Home

Week Seven : Electronics Design

Assignment

Redraw the ECHO-HELLO WORLD Board and add atleast one button and an LED (with current limiting resistor)and check the design rules and make it.

ECHO-HELLO WORLD Board

For designing I came through a new software called "EAGLE"

Downloaded the latest version of Eagle and have downloaded the "fab.lbr" - a library function in Eagle, and added to the software.

Added new project >> Assignment

Assignments related to electronics begins with challenge, our instructors is quite helpfull in these challenging situations.

Wonderfull session on basic electronics and uses of components by instructors made this assignment bit easier.

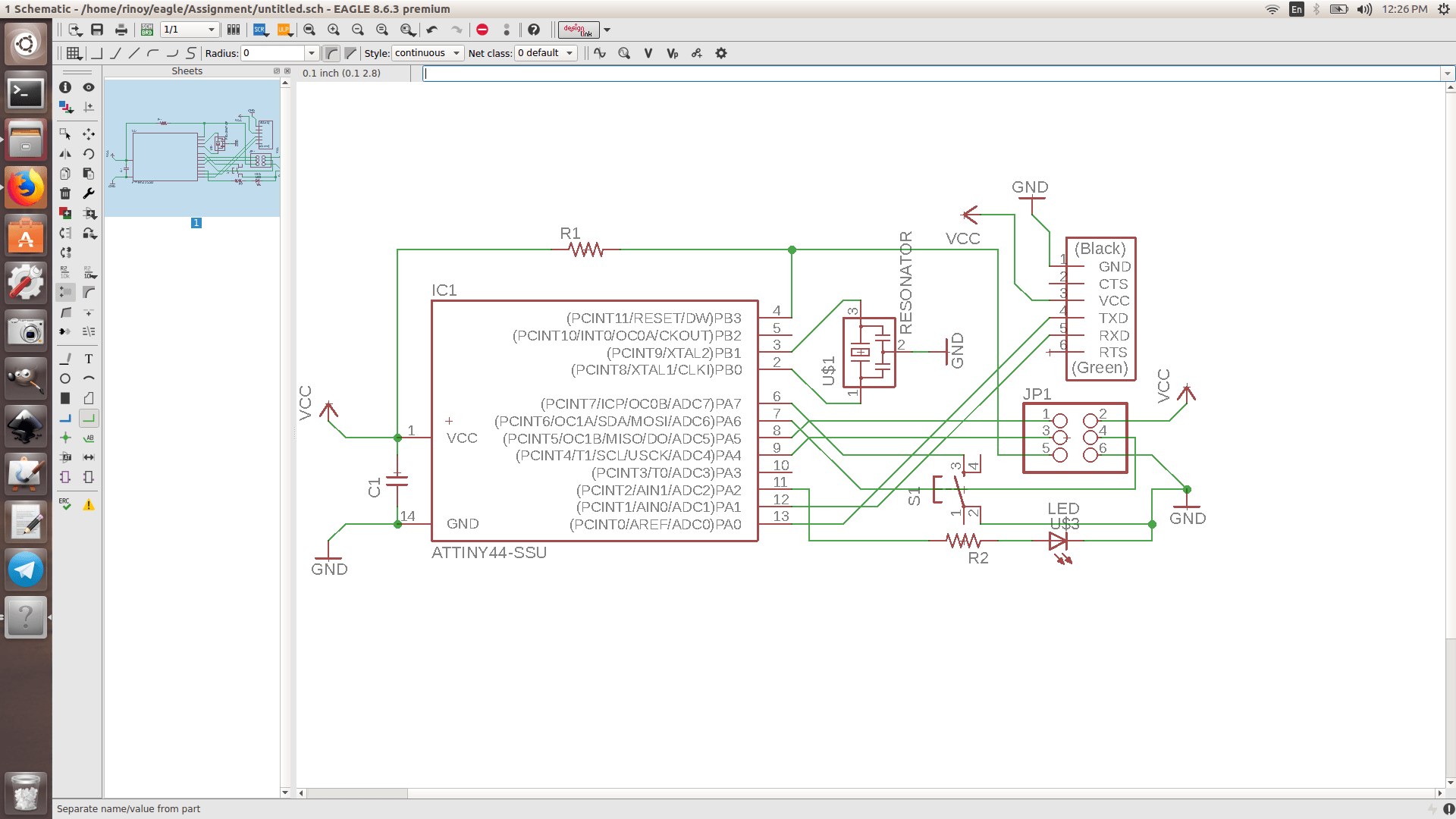

First Step : The schematic representation of my Echo-Hello board is as follows

I have added the components using a command "ADD", and connected the components using "net"

PCB - Printed Circuit Board, mechanical support and electrically connects electronic components using conductive tracks, pads from the sheet of copper layer.PCB is a simplest electronic product.

Here Im using a single sided PCB for my assignment.

Here we use ATTINY44-SSU Microcontroller to flash the Echo program on my PCB

Resonator is connected to Microcontroller, which acts as an external clock(connected to PB0 and PB1 of Microcontroller).The value of Resonator used is 20Mhz.

Capacitor(connected to PB3 of Microcontroller) is connected to Microcontroller, which is used to filter the ripple voltage.Value of capacitor is 1uF.

FTDI(connected to PA0 and PA1 of Microcontroller) chip is connected to Microcontroller, inorder to send and receive data to a programmer.

ISP pinout(connected to PA4 and PA5 of Microcontroller) is connected to Microcontroller, so that PCB can generate necessary programming voltage from system's normal voltage supply and to communicate with the programmer.

Resistor(connected to PB3 of Microcontroller)

Added extra Resistor(connected to PA2 of Microcontroller), LED(connected to PA2 of Microcontroller) and a switch(connected to PA6 of Microcontroller), which will be programmed on EMBBEDED PROGRAM WEEK

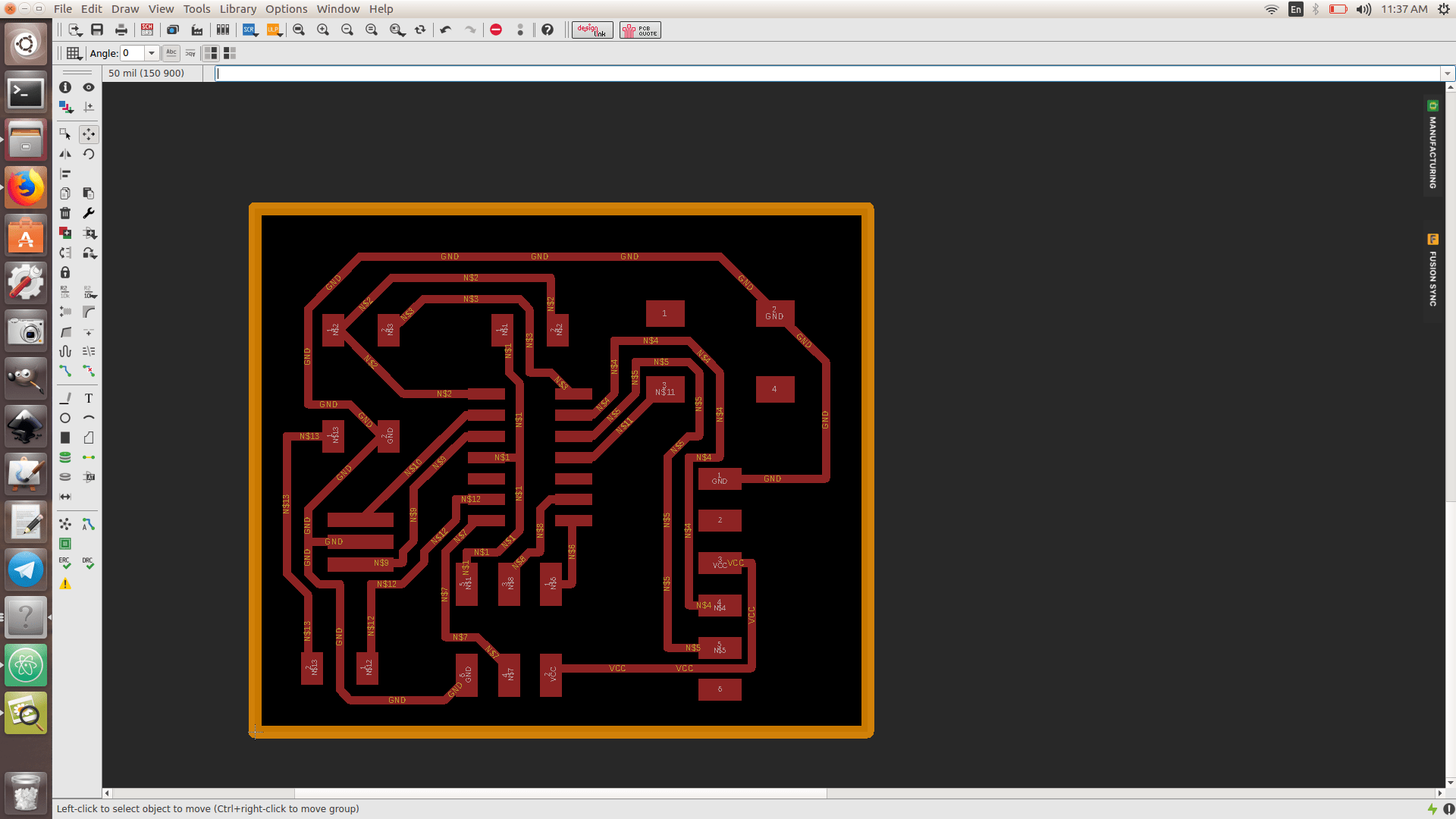

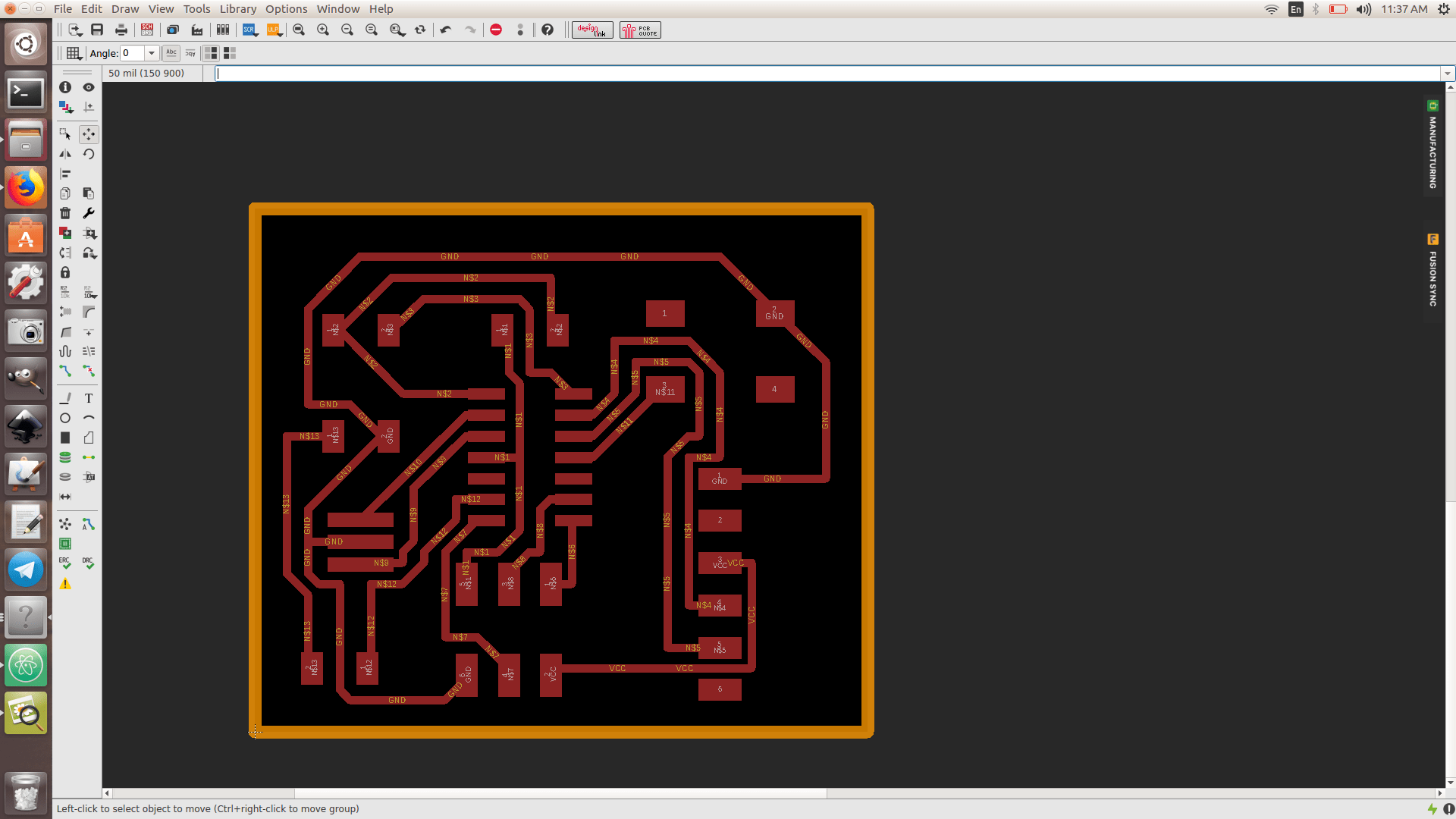

Second Step : Switch to Board

File >> Switch to Board

Here I had to arrange every components manually and orderly.Border dimension are set here.

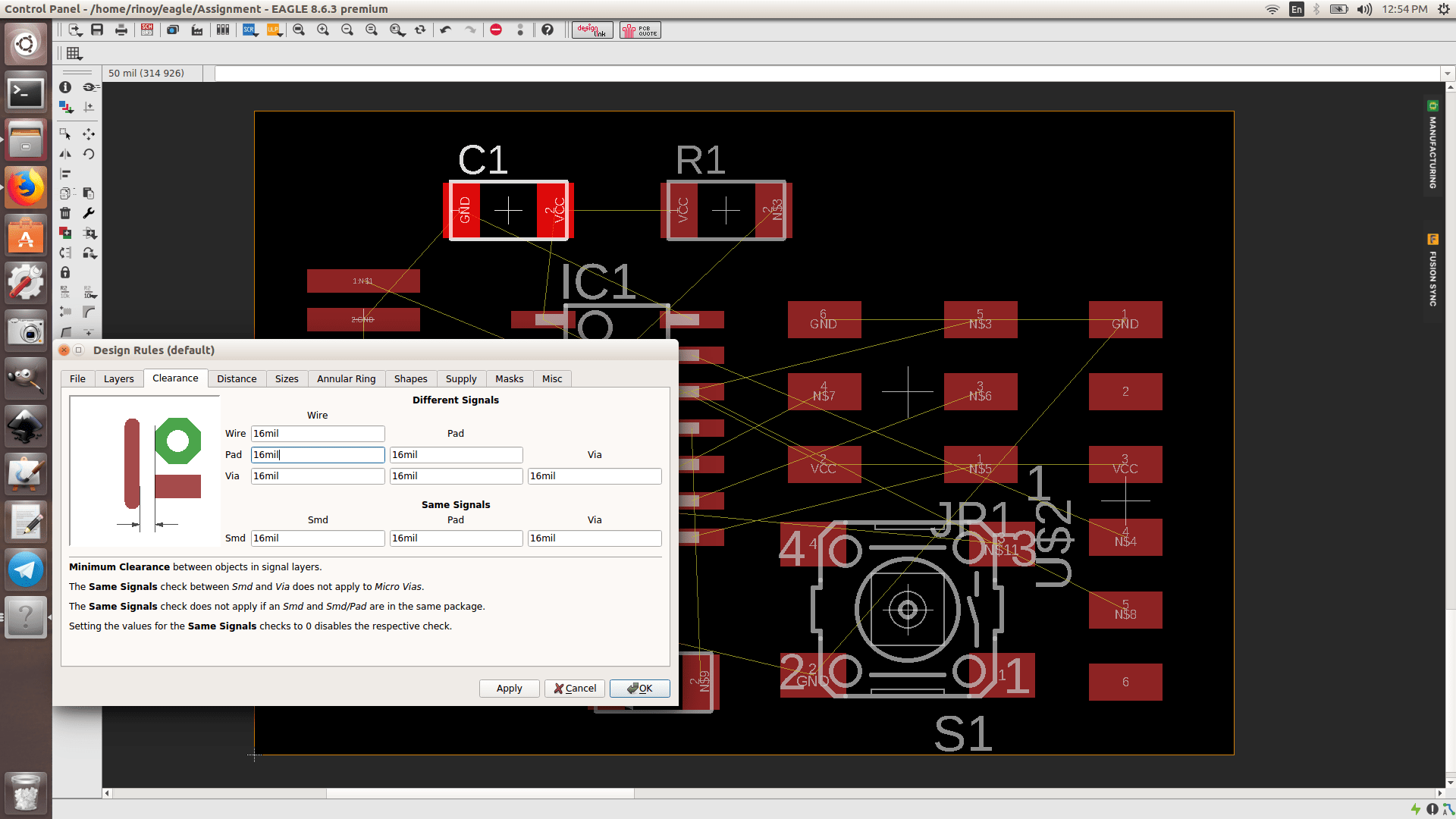

Third Step : Set Design Rules

Had set Clearance values - 16mil for Wire, Pad, Via and SMD

Had set Clearance values - 18mil for Size

Edit >> Design Rules

Fourth Step : Set AutoRouter

Had autorouted many times to make 100% optimized.

Tools >> AutoRouter

Set

Preferred Directions >> Top >> (-) and Bottom >> (NA)

Efforts >> High

Continue

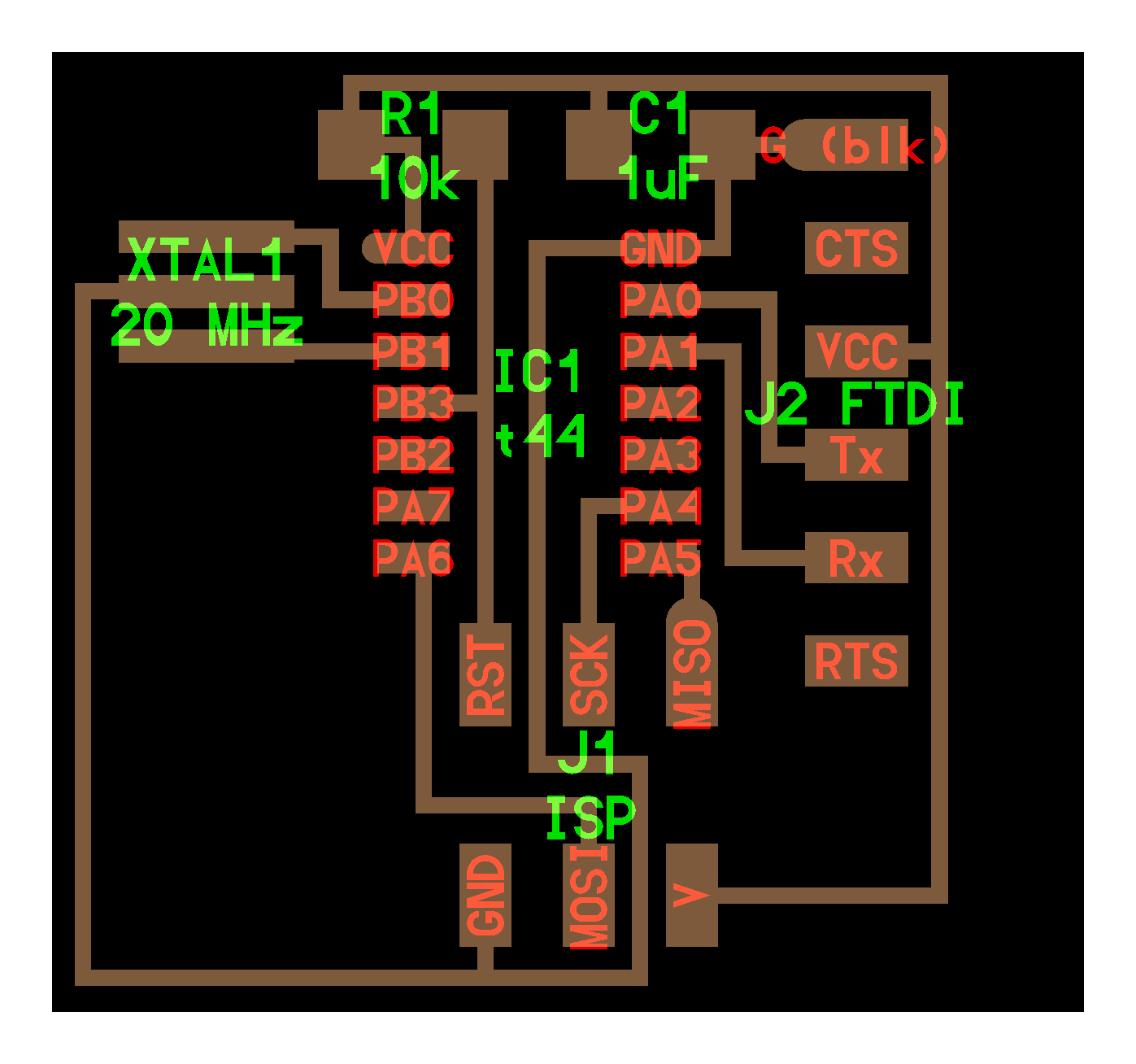

MY BOARD DESIGN

Designed and border width is set.

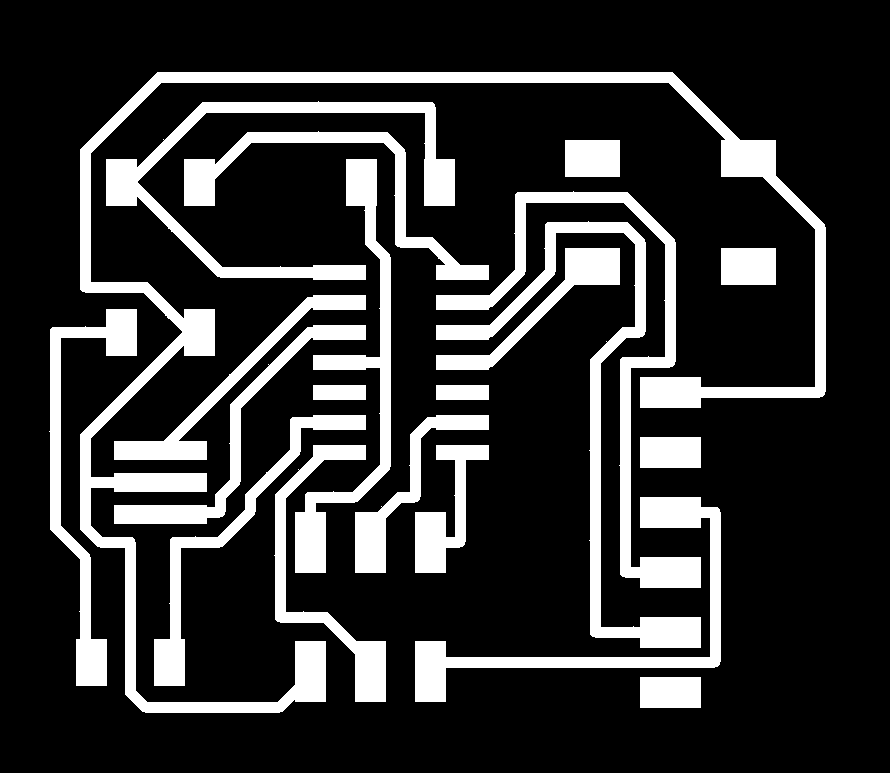

Fifth Step : Set trace to Mill

Had exported from eagle with monochrome and with 600 pixel.

Layer Settings >> Top and Pads

File >> Export >> Image >>Select Monochrome >> Resolution - 600 pixel

OK

Sixth Step : Set trace to Cut

I had a extra surface at the bottom, I covered that by using GIMP, Tools >> Paint tools >> Bucket fill

Layer Settings >> Dimension

File >> Export >> Image >>Select Monochrome >> Resolution - 600 pixel

OK

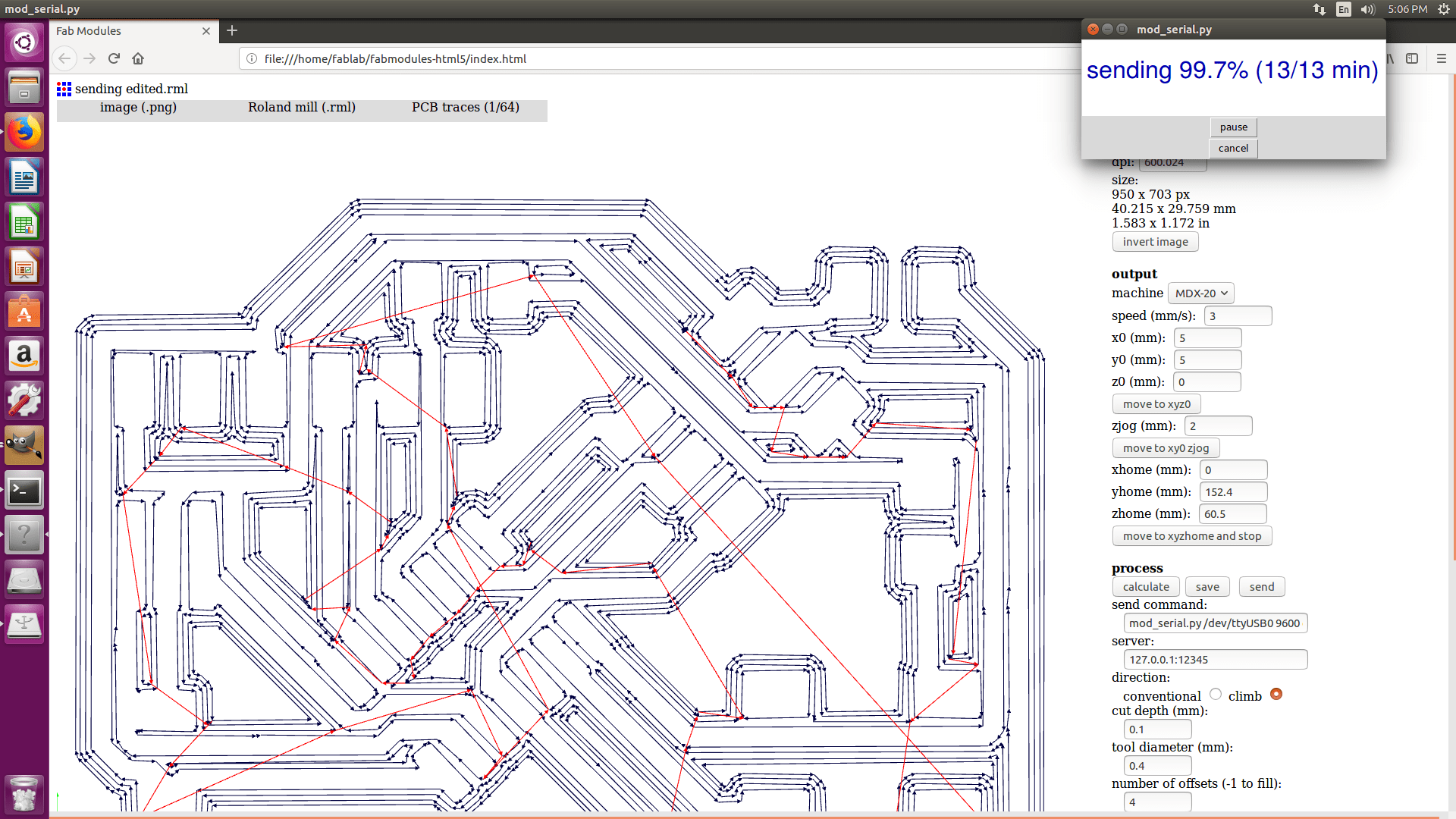

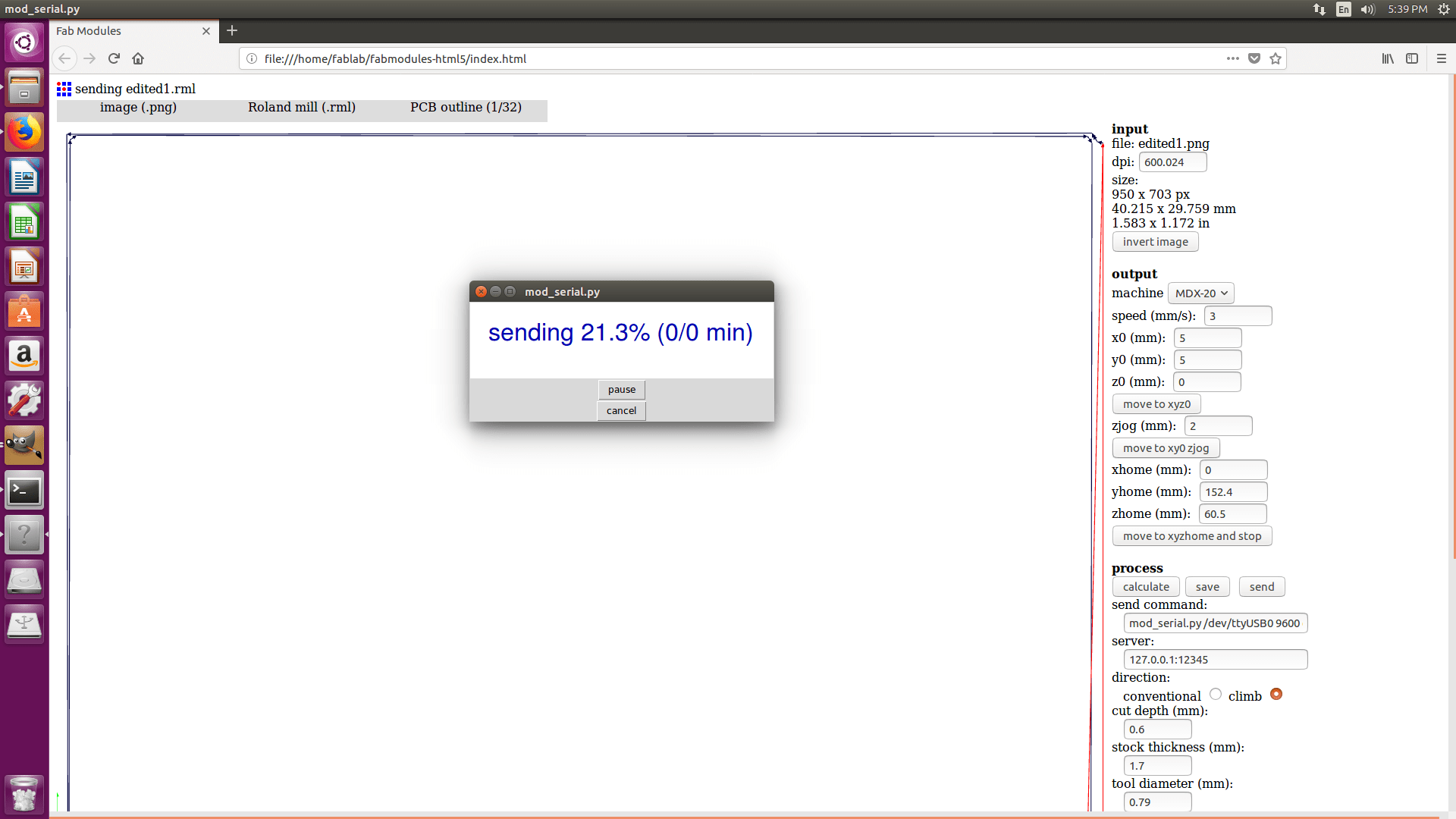

Seventh Step : Milling

Used fabmodules to create the file for milling and Cutting purposes.

1. Load the PNG file(mentioned in 5th step)

2. Select Roland Mill

3. Select tool >> PCB traces 1/64

4. Set bed axis

5. Set the speed

6. Calculate and Send

Eighth Step : Cutting

1. Load the PNG file(mentioned in 6th step)

2. Select Roland Mill

3. Select tool >> PCB traces 1/32

4. Set bed axis

5. Set the speed

6. Calculate and Send

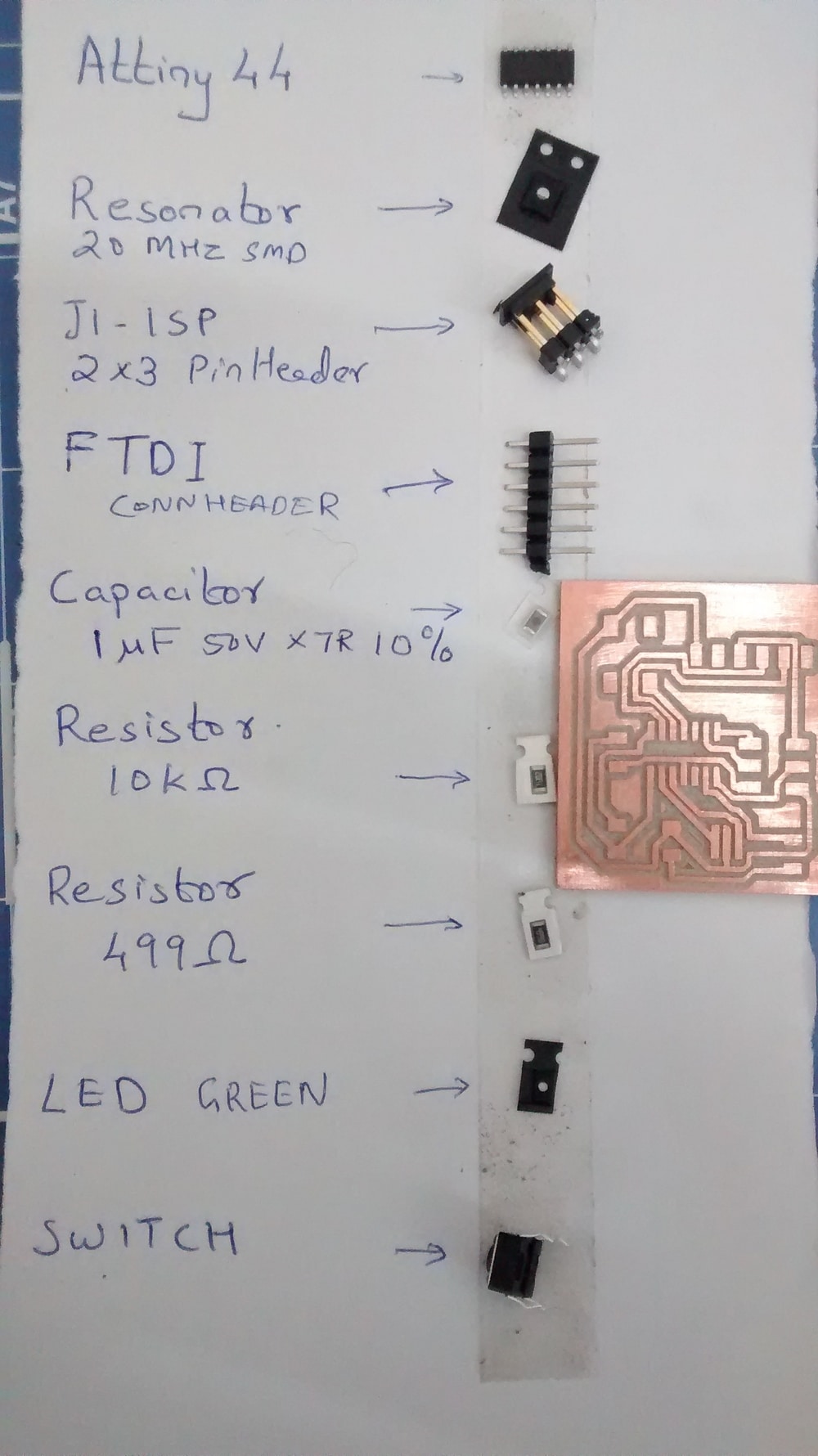

Ninth Step : Soldering

Soldering is the process in which two or more items joined together by melting solder wire into joint.

1. Soldering wire used is Lead

Lead has low melting point, so it is easy to solder components with PCB

2. Soldering Flux

Flux is used to prevent Oxidation of base of PCB and components

Added all components needed for Echo-Hello World Board, namely -

1. 1x ATTINY44-SSU - SOIC14

2. 1x FTDI-SMD-HEADER

3. 1x RESONATOR

4. 1x PINHD-2x3-SMD

5. 1x CAP-UNPOLARIZZEDFAB - C1206FAB

6. 1x 6MM-SWITCH - OMRON SWITCH

7. 2x RES-US1206FAB

8. 1x LED FAB1206

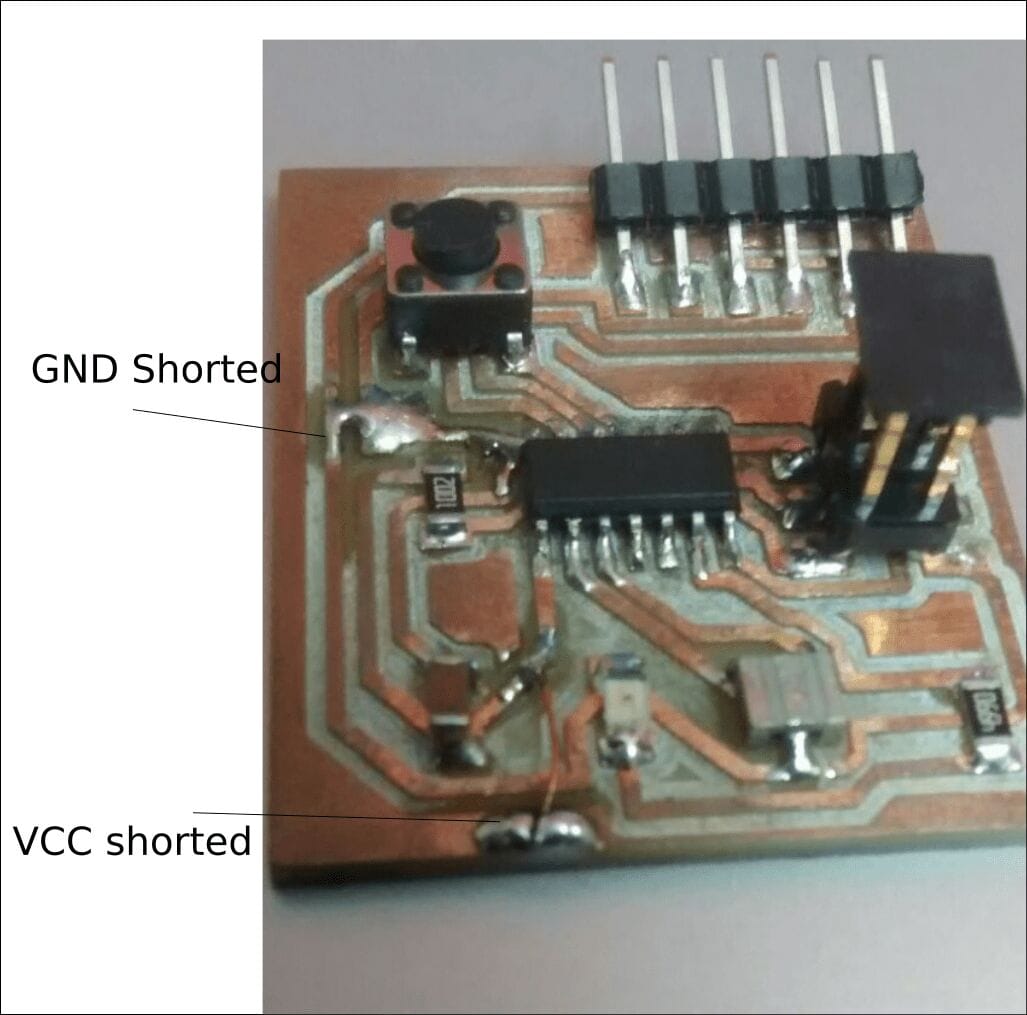

My PCB

Here I made a mistake of not giving VCC and GND to Microcontroller.I have soldered GND and put a jumper using copper coated wire to connect VCCs

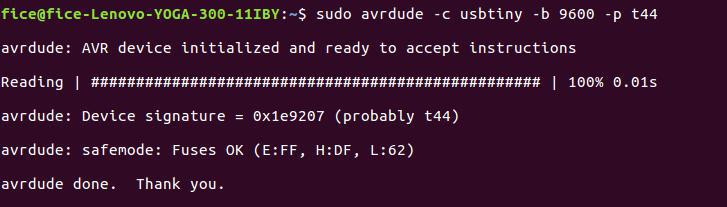

Communication is checked using

sudo avrdude -c usbtiny -b 9600 -p t44

Tenth Step : Programming - Make fuse

Downloaded .make and .c file from schedule in Fabacademy

Renamed .makefile to Makefile

Connect USBtiny to ECHO-HELLO BOARD

Open terminal and enter

make

make program-usbtiny-fuses

make program-usbtiny

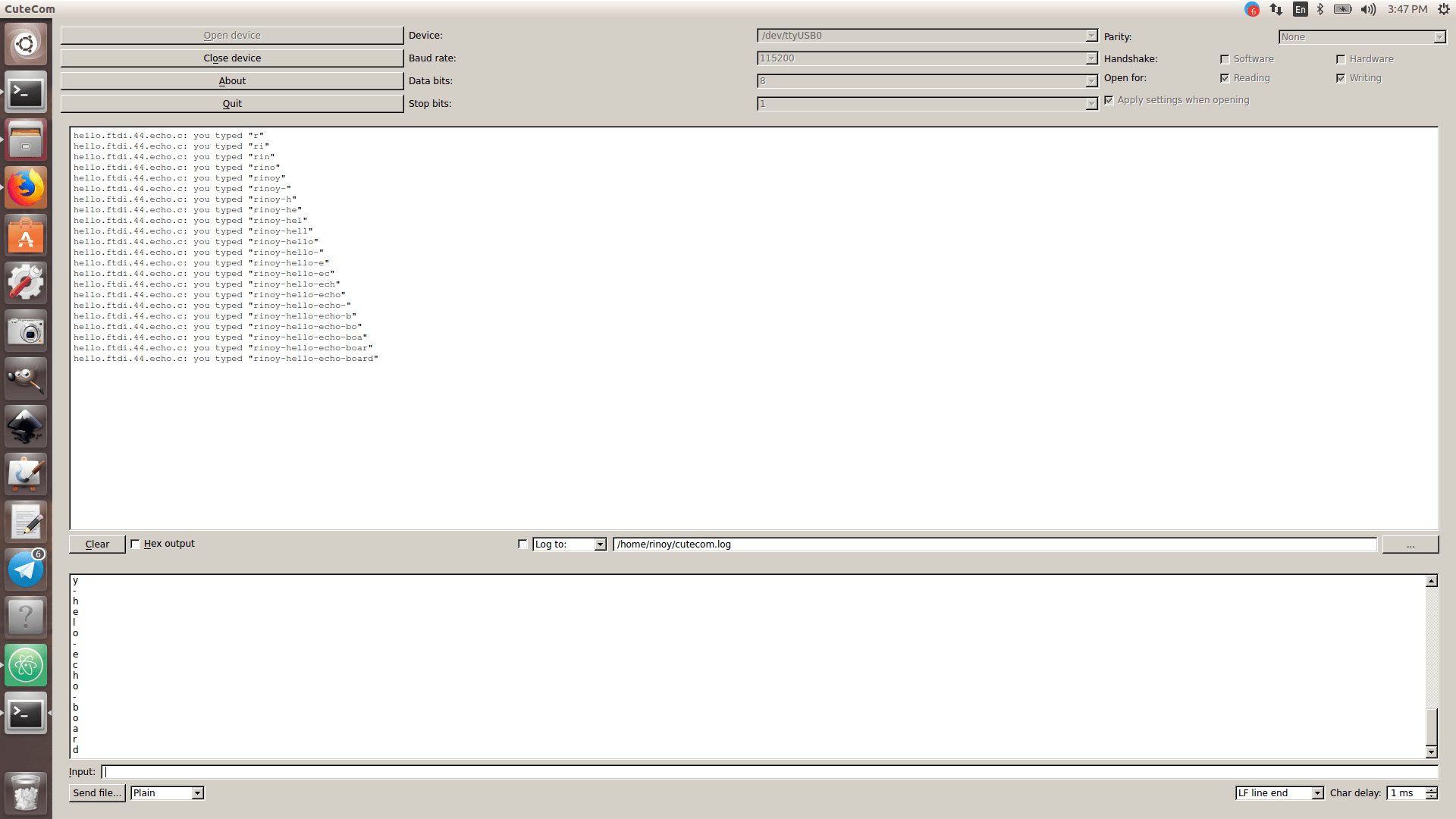

Step Eleven : Install Cutecom and Repeat ECHO-HELLO.

sudo apt-get install cutecom

Connect ECHO-HELLO BOARD to USB-Serial Converter

Add device

Check the working of ECHO-HELLO BOARD

Group Assignment

Characterize the specifications of your PCB Production Process

Our Instructor Vinod gave us great idea on Dual Channel voltage regulator, Digital Oscilloscope and Arbitary Function Generator.

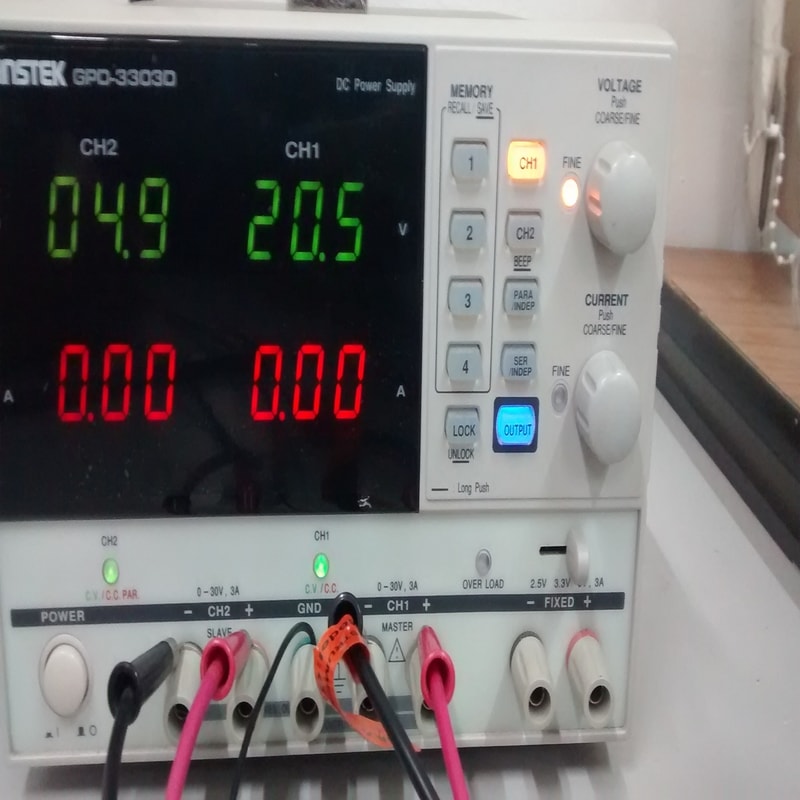

Dual Power Supply

This device can adjust or vary from 0-30V

There is two channels in this device - where we can draw upto 3Amp current

There are individual GROUND and POSITIVE for each channel and common NEGATIVE

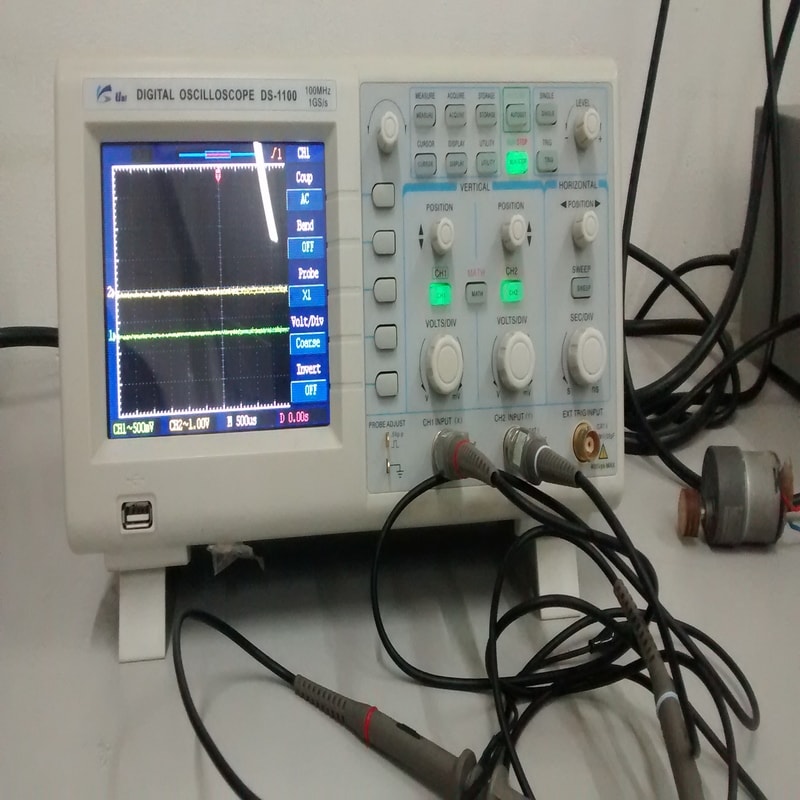

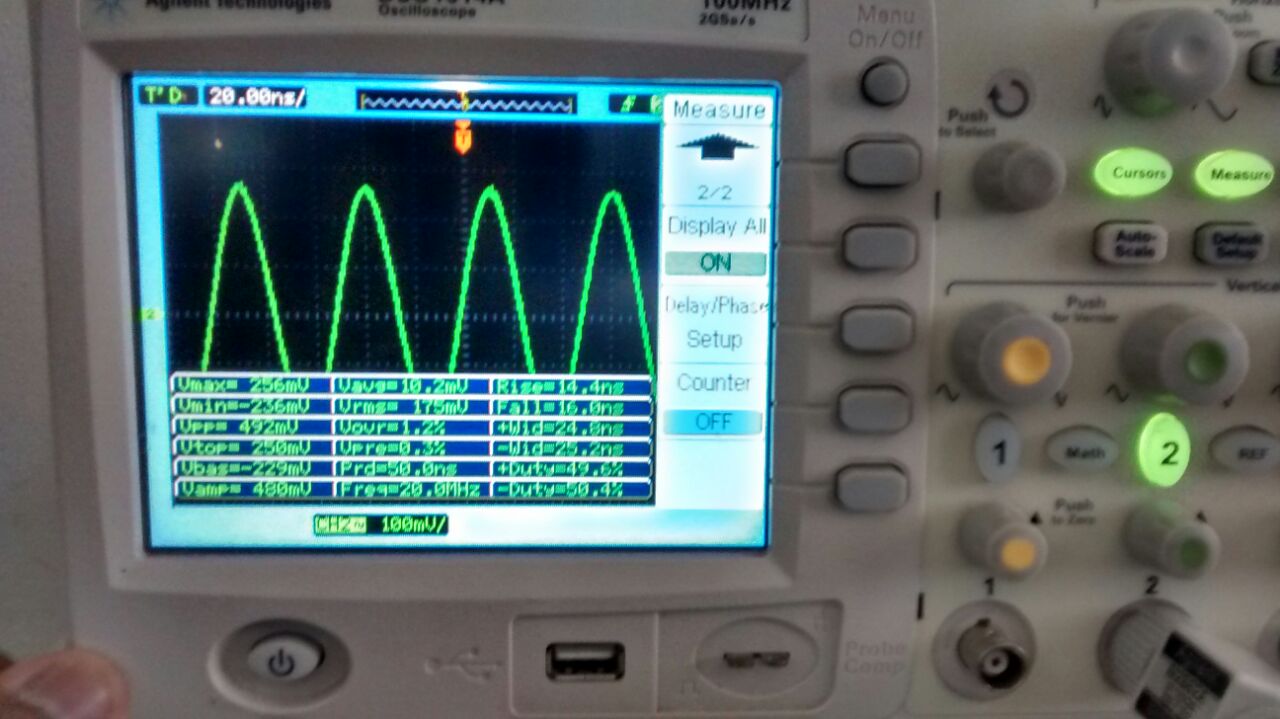

Digital Oscilloscope

This device is used detect signals like Amplitude, Time and Frequency

Contains 2 channels so, Can check upto 2 devices using this machine

We checked our board and measured the value of Resonator.

It shows the actual value of 20mhz in display

Arbitary Function Generator

This device is used to generate waveforms like Square Wave, Sine Wave, Pulse, Triangular Wave, Noise

Multimeter

Multimeter is used to measure Voltage, Current and resistance

Multimeter is also used to trouble shoot electrical problems

Multimeter is a combination of a multirange DC voltmeter, multirange AC voltmeter, multirange ammeter and multirange ohmmeter

Checking the Power Source Voltage of my PCB and output voltage is 5.087