MOLDING AND CASTING

June third week 6/10~16

-according to my plan I casted my head and make a silicone mold for casing. This was my last works because I need to put all the parts in my head as a case. And also I should connect wall holder with this case.

MOLDING AND CASTING

LIFE CASTING

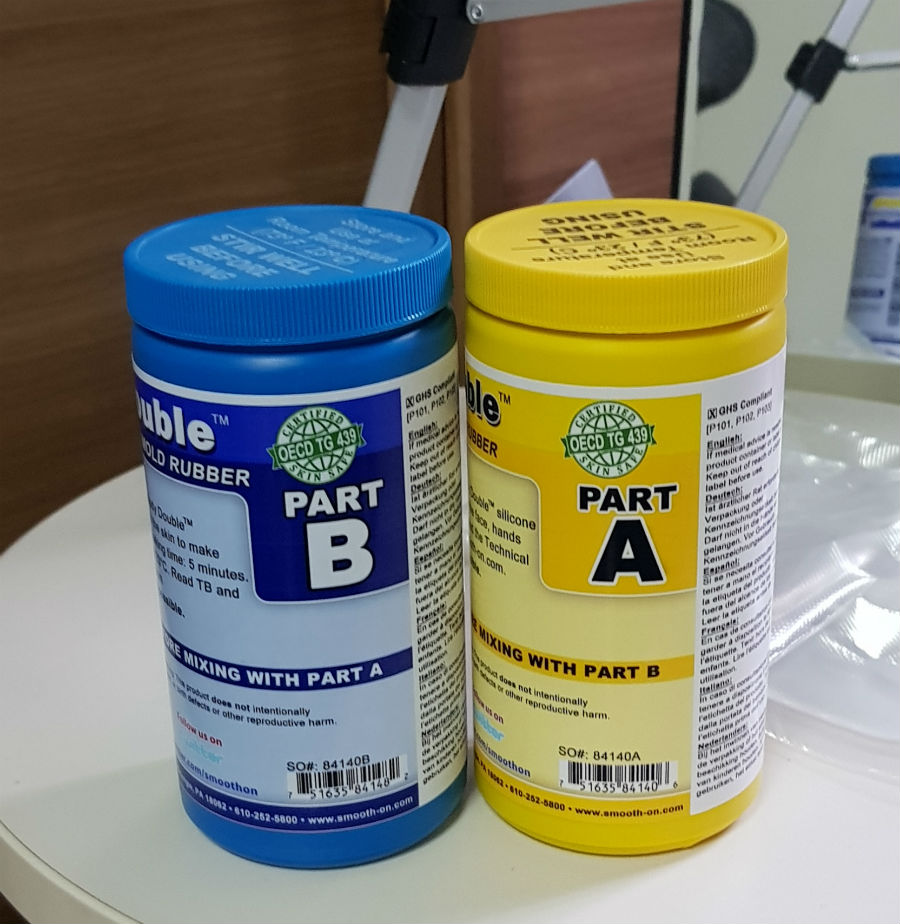

For Life casting my head, I used Body-double standard from Smooth-on. First I remove all hair except precious eyebrow.

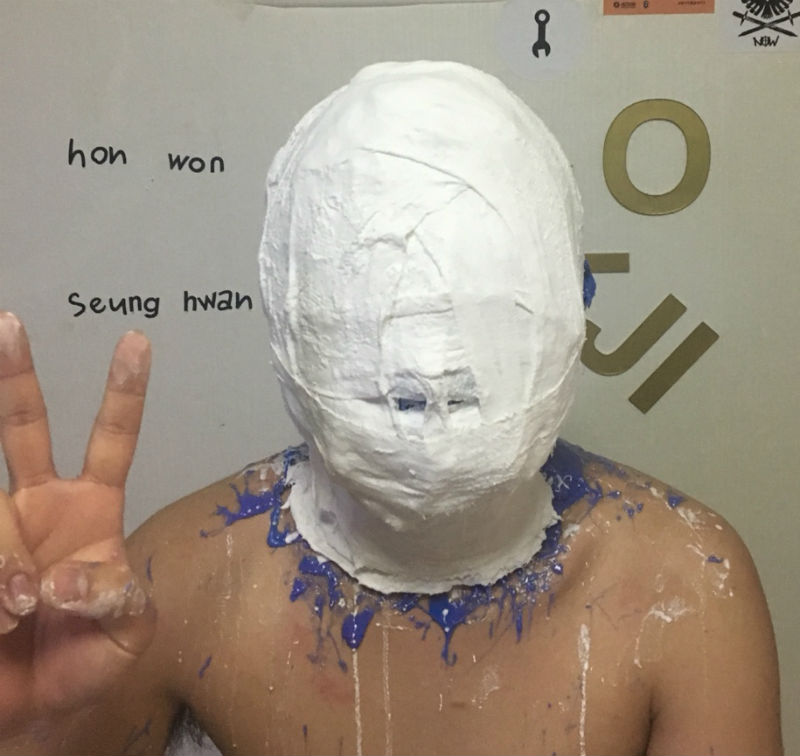

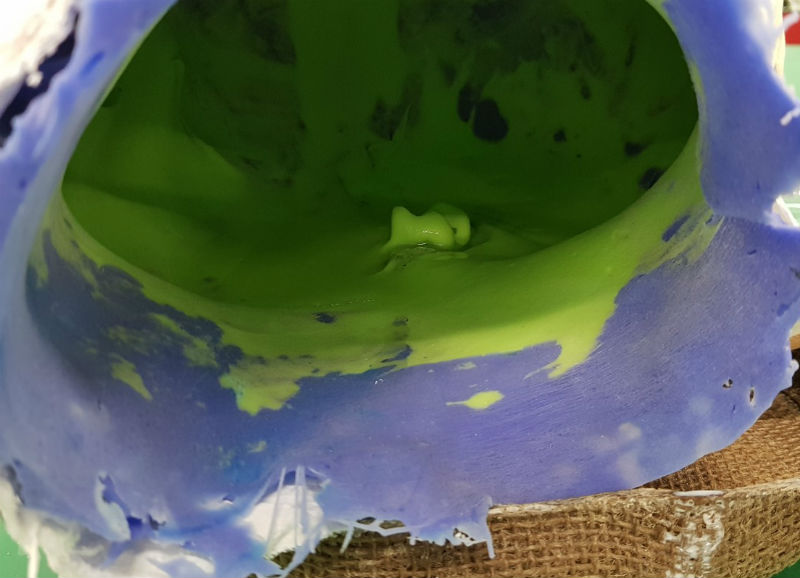

And, put silicone to my head except nostrils to breath. Body-double's pot time is 5minutes so every processes should be done in hurry. With my 2 friends we did several rehearsal.

Body-double's cure time is 20minutes. After silicone cured well, we need to make a mold to hold silicone mold. Because silicone mold is flexble, hard material mold to hold sillicone is needed.

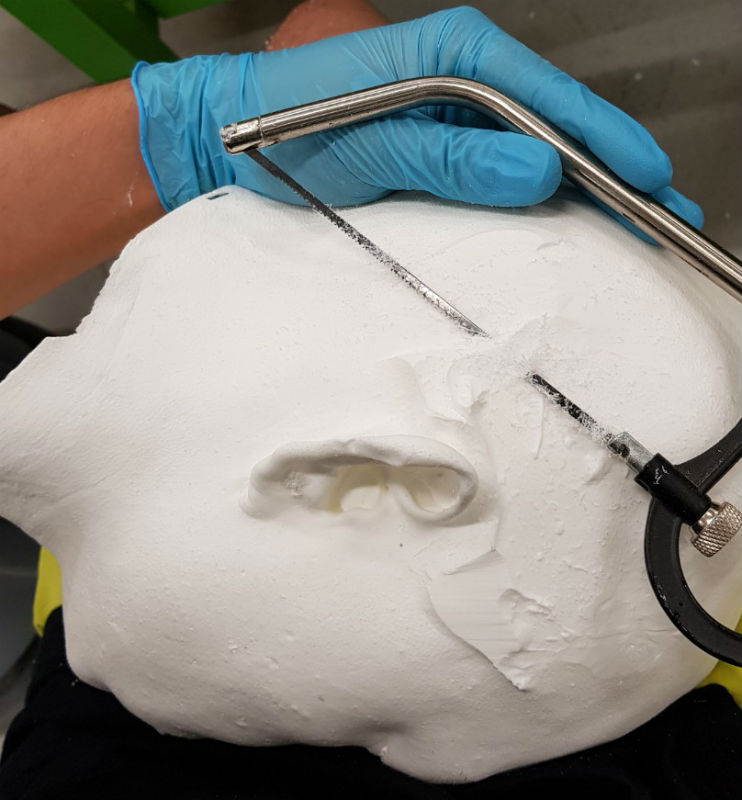

We used plaster bandage which is composites with gypsum and gauze. Dipping plaster gauze to warm water and attaching to silicone, it will be harden in 10 minutes. But to demold, It should be two parts. We did front and back part each.

After plaster bandage hardened well, demold those frames and cut silicone at the back.

But first lifecasted mold was to thin. It doesn't maintain the shape because of the thickness of silicone even there was the mold to maintain the shape.

So i did once again with two bottle of silicone. In this time I bought Body-double statndard and silk boths are from Smooth-on. I did same process again and I got better mold.

After life casting, my room.....

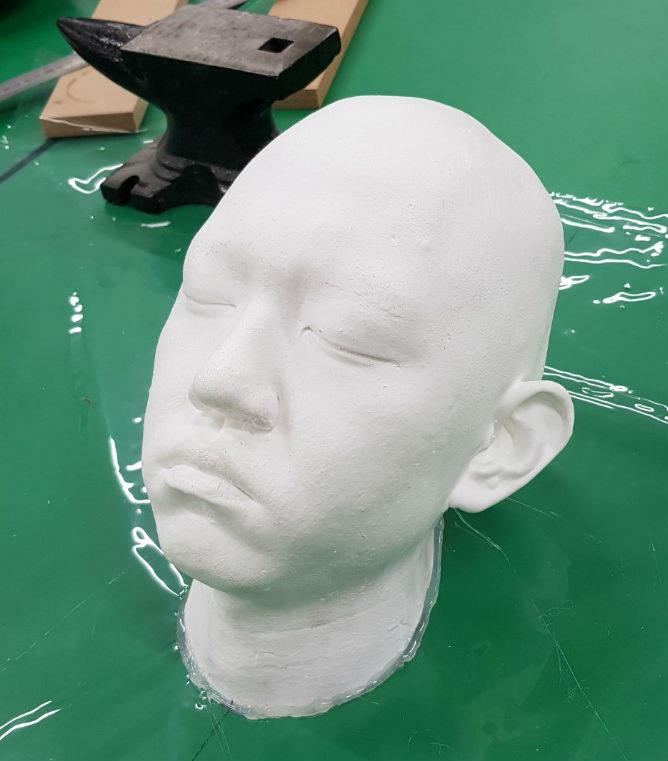

CASTING

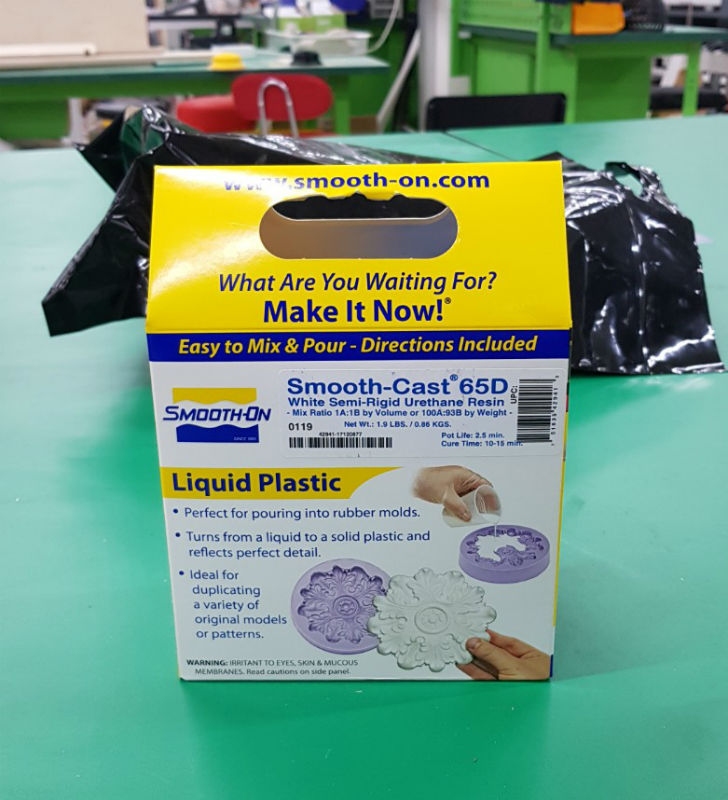

For casting, I need hollow shape because I should put every parts inside the head. So i decided to use fast curing urethane resin. I choose Smooth cast 65D fronm Smooth-on. It has 2.5mins pot time, 15minutes cure time and shore hardness 65D. Those were suitable for use for me. Because of its charaters, this material is good for roto-cast. but I don't have rotocasting machine and there is weak parts like ear, I did manual roto cast.

Before I started, I filled nostril part with glue gun.

I started with ear part because it has deepest form it was very easy to have pore inside.

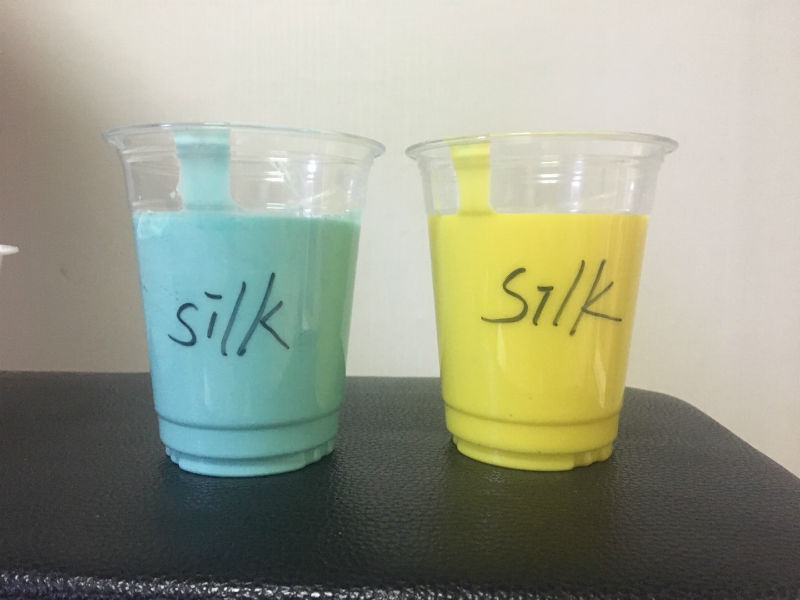

Smooth cast 65D's mix ratio is 1:1 by volume. I prepared two 30ml cups and make 60ml mixture several times.

I divided parts of my head and worked each part seperately first with thin layer.

After all of my head has one layer, I make 100ml mixture and pour into the mold. And make one layer to whole head. And repeat this work.

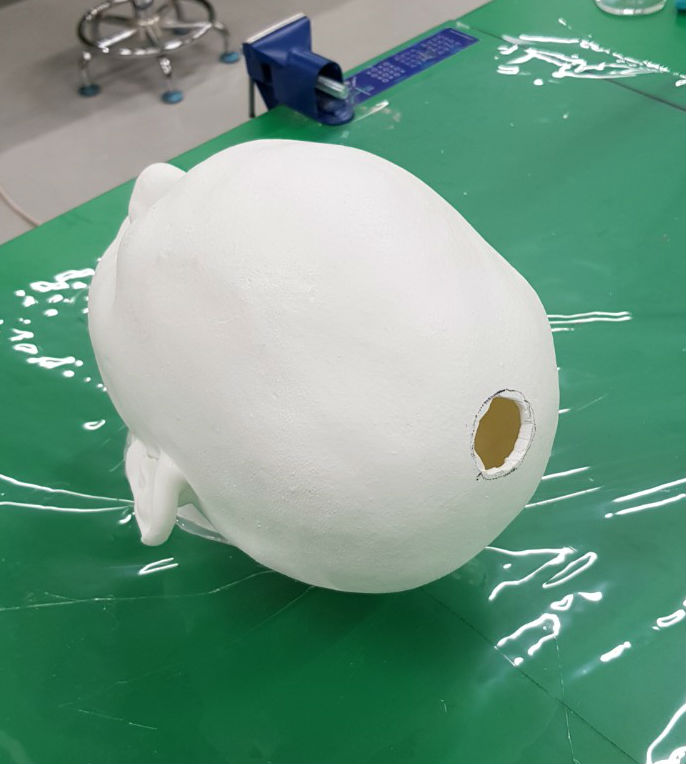

After every parts have thick layer, I demolded gypsum bandage and silicone.

There was some unnecessary parts I didn't intend to. i cut those part with hand saw and sand with sanding paper.

Then I made bottom part which is connected to wall holder parts. For making bottom part I cut and sand the bottom part to make it flat. I used scissors and files.

After sanding, I drilled a hole on crown.

I draw the center line on vinyl. Then attach wall holder at center with glue gun. Also i marked center line on head too. I covered the holder part with head and put glue on bottom to prevent resin flow out.

and I pour urethane resin into the hole to make bottom. It naturally goes down and be flat bottom.

During breaktime, I listened to music.

After cured well I cut the wall holder part. It seems good. and I make crown hole larger to put trumpet in it using rough file.

WHERE I WORK

I'd love your feedback!

Phone: +082 1041950935

Email: jshjshjsh93@gmail.com

Feel free to contact! , or leave me a note: