Task To Do:

- Design a machine (mechanism + actuation + automation), including the end effector, build the passive parts and operate it manually.

Group Project-

MECHANICAL DESIGN

Make a machine

This is the first of two week make a machine project. This is the combination of two assignments. Previous fab academy students are worked on various iterations of XY plotters. Hence we decided to do something new for learning purpose. Before starting this assignments we went through many ideas and finally we zeroddown on robotic arm. We will make a robotic arm which having laser as a end effector. This is group assignment so, my group consist eight members which are:

Everyone is there for assemble, operate and automated the arm. In our team only two people are engineers (Rohan and Rutvij) and luckily one of them is mechanical engineer and other is electronics engineer....

And we are starting ABCD of our arm...

After first meeting we decide our work plan and responsibilities. In which I choose all hands on work.

I Did 1st prototyping, some final design part and all machines related work like epilog laser cutter, plasma cutter and SIL laser cutter.

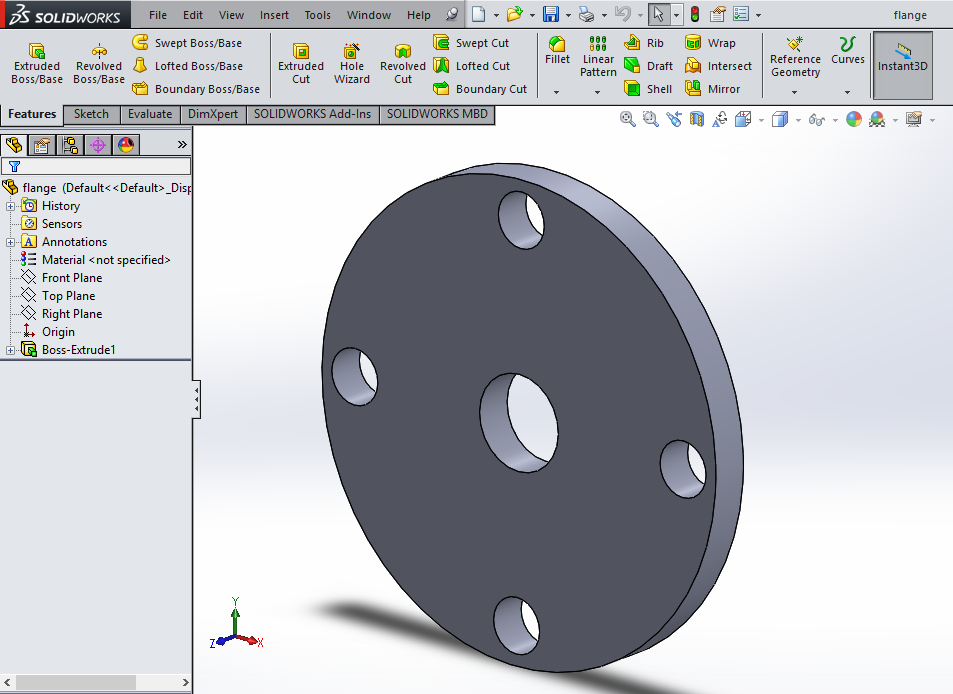

THE ZERO

The Zero is a robotic arm having 4 degrees of freedom, designed to be mounted on any surface and to work with various end effectors, through a modular design. The arm currently is designed for the acute purpose of engraving over flat surfaces. The structure of the arm has been inspired out of the MeArm and other high end robotic arm, to find a mid way solution that could solve our purpose the easy way.

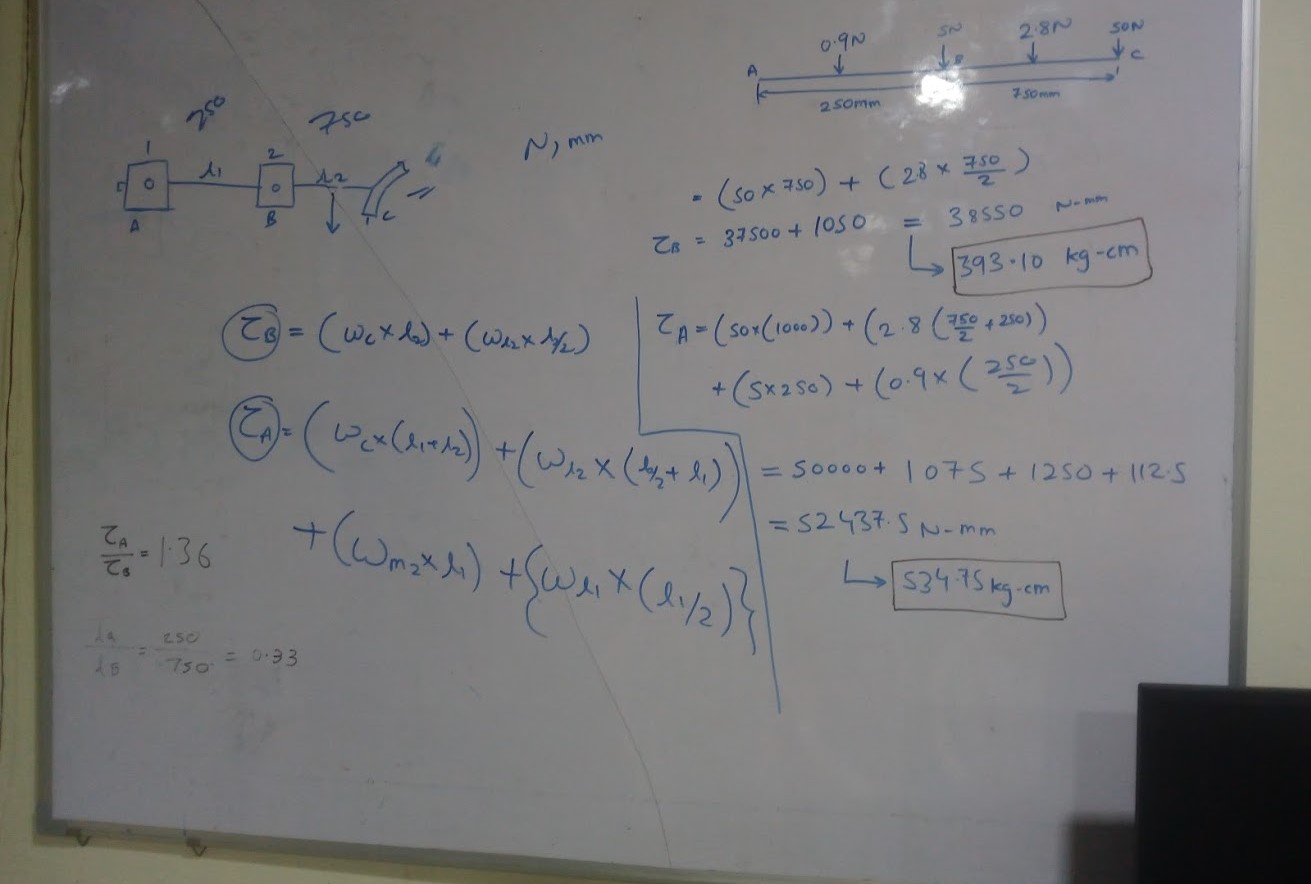

Initially we decided to make the reach of the arm 1m. Rohan and chaitanya calculate the torque, but they are very high.

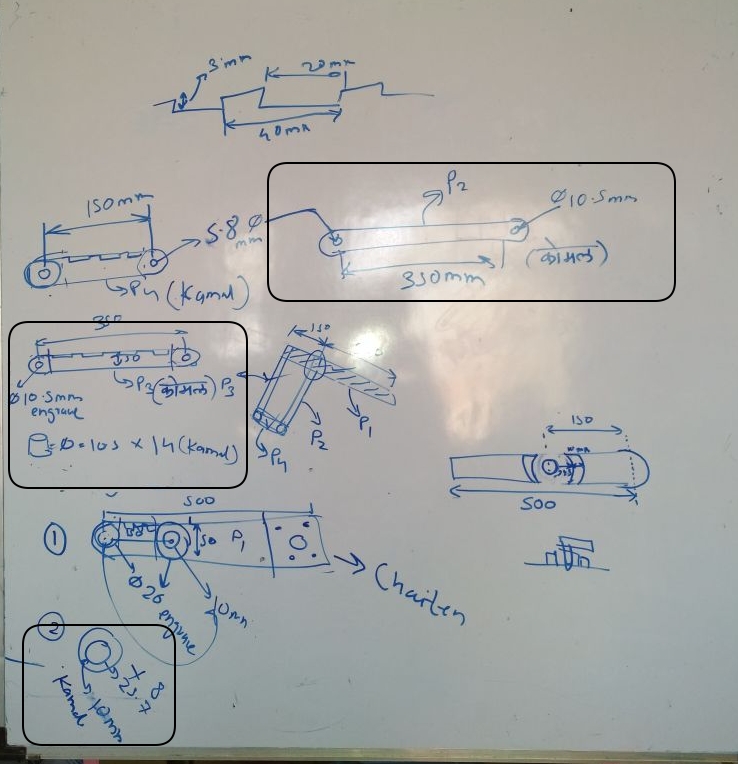

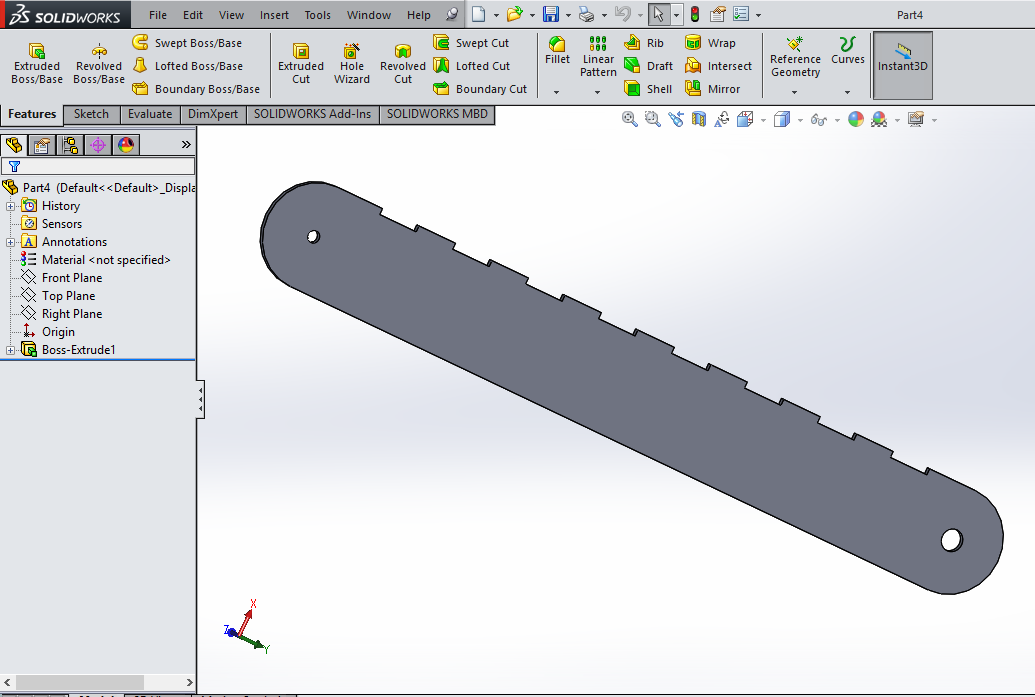

After this, the next task was to find the reach for the arm. This is the first prototype and I made the design files and cut it on the laser. The maximum reach and minimum reach of the arm will depend upon the angles between the two links.

We roughly observed the maximum and minimum reach.

After a long discussion we fixed our arm lengths to 350mm and 400mm.

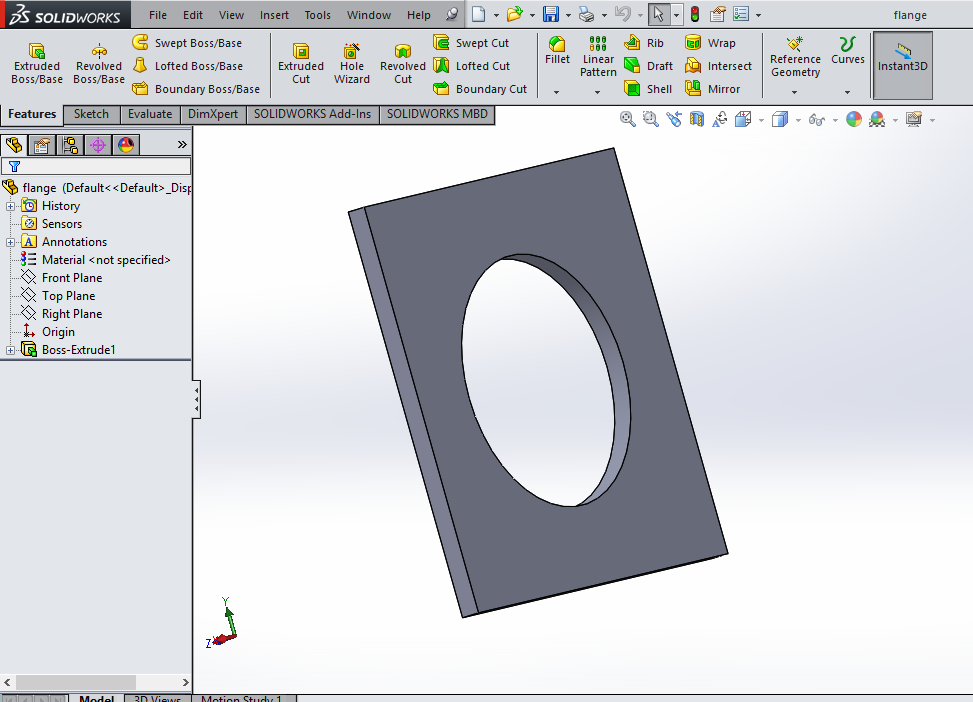

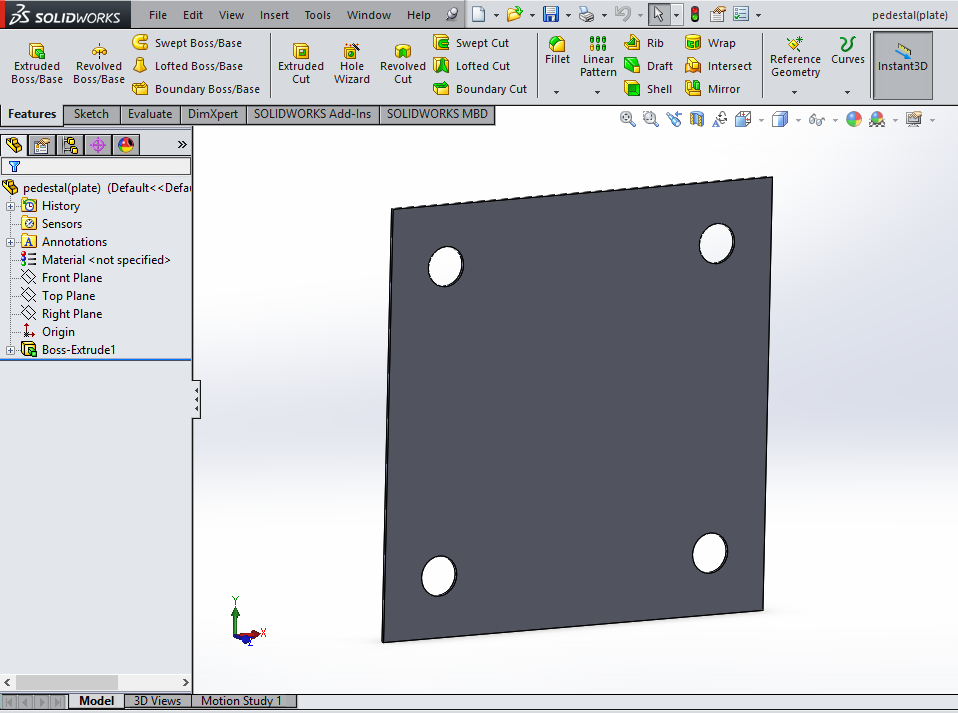

Then we draw the linkages with dimension on white board and everyone choose parts for 3D designing....

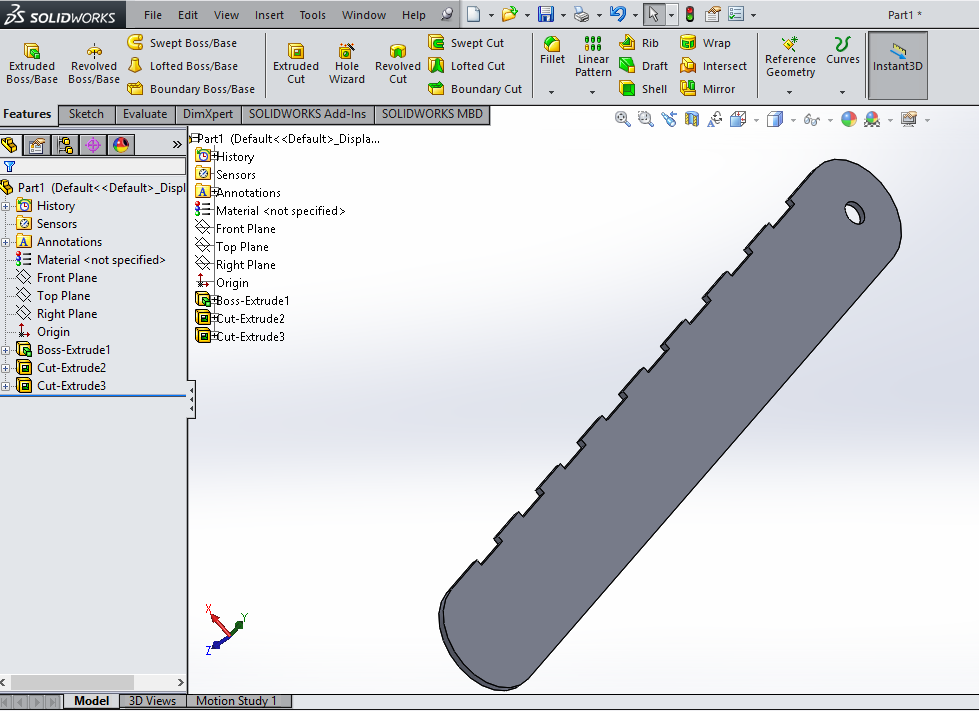

After 3D designing we moved towards cutting....

Me and sanket did this job or cut the parts on epilog laser cutter...

We assemble the parts...join the linkages. Here our arm stands up and we tried to move it by hand...

After this we did some modification and I cut the parts in MDF..

We connect our linkages and Our arm stand-up here....

Future Scope-

The Arm supports a very vesatile design where there could be a range of end effectors that could be attached.

Secondly there is a scope of adding a motor at the end to addup to a degree of freedom.

The project page for this assignment is available here

All the Model files for the arm are available to download here