Wildcard Week

this week assignement are:

- Demonstrate workflows used in the chosen process

- Select and apply suitable materials and processes to create your project.

vaccum forming

This week i decide to work on Thermoforming.

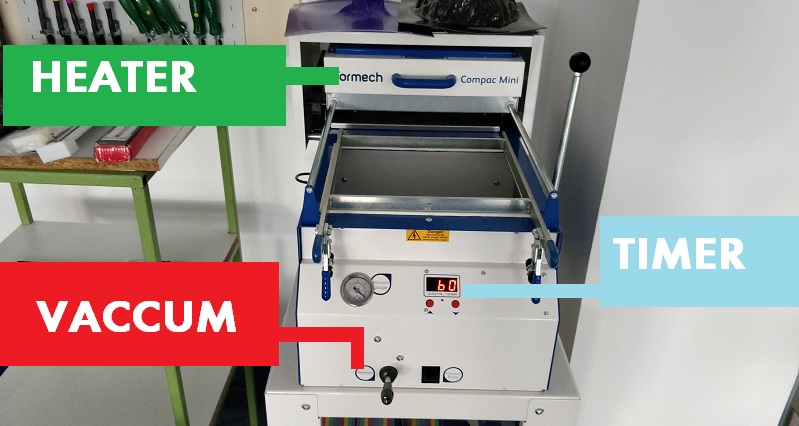

here in paris we have a Formech Mini compact

How it's work

so the thermoforming machine is composed of Three part. So for this week i start by making this small podium for some item in the lab, i make them with some wood chips i got from the Rotocasting machine we made.

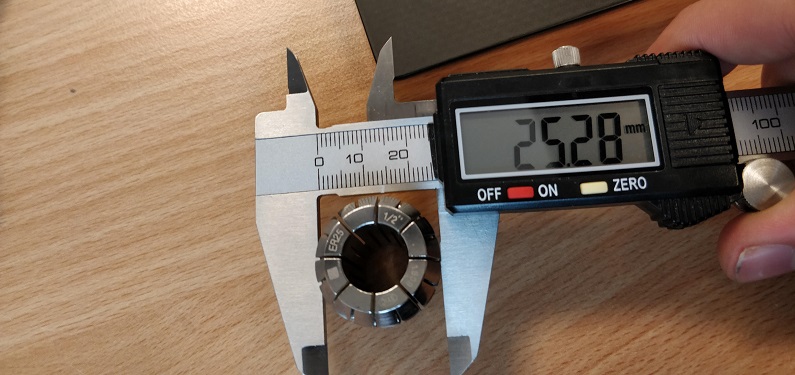

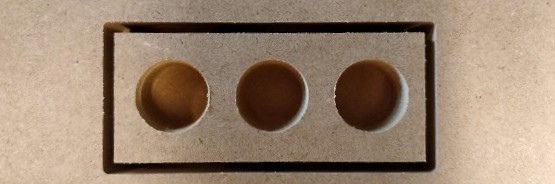

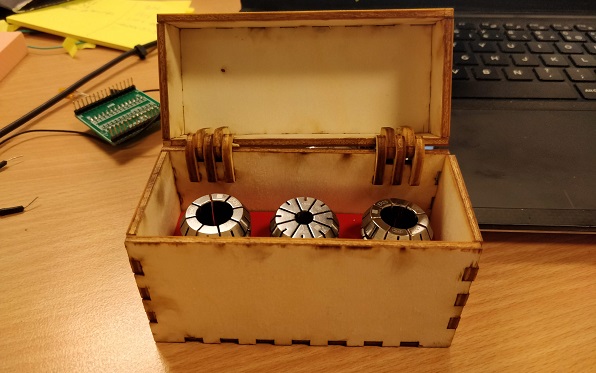

I decide to make a boxes for my collet for the CNC.

i started by measure them

So for this week i start by making this small podium for some item in the lab, i make them with some wood chips i got from the Rotocasting machine we made.

I decide to make a boxes for my collet for the CNC.

i started by measure them

so the thermoforming machine is composed of three part.

so the thermoforming machine is composed of three part.

design file for vaccum forming

When you design a file for vaccum forming you have to keep in mind some constraints.- having a chamfer on the piece at least of 3 degres is really usefull for unmolding the piece.

- don't be against clearance on any part of your piece. it wont unmold proprely

- have in mind the thikness of the plastic you are using an leave a margin

i did'nt made any chamfer on my piece and fortunatly it work but it was hard to remove from the piece.

After i took the measure of the collet. i knew that i had 3 of them really more used than the rest,

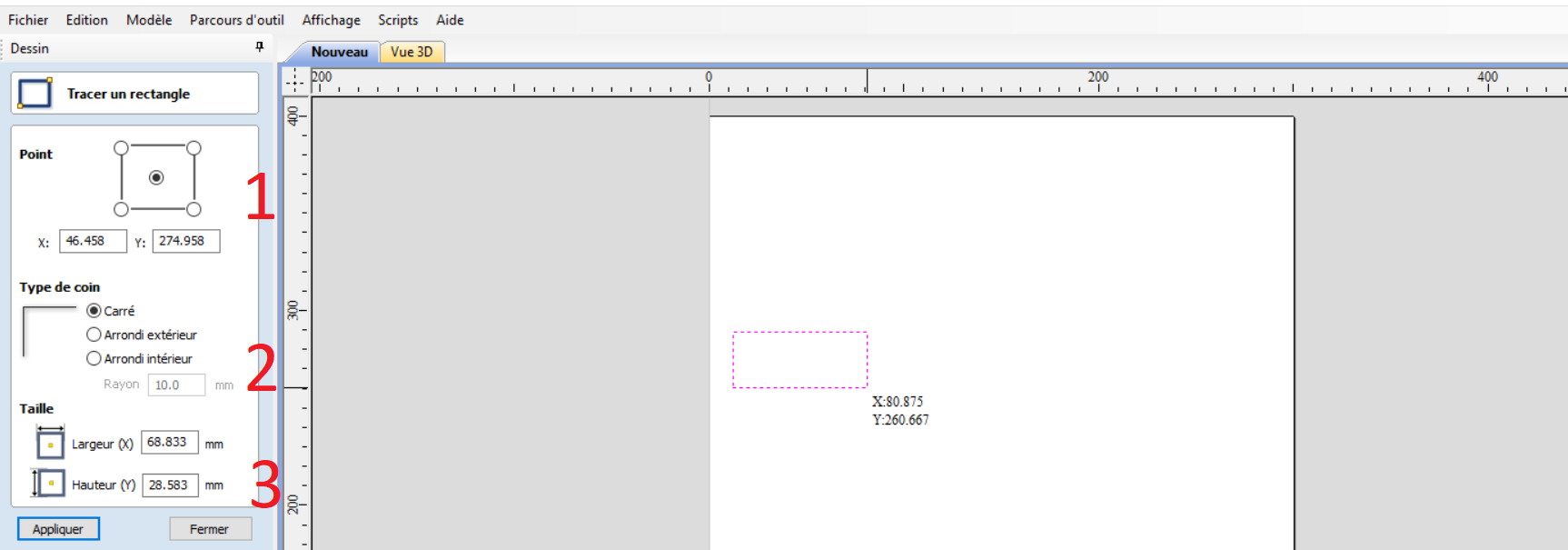

so i decide to make a specific boxe for them. small but quite visible with their own space. with Vcarve you have tool for making squares and Circle. pretty easly. so i used them.

- 1) the coordonate of your rectangle.

- 2) Fillet, what size, it's good to had them, with the half of the diameter you will use to cut your piece.

- 3) the size of your rectangle.

- 6mm diameter

- spindle speed : 7000RPM

- at a travel speed of 40mm/sec

- CRV file (Vcarve file for the master)

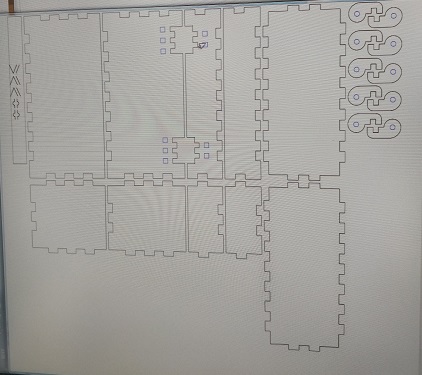

- SVG file (the boxe made with boxes.py )

then i decide to use MDF

The MDF had the particularity to let the air pour into it. so when we want to do mold it a bit better to use this material.

Milling

mill it with a straight mill then i made my thermoforming piece with this master!

first you have to start the Thermoforming,

then i made my thermoforming piece with this master!

first you have to start the Thermoforming,

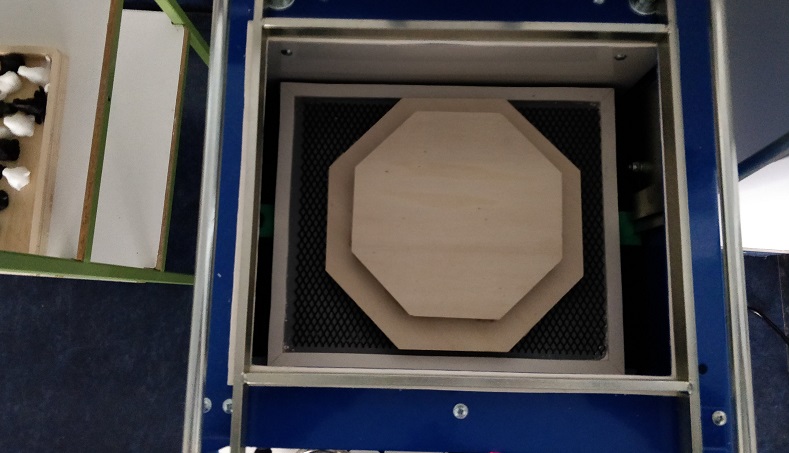

when you start the thermoforming you have to insert on the plate your master (here i'm using a a wood chip)

when you start the thermoforming you have to insert on the plate your master (here i'm using a a wood chip)

then you'll have to add a sheet of plastic, here we are using P.E.T PLASTICS

then you'll have to add a sheet of plastic, here we are using P.E.T PLASTICS

When you insert your material into the thermoforming machine you have to heat it!

When you insert your material into the thermoforming machine you have to heat it!

The timer is programmed fo 60 secondes, it's really perfect for our 0.5mm sheet of PET Plastics.

The timer is programmed fo 60 secondes, it's really perfect for our 0.5mm sheet of PET Plastics.When the timer is beeping it's time to remove the heater and start to move up the plate into the material and start the vaccum

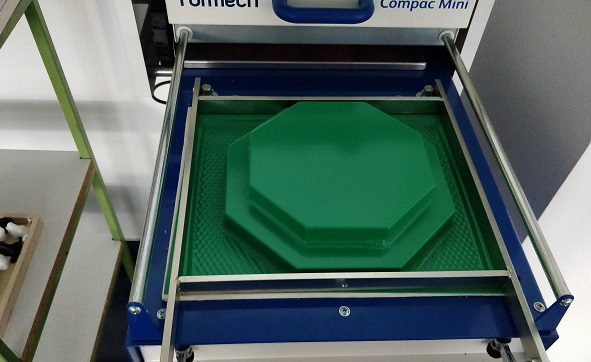

Et Voila!

Et Voila!

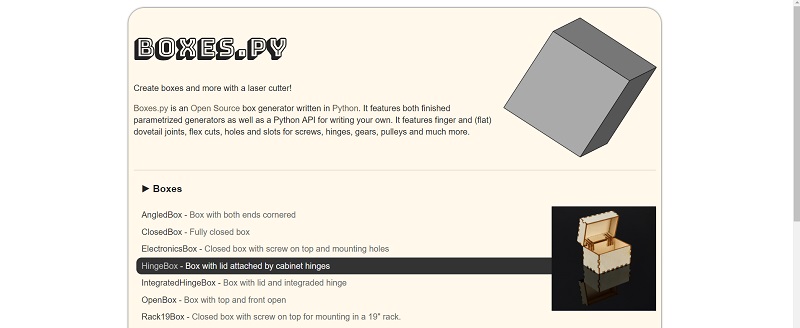

When i did that, i decide to make a small boxe, with boxes.py

When i did that, i decide to make a small boxe, with boxes.py

And Cut it with the laser cutter

And Cut it with the laser cutter

ET VOILA (bis)

ET VOILA (bis)

--

--

file of the week.

here you'll find the file of the week

For downloading

right click and save as