Week 06

3D Scanning and Printing

Individual assignment

- Test the design rules for your printer(s) (group project)

- Design and 3D print an object (small, few cm) that could not be made subtractively

- 3D scan an object (and optionally print it)

Learning outcomes:

- Identify the advantages and limitations of 3D printing and scanning technology

- Apply design methods and production processes to show your understanding.

Have you:

- Described what you learned by testing the 3D printers

- Shown how you designed and made your object and explained why it could not be made subtractively

- Scanned an object

- Outlined problems and how you fixed them

- Included your design files and ‘hero shot’ photos of the scan and the final object

Week workflow

Weekly assignment → Test Printer → design as object → Print object → Scan object → print scanned object (optional)

Tools used

- Delta 3D Printer

- Mini 3D Printer

- Caliper

- 0.4 mm needle

- Uhu glue

Software Used

- Repetier Host

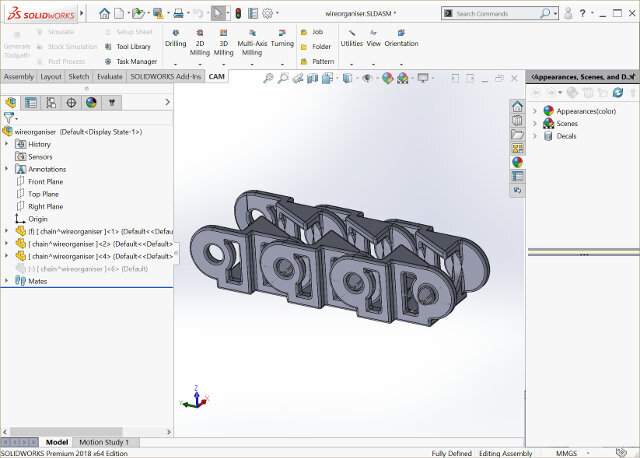

- Solid Works

- Autodesk Recap

Files Generated/used

- Test's stl file: 3D Printer test model from thingiverse

- Gcode file: all week's generated Gcode from STL files

- Solid Works file: 3D model for a wire organiser used on my final project

- Chain's stl file: Generated stl file from the solidworks archive

- Printers preparation

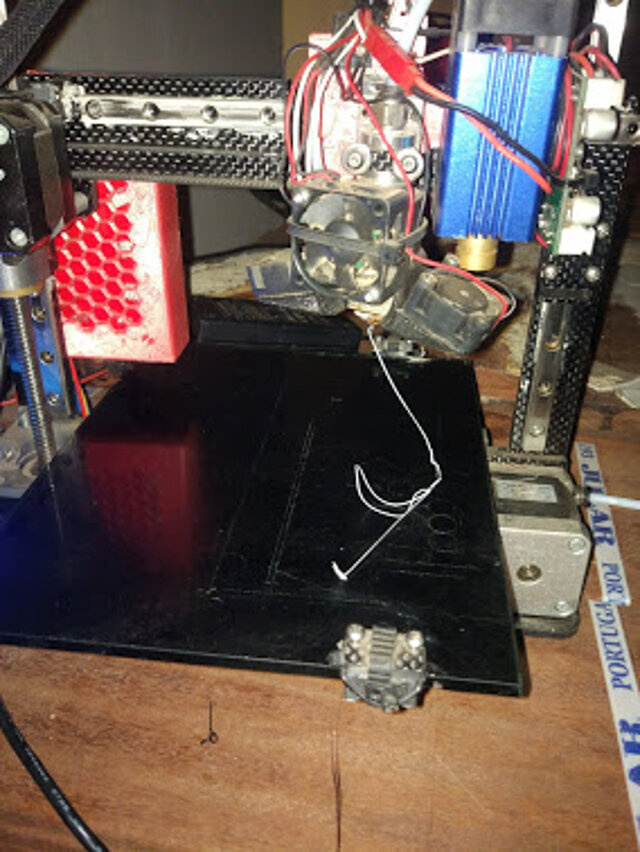

- In order to start the test I prepared the printers by cleaning the nozzles and spreading new glue into the platforms

- I tested the extrusion on both printers and it looks good ;

- The limits of our printers

-

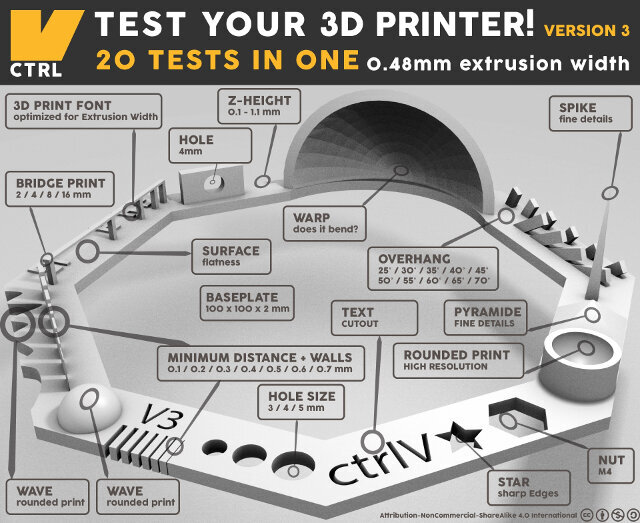

I started this week's assignment by looking for a test pattern on the website

Thingiverse

. Simply by using its search engine with the keywords,

"test 3d print"

it show various results with the purpose of testing the printers.

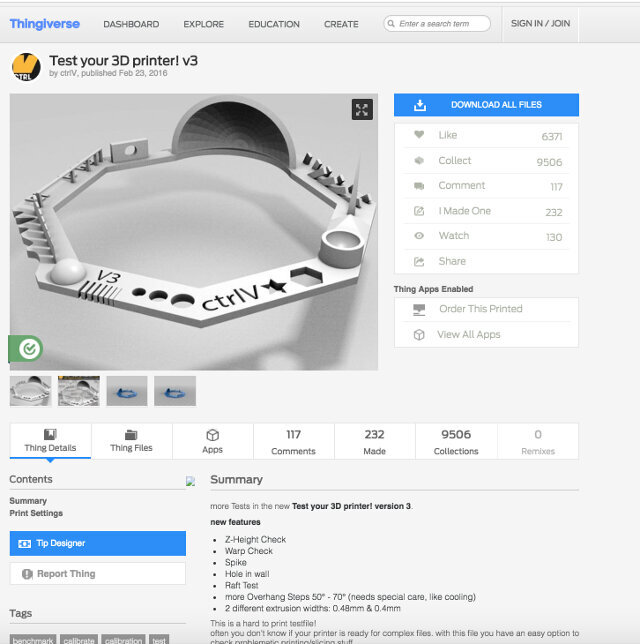

- Then I selected one of the designs. It tests different capabilities of the printers.

- Nut, Size M4 Nut should fit perfectly

- Wave, rounded print

- Star, Sharp Edges

- Name, Complex Shapes

- Holes, Size 3, 4, 5 mm

- minimal Distance: 0.1, 0.2, 0.3, 0.4, 0.5, 0.6, 0.7 mm

- Z height: 0.1, 0.2, 0.3, 0.4, 0.5, 0.6, 0.7, 0.8, 0.9, 1.0, 1.1 mm

- Wall Thickness: 0.1, 0.2, 0.3, 0.4, 0.5, 0.6, 0.7 mm

- Bridge Print: 2, 4, 8, 16 mm

- Sphere, Rounded Print 4.8mm height

- Sphere Mix, 7 mm height

- Pyramid 7 mm height

- Overhang: 25, 30, 35, 40, 45, 50, 55, 60, 65, 70°

- Warp, does it bend?

- 3D Print Font, optimized for 3D printing

- Surface, Flatness

- Size, 100 x 100mm x 23.83 (10mm width)

- Spike, minimum Layer Time, 21 mm height from Bottom (include Baseplate)

- Hole in Wall, 4 mm diameter, check for proper print

- Raft Test, raft should be just under the model

- Retract Travel, check retract settings for longer travel

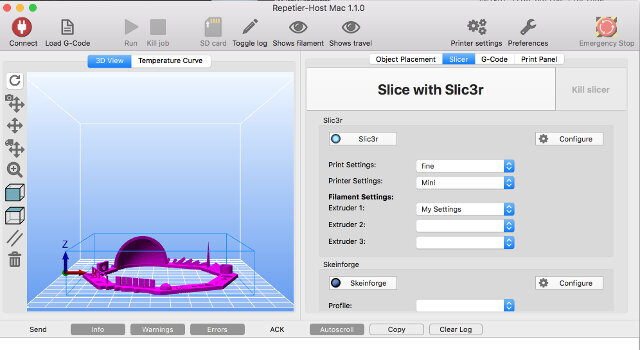

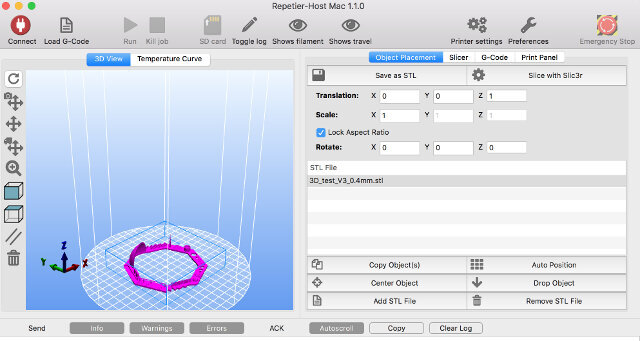

- On the software Repetier Host I loaded the stl file and sliced for each printer. Naming the Gcode with the printer designation in front.

- Next I took the Gcode I had save on the SD card and placed on the 3D printers and started the print.

-

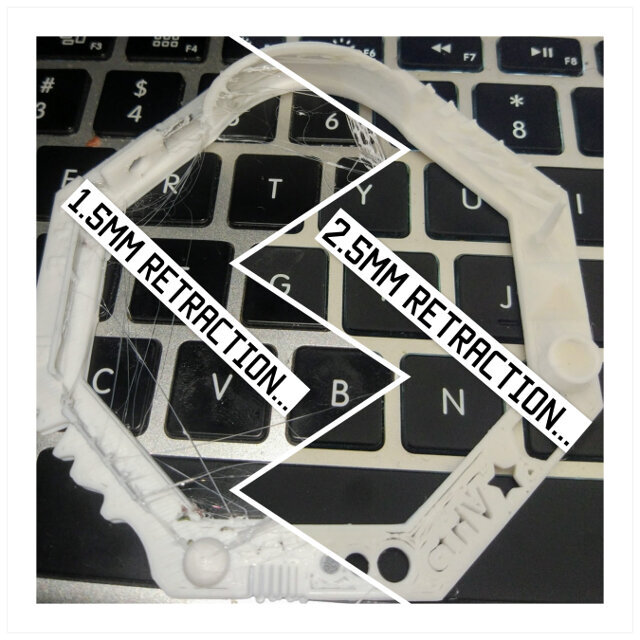

The prints were not bad but there was a lot of oozing (spider web). So I increased the retraction by .5 mm and then by 1 mm the improvements were very noticeable in both printers.

- The results

- Designing and printing an object

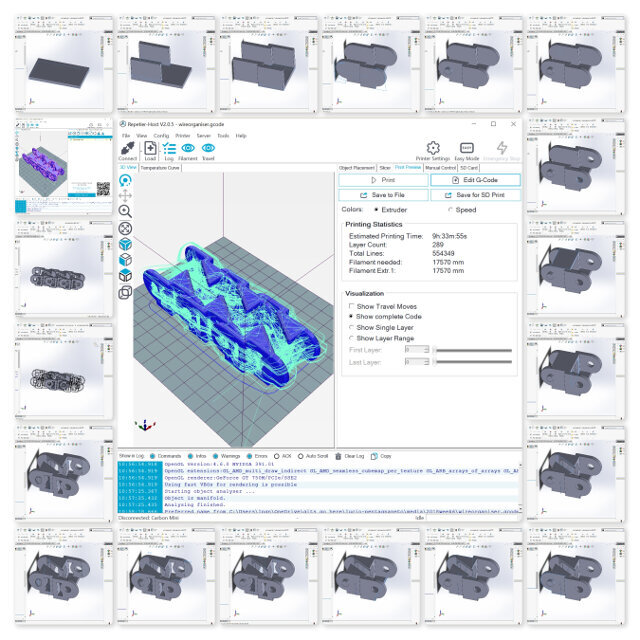

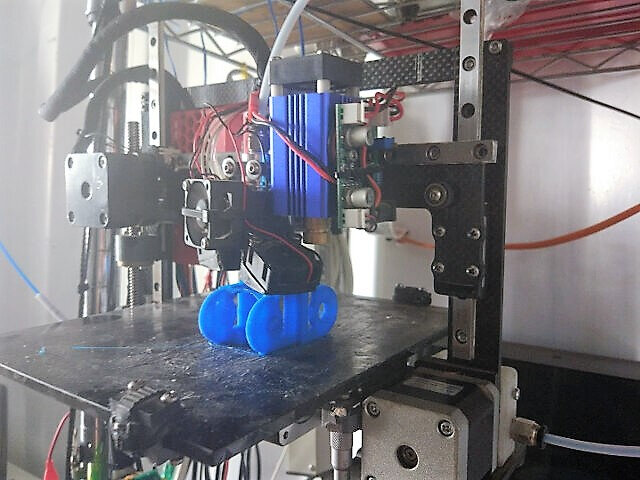

- I decided to create a necessary part of my final project. It's a wire organiser that when connected together works as a chain.

- The design is parametric so I can easily change the size as needed

- As I finished the Solid Works model I then export the file as stl

- 3D Scanning

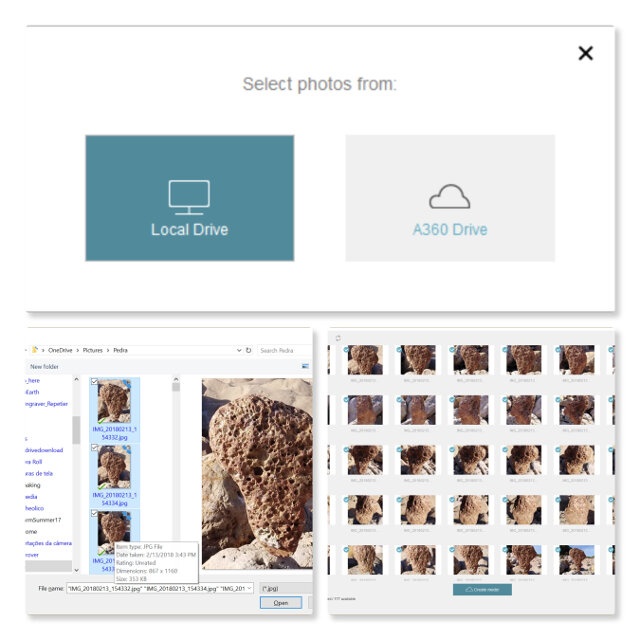

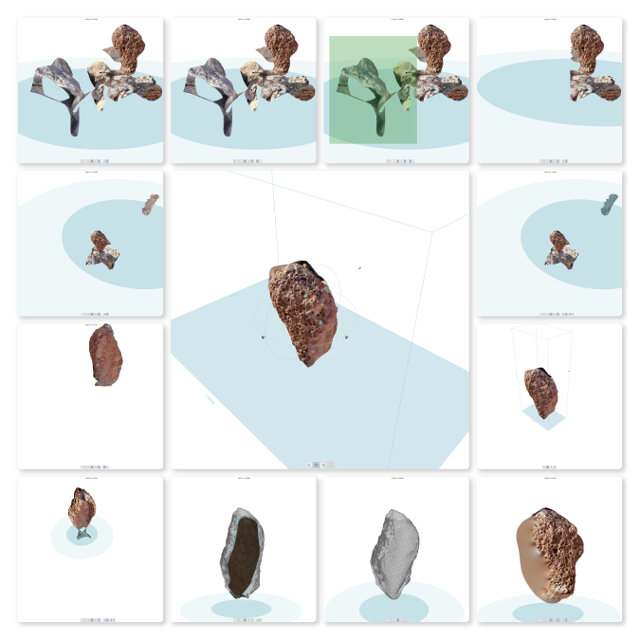

- For that part of the assignment I used Autodesk Remake. It relies on Photogrammetry.

- luckily I was at the beach and I saw a model that would be interesting. Someone had but a large rock equilibrated.

- Next step was to take around 40 photos from all angles and in preference without moving background like people or clouds.

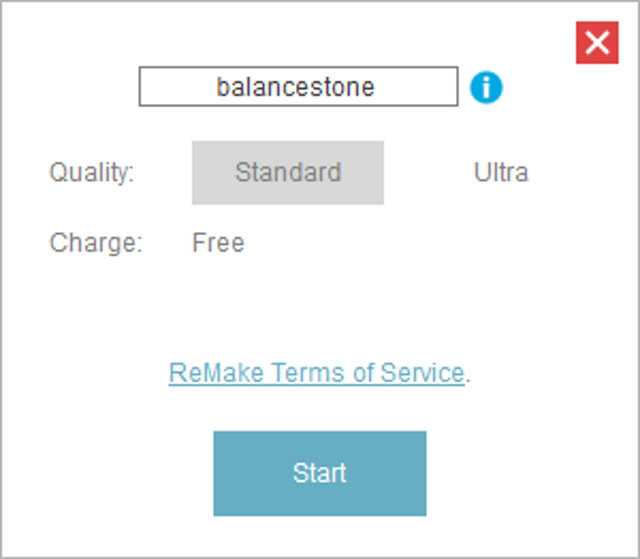

- Next I uploaded the files to Remake. Its important to select only good images and restrict background moving objects. After upload is done press create model. It can take a while during your model generation.

- After upload chose option on the generation process. I chose standard as its free.

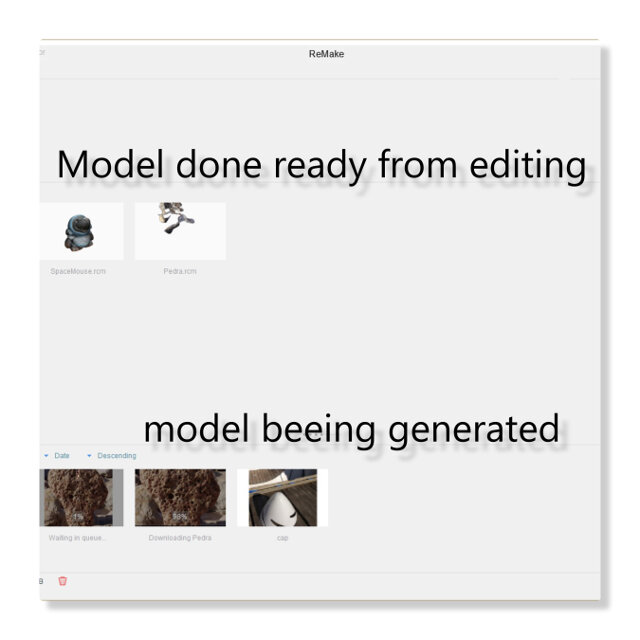

- On the lower part of the screen ReMake shows models being generated and on queue. The top part shows models al ready done.

- With the model ready you can click on it and entering the edit mode of ReMake.

- I compile the editing sequence on the following mosaic, in synthesis. I selected the undesired parts deleted it and filled the holes left. finally I generated a stl file that should be ready to print.

While on the 3D printer test model's page I downloaded the design and took note of all the parameters it intends to test such as:

Bellow is the 3D print test model:

The author also supplies an image for reference when checking the print

| Parameter | Results | ||

|---|---|---|---|

| Mini | Delta | ||

| 1 | Nut, Size M4 Nut should fit perfectly | Yes | No |

| 2 | Wave, rounded print | Yes | Yes |

| 3 | Star, Sharp Edges | Yes | Yes |

| 4 | Name, Complex Shapes | Yes | Yes |

| 5 | Holes, Size 3, 4, 5 mm | 2.9, 3.9, 4.9 | 3, 4, 5 mm oval |

| 6 | minimal Distance: 0.1, 0.2, 0.3, 0.4, 0.5, 0.6, 0.7 mm | 0.1mm not good | 0.1, 0.2, 0.3 not good scale wrong 6.5mm instead of 7mm |

| 7 | Z height: 0.1, 0.2, 0.3, 0.4, 0.5, 0.6, 0.7, 0.8, 0.9, 1.0, 1.1 mm | 0.1mm printed with 0.2 and 1.1 with 1 | Yes |

| 8 | Wall Thickness: 0.1, 0.2, 0.3, 0.4, 0.5, 0.6, 0.7 mm | did't print 0.1, 0.2 next walls printed as 0.5 until last as 1mm | Yes |

| 9 | Bridge Print: 2, 4, 8, 16 mm | Printed as 2.85, 3.9, 7.9, 15.8 | Yes |

| 10 | Sphere, Rounded Print 4.8mm height | 5.1 | Yes |

| 11 | Sphere Mix, 7 mm height | 7.15 | Yes |

| 12 | Pyramide, 7 mm height | 6.95 | Yes |

| 13 | Overhang: 25, 30, 35, 40, 45, 50, 55, 60, 65, 70° | Yes | Yes |

| 14 | Warp, does it bend? | no | Yes |

| 15 | 3D Print Font, optimized for 3D printing | Yes | Yes |

| 16 | Surface, Flatness | a bit rough | Yes |

| 17 | Size, 100 x 100mm x 23.83 (10mm width) | 99.45 x 99.8 x 23.2 (10.2 with) | Yes |

| 18 | Spike, minimum Layer Time, 21 mm height from Bottom (include Baseplate) | 15mm | Yes |

| 19 | Hole in Wall, 4 mm diameter, check for proper print | Yes | Yes |

| 20 | Raft Test, raft should be just under the model | didn't test | Yes |

| 21 | Retract Travel, check retract settings for longer travel | almost no ozzing | Yes |

| Conclusion | For a FDM printer I belive the result is very good. The sizes differences are probably due to a PLA shirincage |

The result!