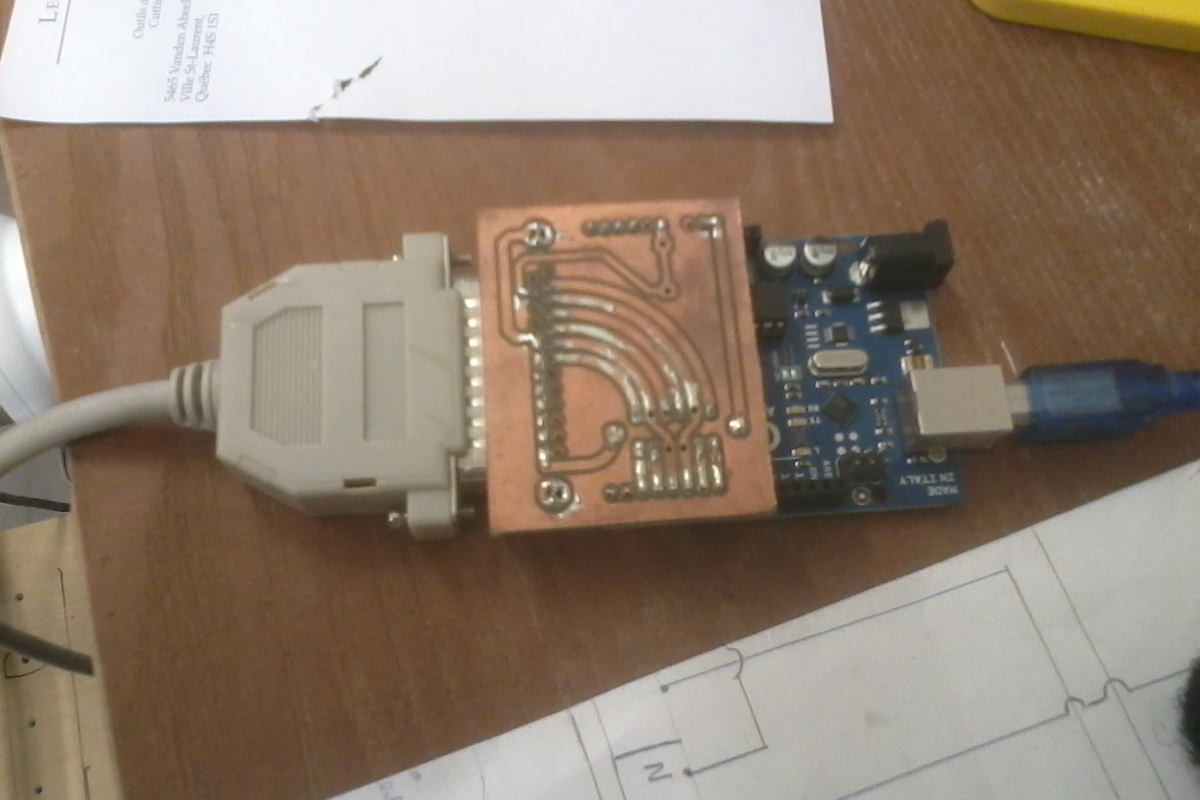

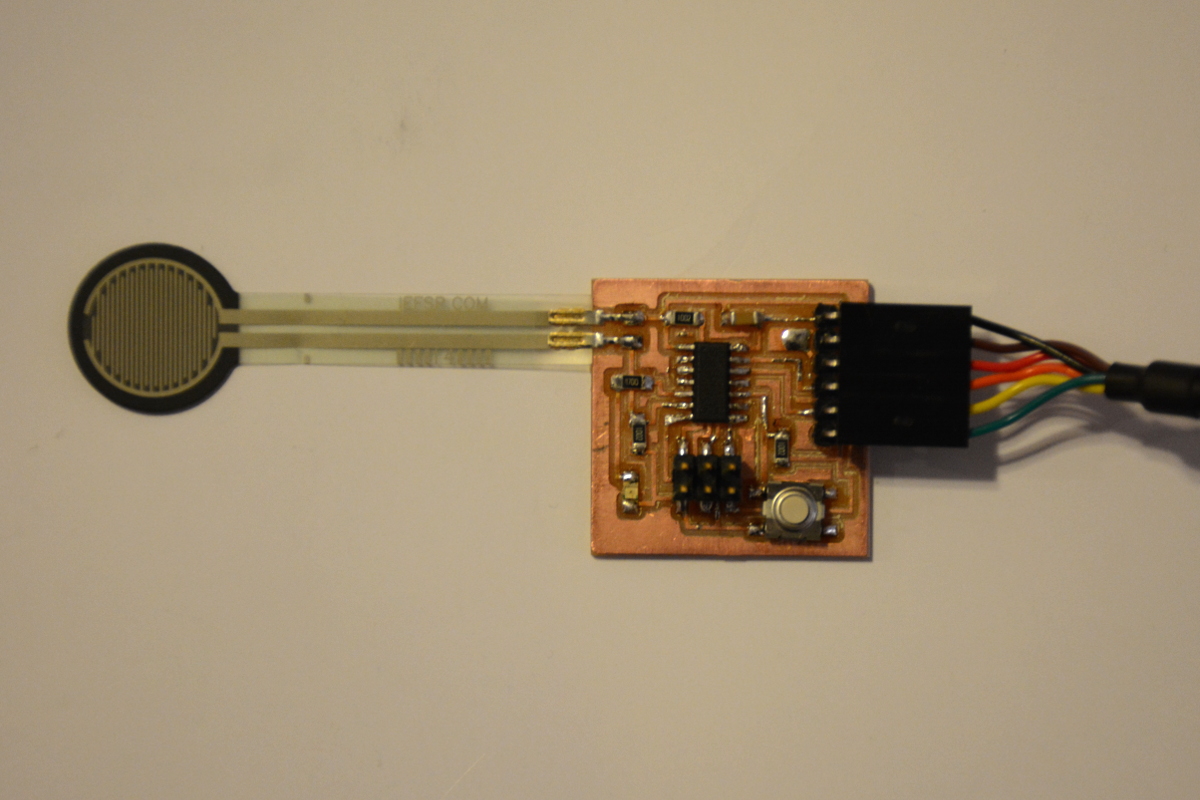

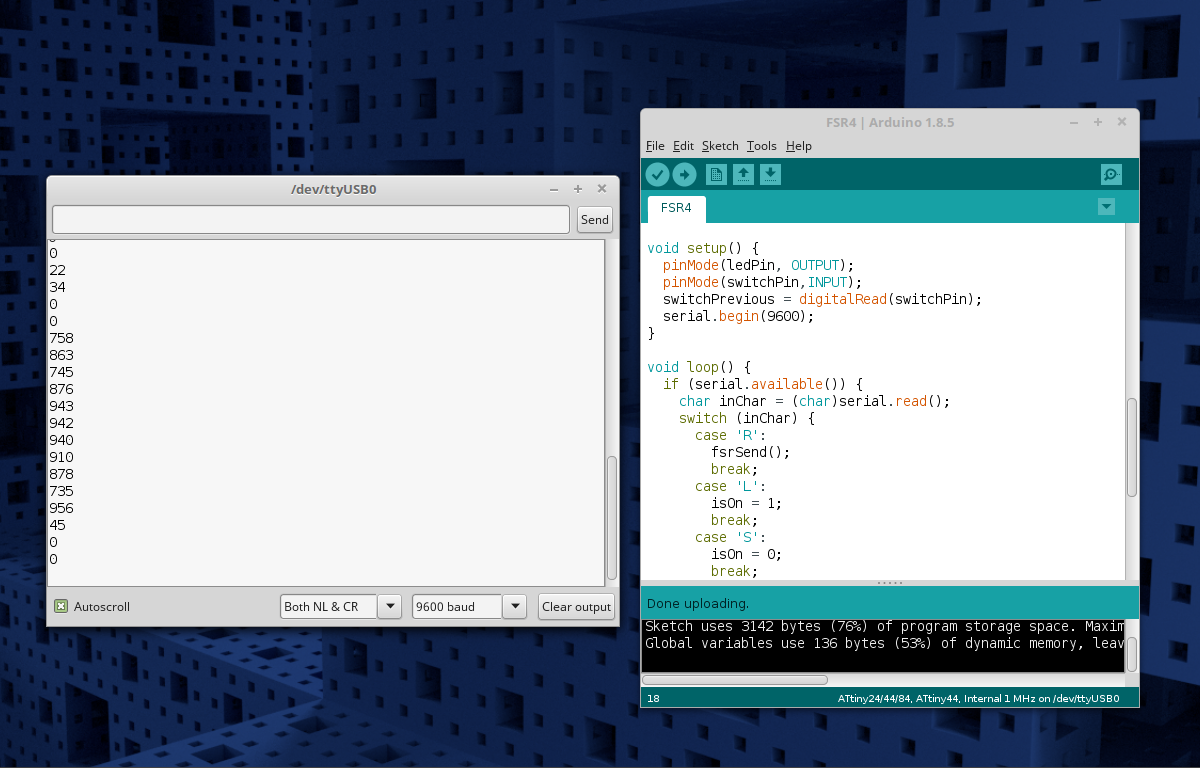

Programs on input device board

Because, I am not in Paris, I didn't have an easy access to multimeter or other control devices.

So, I made different programs to control my board and see if all work right before making my final program.

Led test

/*

* input device

* led test : just blink twice a second

*/

const int ledPin = 8;

void setup() {

pinMode(ledPin, OUTPUT);

}

void loop() {

digitalWrite(ledPin, HIGH);

delay(500);

digitalWrite(ledPin, LOW);

delay(500);

}

Switch test

/*

* input device

* Switch test : turn the led on when switch button is pressed.

*/

const int ledPin = 8;

const int switchPin = 3;

int switchState = 0;

void setup() {

pinMode(ledPin, OUTPUT);

pinMode(switchPin,INPUT);

}

void loop() {

switchState = digitalRead(switchPin);

if (switchState) {

digitalWrite(ledPin, LOW);

} else {

digitalWrite(ledPin, HIGH);

}

}

FSR test

/*

* input device

* fsr test : make the led blink faster when you press the FSR sensor.

*/

const int ledPin = 8;

const int fsrPin = 7;

void setup() {

pinMode(ledPin, OUTPUT);

}

void loop() {

int value = analogRead(fsrPin);

if (value==0) {

digitalWrite(ledPin,LOW);

} else {

value = map(value,0,1023,500,20);

digitalWrite(ledPin,HIGH);

delay(value);

digitalWrite(ledPin,LOW);

delay(value);

}

}