Wheek 16: Machine Design.

This week our team, Carlos Herbozo, Nicolas Newton and Fabricio paredes built the CNC router we designed last week.

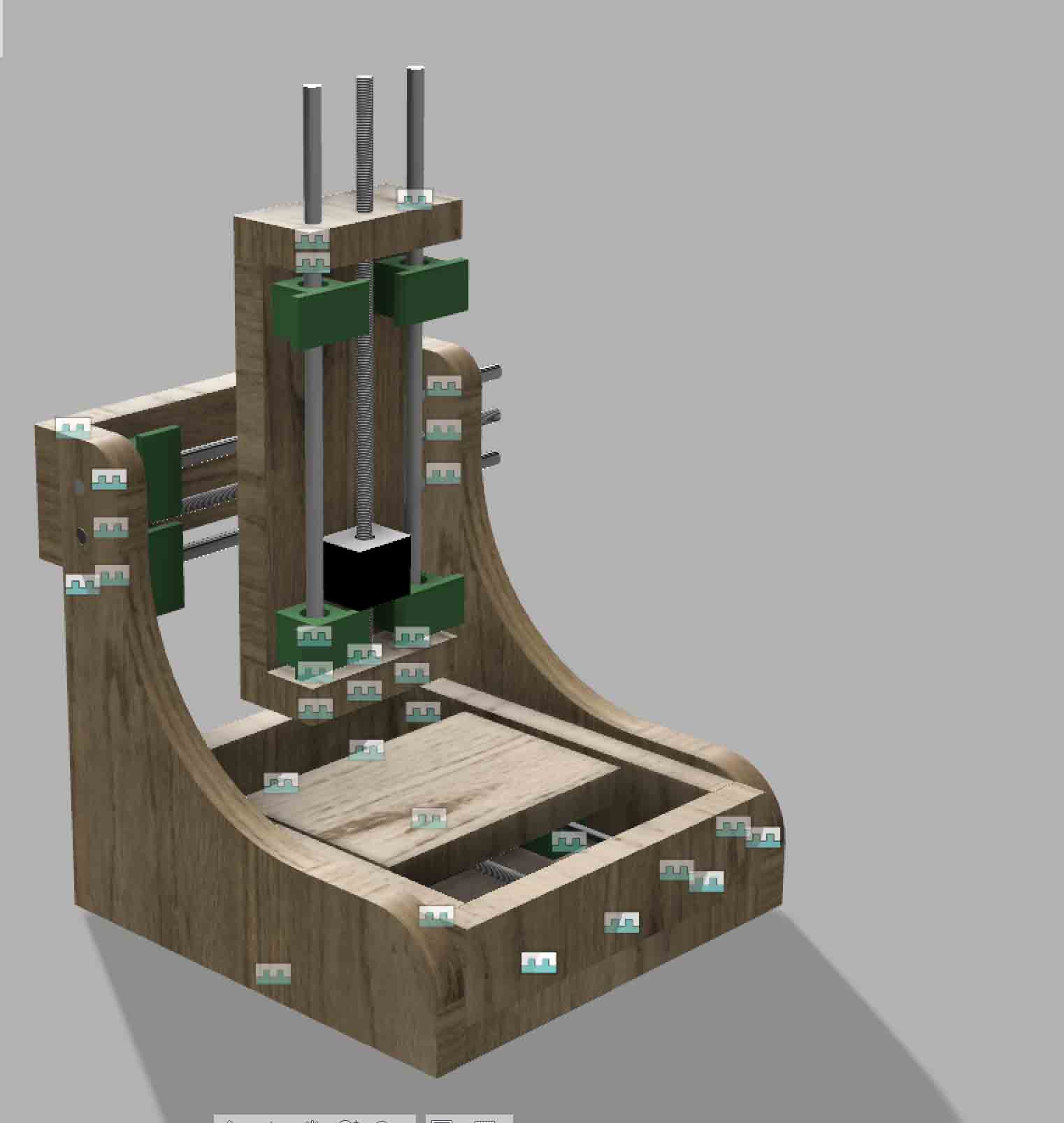

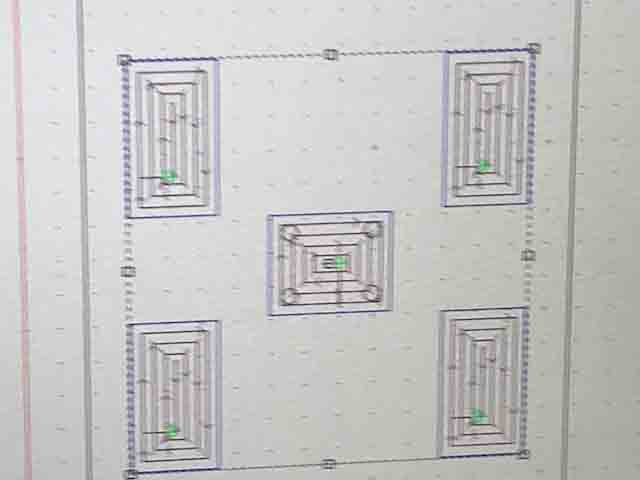

Fig 1. Desing on fusion 360 by Carlos Herbozo

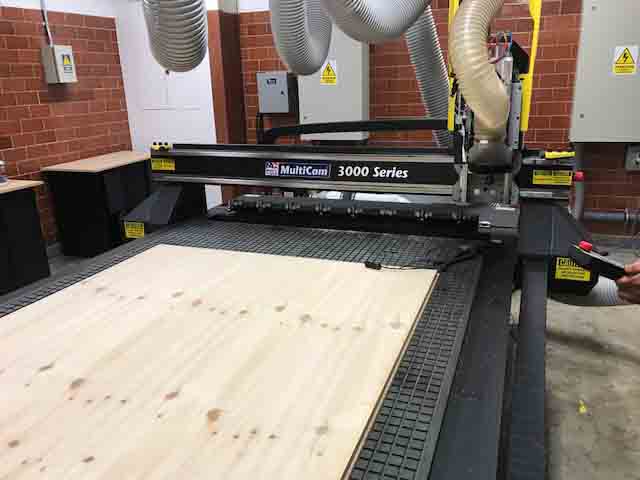

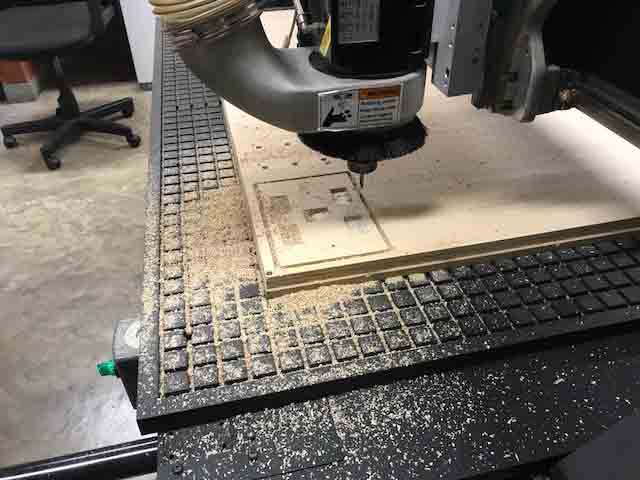

In this case, we used the multicam router for cutting the pieces. The folowing process shows how we made the Z-Axis.

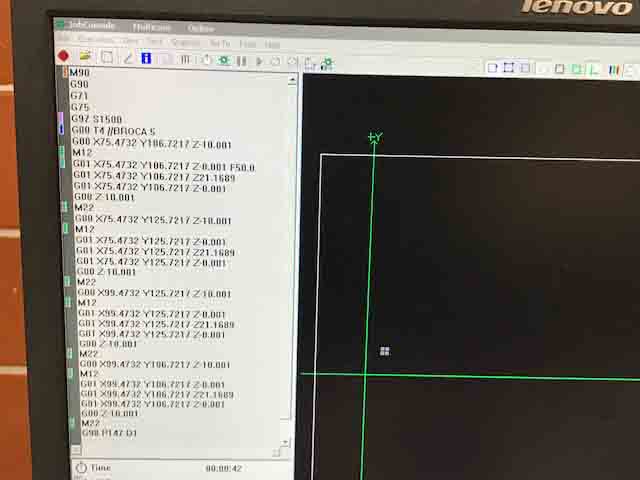

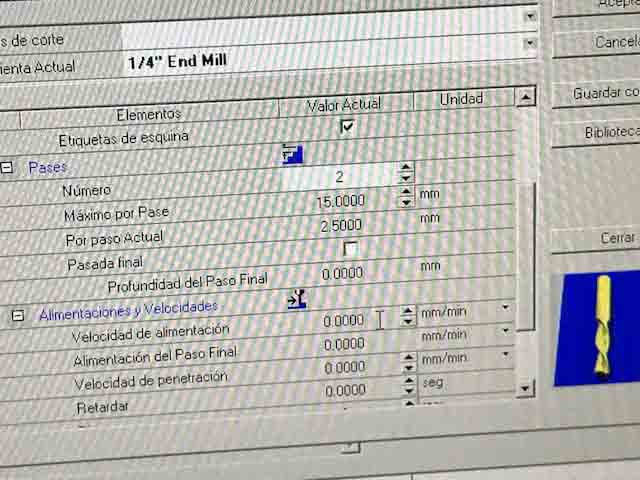

Fig 2. The plywood on the cnc router. Fig 3. Enroute, the CAM software for the router machine. Fig 4. Zero position on the router machine.Fig 5. The set point, mill diameterl, number of passes, spindle speed.

Fig 6. Toolpath simulation on the CAM software. Fig 7. Fabricating one of the pieces foir the Z axis. Fig 8. Another angle on the process. Fig 9. The final process to make the Z – axis.

We made the bed for the Y – axis. The bed will support the material, whether it is for laser engraving or milling. The bed has grooves to hopld the material down.

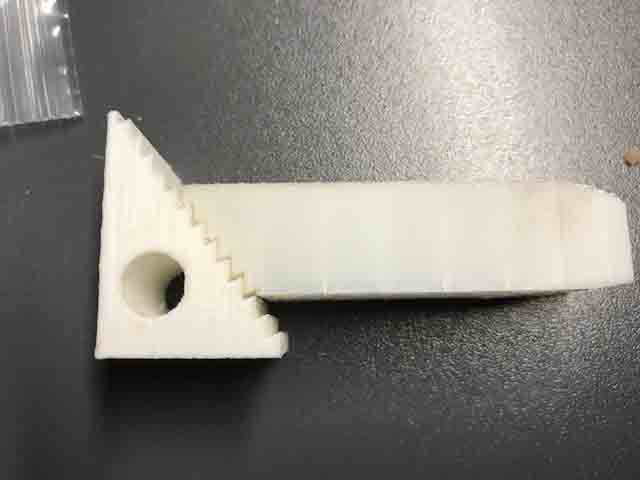

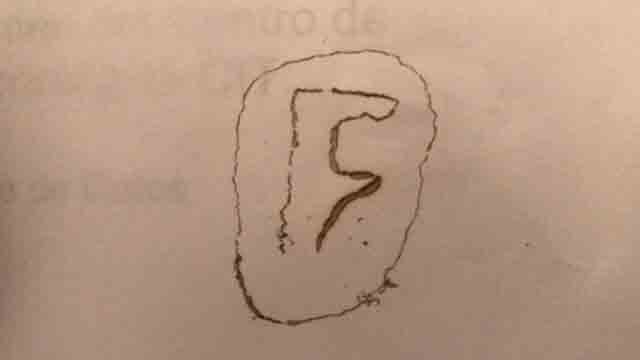

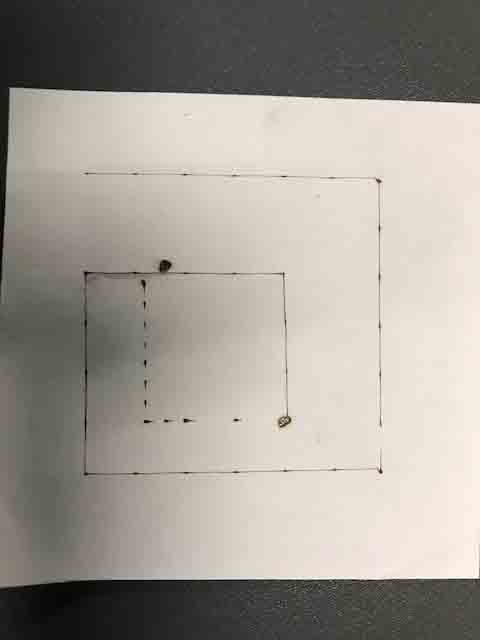

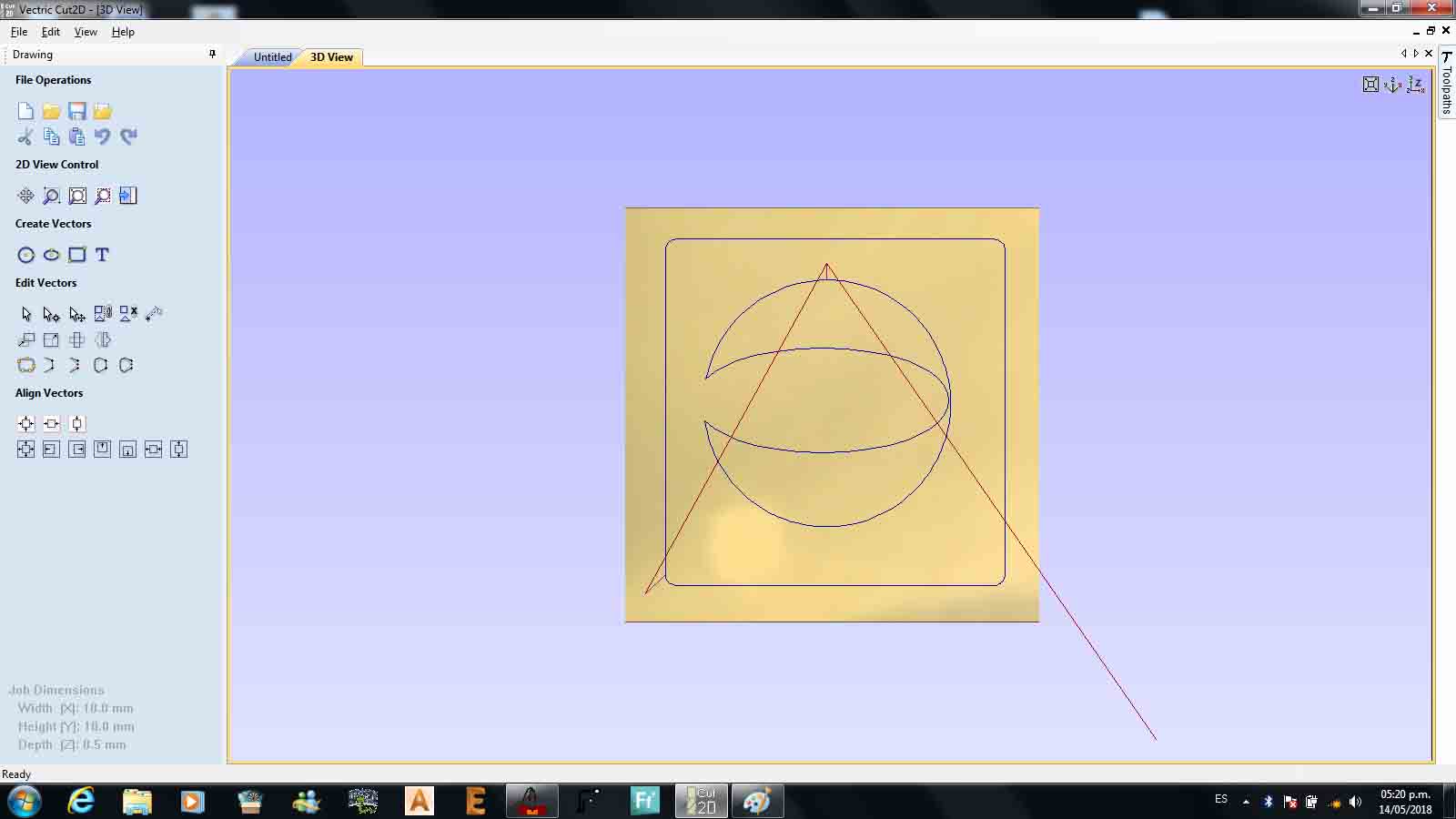

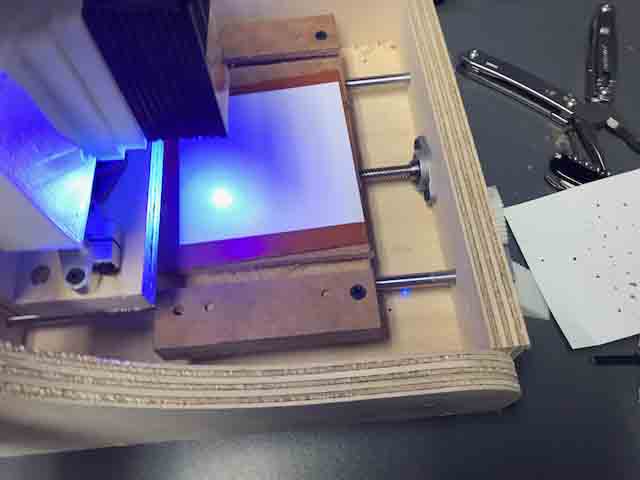

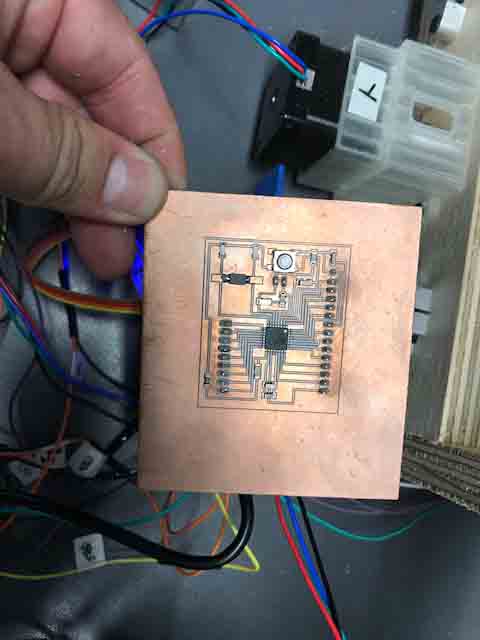

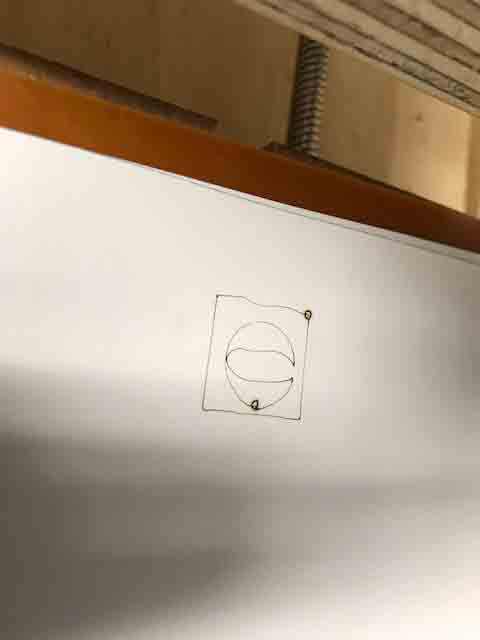

Fig 10. The bottom of the bed of the machine. Fig 11. Making the grooves for the bed. . Fig 12. Screw the base Fig 13. The grips, designed on fusion 360 by Nicolas Newton. Fig 14. The Grips on the bed of the machine, holding steady the material for a PCB. Fig 15. Nut for the grips. Fig 16. The complete grips.The advantage of this CNC consists of the interchangeable two – head tool.The first is a laser engraver and the second is an end mill. Fig 17. Two diferrents heads, one router. I tested the laser manually on paper. Fig 18. The first laser engraving test. Fig 19. This drawing was made on the CNC router, moving the axes manually. Fig 20. Generating the code G with Vectric cut 2d. Fig 21. The CNC router starts cutting 0.12 mm thick paper, the consume laser 0,26 A. Fig 22. The drill mode on the CNC Router. Fig 23. The M3 X 0.5 nut holds the drill into position.

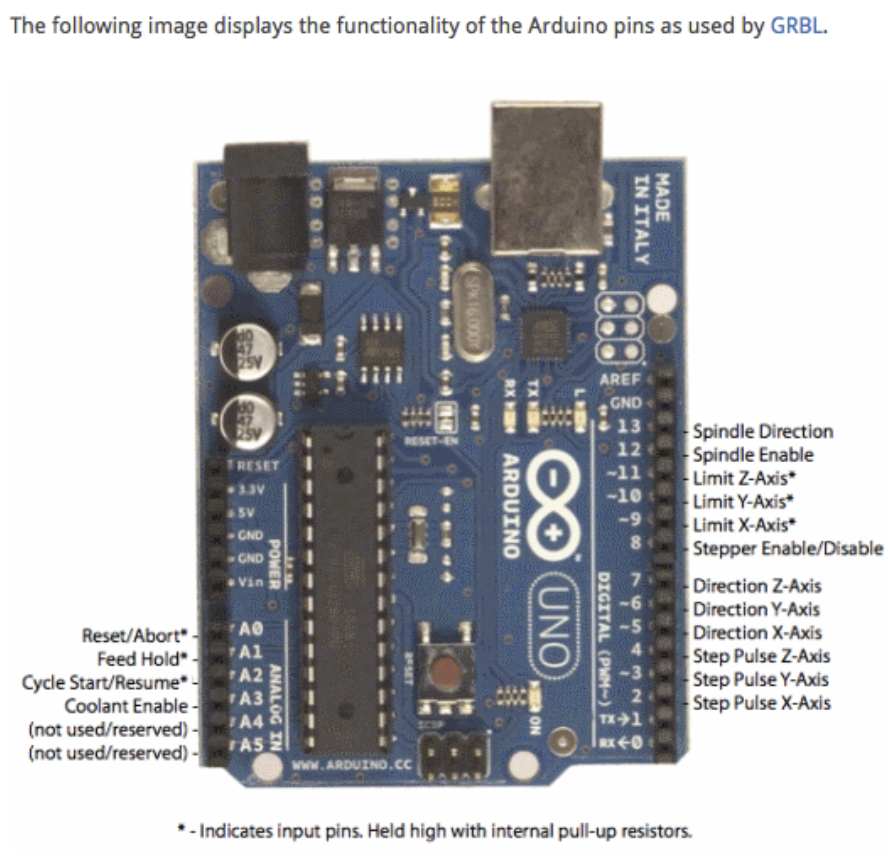

The documentation and firmware required so that the satshakit can read G-code can be found here:

https://blog.protoneer.co.nz/arduino-cnc-shield/

The documentation can be found here:

http://fabacademy.org/archives/2015/doc/projects/fabkit-0.4.htmlt

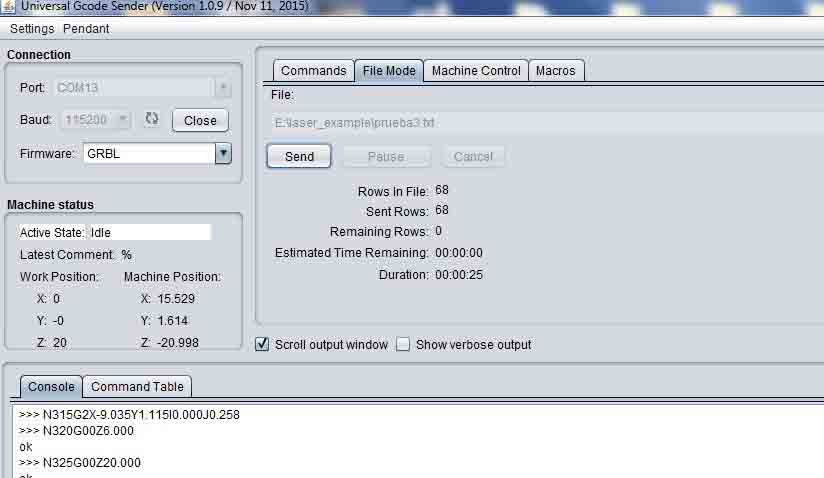

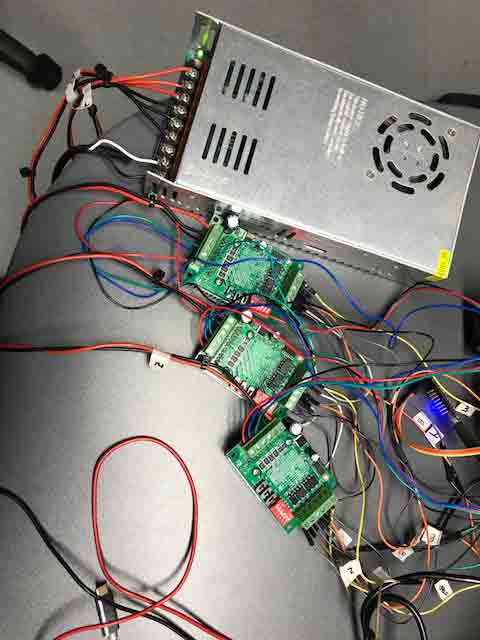

In this assigment we used GRBL to control the machine.

We used the command line to set the parameters for all 3 axes:

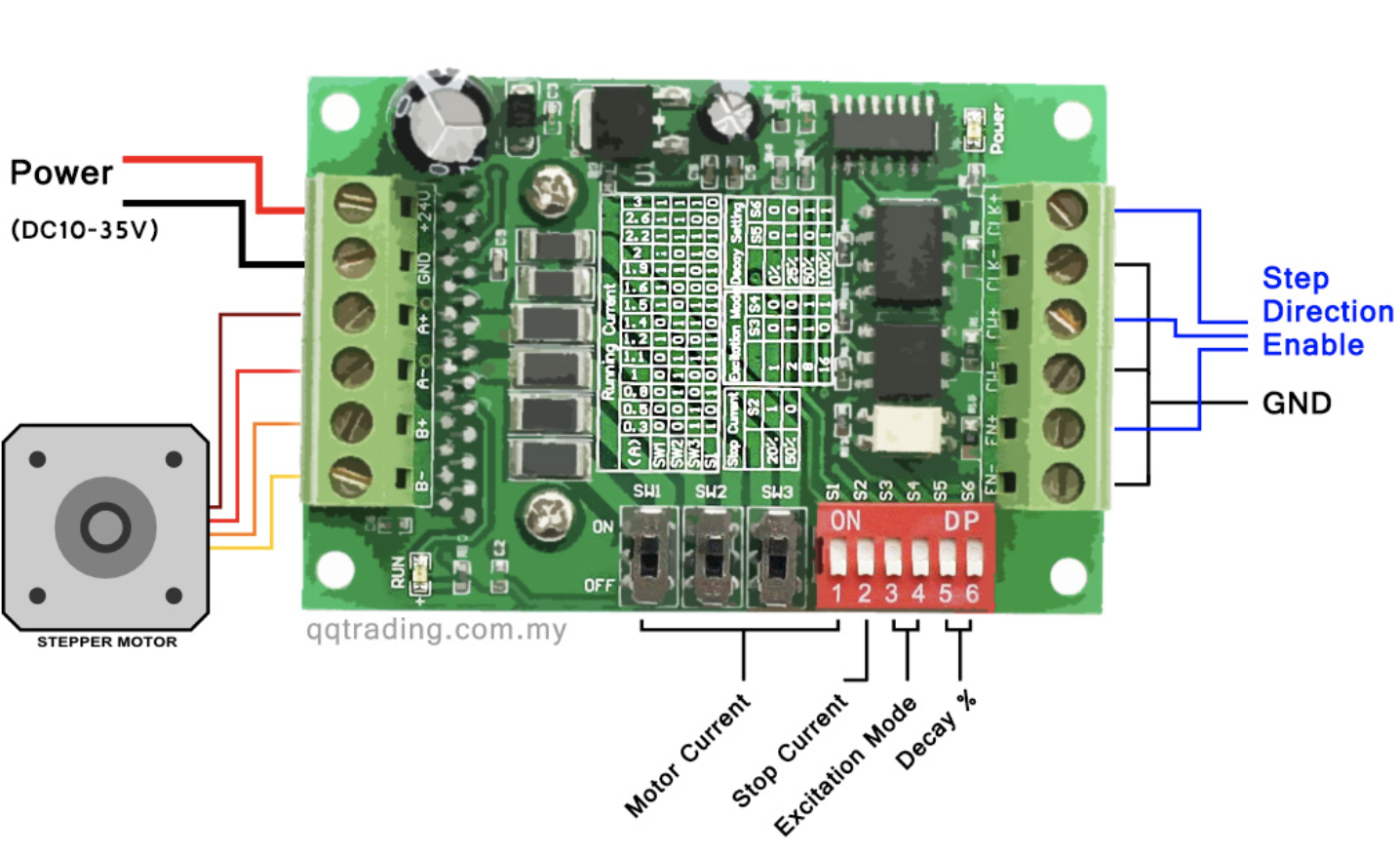

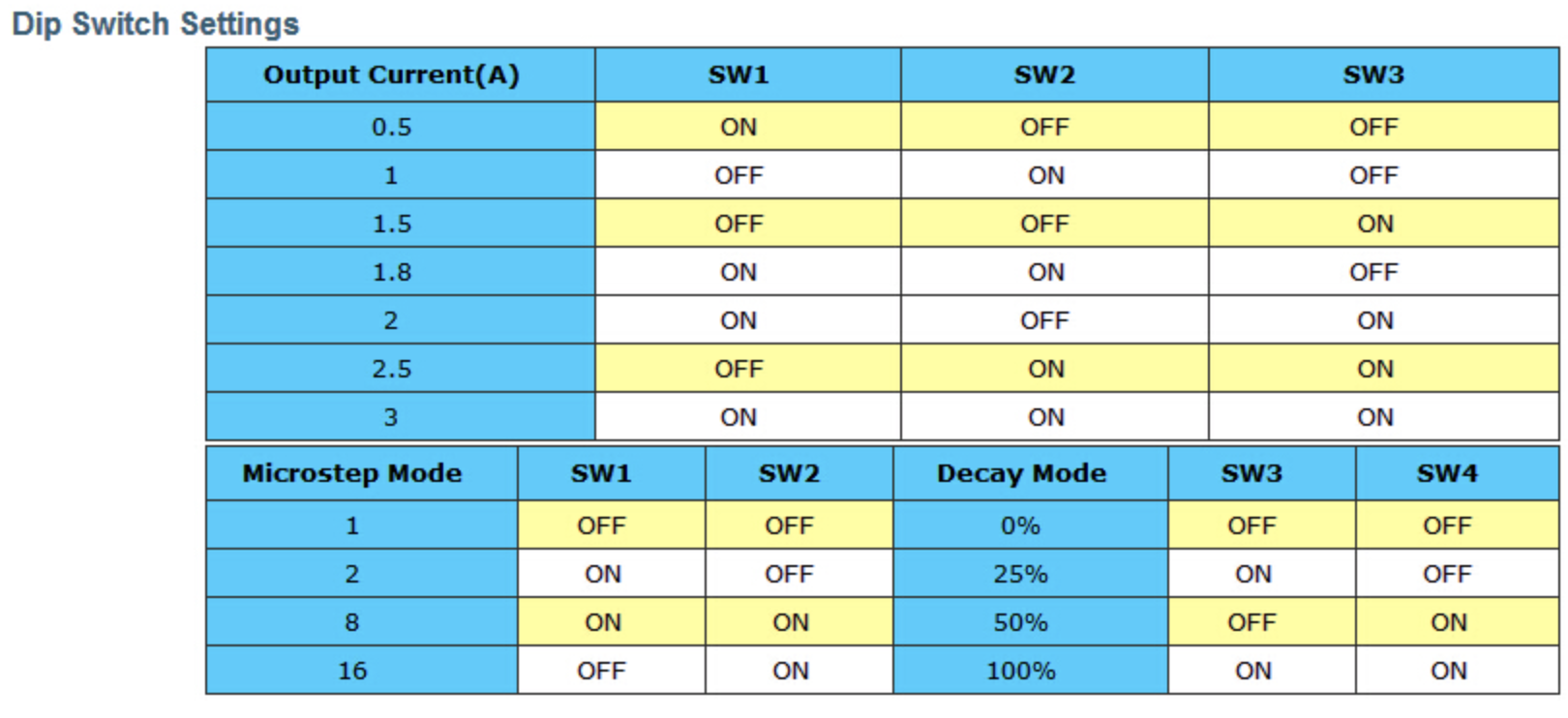

The stepper motor works with 1.8 degrres. Then calculate 360/1.8 =200. The driver has 16 mircosteps and the bolt has 1 rev 4mm. Thus the result: (200*16)/40= 800. This is the step/mm parameter for each of the axes. In the Universal sender code, in the command line wite $$ and then change in the universal sender code $100=800, which changes the X-axis , $101=800 change the Y-axis and $102=800 changes the Z-axis. Fig 25. The software Universal Sender to G code to Satscha kit.

The documentation can be found here:

https://learn.sparkfun.com/tutorials/stepoko-powered-by-grbl-hookup-guide/software-machine-control-universal-g-code-sender

Fig 32. The final drawing with the CNC milling machine.

Videos

CNC Laser / CNC Milling Machine.

This video shows CNC laser.

Right mouse button to play video

This video shows Universal gcode sender.

Right mouse button to play video

This video shows CNC milling machine.

Right mouse button to play video

File example Gcode