| Seonghee Kim | |

| 17. Composites | |

| HOME | ABOUT | ASSIGNMENTS | FINAL PROJECT| CONTACT | |

Week17

Assignments

-group assignment

produce test coupons for your composite fabrication process(es)-individual assignment

read the safety data sheet (SDS) and technical data sheet (TDS) for the resins that you're using design and fabricate a 3D mold and produce a fiber composite part in it, with resin infusion and compactionHardware and Softwares used

-Fusion 360

-Mesh Lab

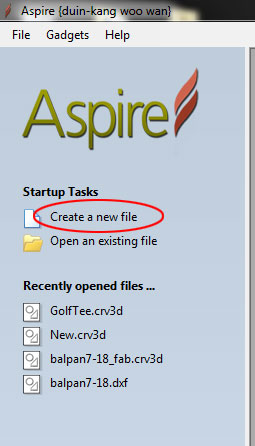

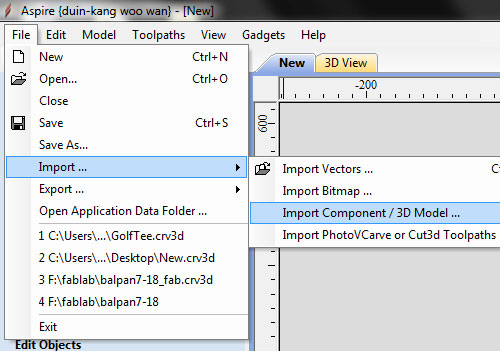

-Aspire

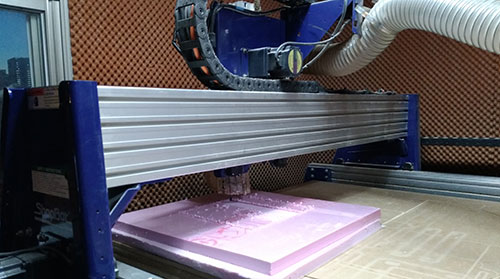

-Shopbot

Outcome

Do 3D cnc cutting, made a fabric composites.

Composites

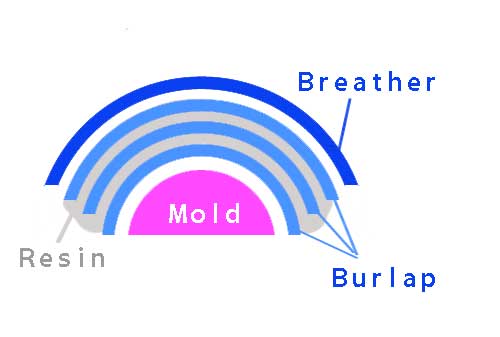

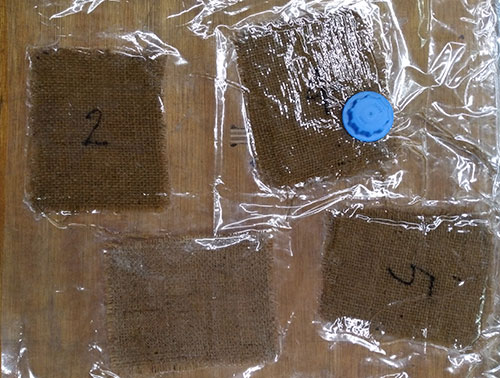

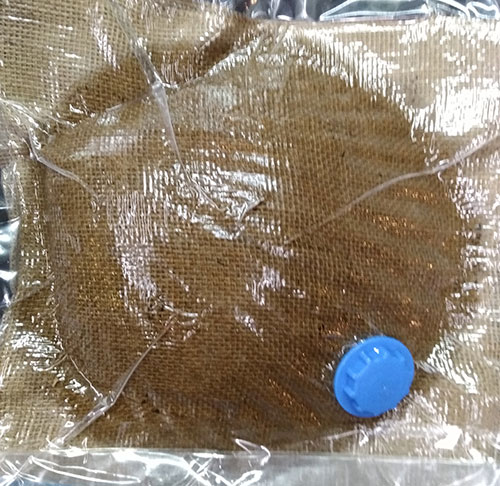

Test burlap composites

As a group assignment, we tested burlap composites. We tested 1 to 5 multi layers of burlap.

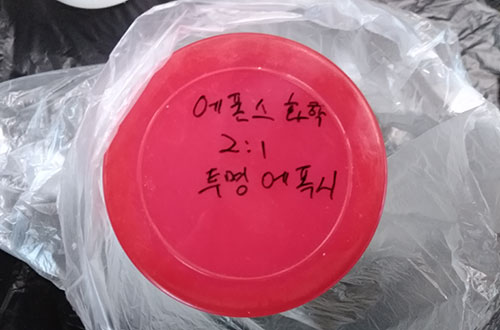

We used a local epoxy. Click here to get a datasheet.

-The mix ratio is Adehsive2: Hardener 1.

-The product is a transparent type and multi-use epoxy adhesive.

-Room temperature curing type.

-Automatic mixer (2 minutes) If you use chopsticks (3 minutes ~ 4 minutes)

-It is about 6 ~ 8 hours for first tack curing time (do not touch by hand) and 24 hours for full curing.

-In case of thermal curing, curing at a temperature of 50 to 60 ° C for about 1 hour.

-wear 3 layers of latex gloves.

-keep the trash bin close.

-wear the gloves and mask.

Fusion 360, Mesh Lab

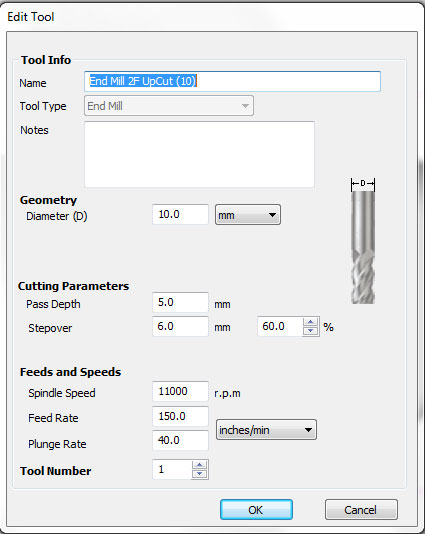

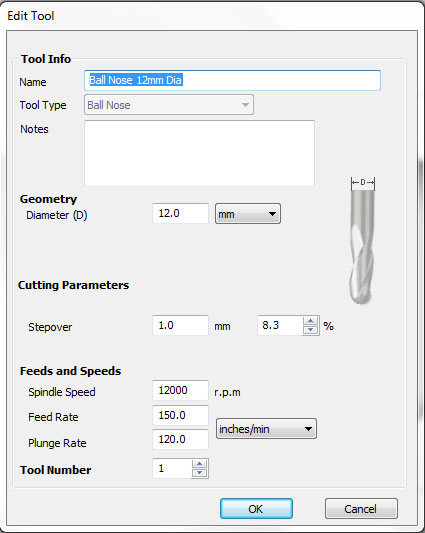

Aspire

- endmill setting for rough cut.

-endmill setting for finish cut.

Shopbot

-I sand the seashell with sand paper. it looks nice.

-Becuase I choose convetional, chips does not look flying away.

Epoxy

I had to put the blue lid aside of seashell.

-Click here to download files( stl, sbp)

Date: 2018-05-22 Author: Seong Hee Kim @ Fablab Seoul