Wheek 18:

Applications and implications.

This week was all aout designing our final project and planning for the upcoming weeks. In order to do so, I have answered the following questionaire:

What will it do?

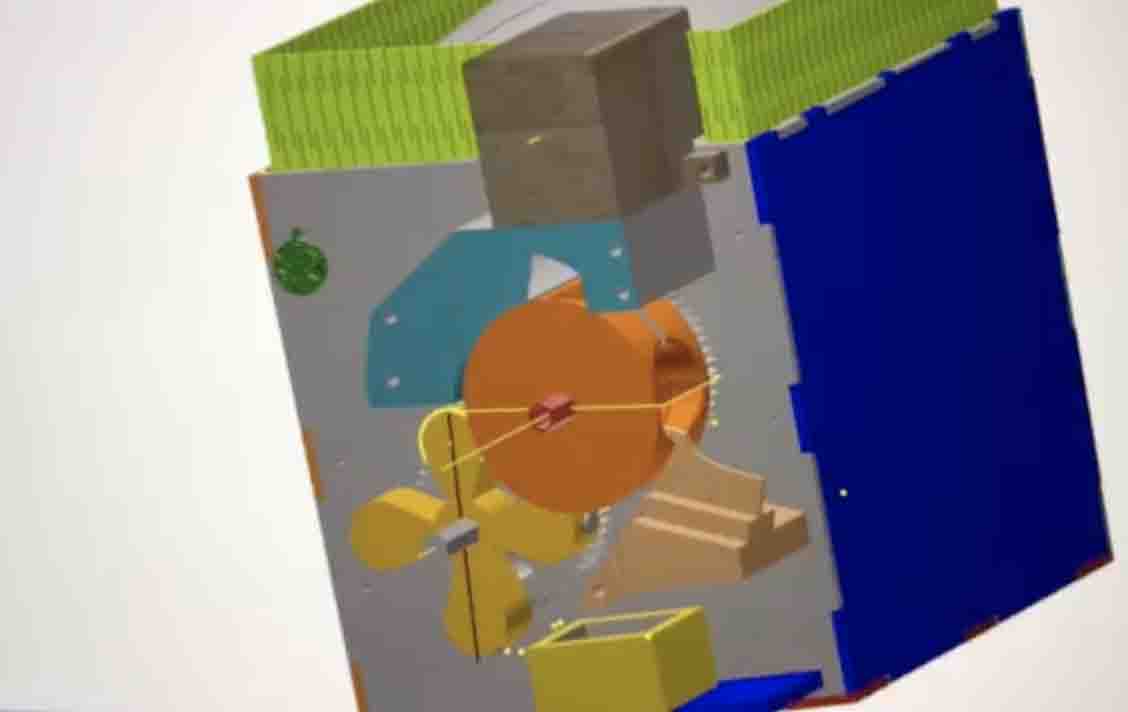

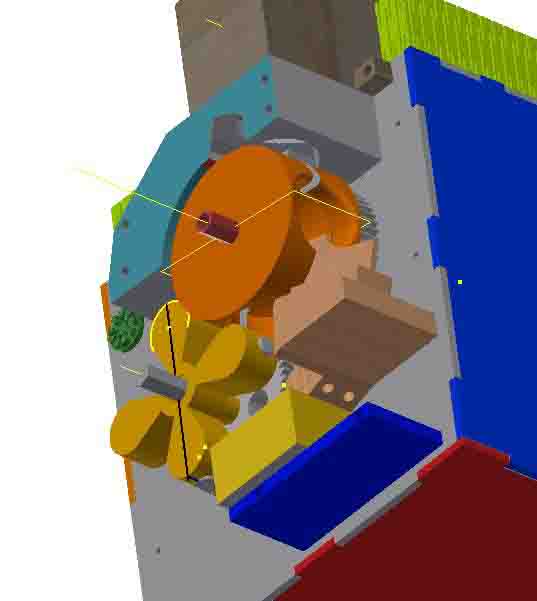

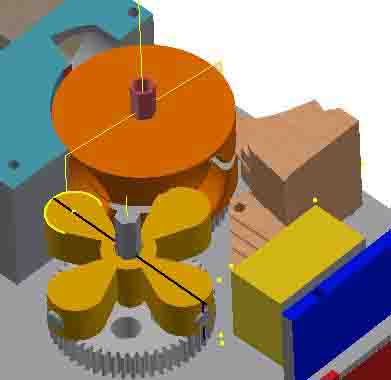

The idea is to make a lemon squeezer machine which can be automated with a main processor, PWM-controlled dc motors and sensors for optimal and safe operation. The top of the machine will have a hopper to feed the lemon into the drum. This hopper rotates until the lemon is set to the feeding position for the squeezer. At the bottom, the machine has a container for receiving the lemon juice, and another one for the remains, which is stored outside the machine.

Who's done what beforehand?

Actually, many companies make lemon squeezer machines, here are some examples:

The first examples:

The link can be found here:

https://www.norwalkjuicers.com

The second examples:

The link can be found here:

https://www.santos.fr/en/products/fresh-drinks/juicers/automatique/32/

The third examples:

The link can be found here:

http://www.orange-juicer-machine.com/sale-2759469-120w-commercial-orange-juicer-machine-orange-lemon-squeezer-for-apple-lemon-22-25-o-mins.html

What was designed?

My design consists of only one drum for cutting the lemon. This is the main challenge for the building of the machine. Another challenge is making the machine small and light.

What materials and

Components will be used?

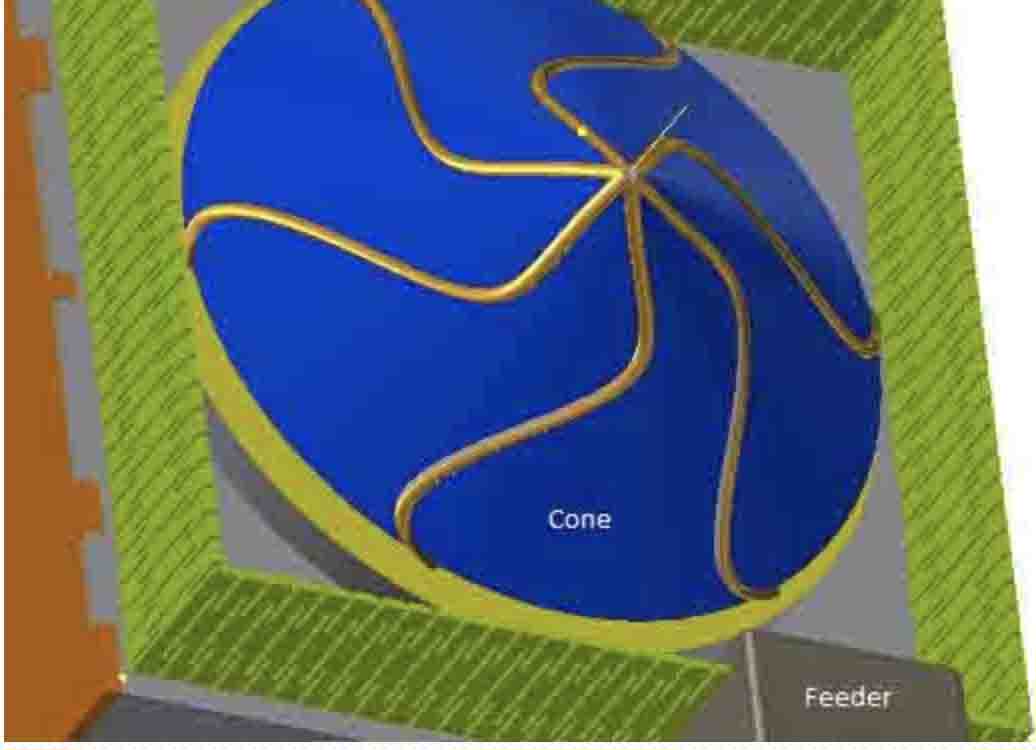

The body of the machine is made on plywood. The feeder, drum, squeezer, and hopper are made on a 3d printer using ABS.

Fab Lab Materials to be used:

• Plywood 3mm.

• 2 DC motors.

• ABS filament.

• Carbon filament.

• Two ballbearing

• Bronze for two shaft.

• Cables.

• Electronic components.

Machines to be used.

• Laser cutter.

• Makerbot 3D printer.

• Markforged3D printer.

• Roland router.

• Shopbot router.

• Multicam router.

Where will it come from?

The material will be requested at the storage from Fab Lab UTEC. In case I do not find any material I can buy from local stores.

How much will the materials cost?

I do not have a detailed budget for the materials I’ll need to use in my final project but I do not believe they’ll exceed the $ 100.0 stipulated for the final project of the Fab Academy

What parts and systems will be made?

All the structure will be manufactured on plywood and the other parts in 3D printer. All the PCB will be manufactured using Roland MDX 540.

What processes will be used?

• Computer Aided Design: Inventor

• Computer Controlled Cutting: Using the laser cutter.

• Electronics Design and production: Eagle and Roland MDX 540.

• 3D printer: Using the Makerbot and markforged.

• Programing: Arduino 1.6.4

What questions need to be answered?

• How are the part assembled ?

• How much speed does the DC motor need?

• How many Amps do I need in order to run motor?

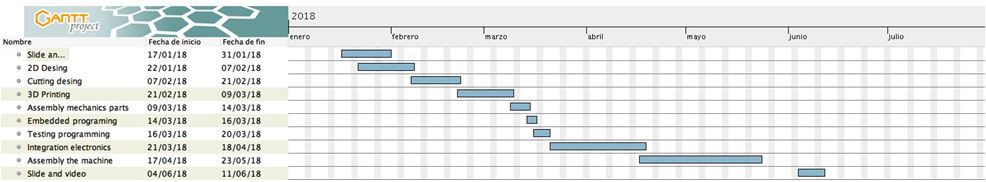

What is the schedule?

The next two weeks, I wiil be assembling the parts. The final process is the most exciting and hard because some things never go as planned. The following schudule shows the strategy for the final project.

Gantt diagram for made Lemon squeezing machine.

How will it be evaluated?

• I will be pleased when the lemon squeezer machine works fine, when the lemon is pressed properly, and the motors rotate freely without problems.

• The supplied current can support the amperage needed for both motors.

• The cone on top of the machine must rotate easily.

• The cone on top of the machine must rotate easily.