Thermoforming

Thermoforming is an interesting way to produce several pieces (small series) quite fast with only a master.

Thermoforming is an interesting way to produce several pieces (small series) quite fast with only a master.

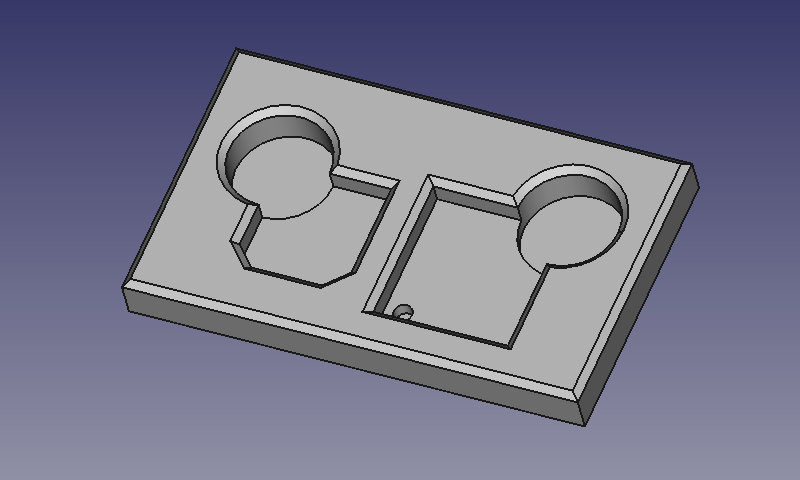

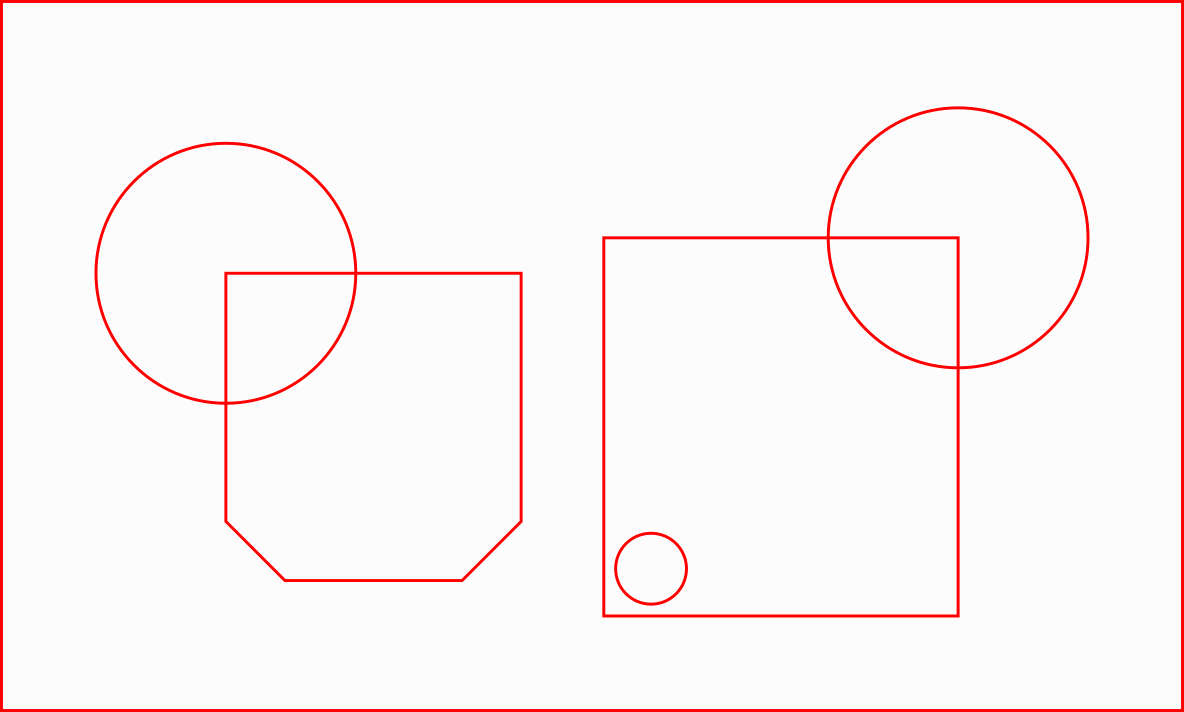

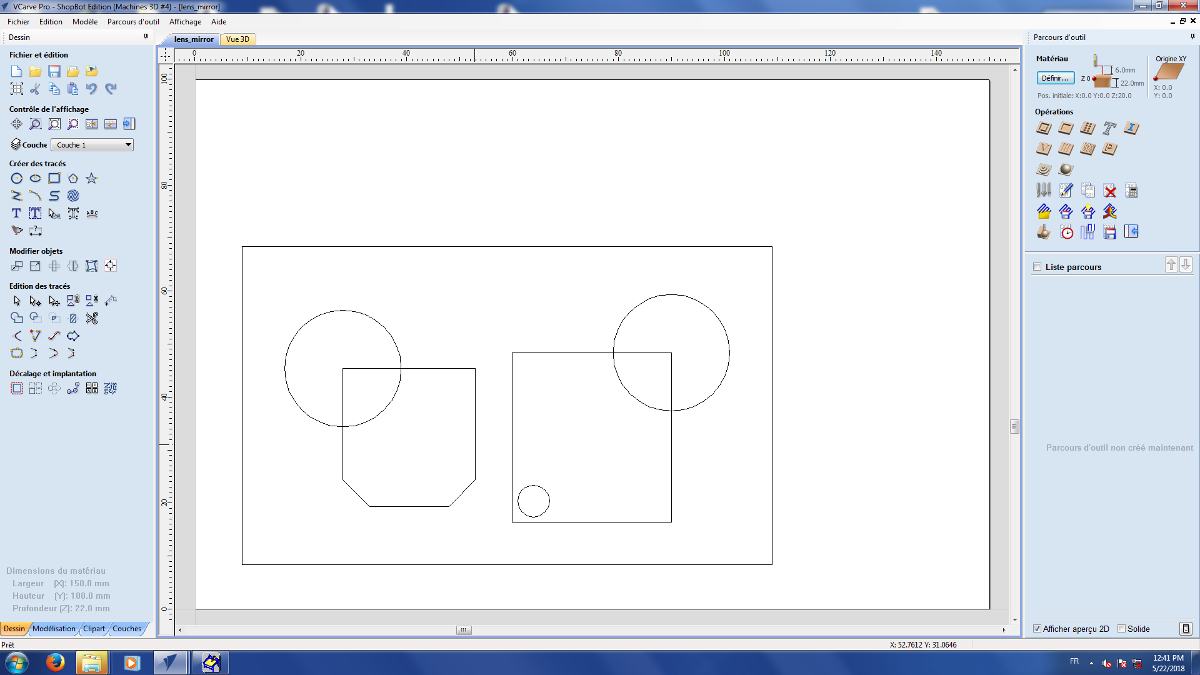

Whith my milled piece, I can now thermoform my store box.

I used a Formech compac mini

Fabrication process is :

- put your piece on a grid in the bottom part

- put a sheet of PET (width 250 mm , height 300mm, thickness 1.5 mm)

- fix it with the interlock system

- pull the heater part above the sheet

- wait the timer (60 seconds fo our sheet)

- remove the heater

- turn up the master piece

- vacuum the air (few seconds are enough)

- release and get the sheet

The most difficult is to remove the master piece after thermoforming. I had to put screws in the master piece to help me to pull.

Next time, I should be aware of it when designing my piece, add chamfer, use conic shapes.

As MDF is a porous material, machine can vacuum through material and plastic can easily go in holes and pockets.

To show that lens and mirror have been cleaned after work, we used to let them unmounted in the laser cutter.

To show that lens and mirror have been cleaned after work, we used to let them unmounted in the laser cutter. Thermoforming a 3D printing piece seems not to be possible because the sheet of plastic is hot and will heat the master piece.

Master piece can distort or glue to the sheet.

Thermoforming a 3D printing piece seems not to be possible because the sheet of plastic is hot and will heat the master piece.

Master piece can distort or glue to the sheet.

Thermoforming is an interesting way to produce several pieces (small series) quite fast with only a master.

Thermoforming is an interesting way to produce several pieces (small series) quite fast with only a master.