|

|

|---|

Assignment |

Final Project |

About Me |

|---|

Week 6

1. 3D printer and filament

Mannequin |  Sindoh DP200 |

|---|

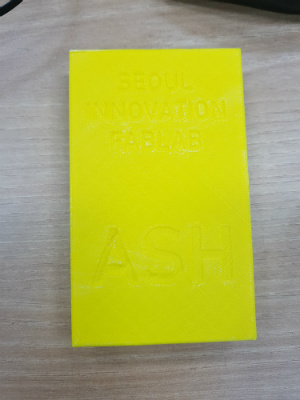

There are two 3d printing machines available in Seoul innovation fablab, mannequin and DP200.

If I do 3d printing, I will use DP200, because sindoh's are more stable.

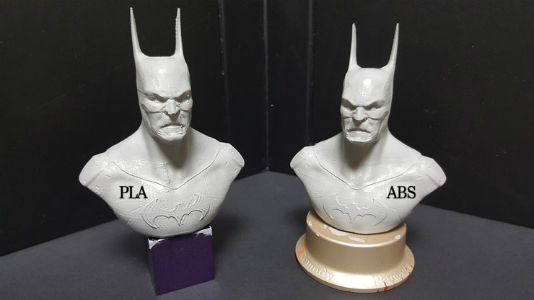

There are two types of filaments used in 3d printers, one with ABS and the other with PLA.

To explain some of the characteristics of ABS, it is no gloss, easy to make prototypes and post-processing is easy.

However, the shrink phenomenon a lot, the harmful gas is generated at the melting point, and it bends because it is soft.

To explain the characteristics of PLA, it has been found that it is relatively shiny, shrink-free,

and contains natural vegetable ingredients, but it is harmful due to recent research.

It is also weak against heat, friction, pressure, moisture and breaks well.

There are various characteristics, so you can use the filament you want.

Difference between ABS and PLA

Source

http://blog.naver.com/PostView.nhn?blogId=zebra38&logNo=220842467490&parentCategoryNo=&categoryNo=1&viewDate=&isShowPopularPosts=true&from=search

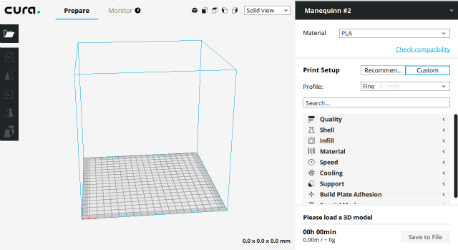

You must use cura, an open source program, to use mannequin. |

This is the default configuration value given by the instructor. |

|---|

But I didn't use mannequin, so there is no result.

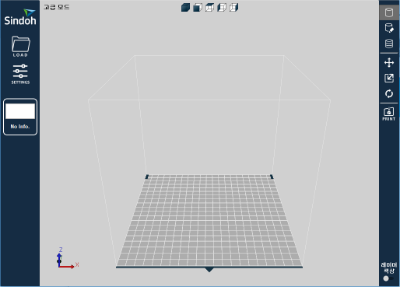

I only printed the output using DP200.

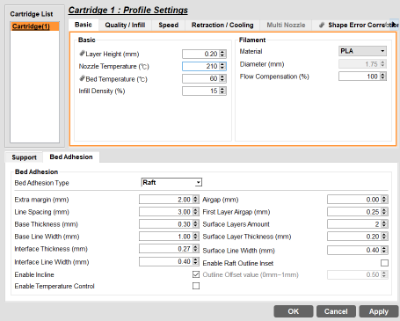

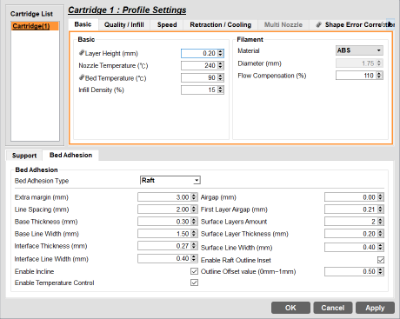

The DP200 is easier to set up using programs provided by sindoh. |  Nozzle temparature:210℃ Infill:10% |  Nozzle temparature:240℃ Infill:10% |

|---|

The default value of the DP200 provided by Sindoh

is the temperature and infill changes, the left is the PLA setting value, and the right is the ABS setting value.

The infill default value is 15%.

The reason I changed the setting value was to increase the temperature

because there was a possibility that it might be wrong, and the infill changed to reduce the time,

but there was little difference.

2. Product

|  |

|---|

Both were better than expected.

However, if there is a problem in each case, the output from the ABS shows a gap in the middle, and the inside is visible through the gap.

I also fixed the bed as a raft, but when I removed it after the output, the part of the mouse that touches the underside of the mouse could not be released.

In the case of the PLA, the left front part of the mouse is raised and the left and right sides are not symmetrical, and the convex part is relatively more than the ABS output.

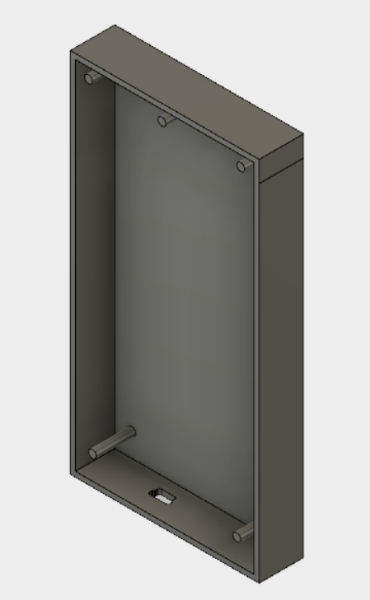

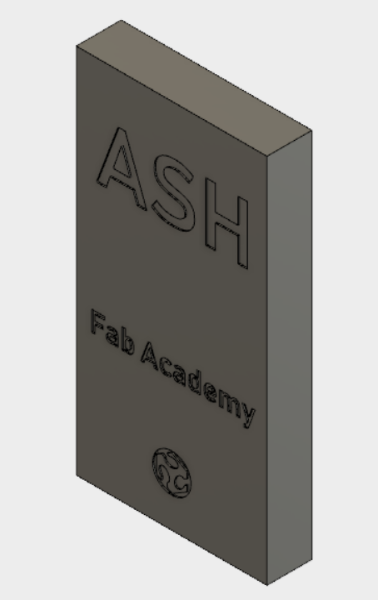

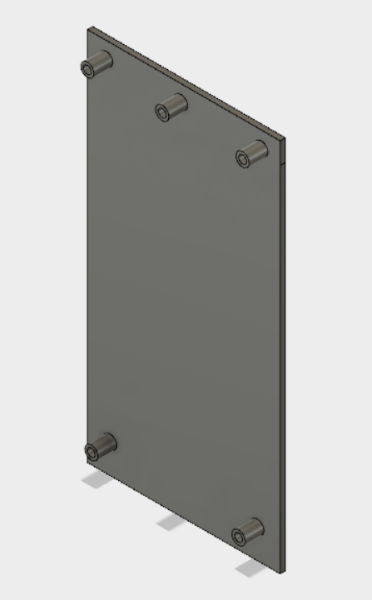

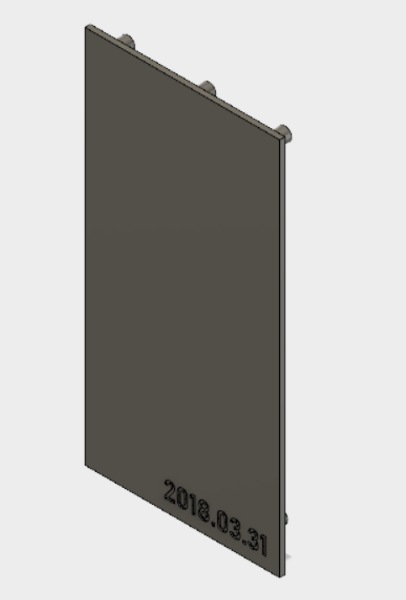

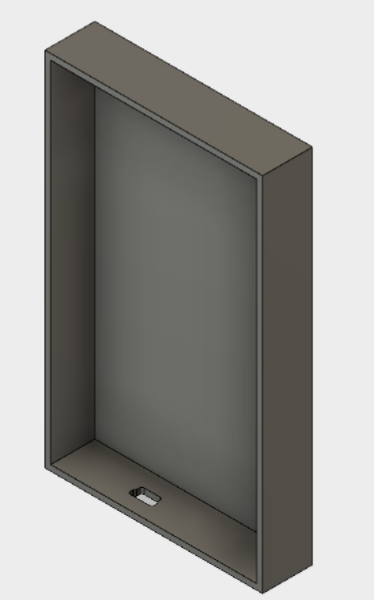

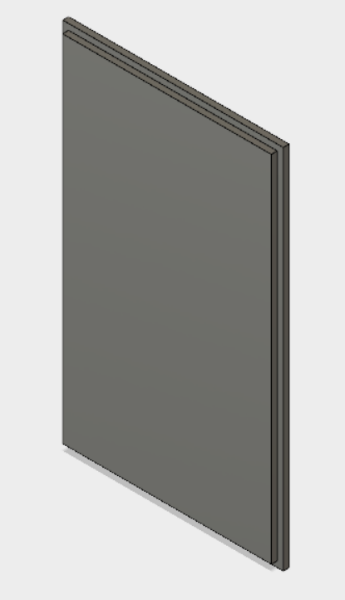

After that, I tried to make a case of an external hard disk.

This case does look like it can be made with subtractive, however because of tiny little hole for the usb cable,

at this time of my machine knowledge it could not be done with 3 axis machine that I can operate which has normal z axis.

Therefore, it could only be made with 3D printer.

what a tiny hole ... that makes a huge difference in choosing the machine.

The case was small because the figure was calculated incorrectly. :(

In addition, the structure between the case and the rod is brittle, and the structure is made different.

I made the structure between the cases by cascading into the interlocking structure, and the size was also corrected.

I thought it was a high level of output, and I used it because I only had a few days to use it.

It is very satisfying, but one problem is that if you drop it, you should be careful not to drop it

because it is thought to be a good structure to separate.

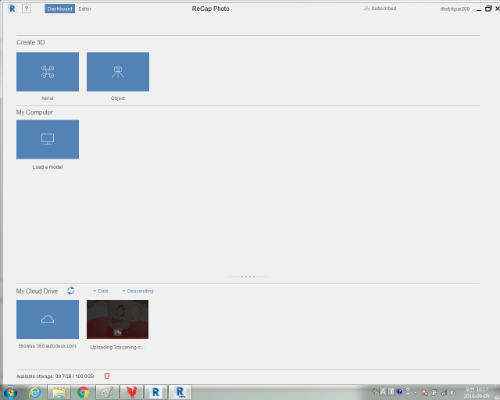

3.Scaning

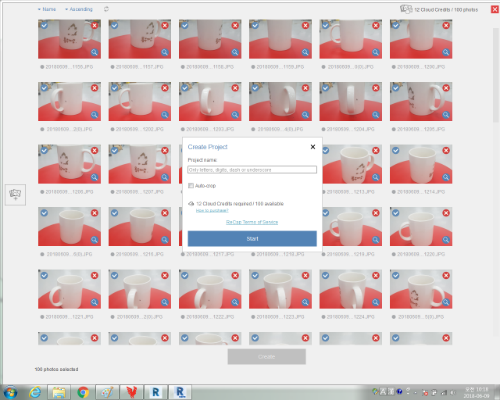

The first thing I scanned was a mug.

I put it on a chair that turns 360 degrees and put 3 parts, about 100 sheets,

I started scanning using the RECAP PHOTO program in autodesk,

Create 3D model - object - insert photos.

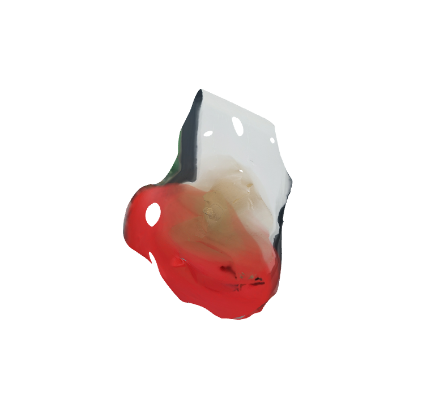

I tried to confirm that the scanning was completed,

but it failed because the background was displayed instead of the desired mug.

So I decided to scan the hat this time,

but I took the background as white as possible and took pictures in various angles.

I checked the scanned image and it showed a shrunken hat.

To make a few guesses about things that did not print properly,

I guess the first scanned mug was focused on the background, so the program did not recognize the mug correctly,

and the mug was white, so the color would have affected.

The second is that it was good to take pictures in multiple angles,

but I guess the program did not produce enough pictures because I did not take enough pictures.

You can download my work here

zip file download