WEEK 05 - Electonics Production

Antonio Garosi, Eleonora Piccinelli, Dario Bernabini, Tommaso Lombardi, Giada Allocca, Giuseppe Allocca

Index

During this week we learned that to mill a PCB, we need an

RML file to mill our boards. Anyway, we always started from a PNG file and each one of us used Gimp and/or Photoshop.

We used mods.cba.mit.edu as Fab Modules in order to generate files to be read by the machine starting from traces in PNG format.

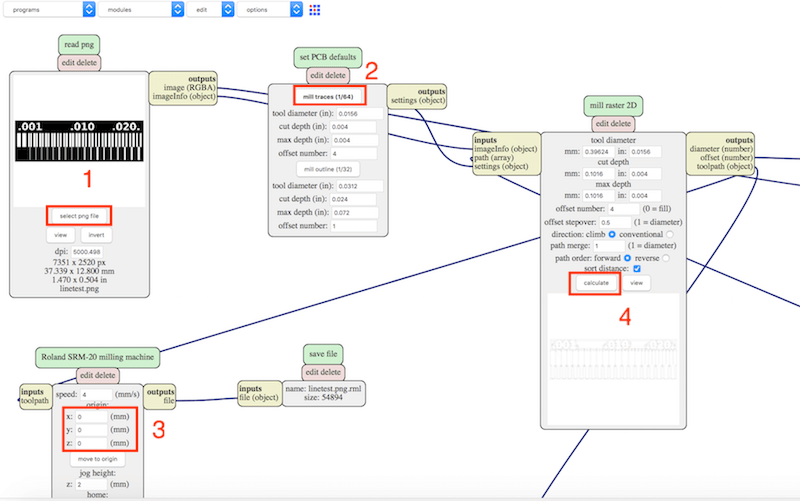

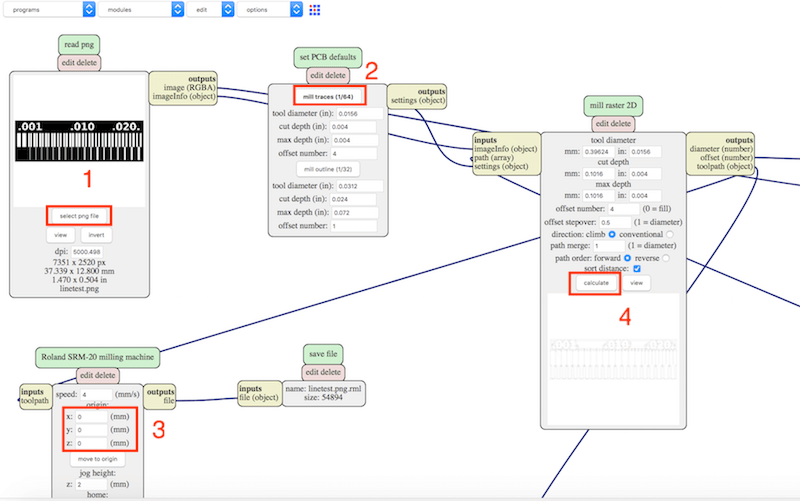

So, we clicked on Programs - Open server program - Roland SM-20 (PCB) that's our Lab's machine code. Than---- Modules - Open server module - File (save).

In the new screen we disconnected the "WebSocket device" module from "Roland SRM-20 milling machine" one by clicking both of them in the yellow rectangle and then we deleted it. In its place we connected the new "file - save" module in the same way. After that, we followed the following steps:1 - Select PNG file (selecting now the trace file)

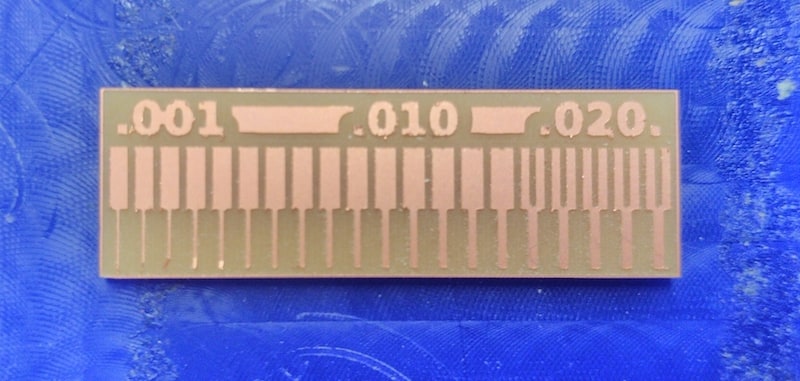

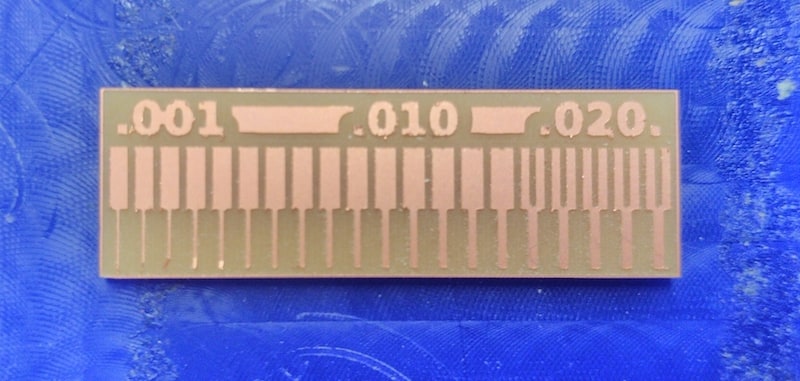

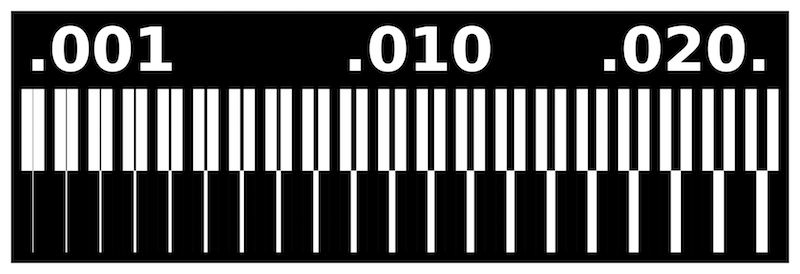

2 - Set 1/64 to mill the traces (remember also to put 4 as number of the offset)

3 - Set X:0, Y:0, Z:0 = origin position

4 - Click on "Calculate"

The next picture is going to show the steps we mentioned above. As you can see, we simply gave them a number, in order to do the actions correctly!

We repeated the same process for oulines file too, but in this case we set:

In the new screen we disconnected the "WebSocket device" module from "Roland SRM-20 milling machine" one by clicking both of them in the yellow rectangle and then we deleted it. In its place we connected the new "file - save" module in the same way. After that, we followed the following steps:

We repeated the same process for oulines file too, but in this case we set:

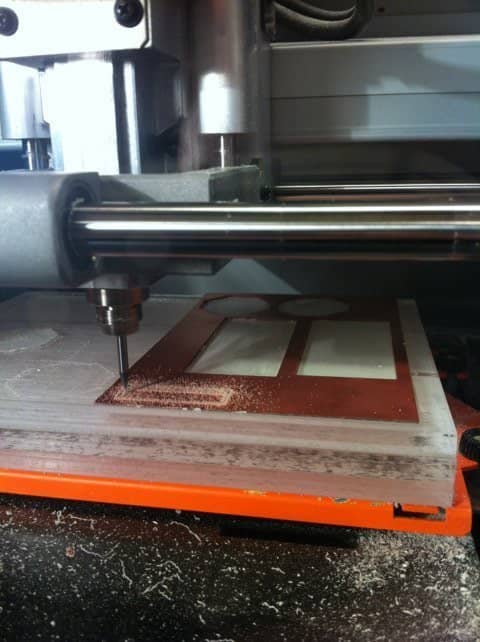

mill traces = 1/32 (instead of 1/64 we used before). Than, we saved the two new RML files on an USB pen and we uploaded them in the PC connected to the Roland machine. Doing so, we were ready to mill our first boards!

After having create the rml files, it is extremely important to set the machine properly. To do that, we moved the plate on the three axes. Fist of all, we set the 1/64 tip to mill the traces. We moved the machine plate to set the X/Y axes. Then, we moved the Z one in order to be near to the material. It could happen to set the Z in the wrong way and it created us a terrible milled board and it risks to ruin the tip.

The Roland Machine use enjoyed us very much. We have learned to use an important machine to mill PCBs and it will be really useful for the next weeks. It is essential to keep the table clean and to have the needed tools on it. Doing so, we can avoid the risk to use the wrong tip and we can clean the plate form the excess material.