FABRICATING

FABRICATING

June second week 6/3~9

-according to my plan I laser cut and machine with lathe all the parts. and I did some metal works to make strong structure. I need to do these works first because all the parts are connected with delicated sizes and value. Also I did some of metal works at my school, I should make structures and connect with the board and motor.

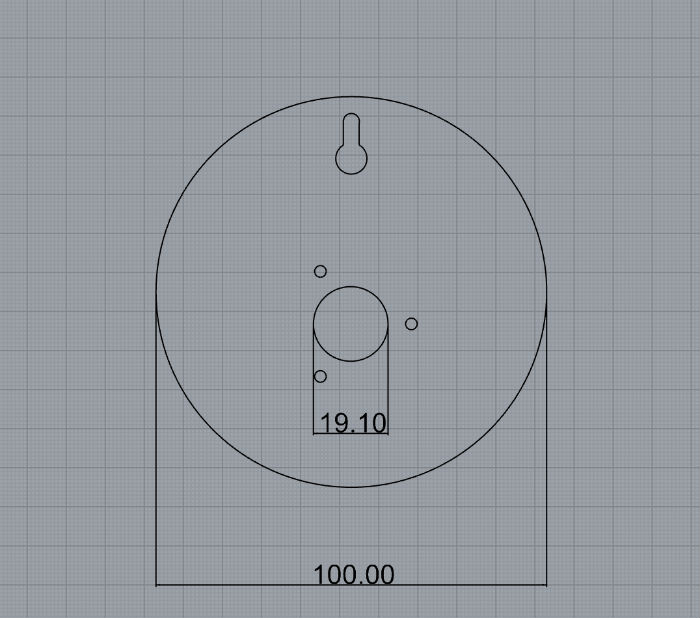

BEARING HOLDER

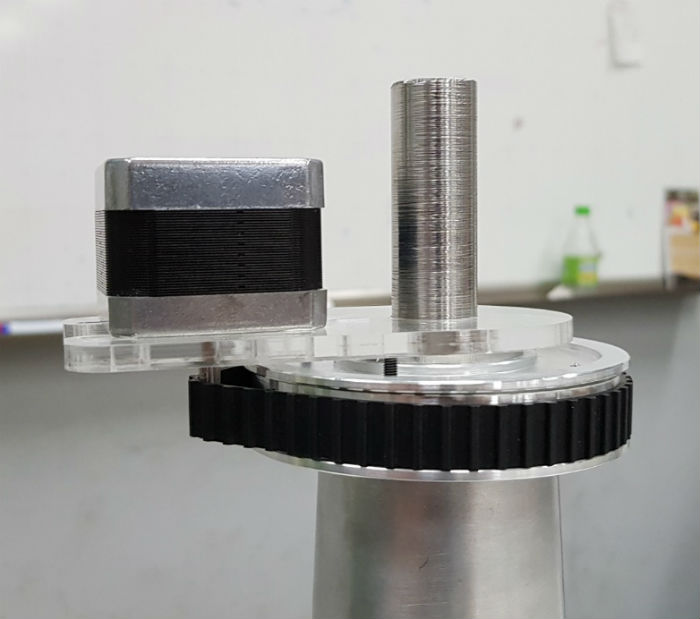

To rotate trumpet with motor, I need to use bearing that can hold shank inside and trumpet connected to timing belt outside. I bought 0.75" 1.62" bearing.

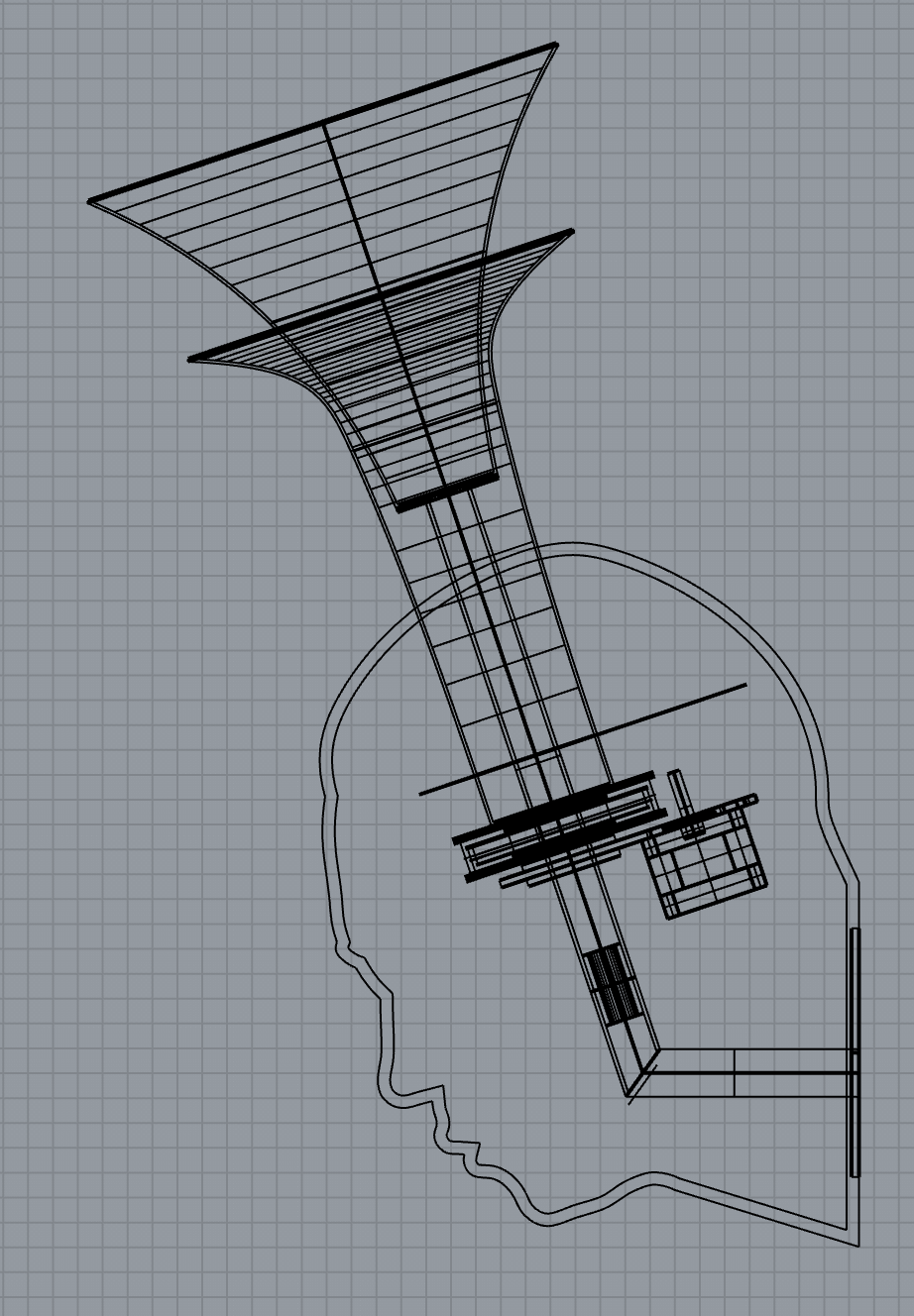

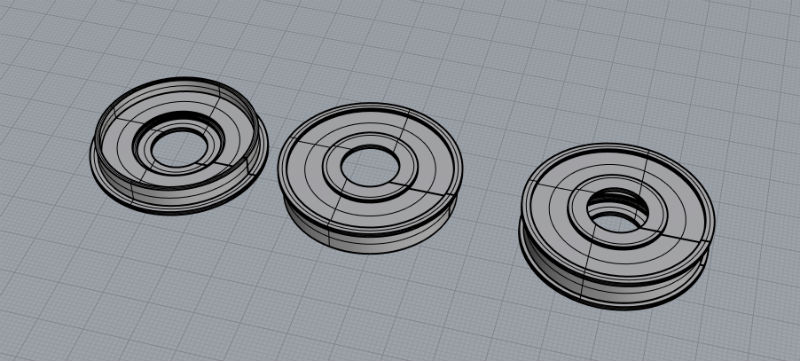

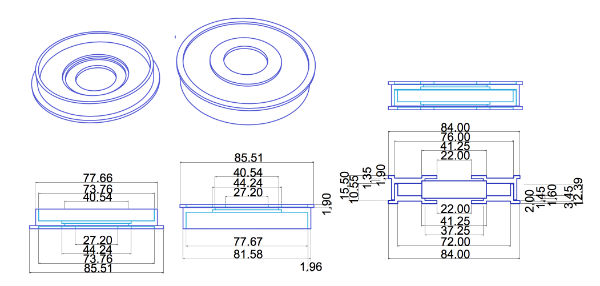

and measured every size to make a holder. I drew the part with Rhino.

Left two parts are bottom and top parts that can be join together like right of the image. That can hold bearing's only outer part with slight ring width 2mm and connected to outer trumpet with bolts. also it has guides for timing belt outside. So bearing's inner hole can be fixed to shank and other parts can be rotate.

After modelling done i need to check it works well. So i printed the parts with 3D printing.

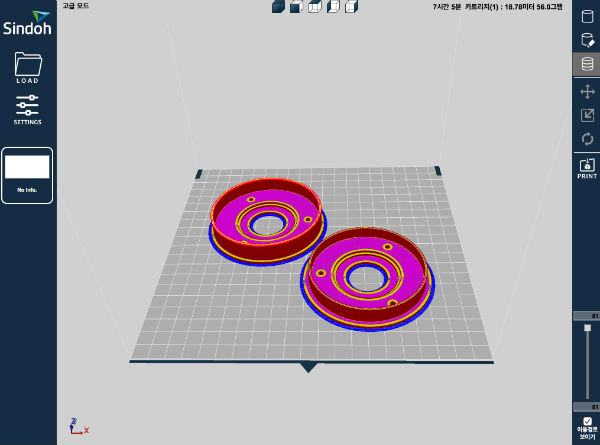

I put two parts together and printed.

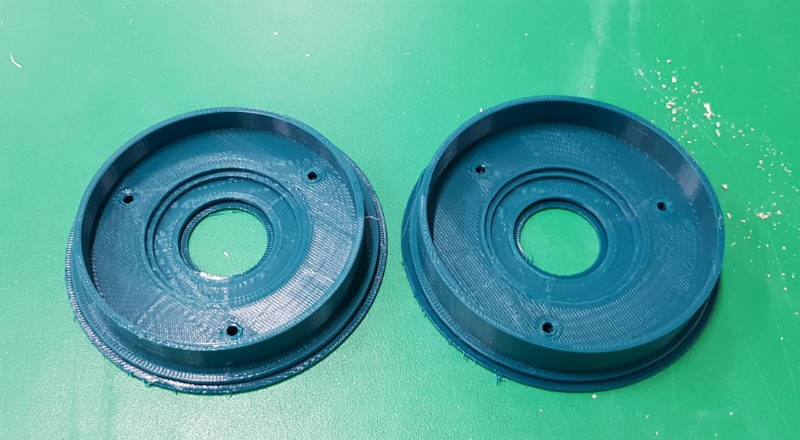

Those were fine. two parts fit well and hold bearing well.

But, I think printed PLA doesn't have enough hardness to bear timing belt and hole trumpet well. So i decided to machining aluminum with lathe.

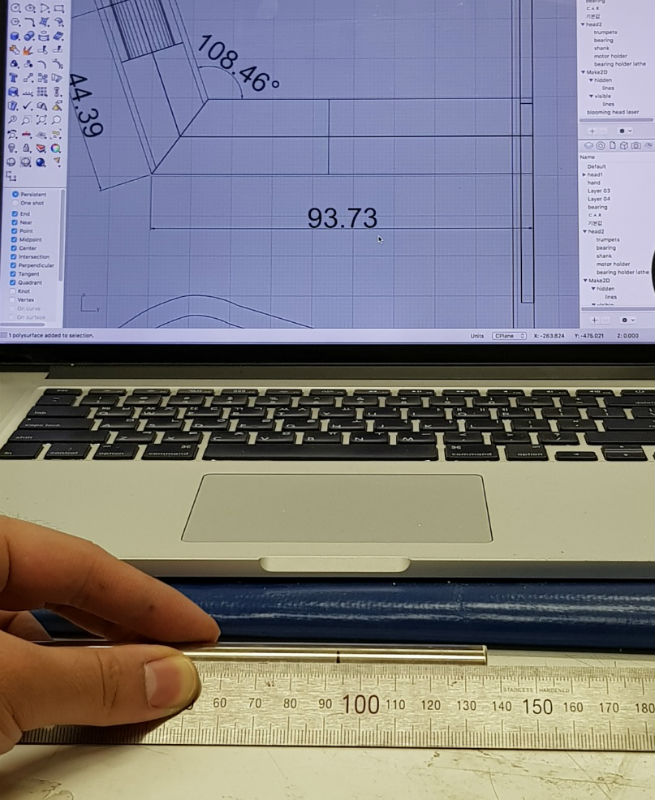

I make 4view 2D drawing and put every velues. And cut aluminum rod with lathe.

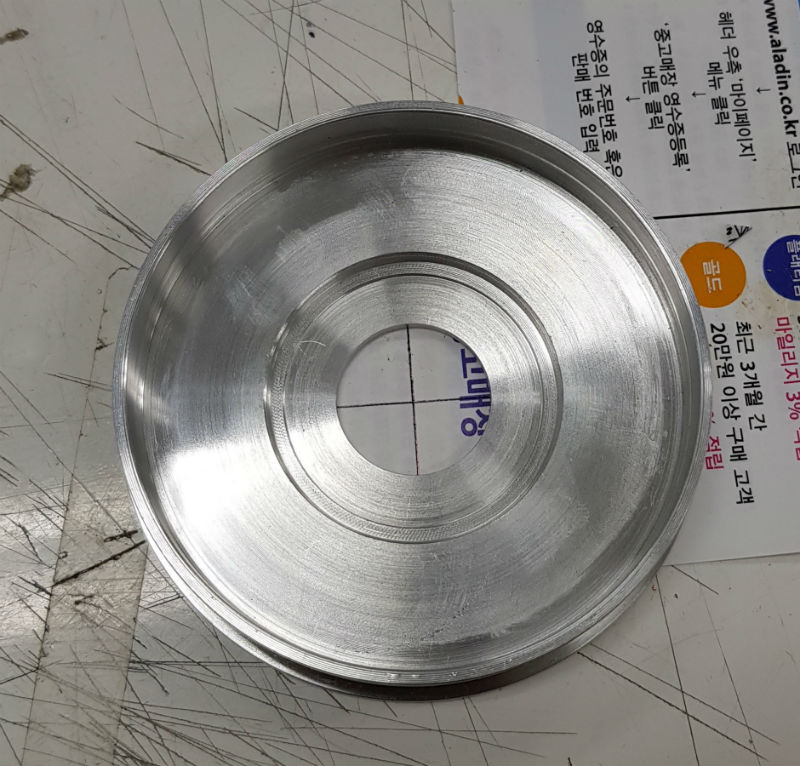

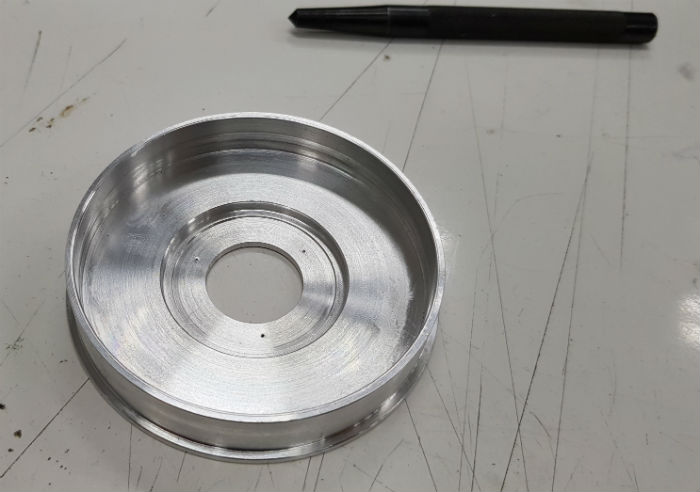

These are the parts. it hold bearing well and more delicated than 3D printing.

to hold bearing inside the two parts they need to be holded with bolt.

so I drilled with 2.4mm drill bit.

and used M3 tap drill to make threads. and also i drilled and make a tap for bolts holding trumpet like this.

and I bought 0.75" stainless steel pipe which is same size with bearing hole.

But it was little bit thicker than bearing hole. So I machined the shank with lathe.

Then it fits well to bearing.

TRUMPETS

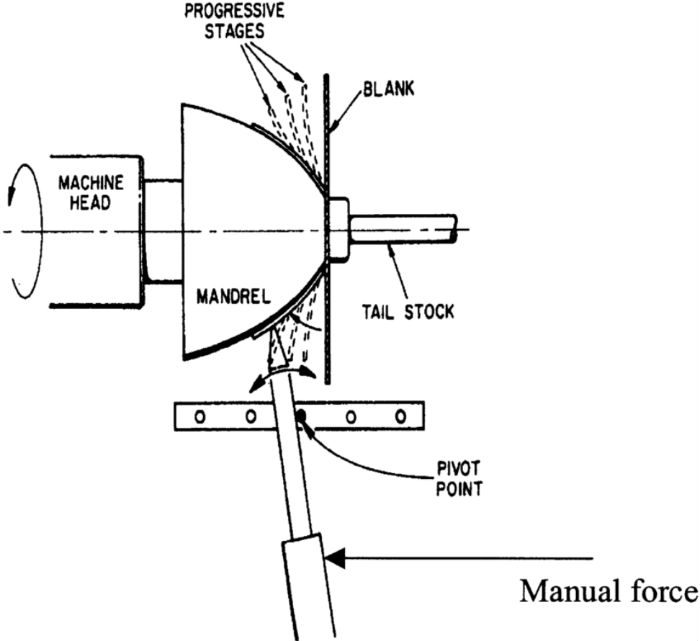

To make trumpets there are several ways to make trumpet shape. I chose metal for material so i decided to spinning to make trumpet shape.

There are lot of metal spinning factories at Euljiro, Seoul.

I went several factories and found suitable templetes. Spinning metal is very efficient technic to form hollow shape.

Fix metal plate with templete and turn fast. With metal rod with wheel at the tip for aluminum, and raise metal plate with manual force.

These are my aluminum trumpet 1.2T.

and like bearing holder, I make holes to join each other.

MOTOR AND WALL HOLDER

I used laser cut to make motor holder. I bought timing belt before making holder.

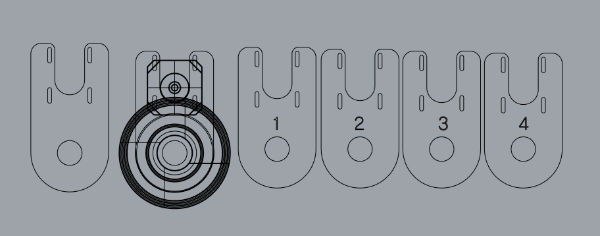

So I need to measure the distance from bearing holder to motor. I drew several holder that have different distance interval 0.5mm.

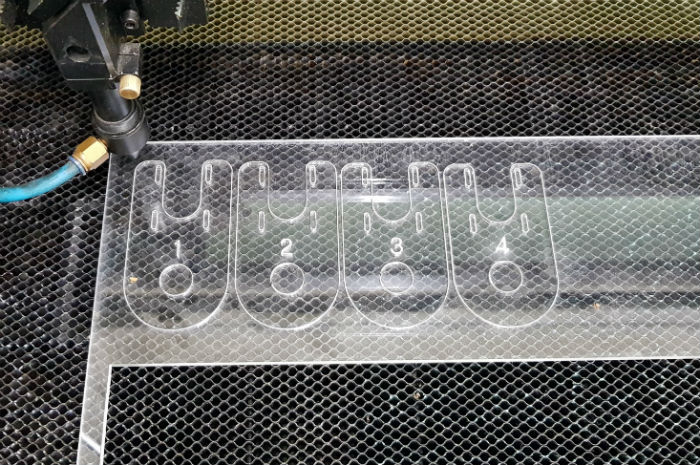

And, laser cutting.

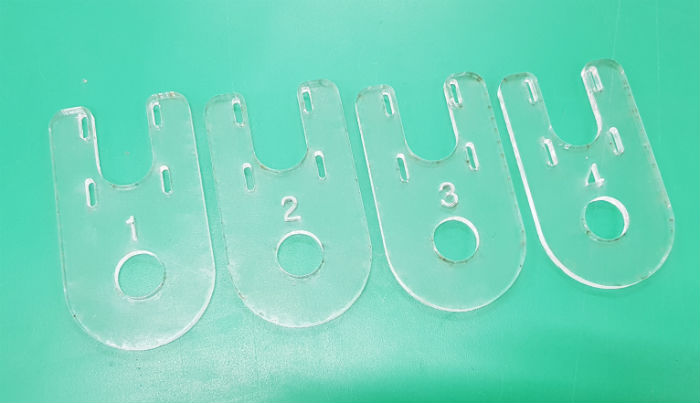

Number 1 was fit for my project.

Like bearing holder, acrylic 5T wasn't strong to hole motor because there is a lot of tension at timing belt. I decided to laser cut stainless steel 3T with same size.

also I laser cut wall holder and another parts to hold inner trumpet.

I drew laser cut path with Rhino like this.

It has hole size 0.75" which is same size with bearing hole and stainless pipe.

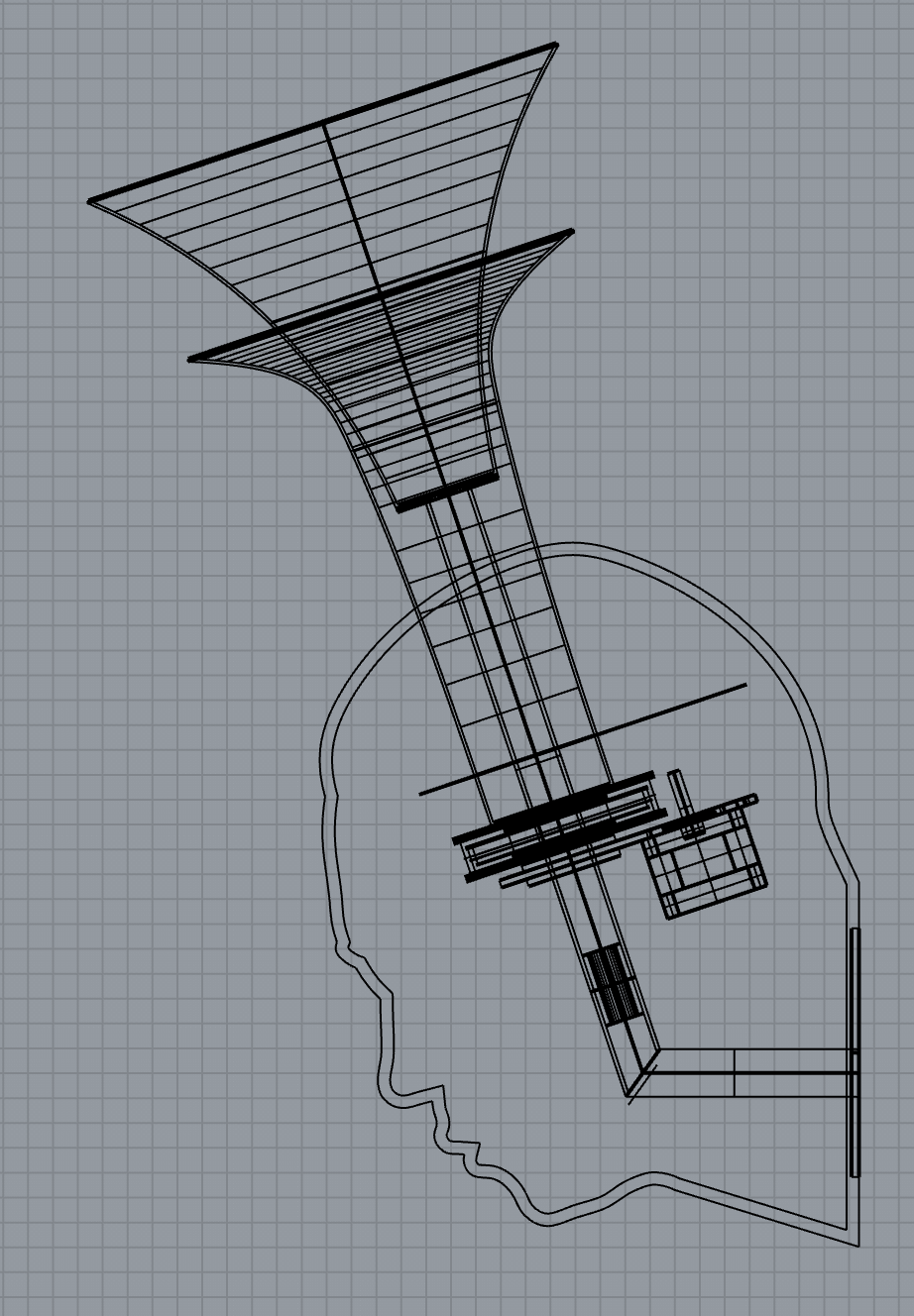

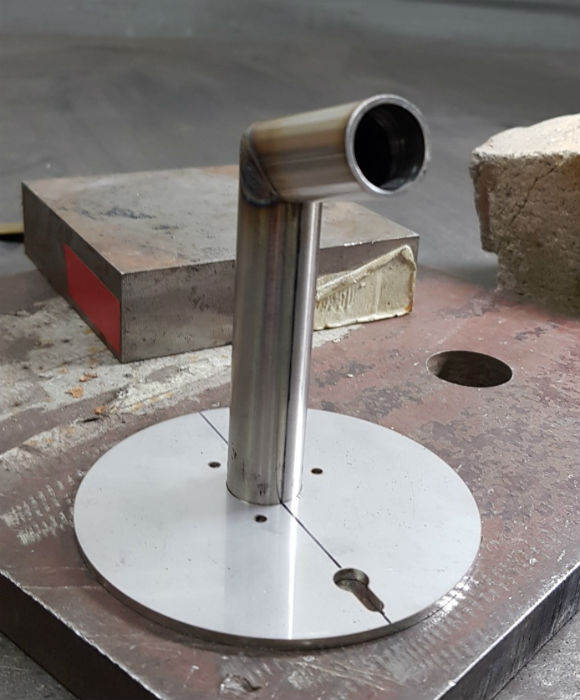

To make wall holder, I should make structure like this model I drew.

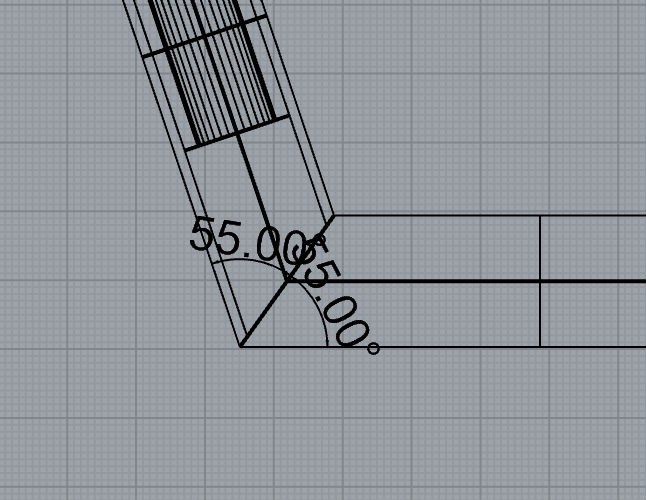

Angle of pipes are 55degree.

so i made a guide to modify high speed cutting machine.

Then I cut those pipes accurate lengths.

Then I welded those parts together.

I marked center guides to two pipes and welded.

And welded pipes to laser cut plate with right angle same as my modelling.

MOTOR AND WALL HOLDER

WHERE I WORK

I'd love your feedback!

Phone: +082 1041950935

Email: jshjshjsh93@gmail.com

Feel free to contact! , or leave me a note: