| Seonghee Kim | |

| 20. Final Project Development | |

| HOME | ABOUT | ASSIGNMENTS | FINAL PROJECT| CONTACT | |

Week20

What is the deadline? How much time do I have left?

Final Presentation: June 18th.Deadline: June 22th.

What tasks have been completed?

-Prototyping of the gear mechanism

-cnc milling of tree, box

-laser cutting of gears

-3D design and printing of gear rods

-molding and casting of flowers

-soldering for neopixels

-Capacitance sensor and neopixel test with arduino

-PCB board design, fabricating, coding, programming

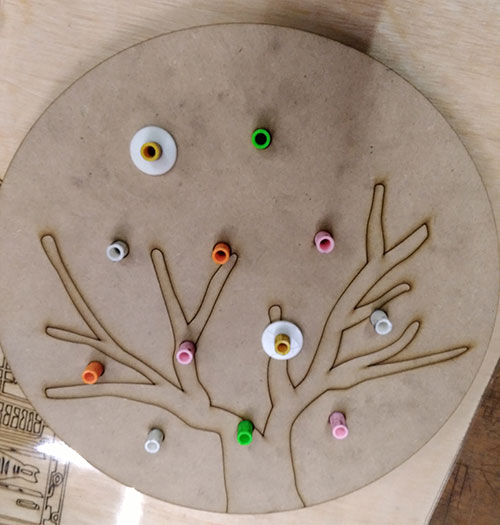

Prototyping

First, I tested prototyping with mdf before cutting expensive wood to see if the mechanism works well. The rotation is a bit stiff, but using acrylic will reduce friction and make it a little easier than mdf.

CNC for tree

When cutting a tree with cnc, the design of the leaves was so complicated that pocketing was not easy. Whenever I calculate the Gcode with Vcarve, the gaps between leaves is smaller than the end mill size and Vcarve continued not to be calculated. In the end, I chosed a oncut, and I'm glad that it came out nice and pretty.

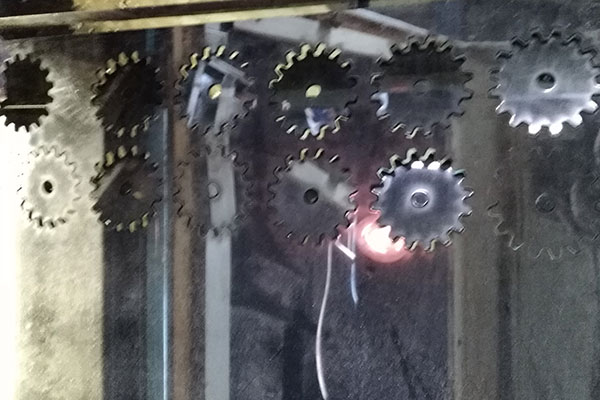

laser cutting of gears

3D design and printing of gear rods

To make the gear I usesd a laser cutter. Small gears are 3t and large gears are 5t acrylic because they have less friction than wood. I wanted to reinforce a little stiffer rotation in prototyping. So we made a large gear on the vertical axis and connected it. So it has been reinforced and can be rotated with less force.

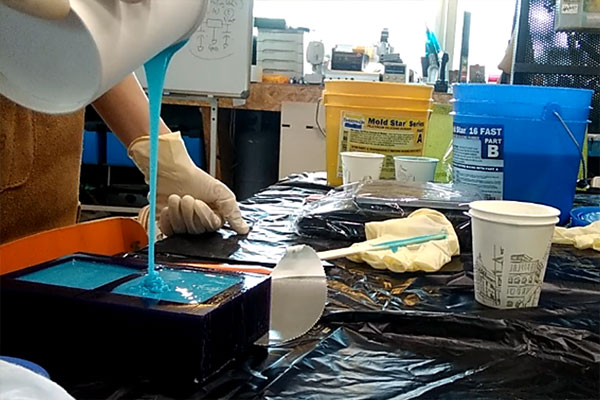

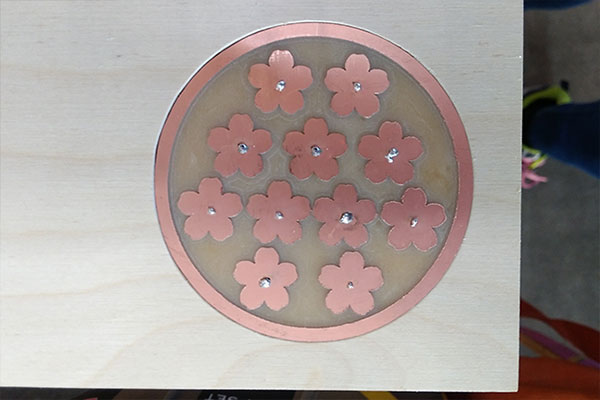

molding and casting of flowers

Because cherry blossoms require 11 pieces in the same design, it was good to use molding and casting. But since long cure time, it took a long time to finish. I like the result very much so after fab academy I will make the fridge magnets with the same moldings.

Because cherry blossoms require 11 pieces in the same design, it was good to use molding and casting. But since long cure time, it took a long time to finish. I like the result very much so after fab academy I will make the fridge magnets with the same moldings.

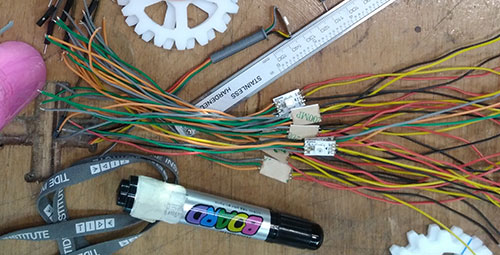

soldering for neopixels

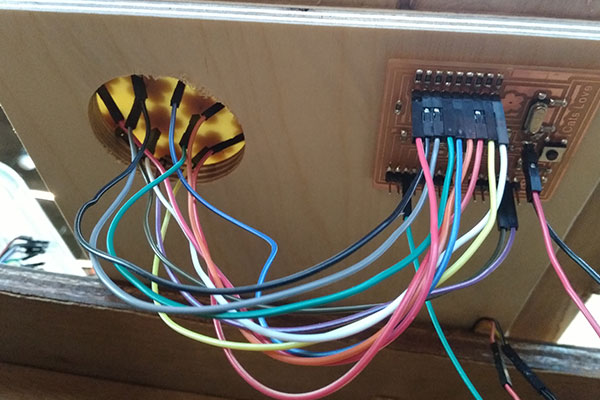

I need eleven Neo-pixels. The neo-pixels of the string type are slippery to solder. It was hard because the lead did not settle sufficiently. so I had couple of fails. After a few tries, I got used to it, but it was helpful to have plenty of flux. Since I had to connect each wire on the back of the tree later, I distinguished the in and out and soldered each of the with same colors of wires.

PCB board design, fabricating, coding, programming

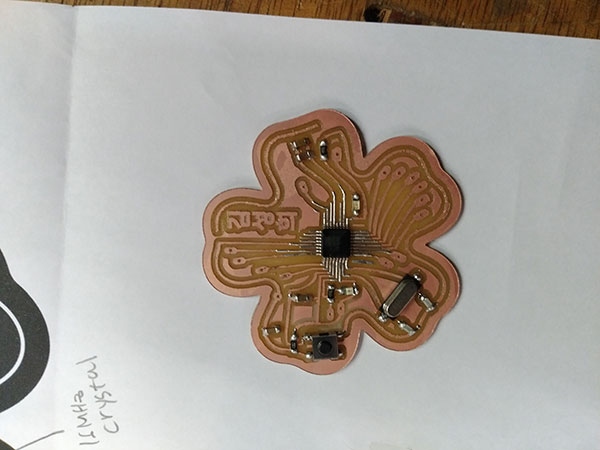

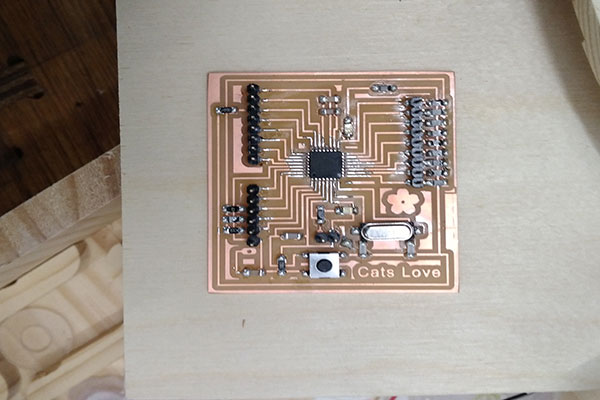

I first made a beautiful pcb in flower shape. However, I could not test the coding because I did not create a serial port. I used Arduino to complete the code and upload it to my pcb, but it did not work. I had to re-create it because I can not test with serial monitor. I had to re-create it. Because I did not have enough time I chose a simple and safe design. I made it refered on satshakit. The touch sensor was simplify tree design and each flower was connected to the same position. Assembly

The back side was covered with transparent acrylic so that the mechanism could be seen clearly. I think watching the mechanics is a fun part of automata. But I wanted to show a well-organized look, so I was carefully choose colors and alignment and I will connect the wires through the acrylic, which will prevent the wires from tangling when the gears are turned.Motor

I finally connected the motor. It was hard for me to operate the motor, which is to adjust the length of the chain. Even if it is too long, it does not turn. And I had to adjust the gear teeth too. I am so glad that it is well done.

what tasks remain?

-Everything is done.

How will I compleat the remaining tasks in time?

-5,6th: tree design and milling

-7,8th:design of flower(molding and casting)

-9,10th:box design(cnc)

-11,12th:gear rod(3d printing)

-13,14th:pcb milling and coding

-15,17th: assembly

-18,19th: motor

-20, 22th: debugging

What has worked?

-When I tried to operate the gear prototyping manually, it worked well but a bit stiff .-It was possible to control neo-pixels with capacitive touch sensors.

What hasn't?

-The torque of the gear is not enough so I have to replace the more powerful motor.

-When I pretend to power the gear torque, the shaft broken. I need to make strong shaft to stands gear torque.

What questions still need to be resolved?

-I want to add more flowers like the original work, 55 flowers and controlling more neo-pixels will remain as a challenging task for after fab academy. I will look for a right motor and use a bearing on the shaft to rotate the each flower and finish it, I need investigating the suitable motor and bearings to make the rotation.What have you learned?

I learned a lot about the electronic part. During Fab academy course, creating a pcb and the coding was totally a new experience. Now I can make pcbs and find, interpret and change the code to what I want to by myself. For the final work, it was a pleasure learning to control capacitive sensor/neo-pixels in various colors. Complex patterns of cnc cutting and operating the gear system is nice to learn. And to learn molding and casting was fun too!!up previous next

Date: 2018-06-07 Author: Seong Hee Kim @ Fablab Seoul