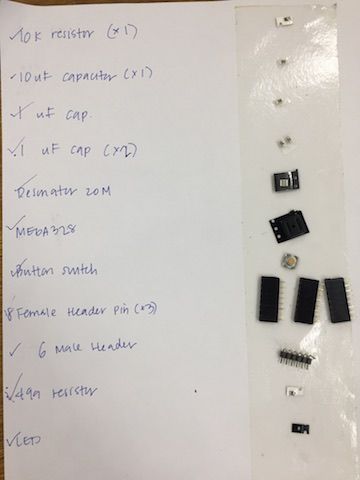

Components List

- 10k Resistor

- 10uF Capacitor

- 1uF Capacitor (x2)

- 20MHz Resonator

- ATMega328

- Button Switch

- 8 Header Pin (x3)

- 6 Pin

- 499 Resistor

- LED

Soldered FabKit Board

TroubleShooting

ATooTiny

<

Check the size of object you are milling in the top right corner of fabmodules pages.

Outline Fail

<

Forgot to switch out the milling tool head. Sorry Rodrigo. Luckily, tool head was not broken.

-

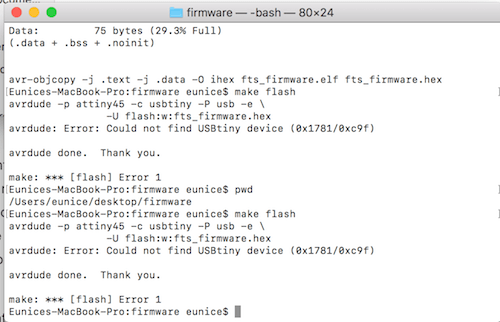

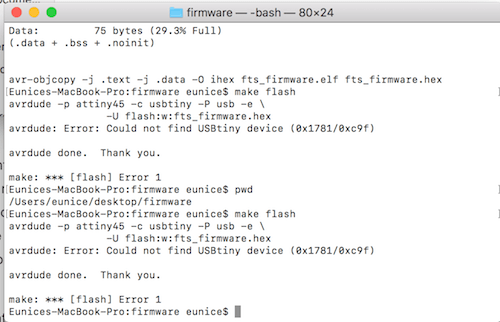

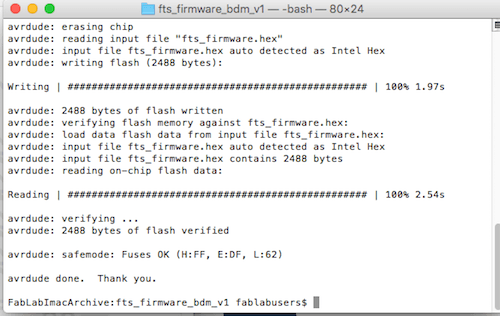

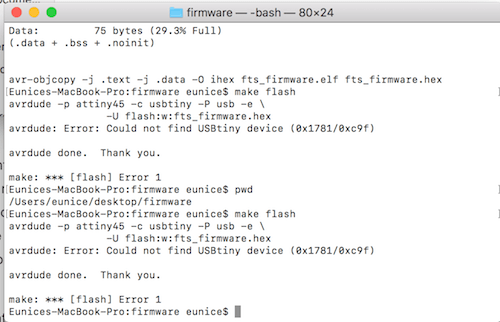

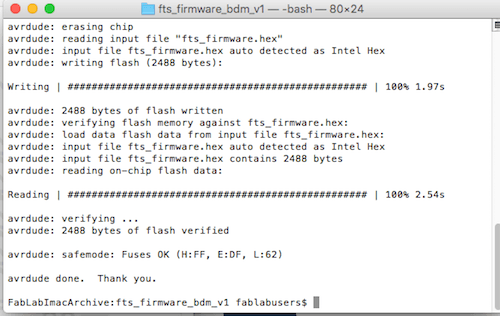

Make flash error message. Cannot read tinyISB

Running Make flash on another computer

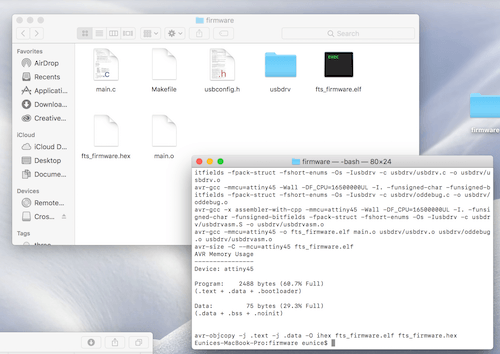

Tried on a different computer. Redownloaded firmware & crosspack. Tried make flash on another mac. It worked. Guessing that because new macs don't have build in USB ports, only firewire/ USB adapters.

-

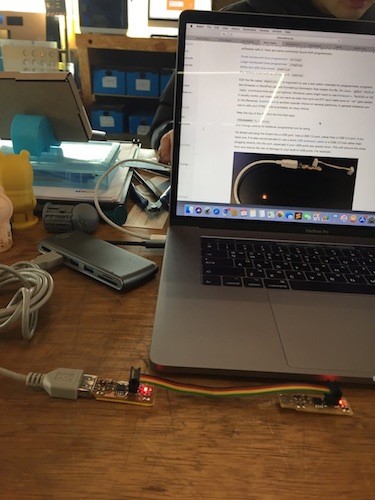

USB not recognized

When plugging my first FabTiny ISP into the USB port, the computer does not recognize the device.

This one took me a while to figure out. This ISP is connected to the computer by directly plugging into a an USB port(or hub) on the computer. The material however is quite thin so even though I put on extra solder on the ISP's USB pins, it still wasn't reading. I found that the solution to this was to put a thin piece of plastic on the back to give it the thickness to adequate contact with the computer's USB. I took some leftover PLA and put it onto the back of the board and it was able to be read by the computer.

Download Files

Equipment

- Hardware: Roland RM20

- Software: Fabmodules, VPanel, BashTerminal

- Material: Copper PCB board

Fab Modules

I used Brian's FabTinyISP design.

Download both trace & outline files.

Creating STL file using FabModules

Go to Fab Modules

Trace Files

Input: Select png and find ISP traces file

Output: Roland mill (.rml)

Process: PCB trace (1/64)

Offset from origin

XO: 0

Y0: 0

Z0: 0

zjog (mm): 10

number of offsets: use minimum 4 or (-1 to fill)

Outline File

reset Fab Modules

Input image(png) -> Outline file

Output -> Roland Mill (.rml)

Process- PCB outline (1/32)

Outline Speed- 0.5 ***

Put offset origin to 0,0,0.

zjog (mm):10

Offset: 1

Machine- SRM 20

RML Outline file

Note: When importing files, check that traces and outline files are the same size

Milling Process

Roland SMR-20

1/64- Tracing Tool

.4 x .8 x 38L = .4 diameter x .8 cut depth x 38 length of tool

1/32- Outline Tool

.8 x 1.6 x 38L = .8 diameter x 1.6 cut depth x 38 length of tool

For Tracing, use the .4 tool.

Estimate your X/Y origin (bottom left). Lower the Z so that the tool tip is close to the surface. Use the wrench to loosen the tool to manually and gently lower so the tool tip just touches the copper. Set X/Y/Z origin. Use the machine to increase the Z to about 10-12 (Zjog).

Starting Position for Trace

Ready to Cut- Delete all previous files and find the tracing.rml file and when ready to mill -> Output.

Finished Traces

Replace the milling tool to .8 head when running the outline cut.

Move the milling tool so the tip touches again the surface again and reset Z origin to 0. DO NOT CHANGE THE X/Y origin as it is relative to the tracing file.

Increase Z and GO TO X/Y origin.

Ready to cut- delete previous file and add outline.rml file -> Output

Milling Outlines

Finished Outline

Soldering

Components List

Diodes have positive and negative values so important to check the polarity.

LEDs too- color is on the positive side and negative (line) on the bottom

Resistors & Capicitors do not have polarity so orientation doesn't matter

Resoldering LEDs

LEDs were attached incorrectly so they had to be desoldered and resoldered.

Soldered Board

Check connections with Multimeter

Dial turned to arrow when checking Continuity

Checking resistors- Set dial to next higher scale

All connections seem to be fine and resistors working as they should

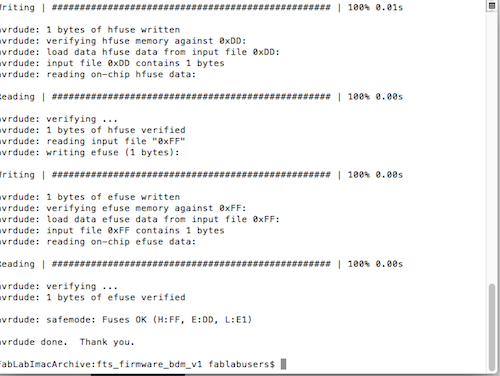

Programming

-

Run Make

-

Connecting ISP to Programmer ISP

-

Run Make fuses

-

Check to see if ISP is recognized on device.

-

Run Make rstdisbl

-

Unsolder Jumpers

Making FabOptimus

I was having some trouble with my first board not being recognized by the USB Port on my computer.(See debugging below) I knew I needed a working programmer for future assignments, so I tried another ISP to get more practice and in the case that I wasn't able to program my first one, then I would have a backup. I used Ali's FabOptimus

from the Fab Academy website.

Everything worked on the first try with this board. Yay!

Building FabKit 2.0 Board

FabKit Board & Schematics

Components List

- 10k Resistor

- 10uF Capacitor

- 1uF Capacitor (x2)

- 20MHz Resonator

- ATMega328

- Button Switch

- 8 Header Pin (x3)

- 6 Pin

- 499 Resistor

- LED

Soldered FabKit Board

TroubleShooting

ATooTiny

<

Check the size of object you are milling in the top right corner of fabmodules pages.

Outline Fail

<

Forgot to switch out the milling tool head. Sorry Rodrigo. Luckily, tool head was not broken.

-

Make flash error message. Cannot read tinyISB

Running Make flash on another computer

Tried on a different computer. Redownloaded firmware & crosspack. Tried make flash on another mac. It worked. Guessing that because new macs don't have build in USB ports, only firewire/ USB adapters.

-

USB not recognized

When plugging my first FabTiny ISP into the USB port, the computer does not recognize the device.

This one took me a while to figure out. This ISP is connected to the computer by directly plugging into a an USB port(or hub) on the computer. The material however is quite thin so even though I put on extra solder on the ISP's USB pins, it still wasn't reading. I found that the solution to this was to put a thin piece of plastic on the back to give it the thickness to adequate contact with the computer's USB. I took some leftover PLA and put it onto the back of the board and it was able to be read by the computer.

Download Files

Run Make

Connecting ISP to Programmer ISP

Run Make fuses

Check to see if ISP is recognized on device.

Run Make rstdisbl

Unsolder Jumpers

ATooTiny

<

Check the size of object you are milling in the top right corner of fabmodules pages.

Outline Fail

<

Forgot to switch out the milling tool head. Sorry Rodrigo. Luckily, tool head was not broken.

Make flash error message. Cannot read tinyISB

Running Make flash on another computer

Tried on a different computer. Redownloaded firmware & crosspack. Tried make flash on another mac. It worked. Guessing that because new macs don't have build in USB ports, only firewire/ USB adapters.

USB not recognized

When plugging my first FabTiny ISP into the USB port, the computer does not recognize the device.This one took me a while to figure out. This ISP is connected to the computer by directly plugging into a an USB port(or hub) on the computer. The material however is quite thin so even though I put on extra solder on the ISP's USB pins, it still wasn't reading. I found that the solution to this was to put a thin piece of plastic on the back to give it the thickness to adequate contact with the computer's USB. I took some leftover PLA and put it onto the back of the board and it was able to be read by the computer.