Week 4 : Computer-Controlled Cutting

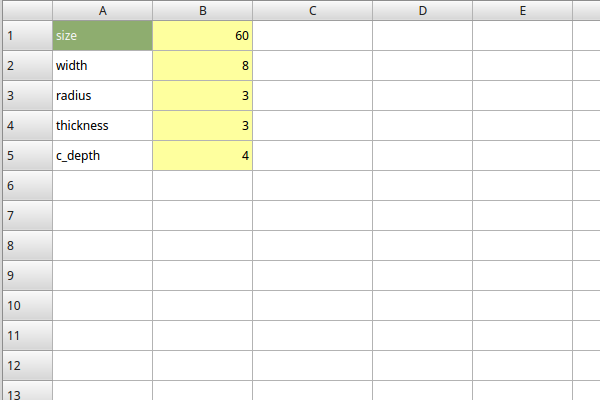

- make lasercutter test part(s), varying slot dimensions using parametric functions, testing your laser kerf & cutting settings (group project)

- cut something on the vinylcutter

- design, make, and document a parametric press-fit construction kit, accounting for the lasercutter kerf, which can be assembled in multiple ways

Vinyl Cutting

There is no specific project that is focussed on this very useful tool. There are a range of ways you might utilise it throughout the programme, or your local instructor may set a specific project. You might make:

- stickers

- flexible circuit boards

- a textured surface/relief pattern

- screenprint resists/stencils

Ensure that you have used it in some way during this time and met the objectives below.

For my press-fit construction kit, I thought about a triangular module with different holes inside to let the light go through.

For my press-fit construction kit, I thought about a triangular module with different holes inside to let the light go through. I like clones very much because you can easily change size of all parts but cloning is not strictly parametric.

I like clones very much because you can easily change size of all parts but cloning is not strictly parametric. At home, my children always forgot to close the toilet cover.

Rather than repeat again, I decided, this week, to make a sticker. Cover lid will ask my children to close it.

First, I think about the message. I want it to be more a wink than an order just for my kids to remember to close the cover.

At home, my children always forgot to close the toilet cover.

Rather than repeat again, I decided, this week, to make a sticker. Cover lid will ask my children to close it.

First, I think about the message. I want it to be more a wink than an order just for my kids to remember to close the cover.