Something Big!

this week assignement is:

- Make something big (on a CNC machine).

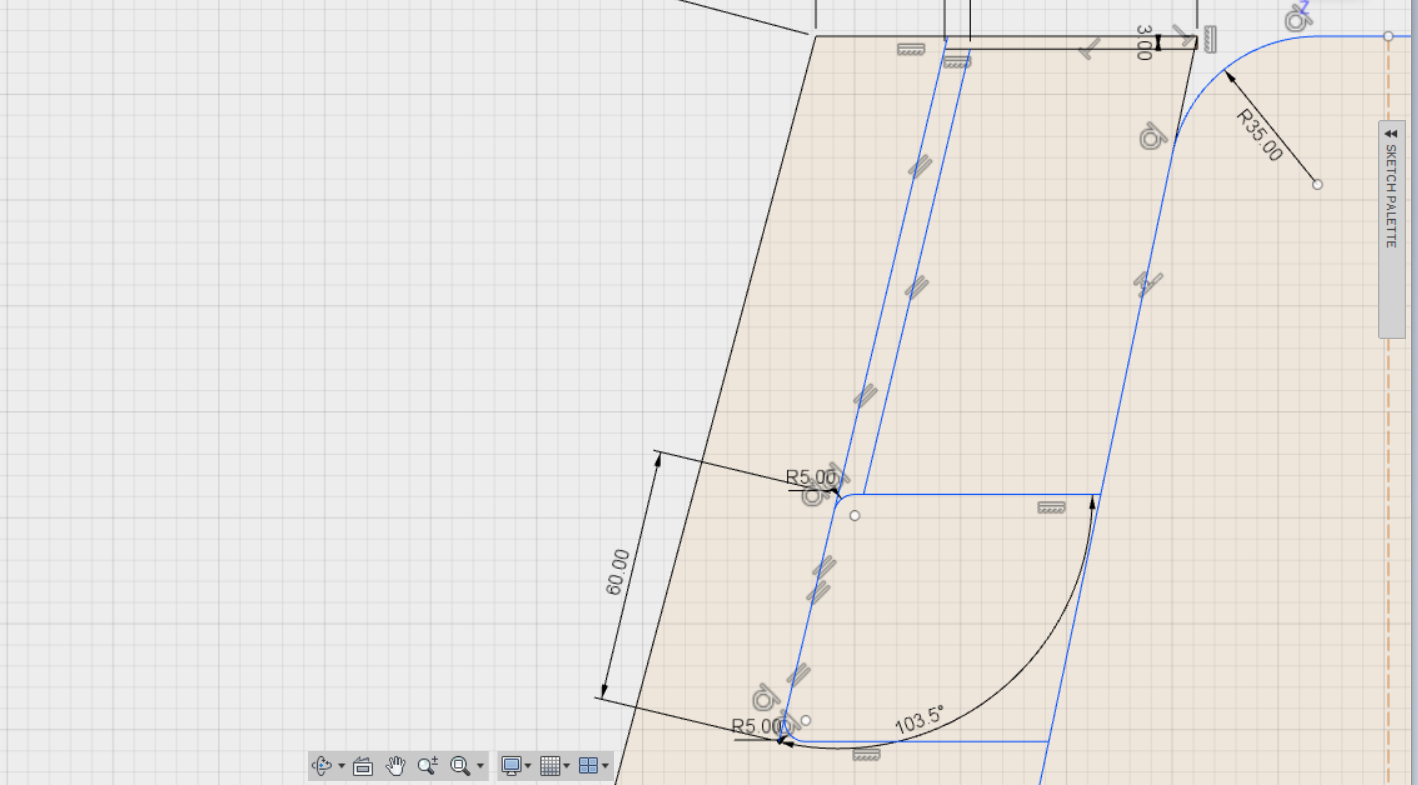

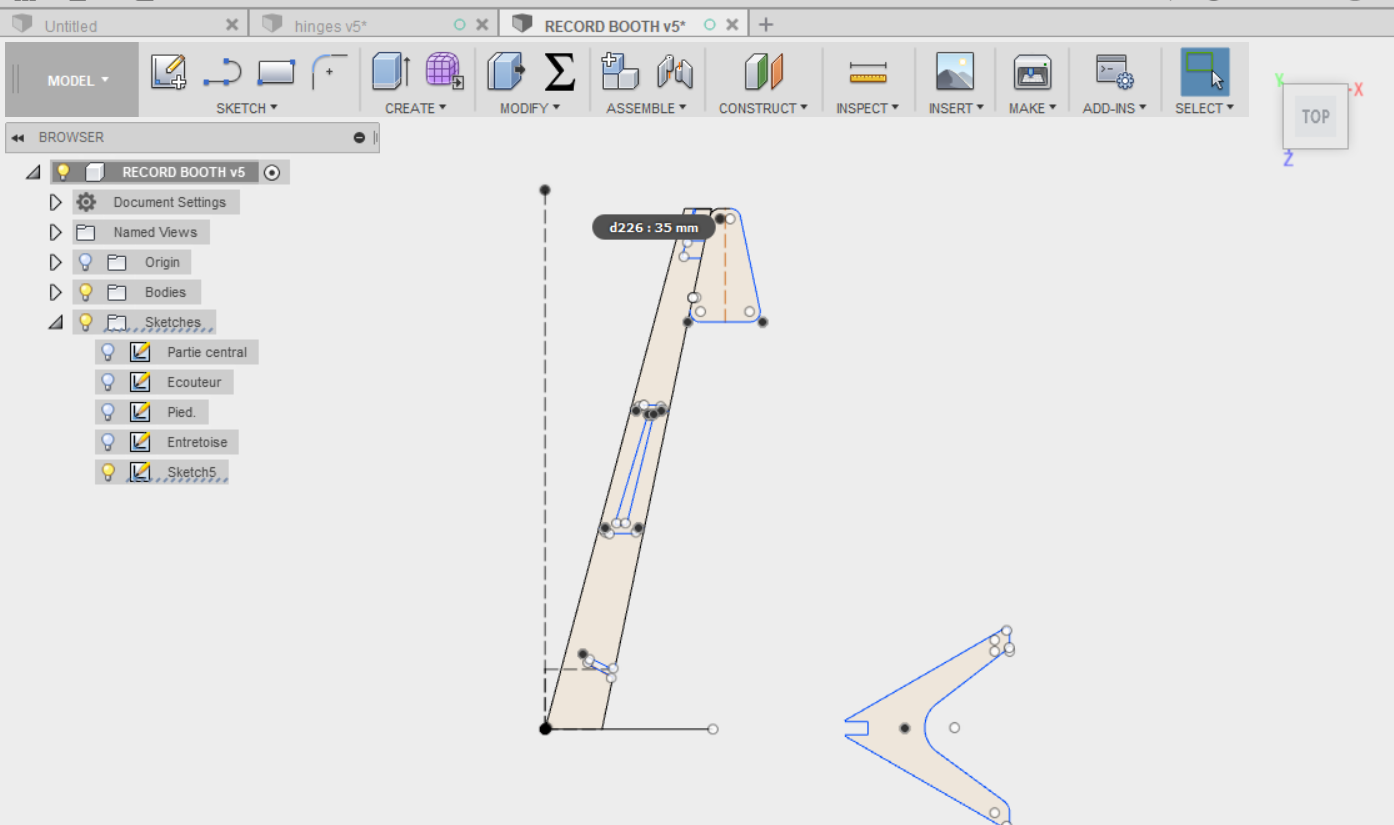

make something big On fusion360

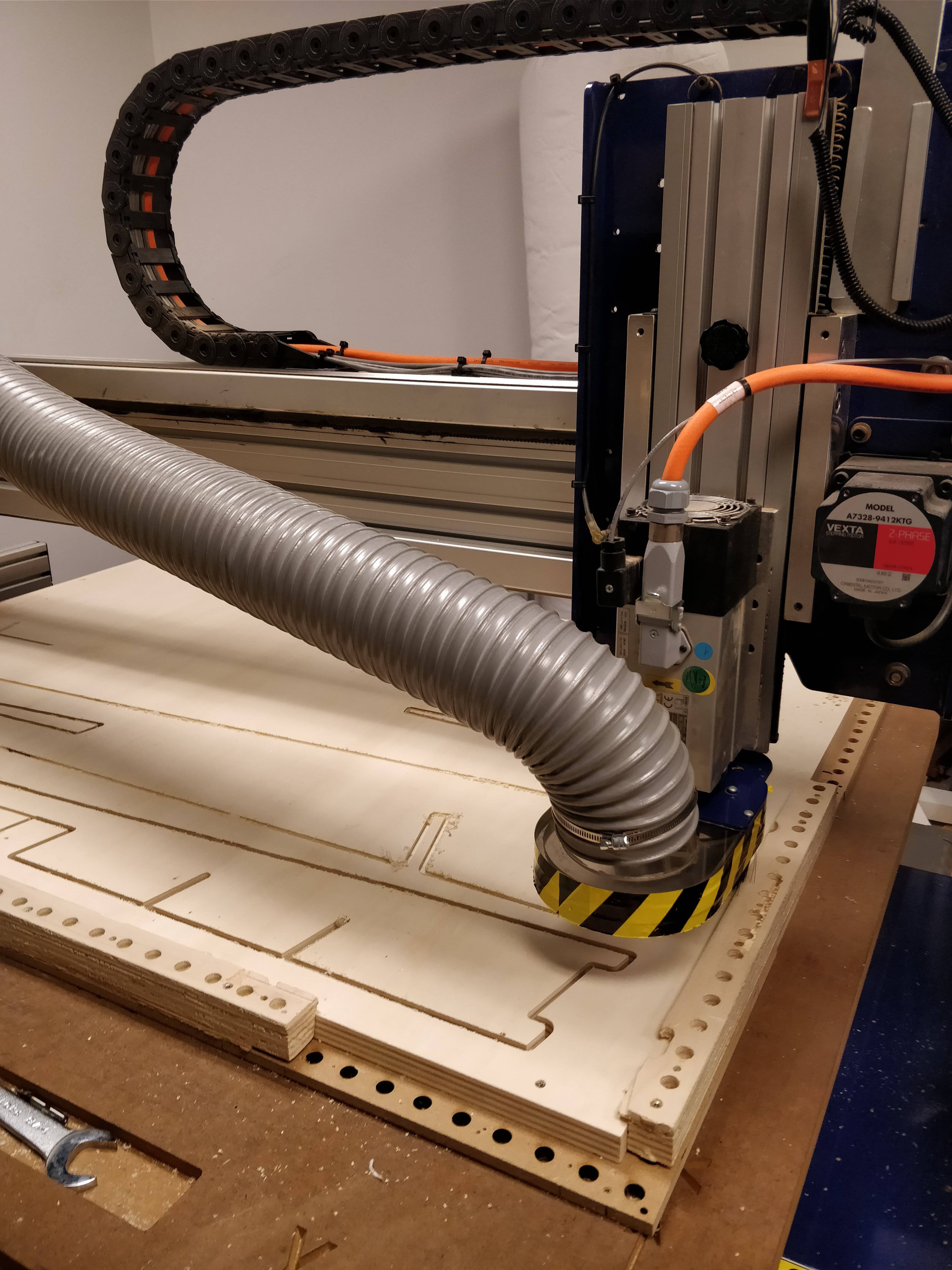

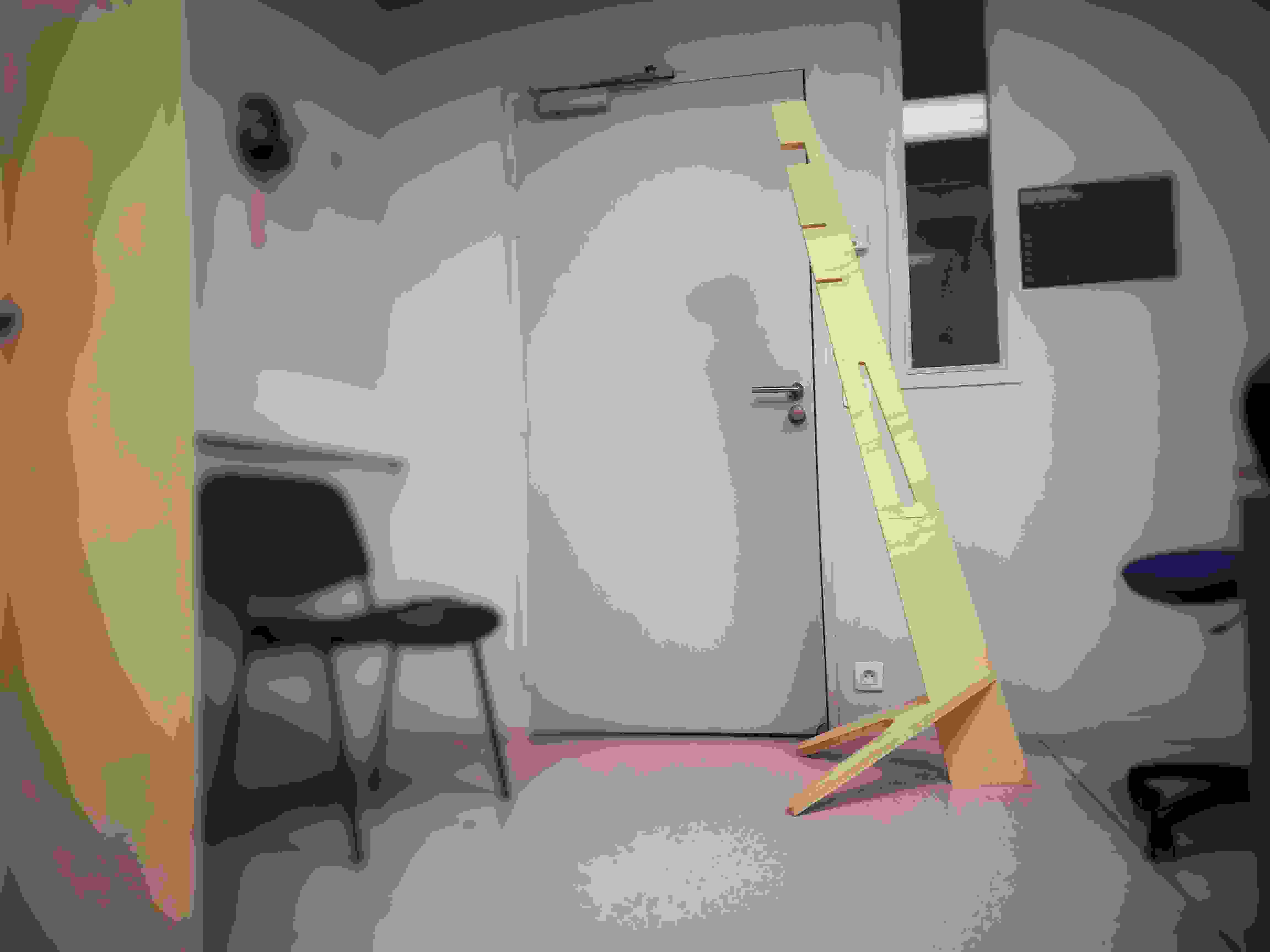

This week i worked on my final project, the record studio. the main part of my record booth is made in multiple part for a couple of reason: the first reason is about the size. i want to make something going to 1800mm, and the cnc we have go only to 1200mm, the second reason, is making it modular for an smaller person and a bigger one. so i resolve this two thing with one solution. making multiple part that can move.

In my file i made some Specific design, like. i made some inner trace for the cable between the electronic boxe and the led light.

In my file i made some Specific design, like. i made some inner trace for the cable between the electronic boxe and the led light.

when my file is ready i export it in DXF File for Vcarve Pro.

when my file is ready i export it in DXF File for Vcarve Pro.

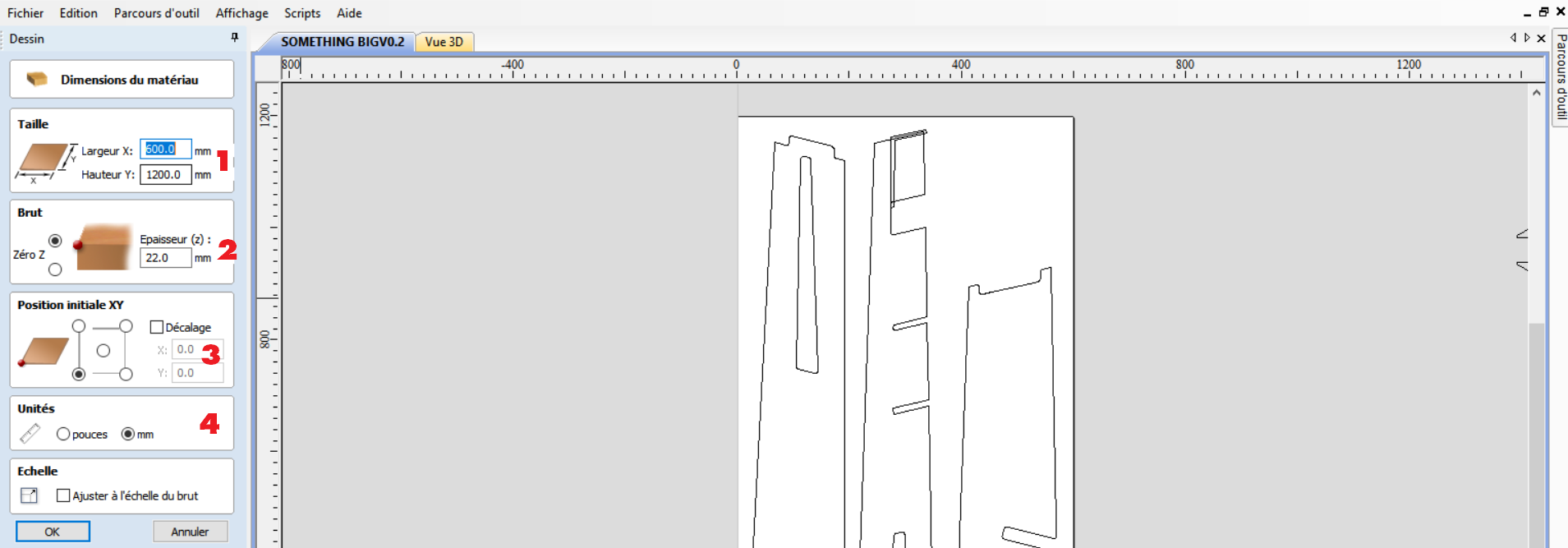

Vcarve Pro

On Vcarve we open the dxf file . vcarve is made for transform vector file to GCODE, so the first step is open the dxf file.

- 1) this is the value of your sheet of wood (here in our lab is 600X1200mm)

- 2) this is the thikness of your material here my sheet of wood is 22mm

- 3) this will is your origin point. always start bottom left, if you want to change that, be sure of what you doing.

- 4) This is the unit, here in paris we using our machine is in millimeter not in inch

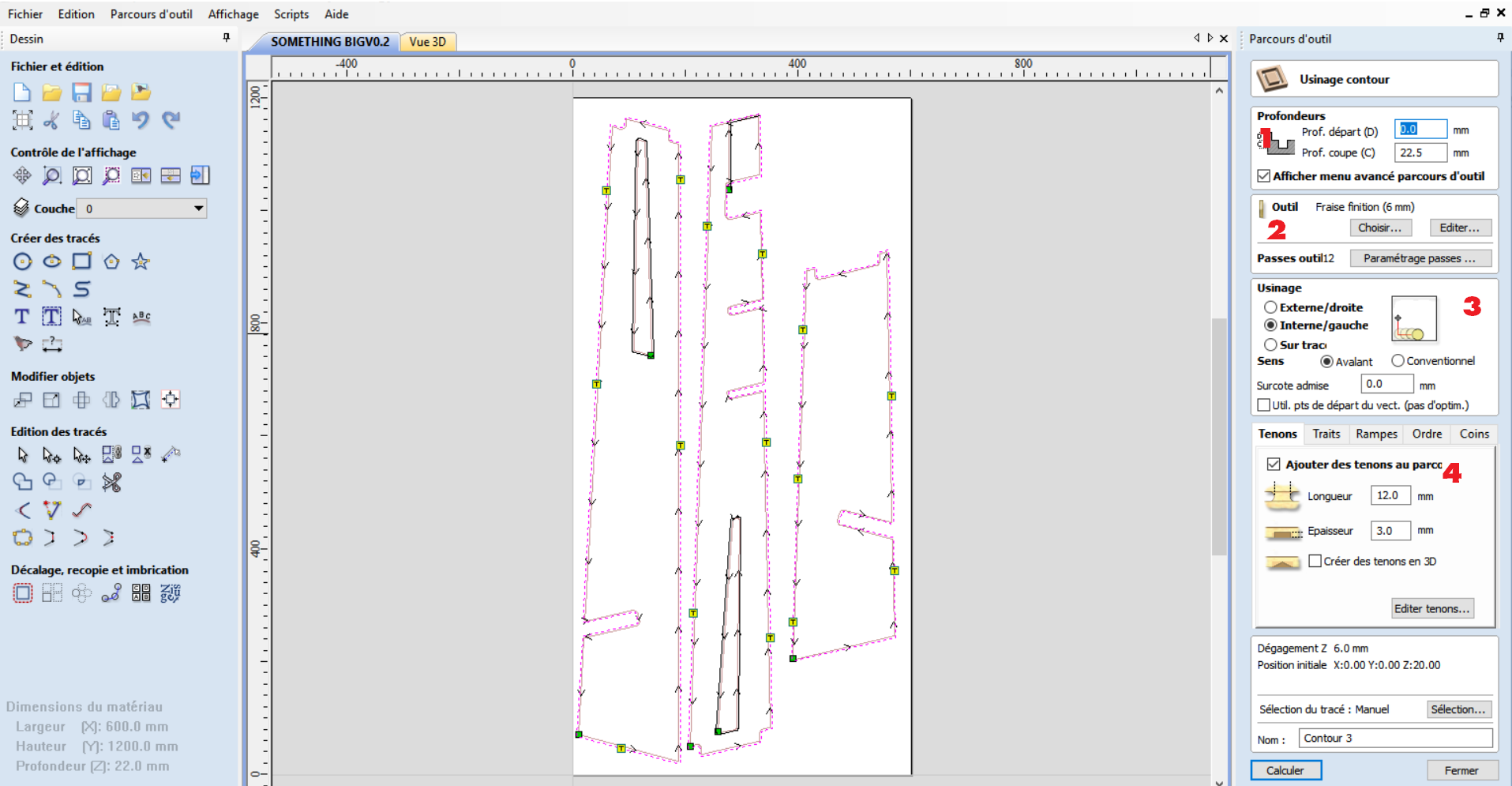

Making the cutting path

when you make the cutting path, we should always start from the inside to the outside, so here i selected the part i want to cut.

- 1) this is the depth cut you want to achieve

- 2) choose your mill, here i'm choosing a 6mm End mill.

- 3) choose the way you want to cut your file. inside cut, outside cut or on the line.

- 4) add some tabs (yellow rectangle) at least 4 it will block your object during the final cut.

How to choose the good feedrate/spindle speed

When you cutting something with the cnc, it's not like cutting something with the laser cutter. here the cnc is removing material by a mecanical motion. for knowing when your working on a good speed you should look at the chip of wood.on my capentry class i learned how that a good cut can be look at the chip.

it should be not to big and not to small.

to big:

- the flexion on a tool is to high.

- you'll have More vibration.

- a bigger stress is made on the tool and could create a gap or broke.

- overheating during the cut & burn the tool or the wood.

- creation of fine particle.

we know that the good thikness for a chip of wood need to be between 0,1 and 0,5mm

With all this information i was able to determine the good speed of cutting!

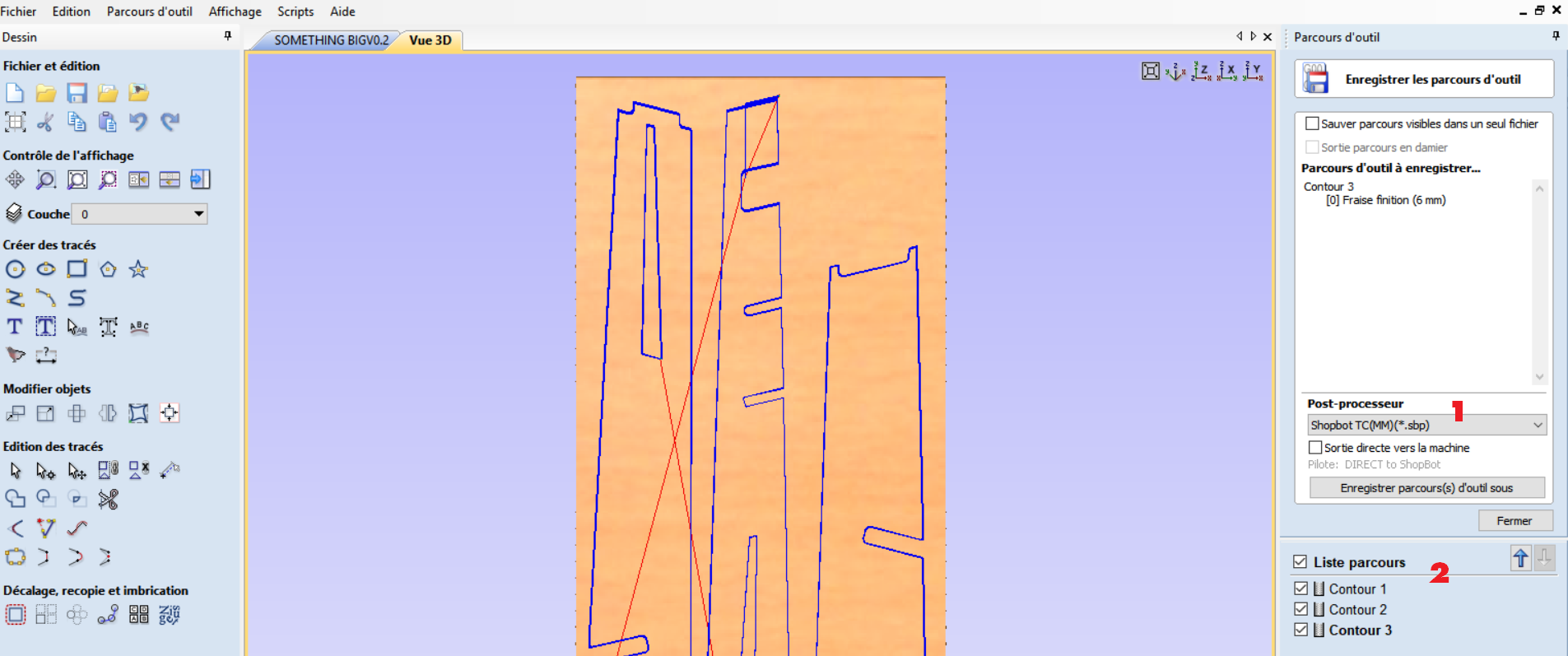

Export your file in SBP file

- 1) choose your post processor, here in paris, our cnc is on mm so the file need to be in Millimeter.

- 2) this is where you can find every layer you made for cutting. check the box you want to export in one file.

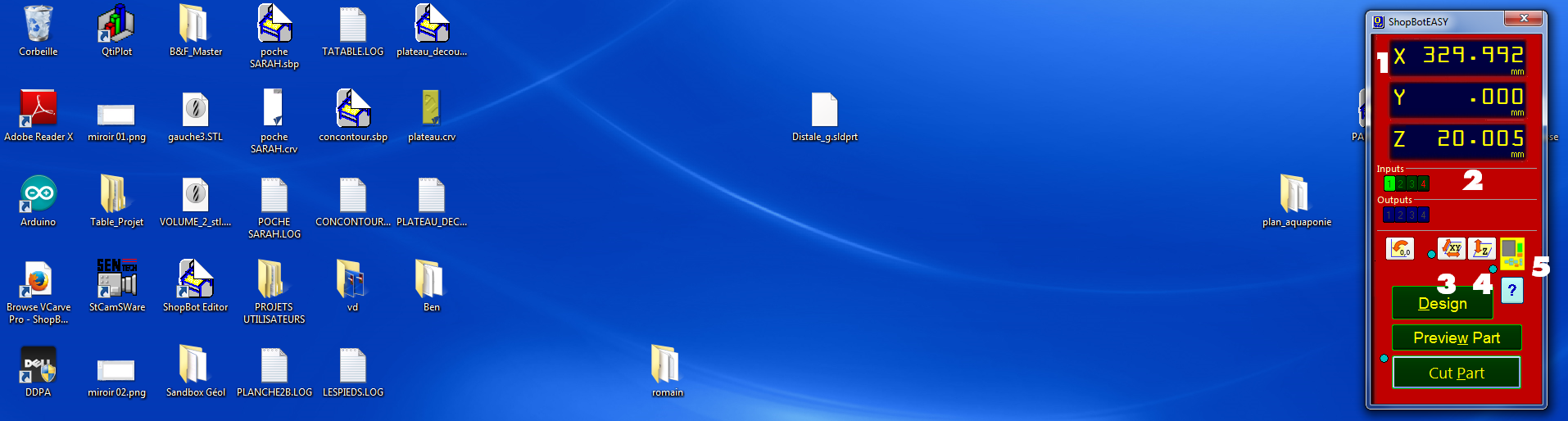

open shopbot3

Shopbot3 is the software for controling our cnc. Pretty simple we have to open it :

- 1) is the position of the spindle on the cnc

- 2) are the inputs you can have on your cnc (for exemple The 1 light up is for the automatic ZERO Z)

- 3) is an automatic tool for making the absolute zero on X.Y of your machine.

- 4) is an an automatic tool for making the Relative Z zero

- 5 it will open the control box for moving the cnc

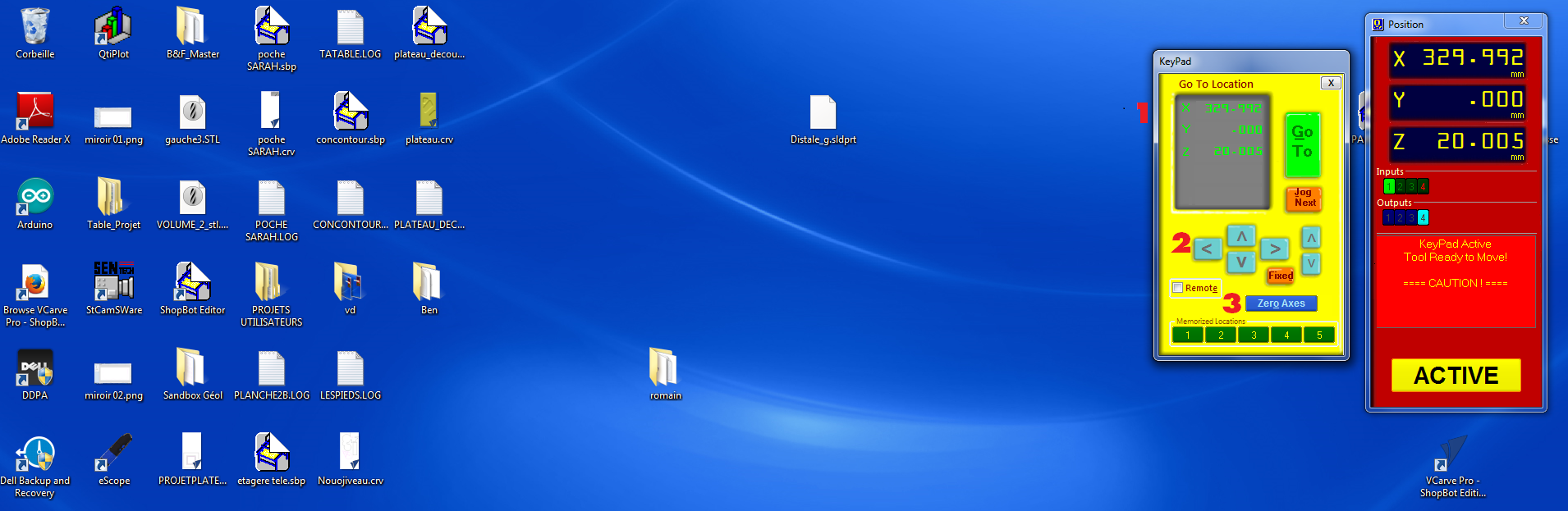

here you have multiple tool.

here you have multiple tool.

- 1) is the position of the cnc, you can modify the value and clic on "go to"

- 2) is for moving your tool too, but manually, just click on the arrow and it will move

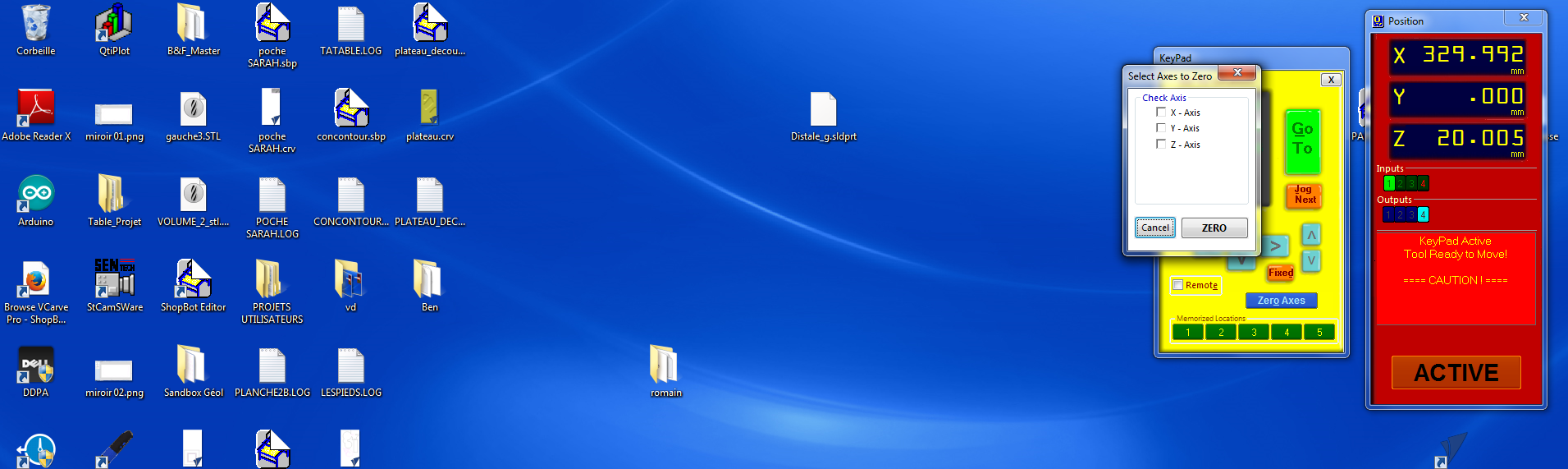

- 3) Zero axes, is made for making a relative Zero for starting your file

check the box you want to save. and it will change the zero of the machine.

after that you have to make the Z zero. For that you have two thing. the alligator clip and the plate.

check the box you want to save. and it will change the zero of the machine.

after that you have to make the Z zero. For that you have two thing. the alligator clip and the plate.

place the plate under the endmill and above your sheet of wood, clip, the aligator clip into a metallic conection of the spindle. when the endmill will touch the plate it will record the position add the thikness of the plate and make this value his new ZERO Z.

after that it is the moment to start to cut your file!

place the plate under the endmill and above your sheet of wood, clip, the aligator clip into a metallic conection of the spindle. when the endmill will touch the plate it will record the position add the thikness of the plate and make this value his new ZERO Z.

after that it is the moment to start to cut your file!

file of the week.

here you'll find the file of the week

For downloading

right click and save as

- fusion File (f3d file)

- vcarve file (crv file)

- shopbot gcode (sbp file)