Electronics production-group assignment

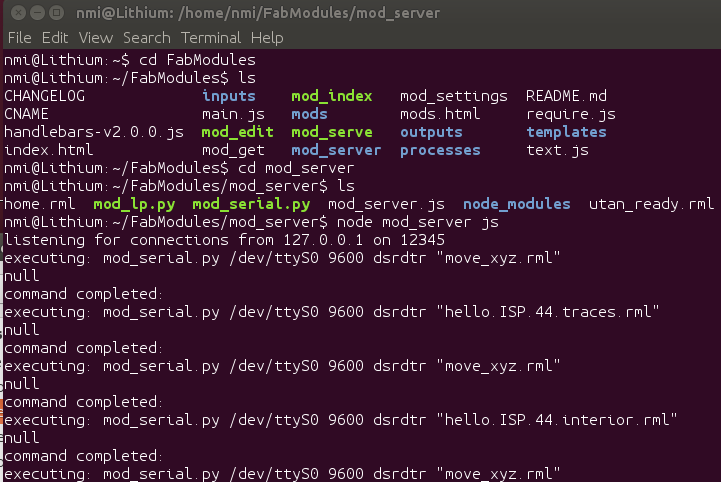

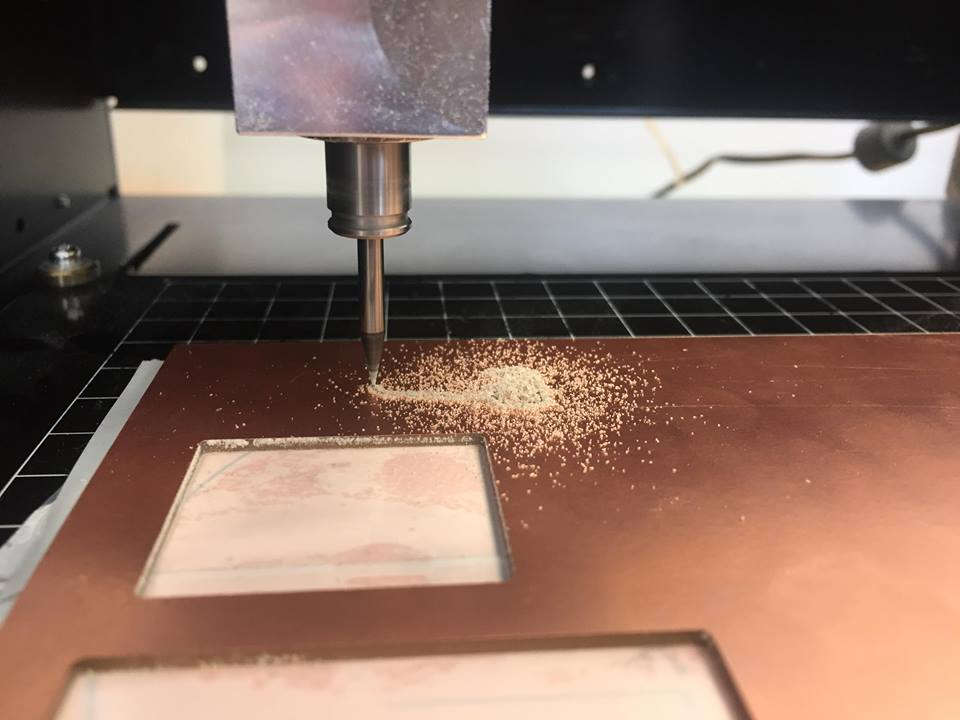

We ran the line test on our Roland Milling Machine.

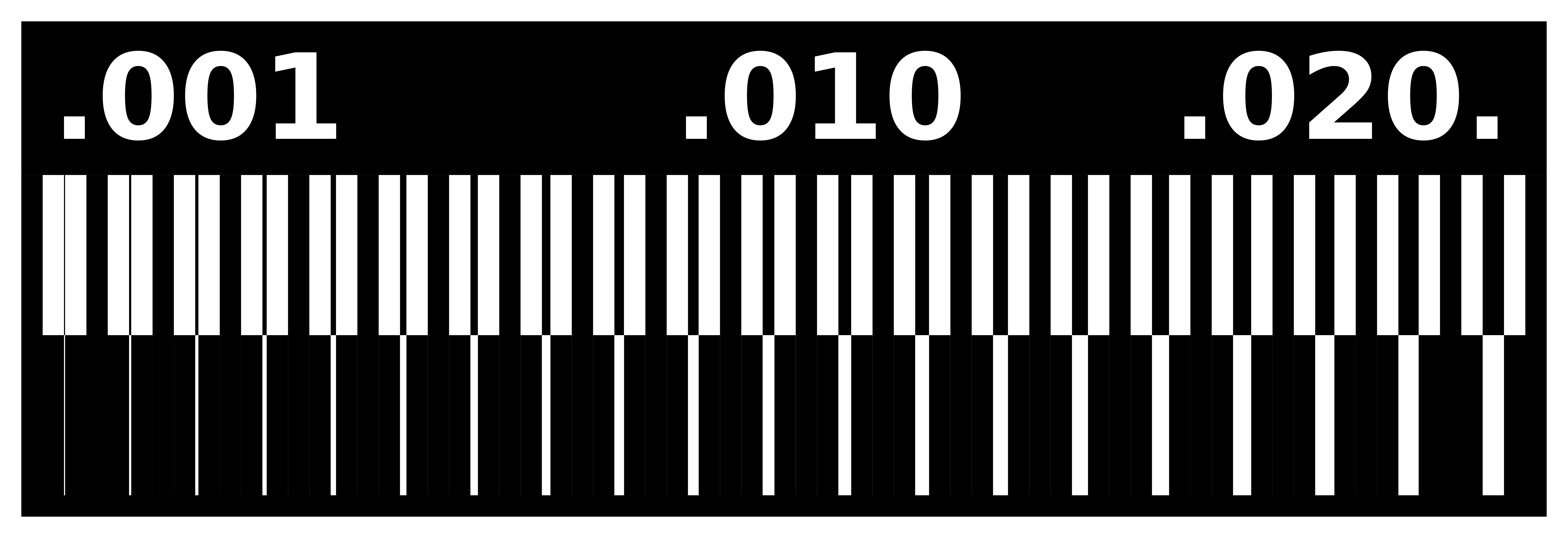

We used the settings advised by the Video created by Frosti as a guideline for our settings

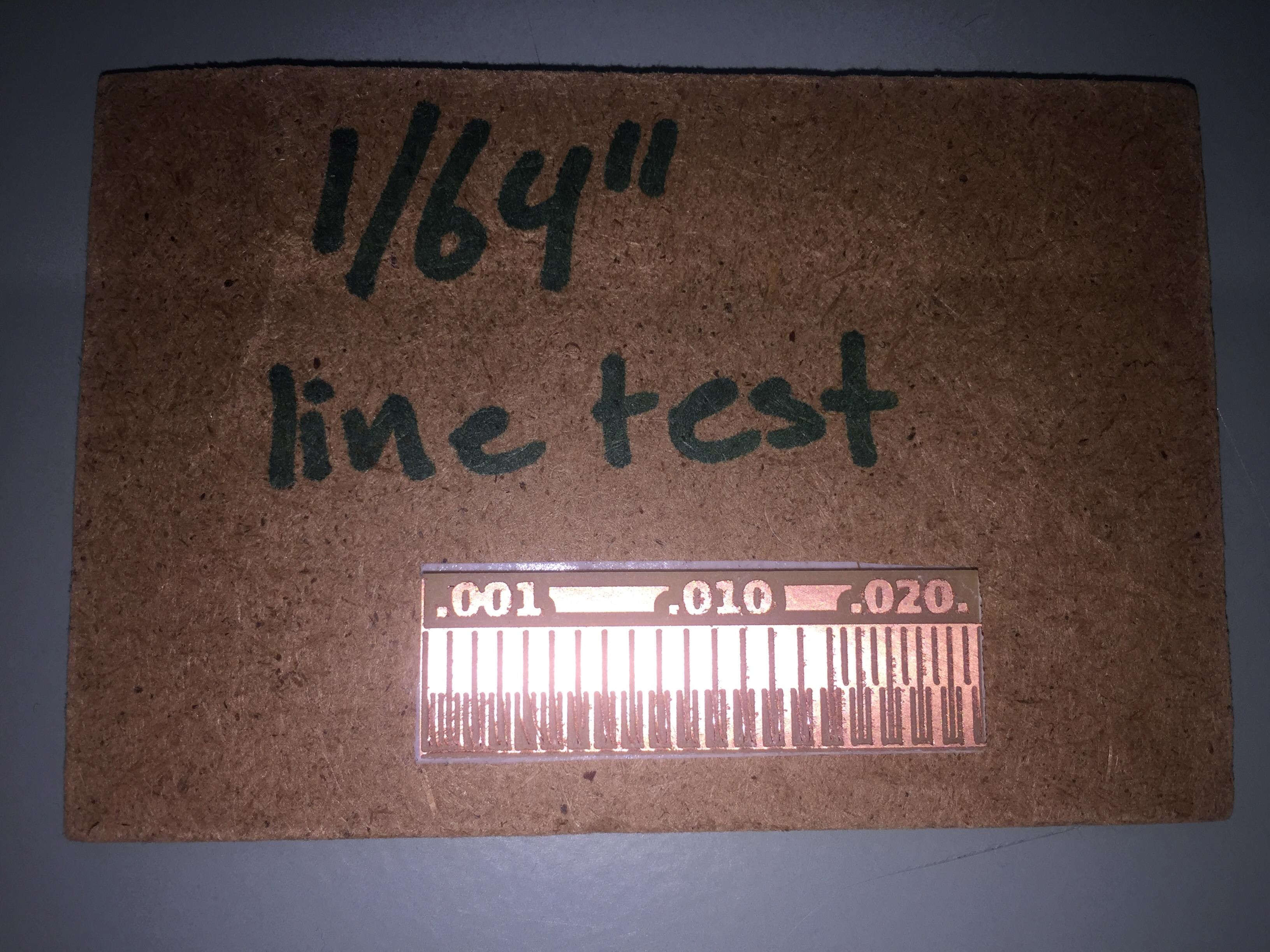

The tracing of the first run, with the 1/64 inch drill bit went fine, although we were surprised by the roughness of the cut. Only the largest four lines were close to being smooth.We think that happened because the milling bit had been used alot and was probably a bit worn down.

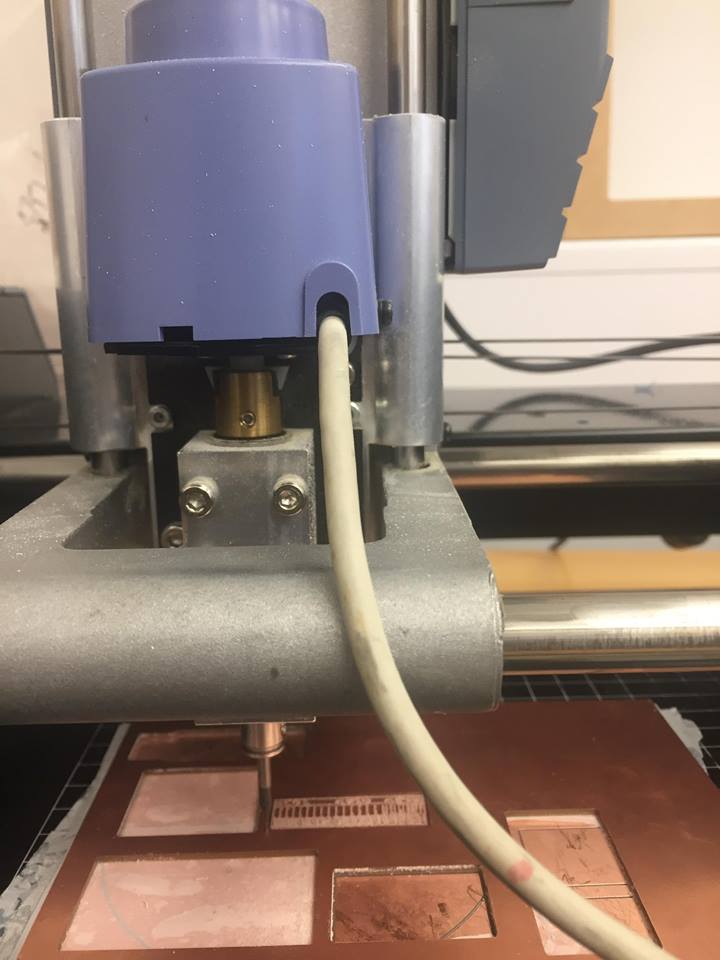

When it came to drilling the interior line we ran into some problems. The drill did not go down into the material, instead drawing a shiny line along the very top of the plate. We did not understand what the problem was, until Frosti came and pointed out that we had lowered the head too close to the board, so that it was flush with the machinery. This meant that when the "down" command was issued, it could not physically go any further down, and instead moved around at that same level.The solution was to raise the head, lower the drill bit out of the colette, and mill it again.

When we had figured out what was wrong we tried milling it again but the traces for the oulines didn't work. It always wanted to jump over a part of the outlines but when we told Bas about it he told us it was happening because FabModules thought the bottom line was to thin to cut and that it wouldn't happen if we used Mods. To fix it we changed the tool diameter to 0,4.

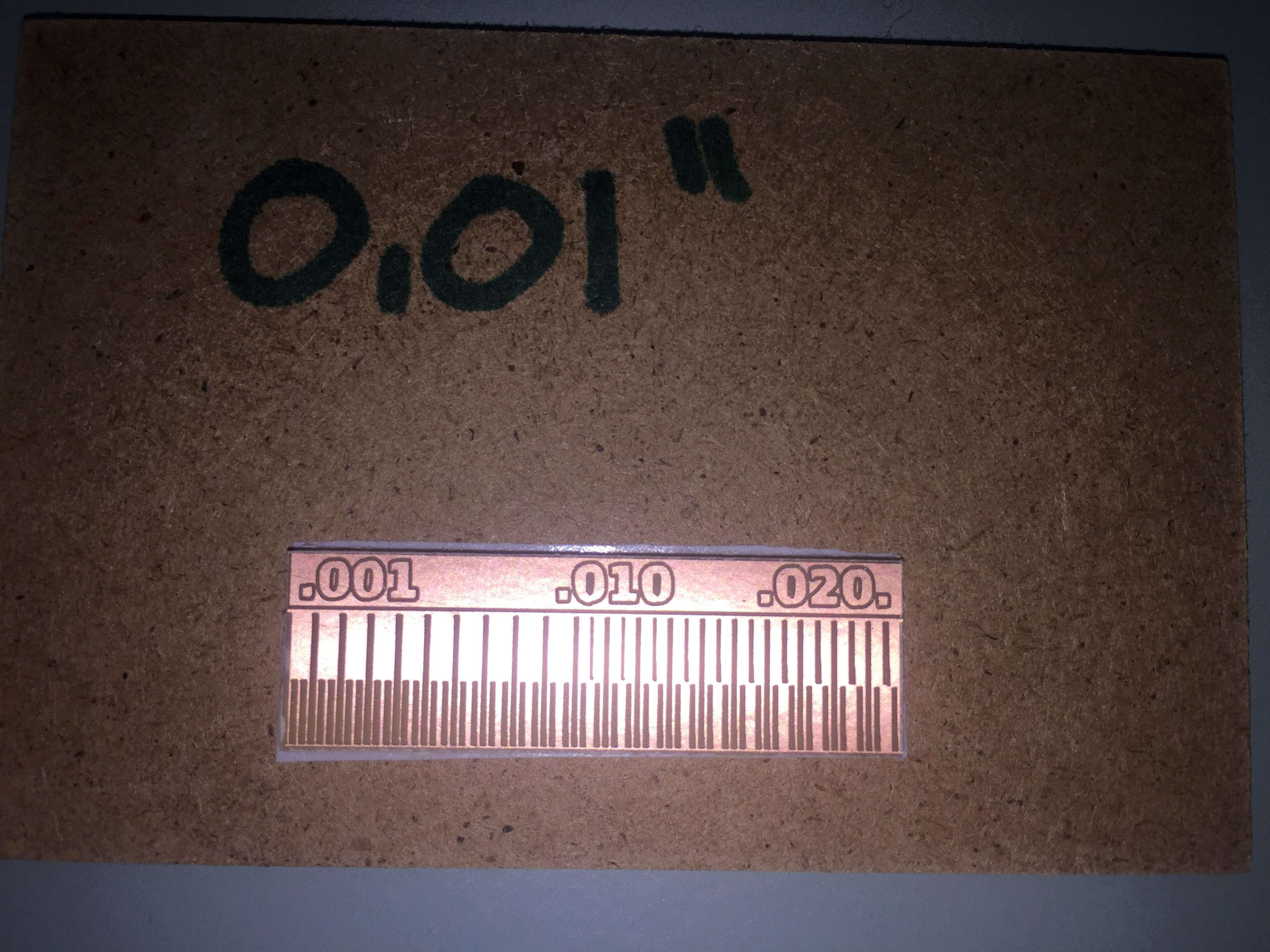

After this, we very carefully switched the drillbit to the 0.01" bit. Using our knowledge of the settings, we were able to run this without any issues, and were happy with the incredibly clean cut that this drill bit created