VINYL CUTTYING

1.ROLAND VINYL CUTTER

Vinyl cutter is a type of machine using for the cutting of thin vinyl sheets,copper sheets . This machine is using for making stickers in verious types and can print soft electronic circuits ROLAND VINYL CUTTER is using in our lab. In this machine there is a knife which rotates its on axsis also have two rollers in either side which roles the sheet up and down and make tight the sheet at cutting prosses . The CNC arrangement give leniar motion to the knife and the cutting velocity and force can change according to the material as you use it.

MACHINE SETTINGS

Press the handle to the left side

Load the sheet from the back

Make the Roller fit in both sides, place

it in the white line and make sure the region of draw inside that

roller

On the machine and bring the head into

position

Select the type of sheet.

Move tool at location want to start using

Arrow keys.

Set the origin at a longpress in origin button.

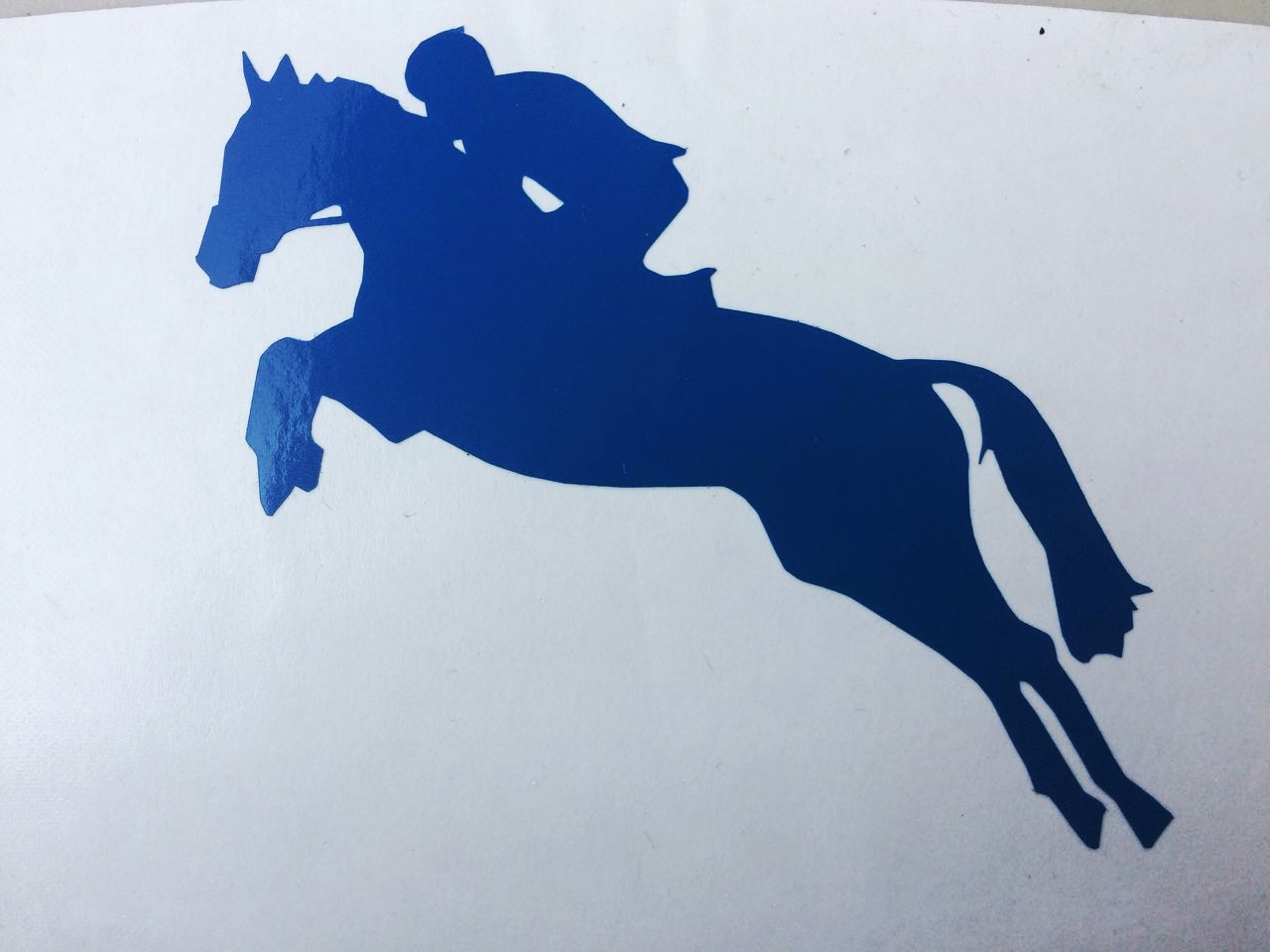

2.MY EXPERIMENT IN VINYL

I want to make a sticker when i saw the working of the machine . The idea is very simple but i want make the start in simple way where i got more idea to study how we can use the device . Then I searched an image on google for cutting in the machine

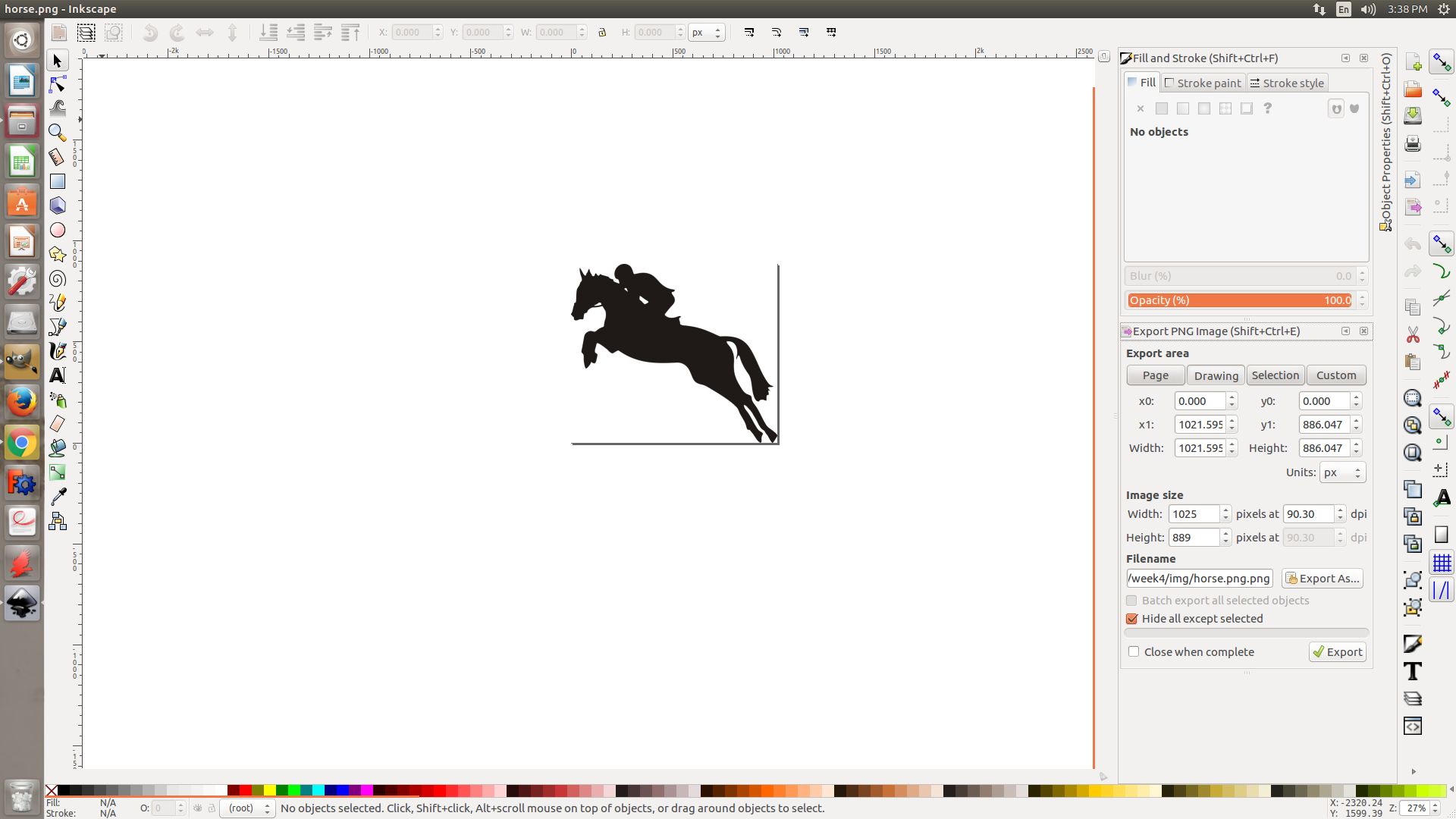

The image was in .jpg file in the cutting prosses we want give .png file on the machine . Only .png image file can cut on the device , we can convert .jpg into .png through any vector file software so I used INKSCAPE for convert my file into .png

I already download a vector image so i didn't want make that into vector image through bit mapping in inkscape.

How to use the device

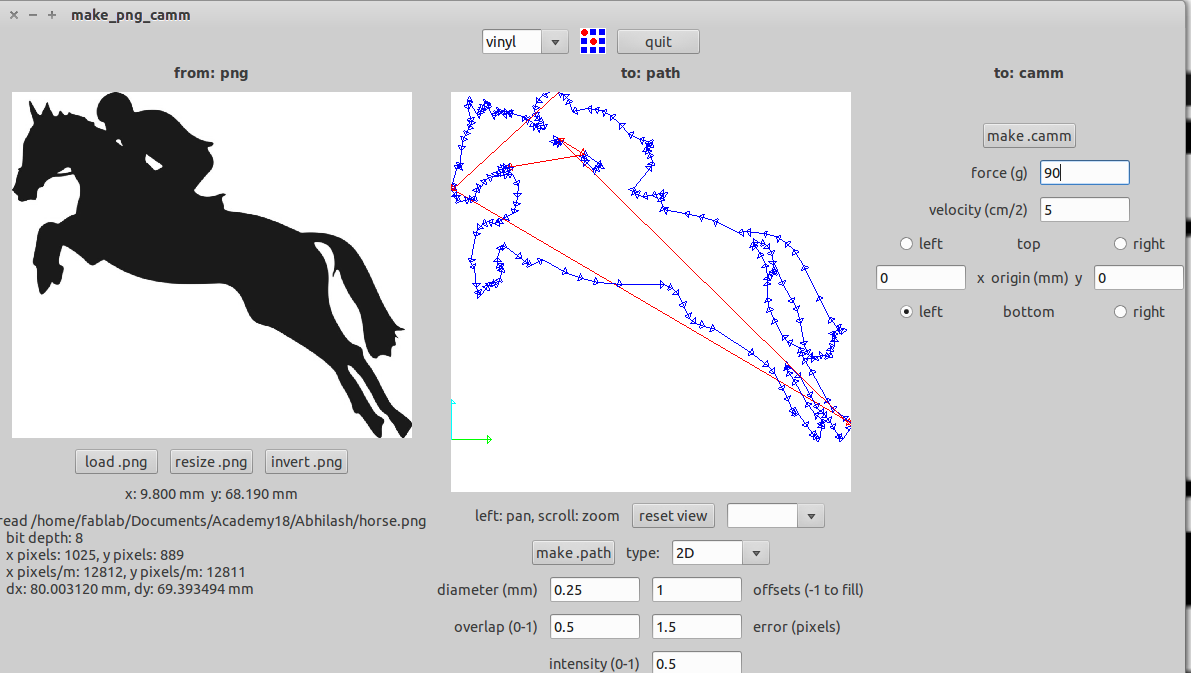

We convert our .png file into toolpath by fabmodule.using fab module give the INPUT FORMAT and OUTPUT PROCESS then MAKE PNG CAMM. Then a new window will appear with these keys

LOAD.png < select your image

Then give FORCE and VELOCITY < for clear cutting

Resize .png < fore giving scale

Then MAKE.CAMM> SENT IT

Here I use FORCE=90 & VELOCITY=5 also gave the error as "1" but i got a mistake in giving the scale of the file ,after i make sent it the machine take more space for cutting due to high scale. Then suddenly i pause the device for recreating the scale for cutting

I resize the .png file as x=9.8mm & y=68mm the balance are the same the sent it for cutting.After cutting i pealed succesfully that i want .

Here i got an exicting experence on laser cutting Introduction of new machine that we can use for cutting ,engraving through laser beam .Here we can make press fit kit that can assemble into any models . Our lab has TROTEC SPEEDY 100, here co2 laser beam is generating

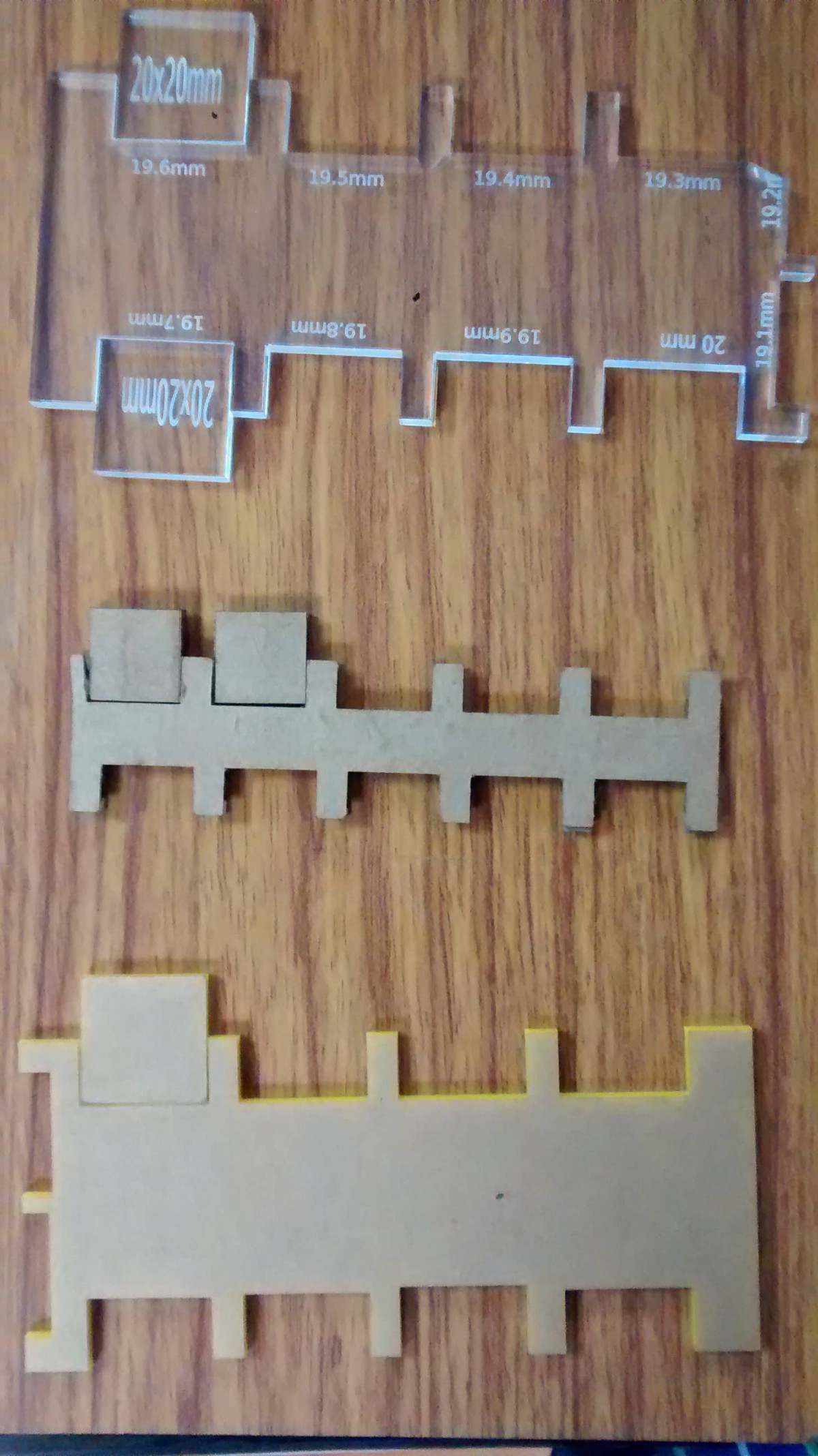

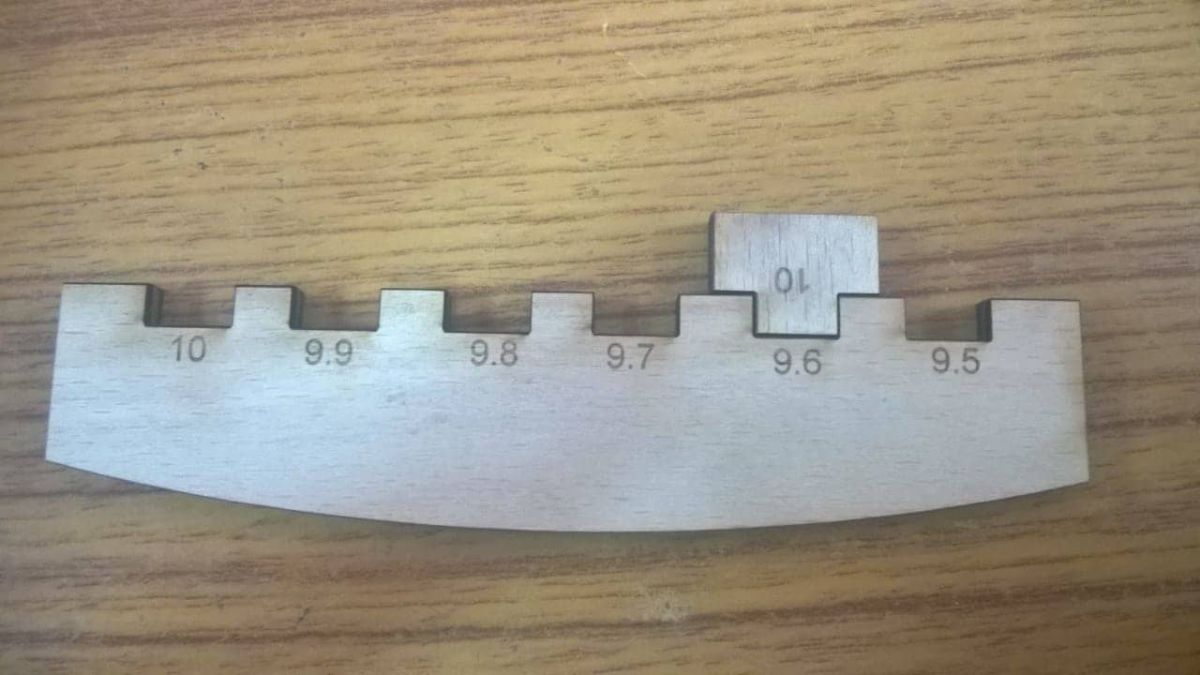

GROUP ASSIGNMENT

Our group assignment was to find the kerf (Dimension reduced due to the cutting operattion)value of various meterial like ACRYLIC,CARDBORD,WOOD .After making some desings for finding the kerf with lowering order of almost reading corresponding to the thickness of meterial . Then we got the kerf values of ACRYLIC =0.3mm,WOOD=0.3mm & CARDBORD=.2mm

MACHINE SETTINGS

Inside the machine there is a laser head ,at first we want to set the origin then focus the laser by Focusing tool as follows,we can move the bed up and down using the button and also we can move the laser head in leniar motion by the keys.Then load the sheet on the bed ,after focusing the laser set the orgin and cut.

Working of the machine

Here Inkscape vector software is using for simple editing operations , Boundary creation and mainly using for select RED 255 colour for easy cutting also BLACK for engraving by the machine .

Open the dot file into inkscape then copy the number of pieces necessary .Select all give the strok paint RED255 for cutting and BLACK for engraving give the scale then print .ok

A new window will be open give the height and width of the print document then give print. The device starts working .

creation of my press fit

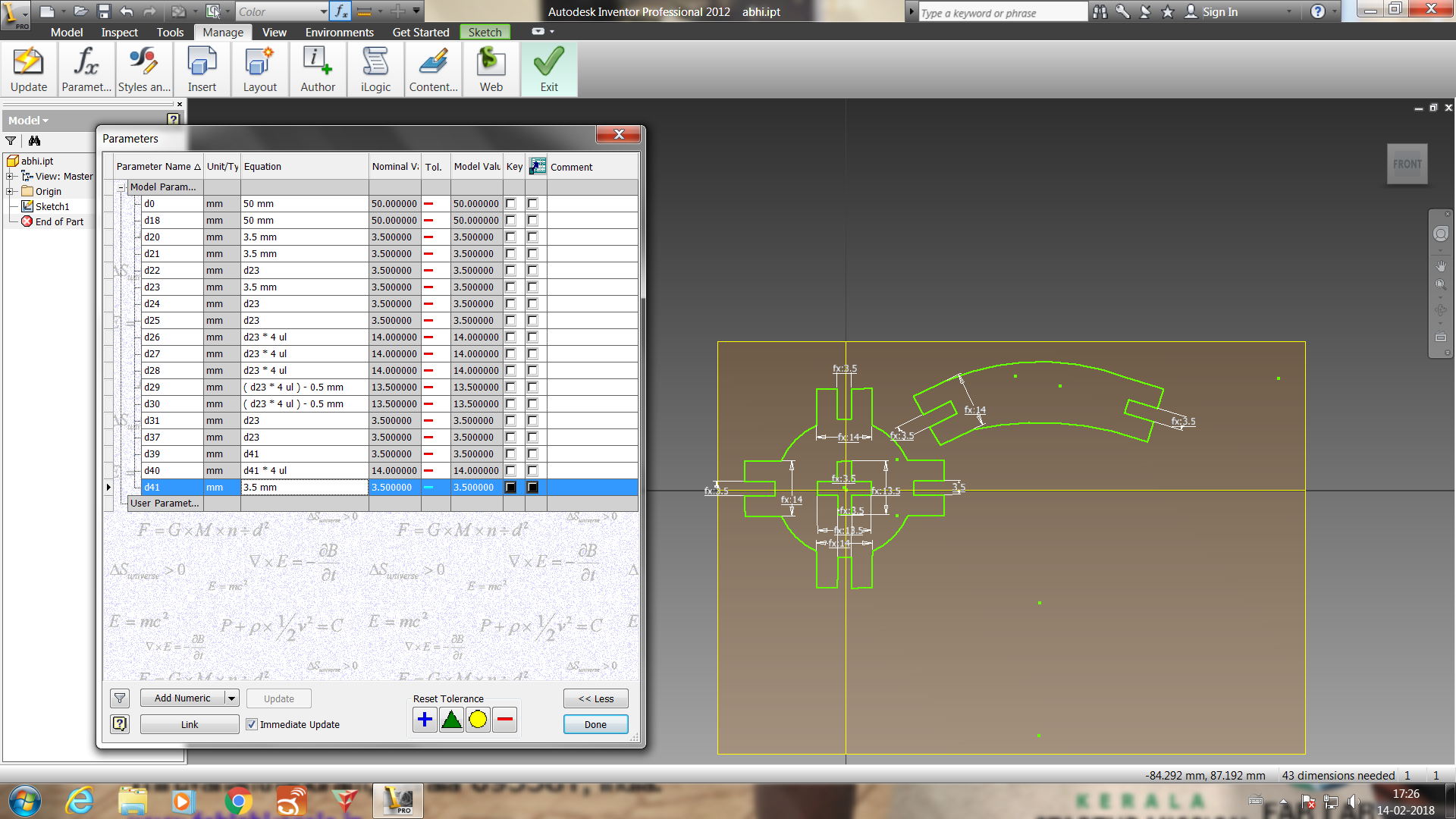

I just a created press fit kit for making more shapes .I draw some shapes having multiple fit in INVENTOR ,For drawing I just selected a plane first for that I take the new file as 2D model,Here I used line , cirle and arc tools only the I just gave the fuction paramiter for each slots that help me to give the wright diamension to all sides

just draw a simple model by giving parametric functions download as .dxf file then open it in the INKSCAPE. After copied I only want to cut so gave the stroke paint as RED255 then gave print .Then in the new window i gave the scale as 300*300 gave the name of meterial print.

Then i assembled it into a 3D state

.PNG file for vinyl

press fit file you can download here