10. Molding and casting¶

Assignmnets¶

-

Group assignment: Review the safety data sheets for each of your molding and casting materials, then make and compare test casts with each of them.

-

Individual assignment: Design a mold around the stock and tooling that you’ll be using, mill it (rough cut + (at least) three-axis finish cut), and use it to cast parts.

Group Assignment¶

In our lab, we had these materials- Aditya 1010 RTV liquid silcone & Aditya Easy Cast Transparent Epoxy Resin -33

Understanding data sheet

- Aditya Silione Rubber RTV – 1010 is a condensation cure type Silicone Rubber. It comes in 2 parts. One is Silicone Rubber and second is Curing Agent.

- Curing Agent is mixed into Silicone Rubber in a given ratio (40-50 ml in 1kg of silicone).It cures at room temperature. Plaster, Resin, Epoxy Resin, Polyurethane, Wax and other resins can be casted into the cured silicone mould.

- Easy Cast Transparent Epoxy 33 can be casted into moulds of Silicone Rubber to Create Transparent Crafts, Lockets, Jewellery and Trophies. Pigments are available to make Opaque Colour Castings. It comes in Part A and Part B.

Silicon rubber features

- Low Viscosity

- Transparent

- No grinding or sanding after casting

- Can Cure in 30 minutes if heated at 65 degree centigrade and poured

- Part A 100 parts : Part B 50 parts mixing ratio

- Non-Yellowing

Technical Properties

- Viscosity - .10000 Pi

- Curing Agent / Hardener Ratio 4 %

- Curing Time - 6 Hours

- Colour - Milky

Research¶

For this week’s assignment, I watched some youtube videos on How to make molds and I found these ones best.

Then I read about molding and casting on various websites and below are my learning-

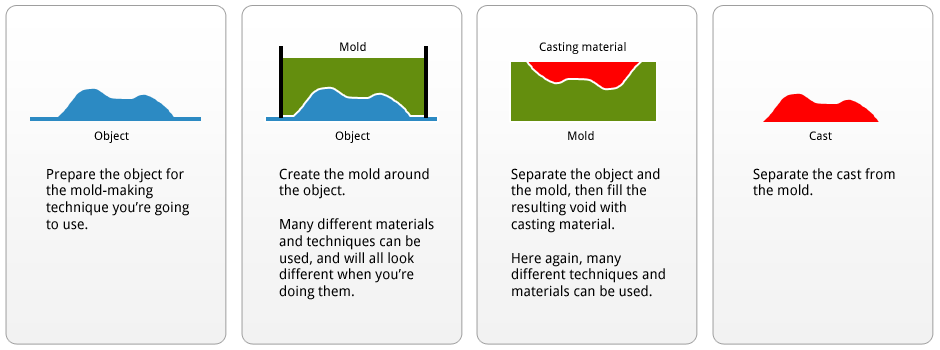

- Mold making is the process of creating a hollow, usually rigid vessel around an object. Once a mold is made around an object, the object is removed, leaving a hollow void in the mold exactly the size and shape of the object.

- Casting is the process of filling this resulting hollow void in the mold with liquid or molten material.

Process of Molding and Casting

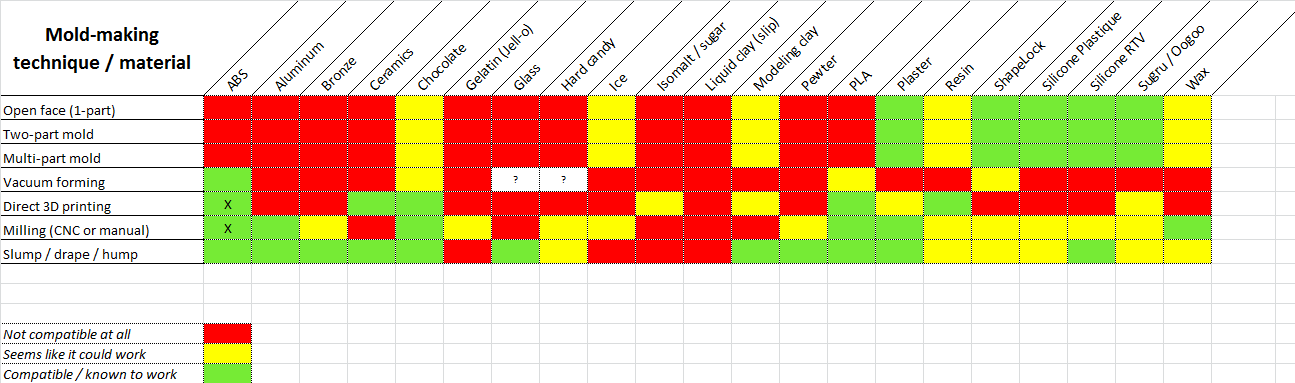

Mold making techniques¶

- Open face (1-part)

- Two part mold

- Multi-part mold

- Vacuum forming

- Direct 3D-printed ABS / PLA

- CNC Milling

- Slump / hump / drape molds

I used two-part mold techniques to create the mold for the assignment.

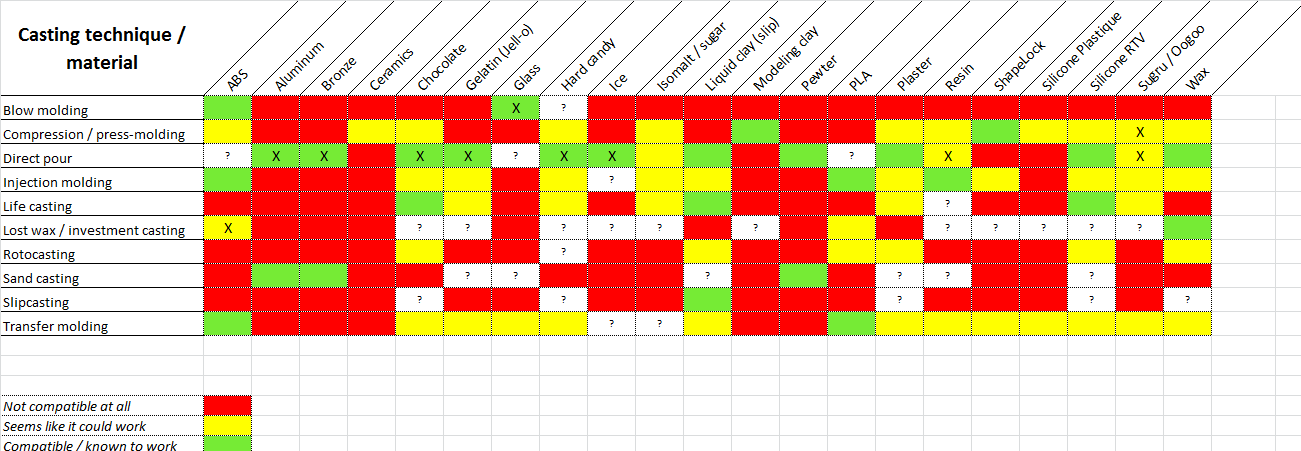

Casting techniques¶

- Lost wax

- Direct pour

- Investment casting

- Sand casting

- Compression / press-molding

- Injection molding

- Blow molding

- Transfer molding

- Lifecasting

- Slipcasting

For casting, I poured silicon rubber with mixed with curing agent directly into the mold.

Material used in mold making and casting¶

There is an absolutely huge list of materials that can be used with the various mold-making and casting techniques out there.

I used MDF board to create the negative of mold, some of my labmates used machinable wax. For mold, we had silicon rubber and curing agent to harden the silicon.

Mold making techniques with different materials¶

Casting techniques with different materials¶

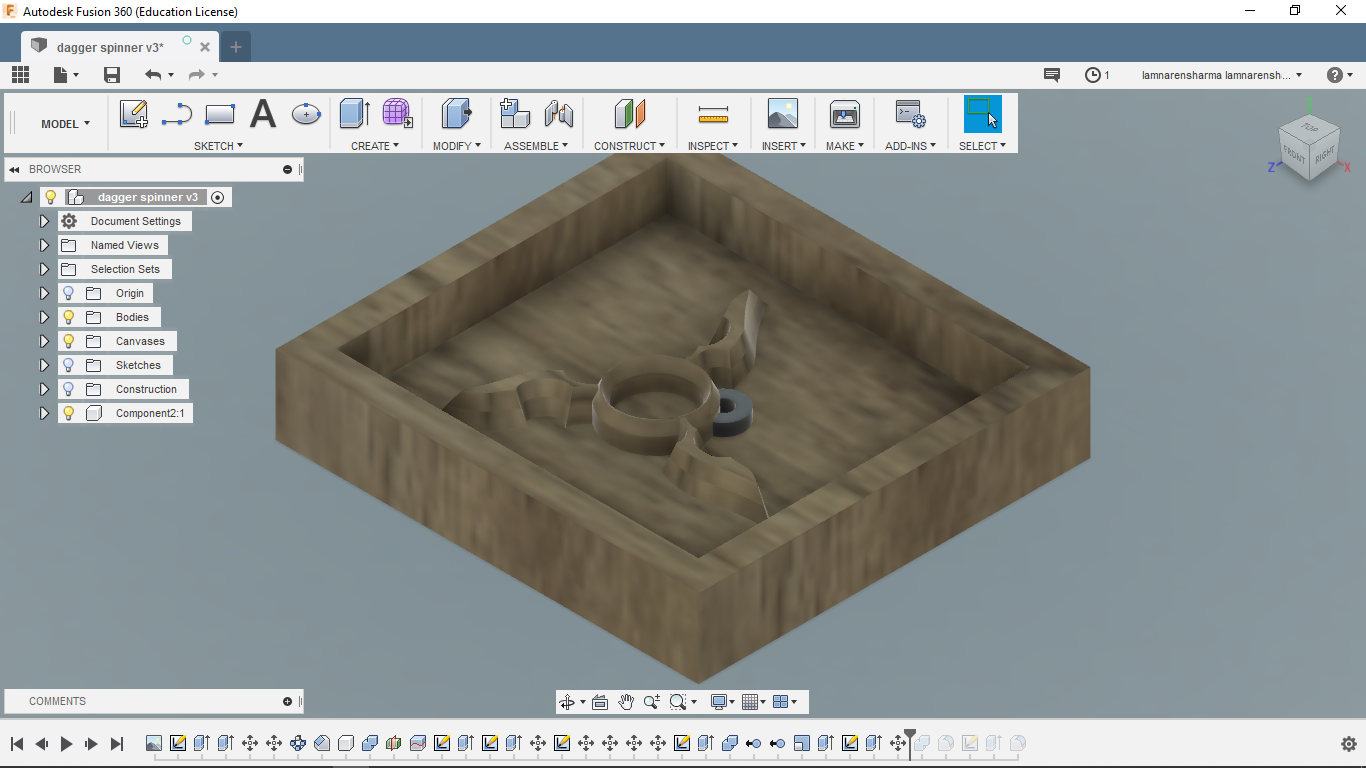

Mold designing¶

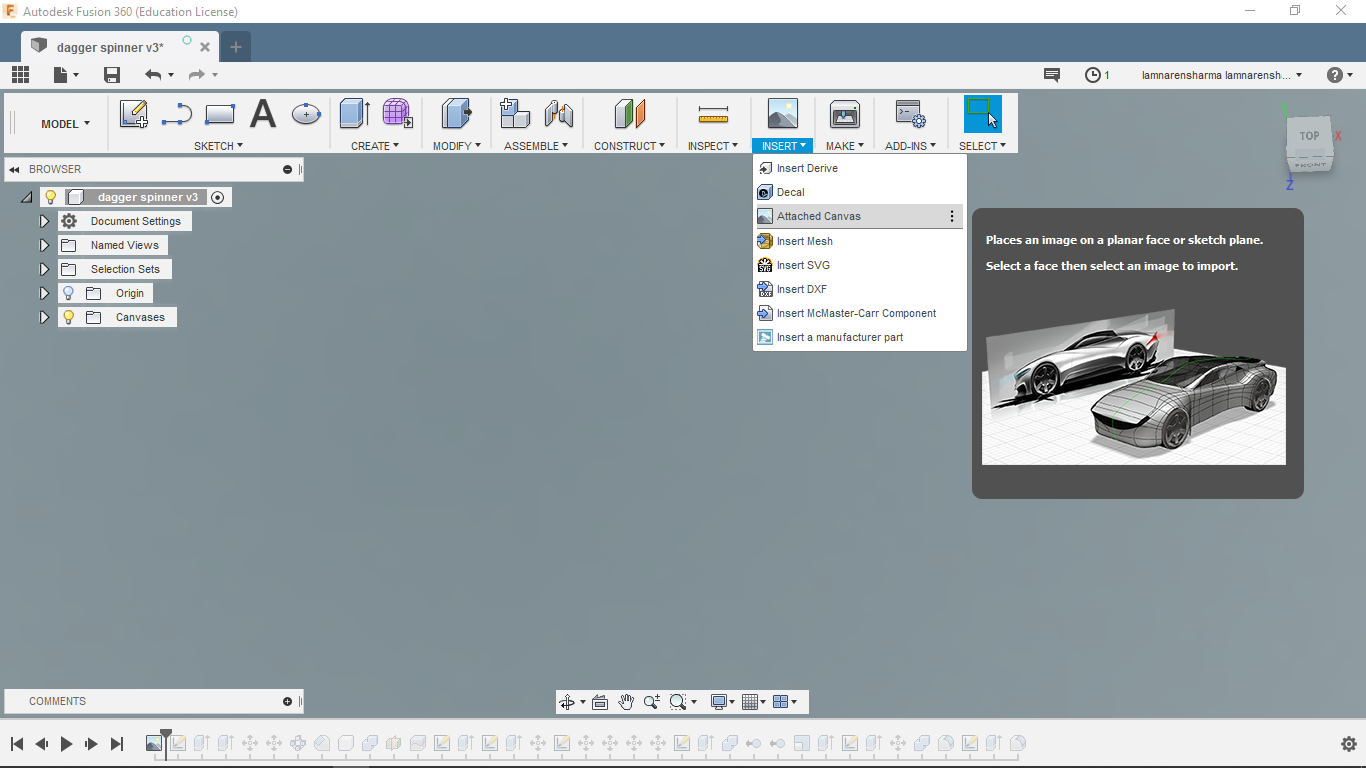

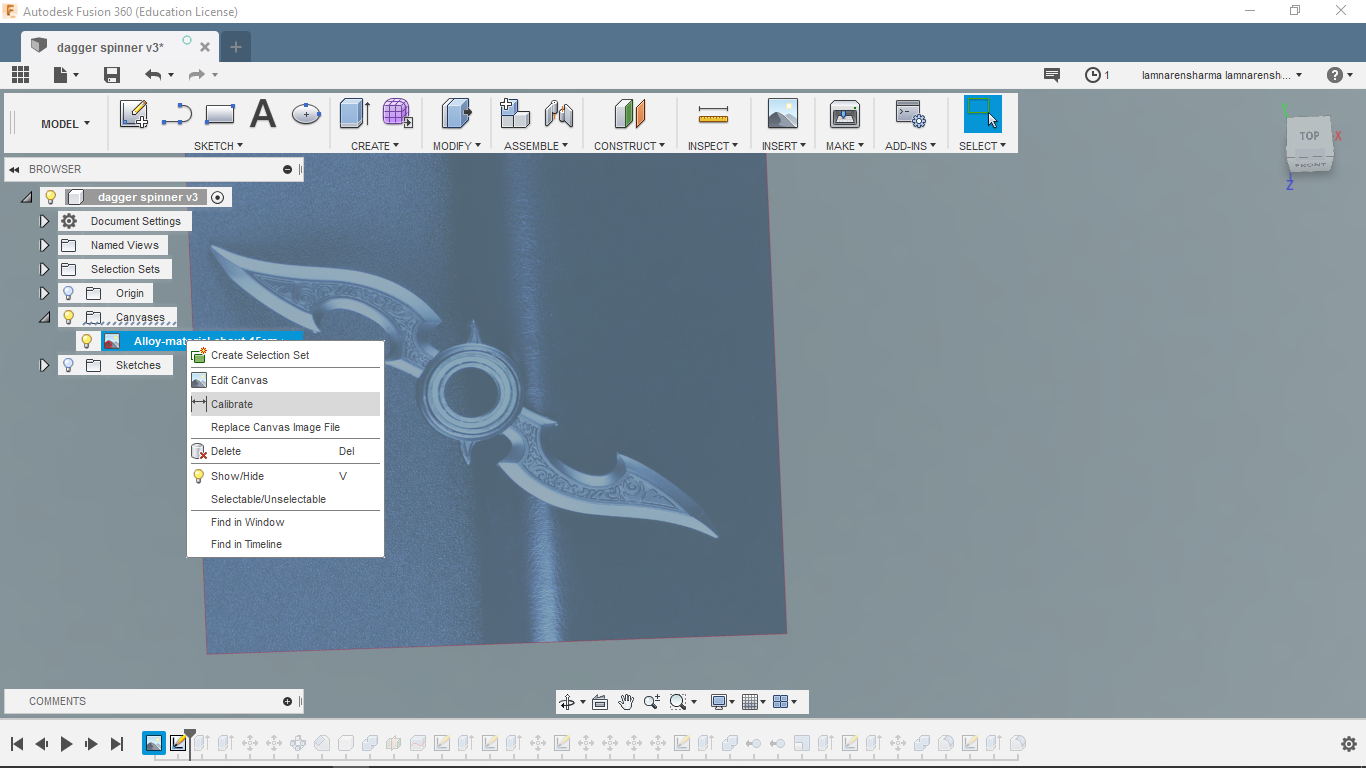

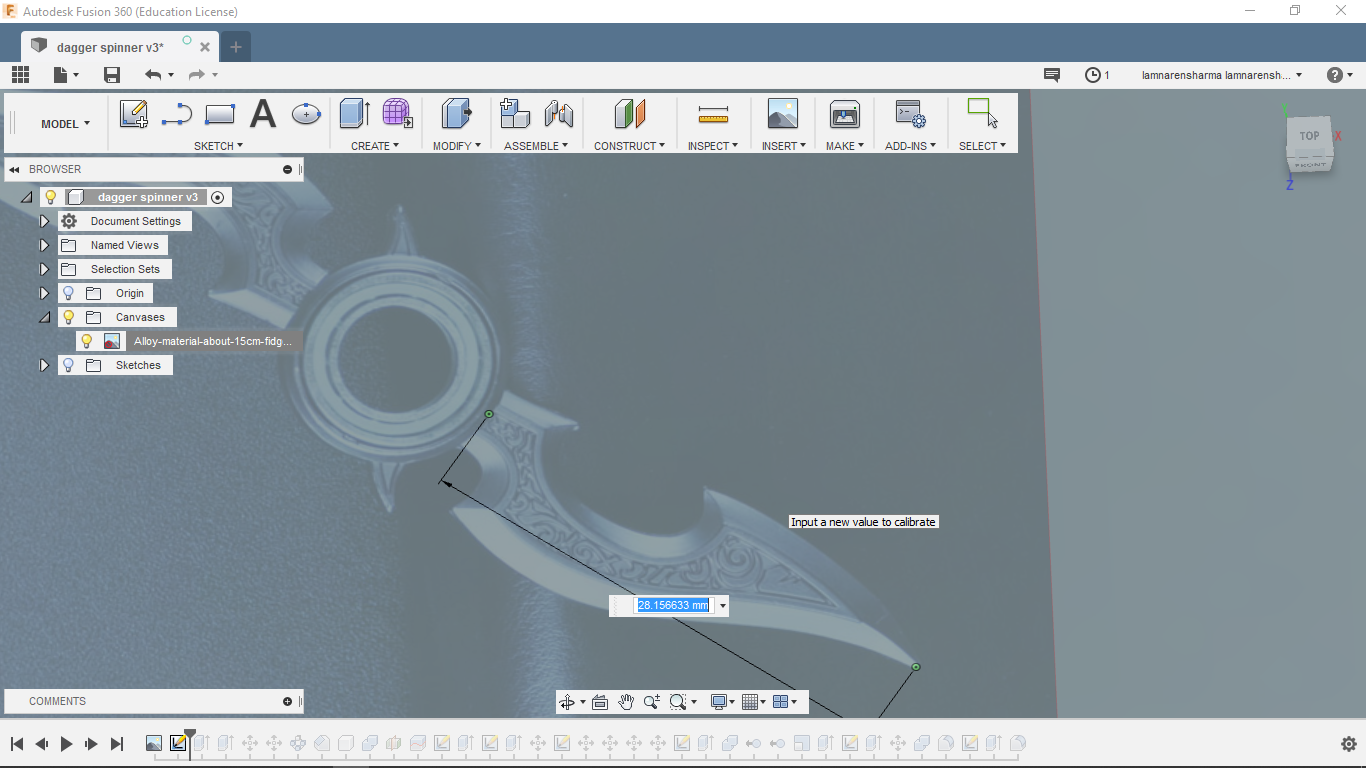

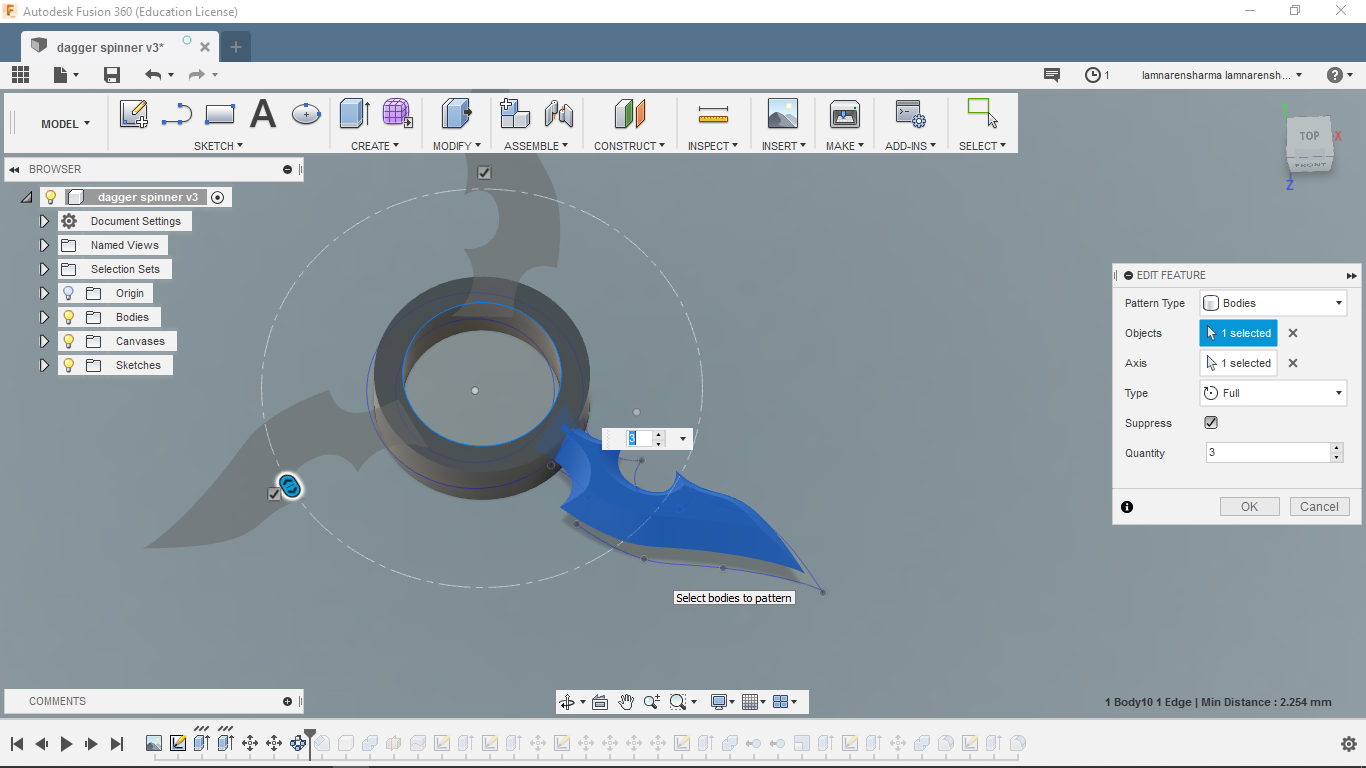

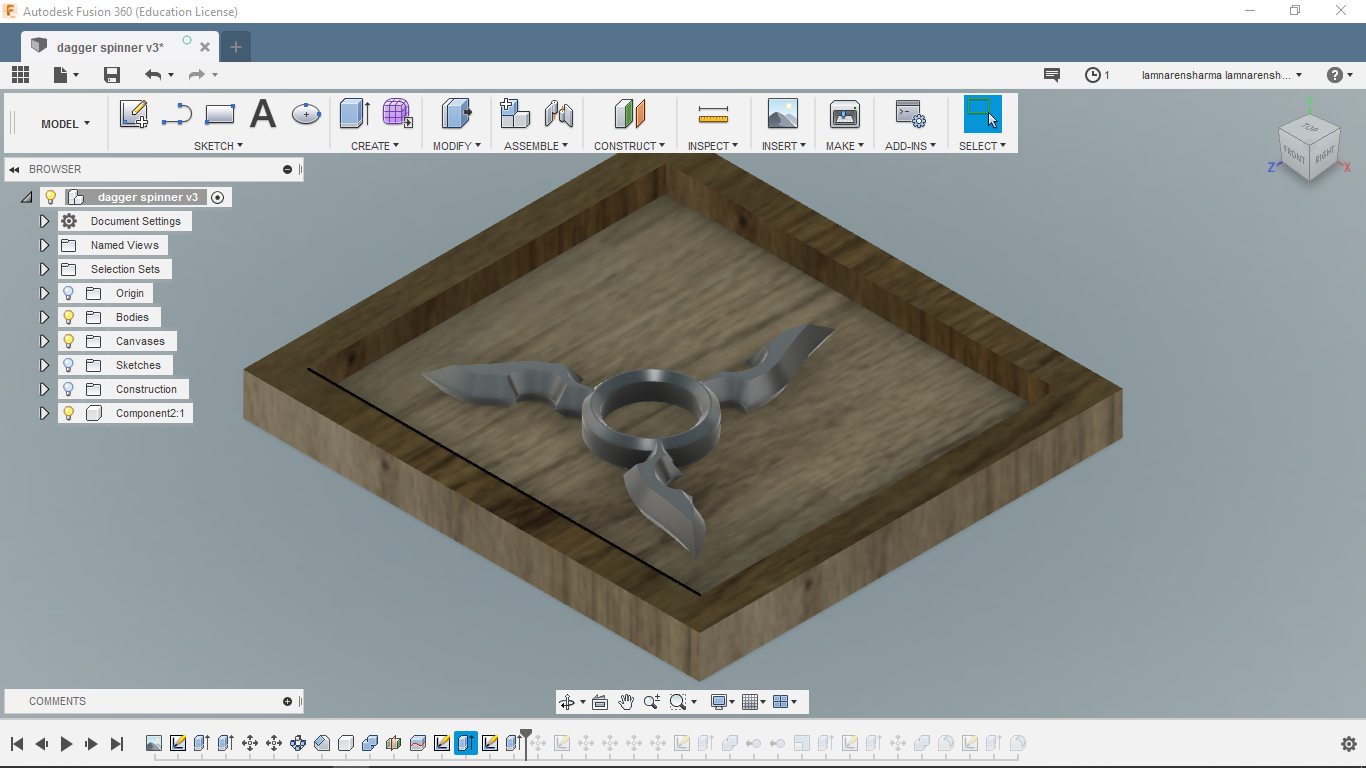

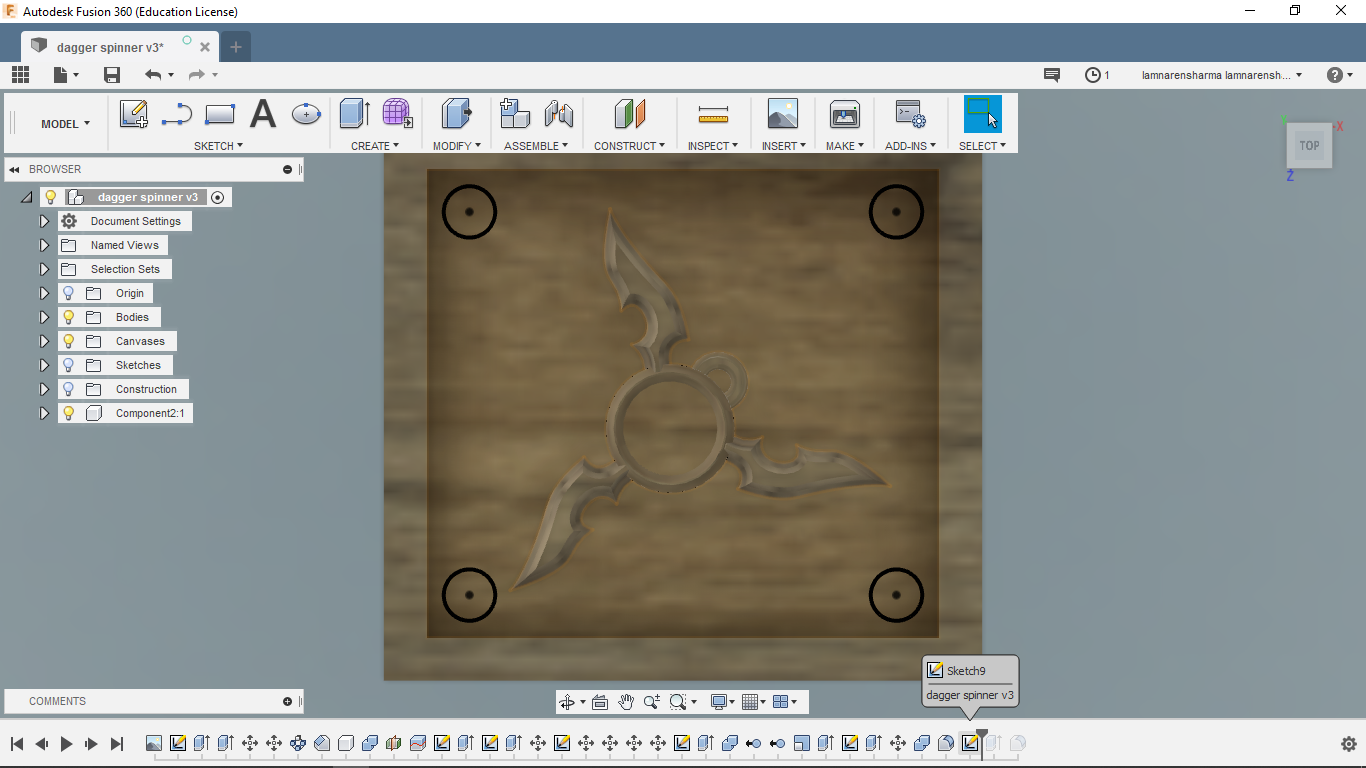

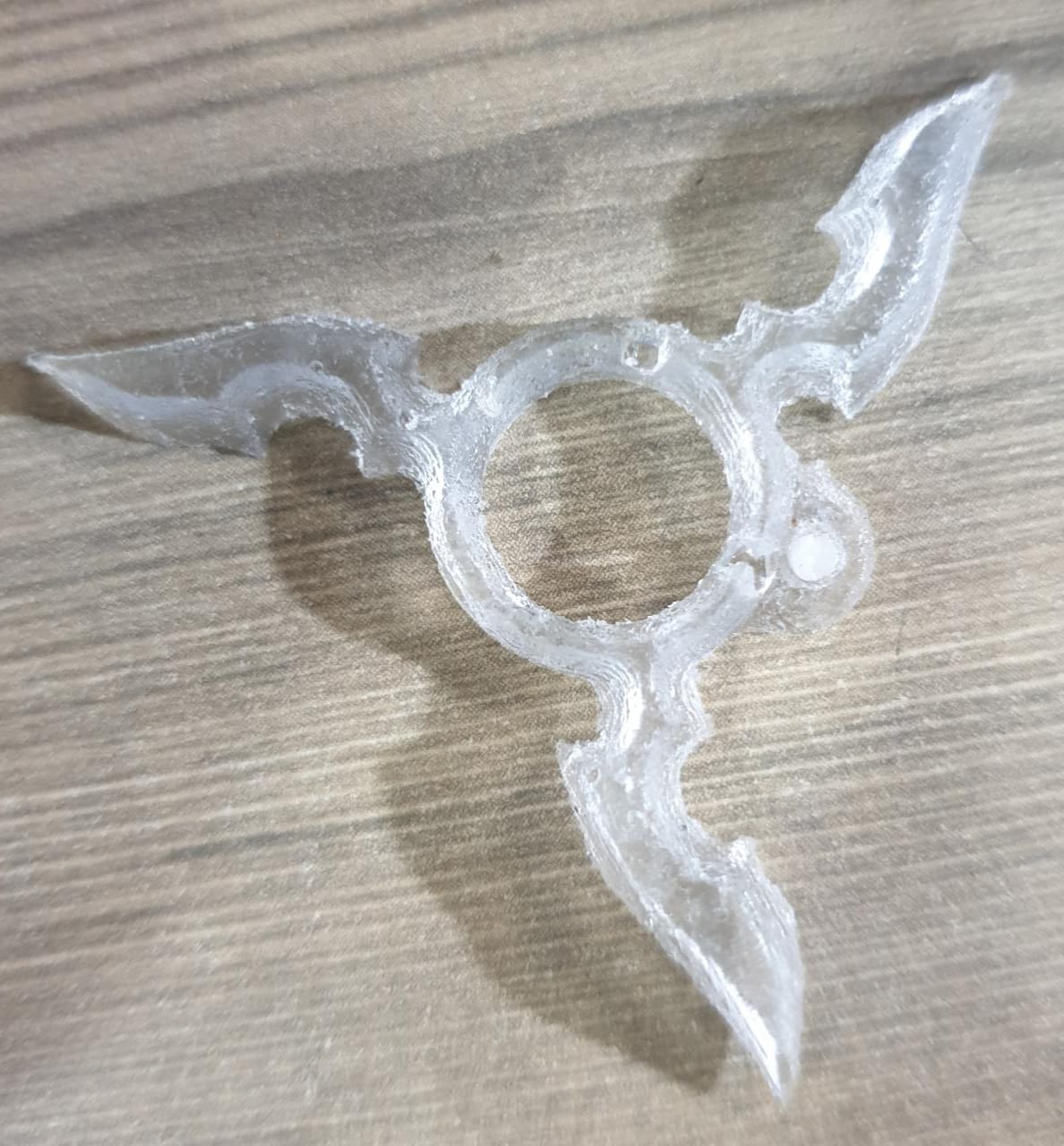

I used Fusion360 software to design the mold. I wanted to make a fidget spinner so I searched some reference images on the internet and finally selected this one.

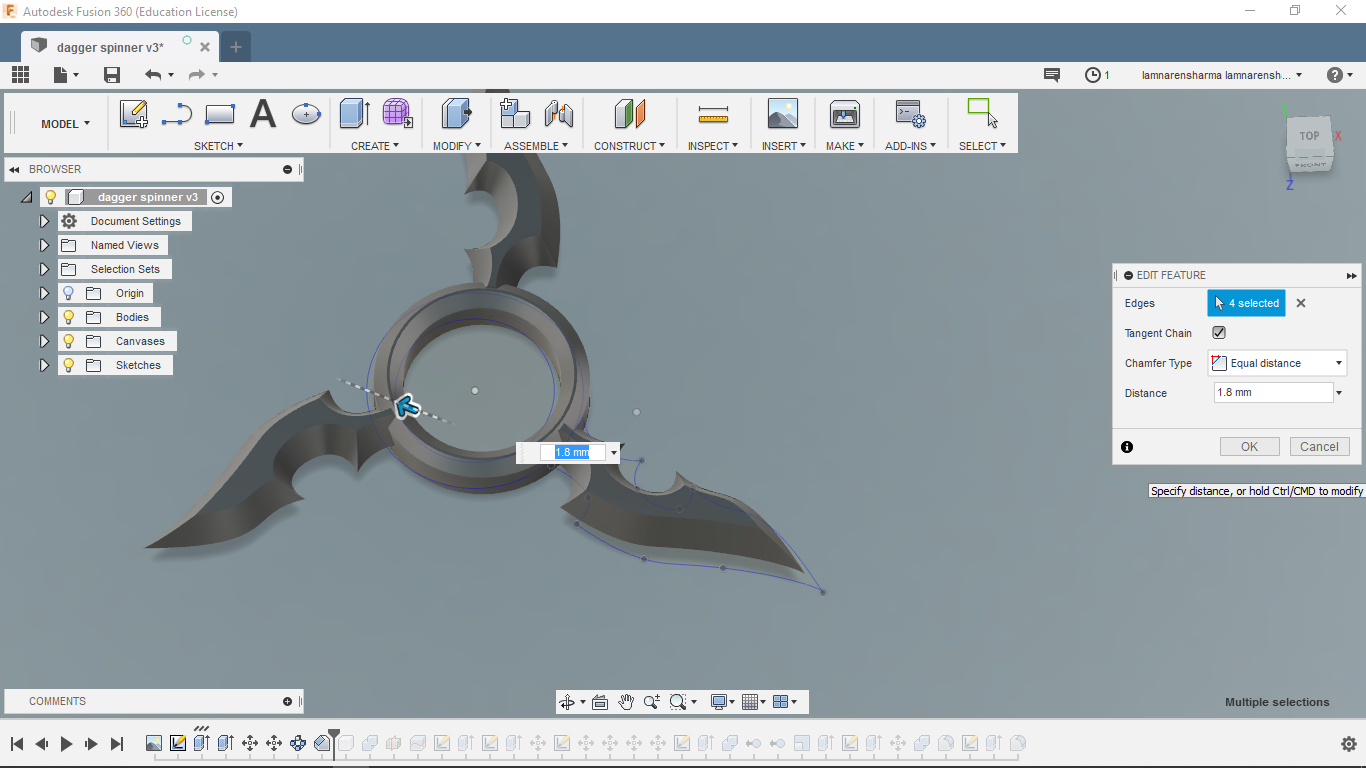

Designing steps

- First, import the image in fusion360. Go to Insert –>Attach Canvas

- Then calibrate the size of the canvas by right-clicking on the canvas in the browser and select Calibrate.

- I selected 30mm length for the blade.

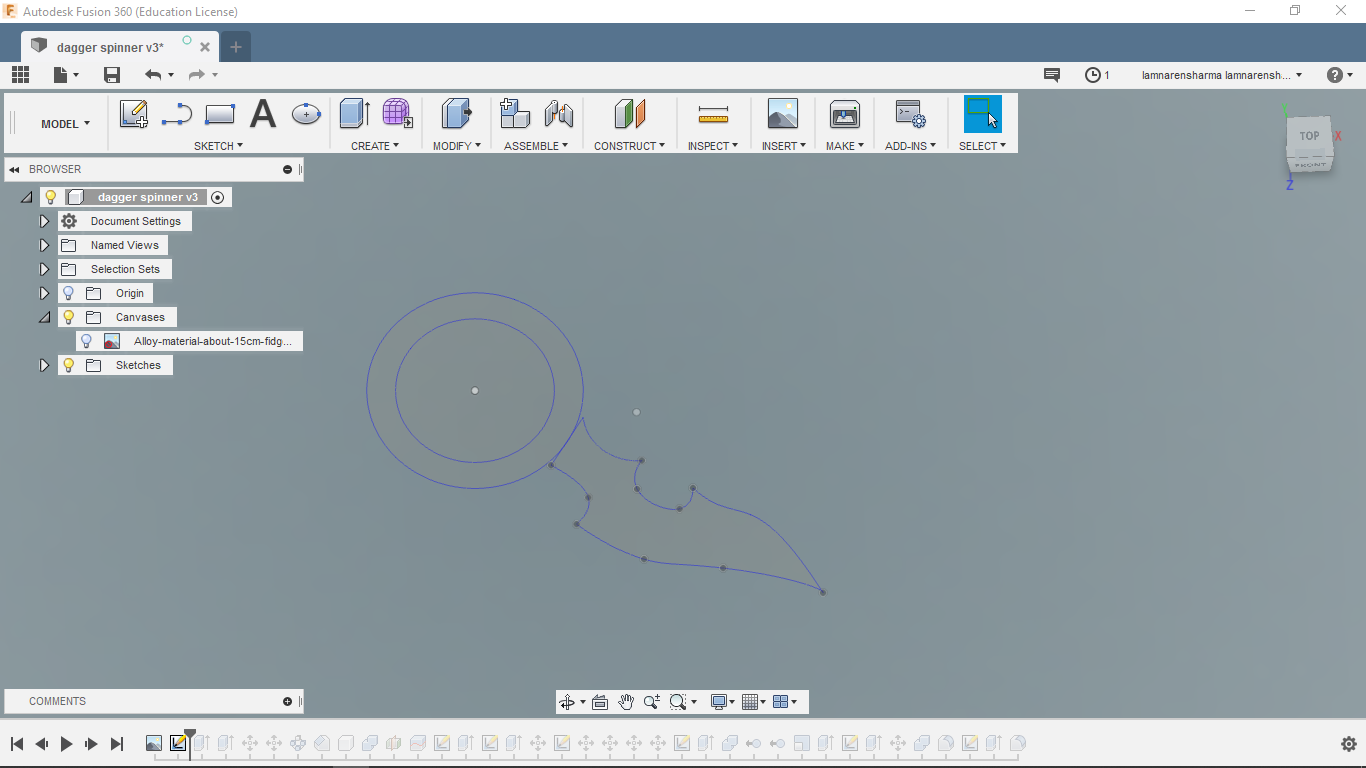

- Now design a 2D sketch of the blade using spline, line, arc and circle tools.

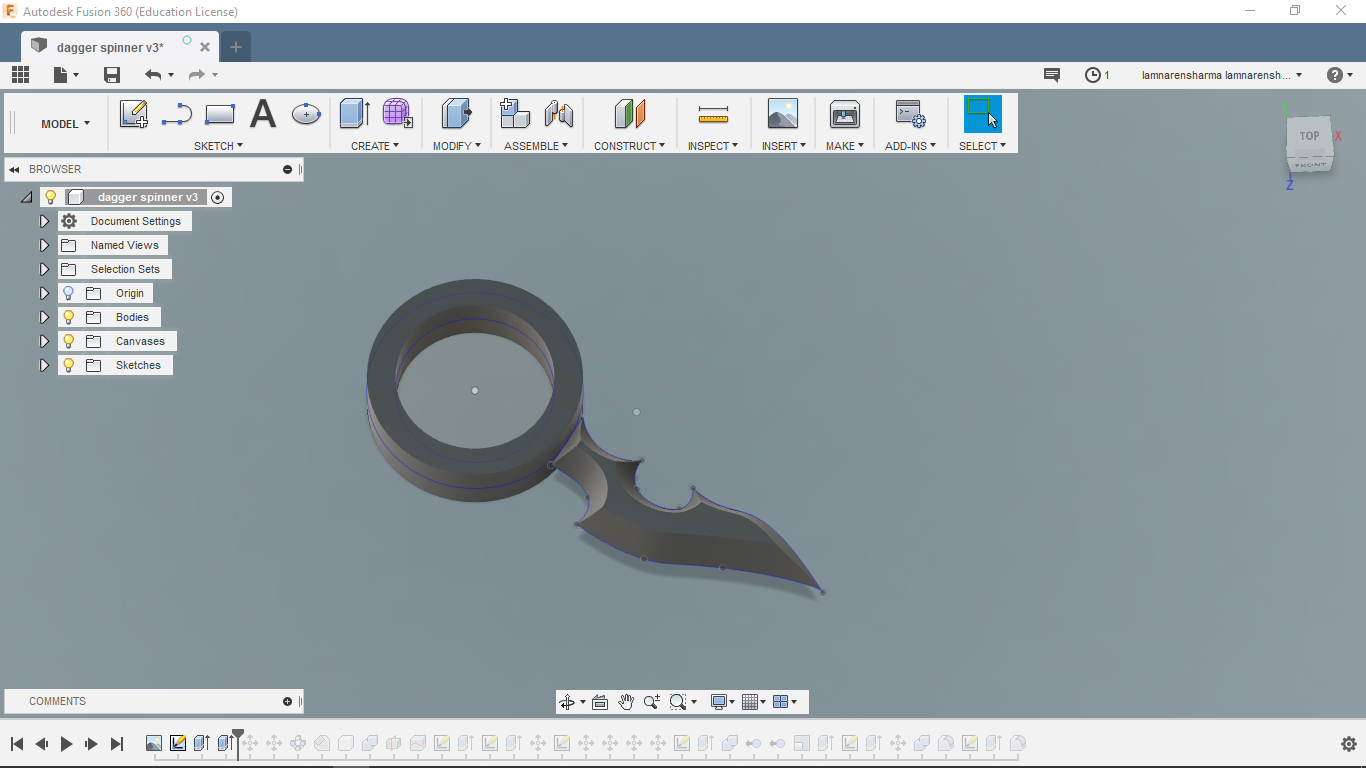

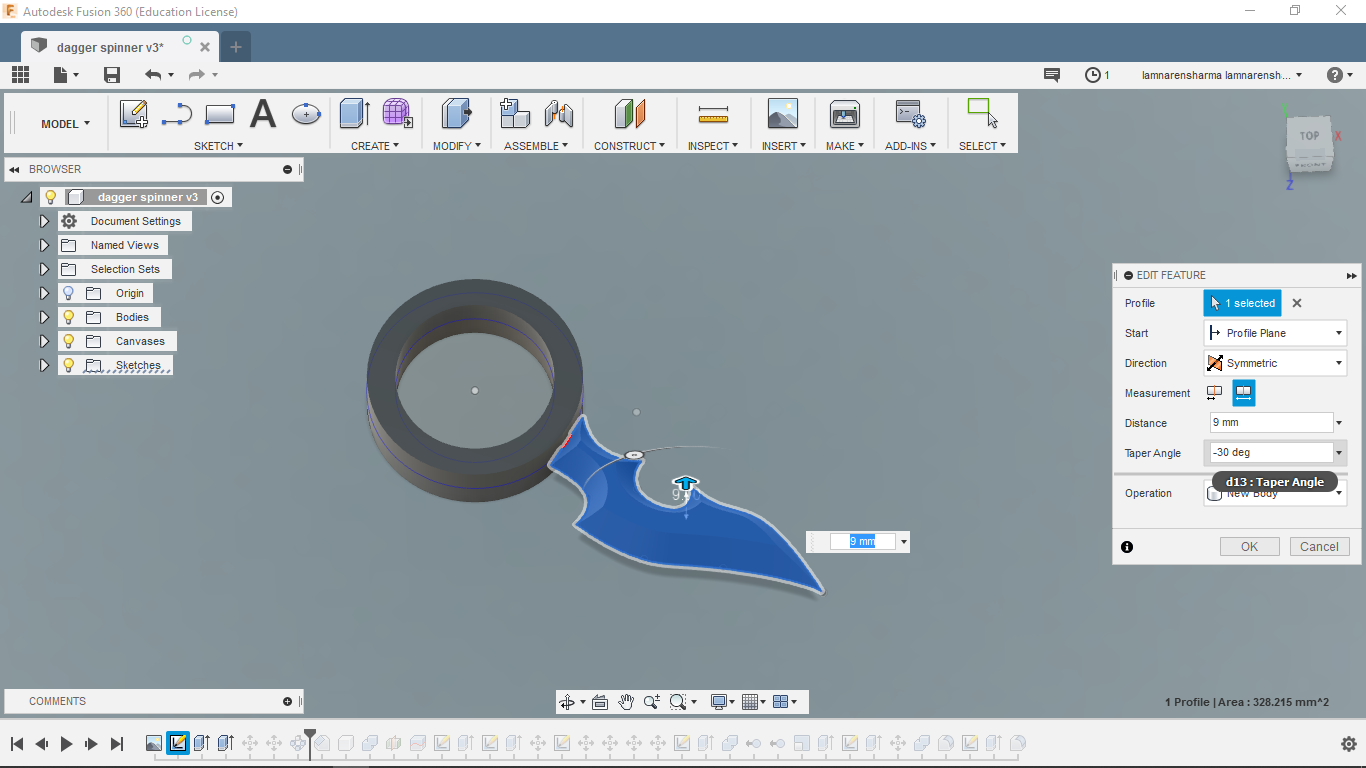

- Then, extrude the sketch. I extruded it to 9mm.

- Go to Create –> Pattern –> circular pattern to make 3 blades.

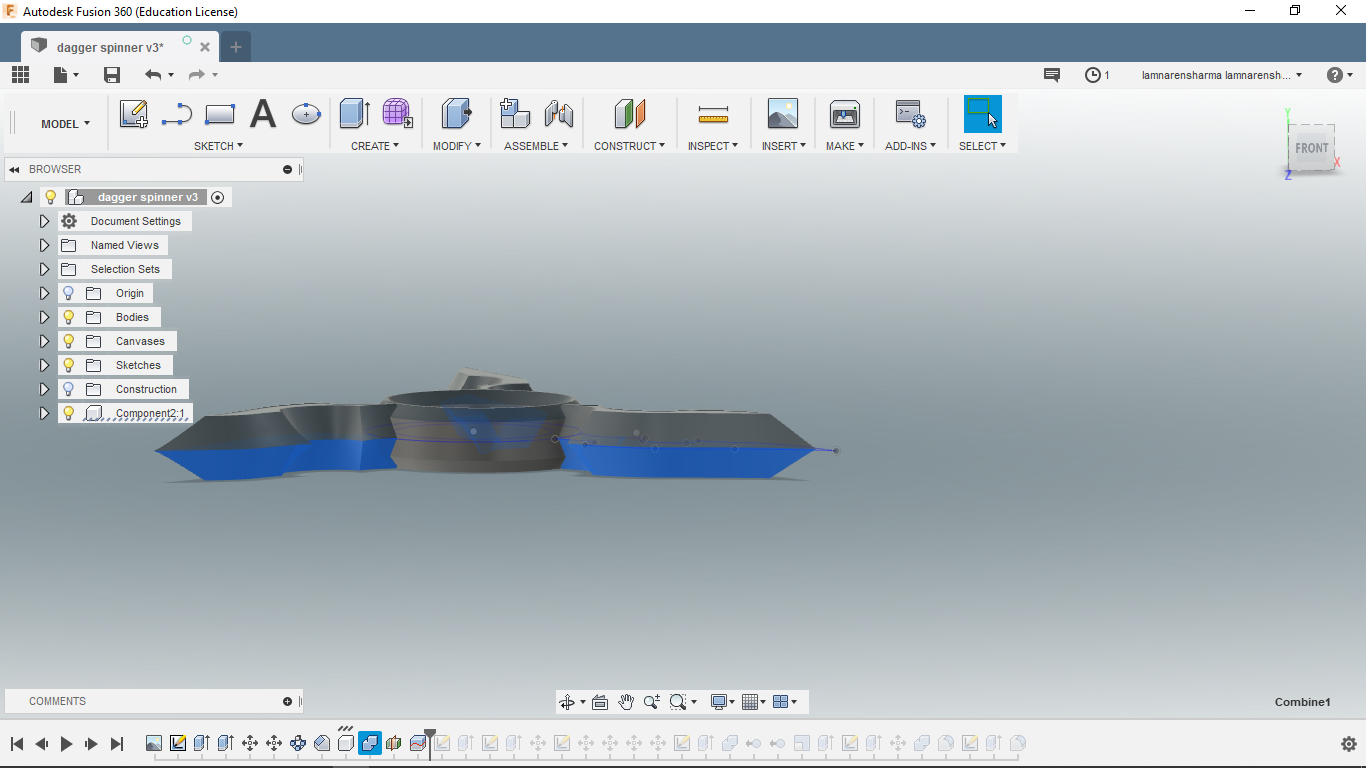

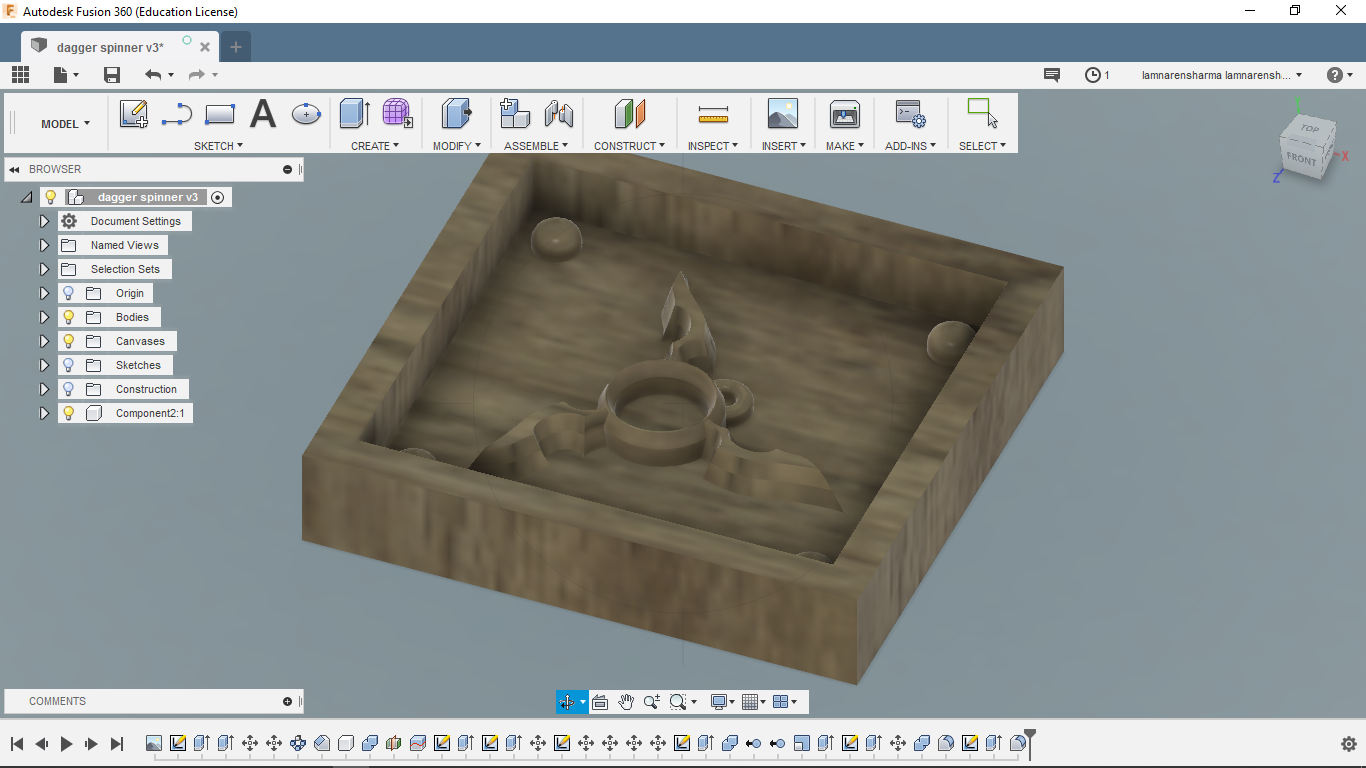

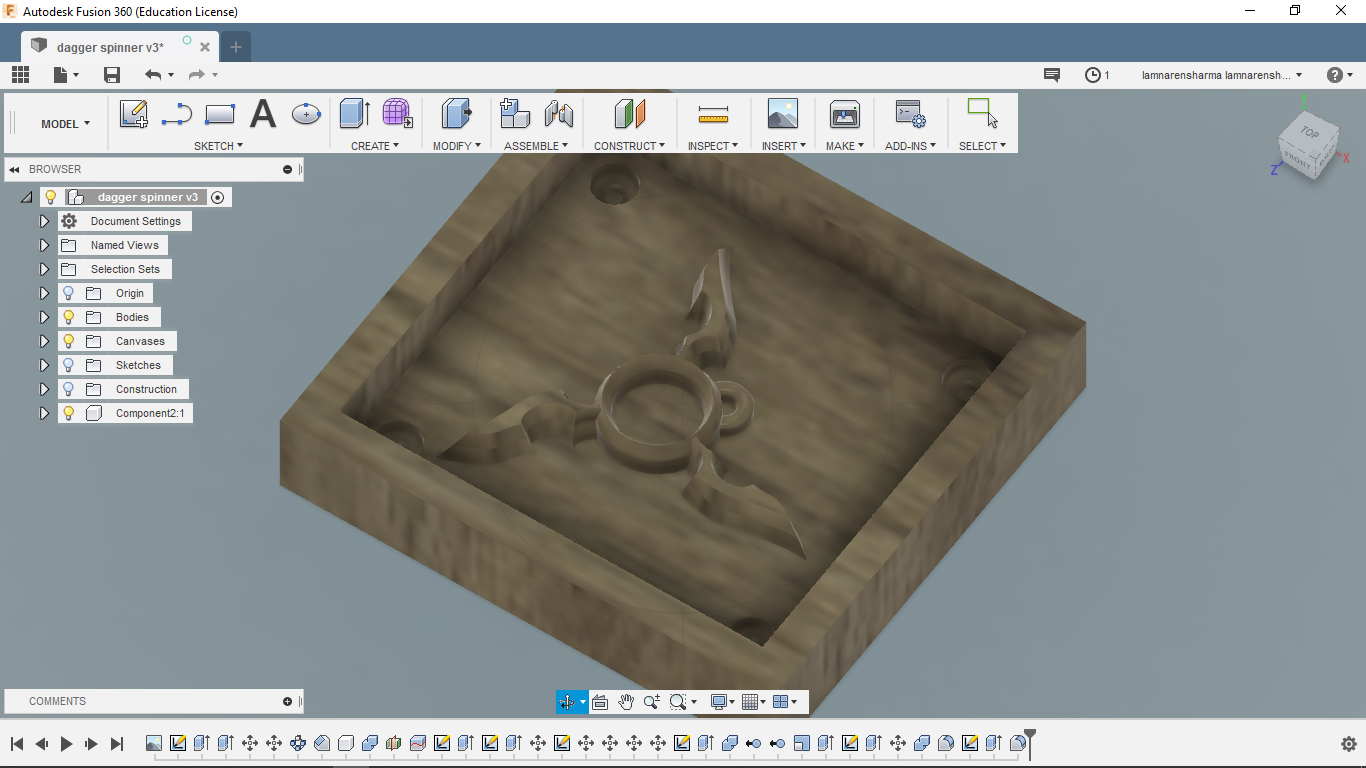

- Here, Split the body into two halves if you want to make 2 piece mold, one for top mold and one for the base. Go to Modify –> split body, then select the body and plane along which you want to split.-

- Now create a box around the model.

- Here, the size of the mold was too big and I figured out that it will take too much time to mill this. So, I changed my thought of making spinner to make a pendant. I scaled down the whole part to 50% of the original size and added a ring to make it a pendant.

- Now create one circle at each corner and extrude them to 3 mm to make registration marks. Use fillet tool to smoothen the edges.

- Repeat the last step in another half of the body and extrude circle in reverse direction.

Click here to download the design file.

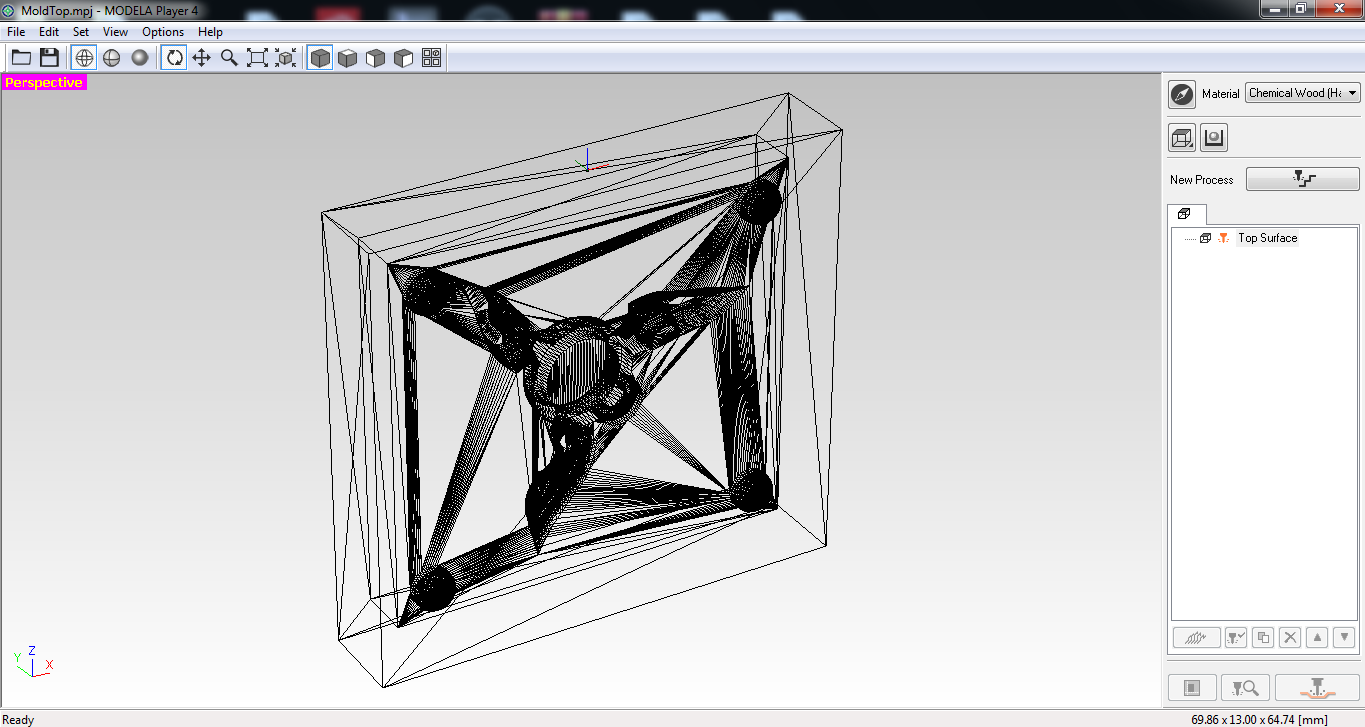

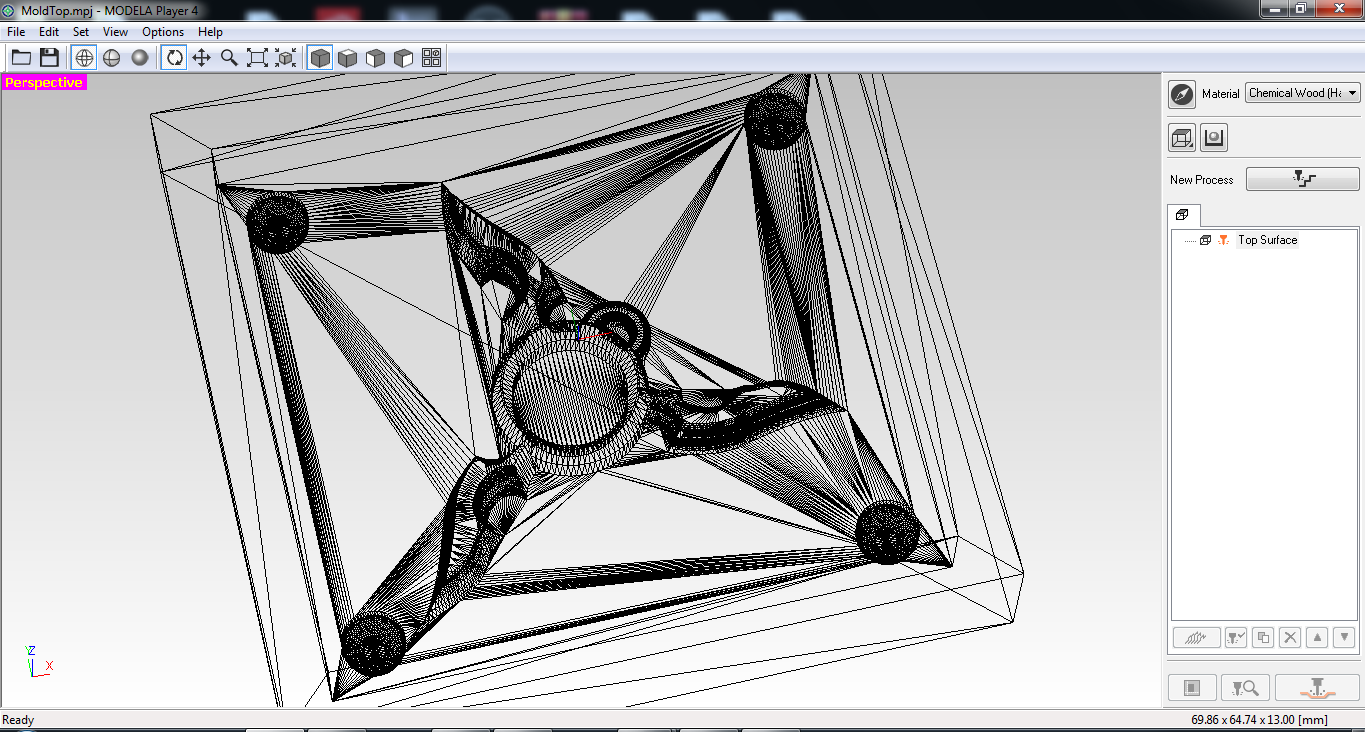

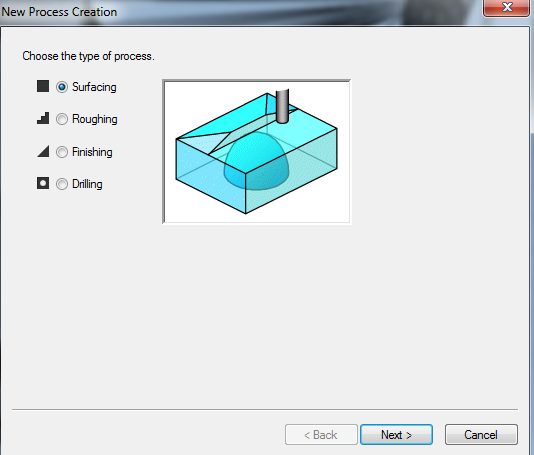

Creating toolpath for milling¶

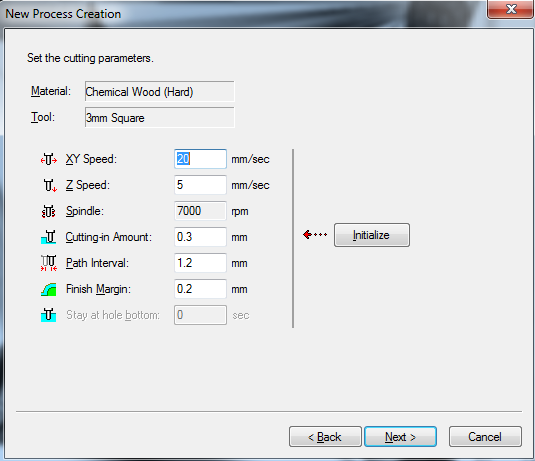

For creating tool-paths, we used Modela software.

Steps

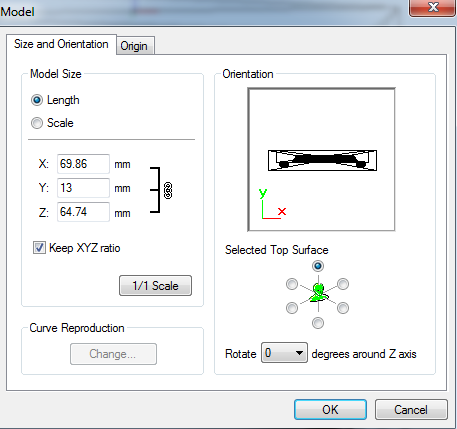

- Import the mold

- If needed, set the orientation.

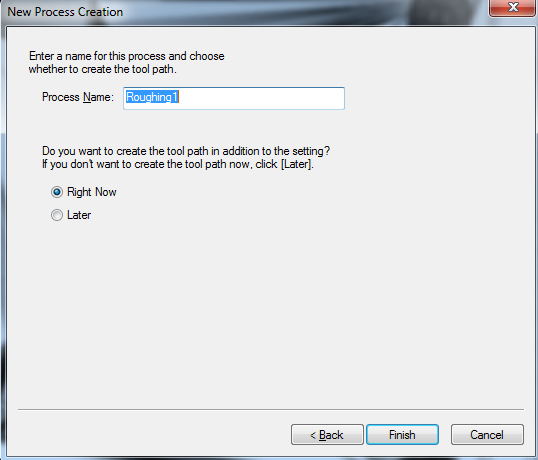

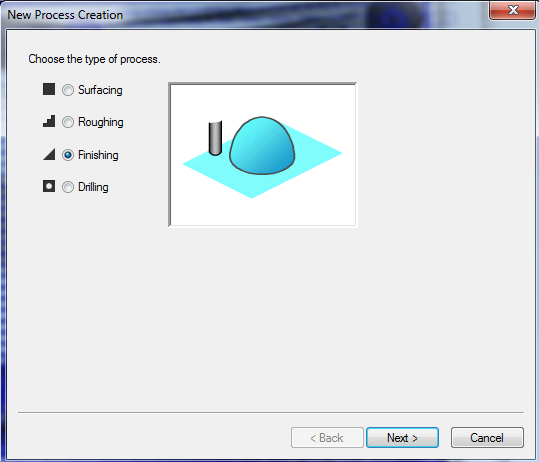

- Create roughing process.

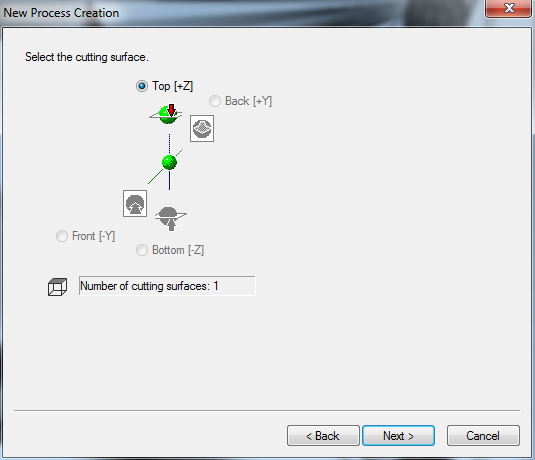

- Select the cutting surface.

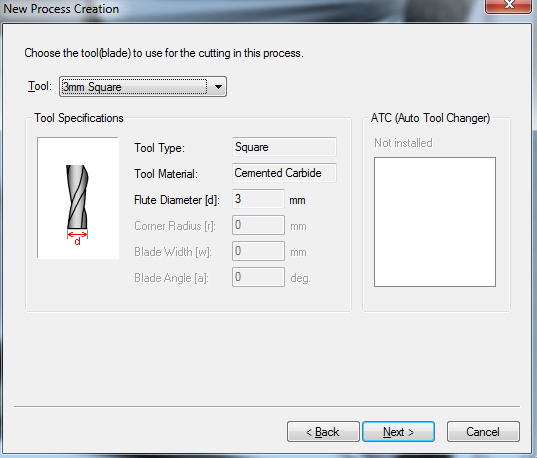

- Select the tool.

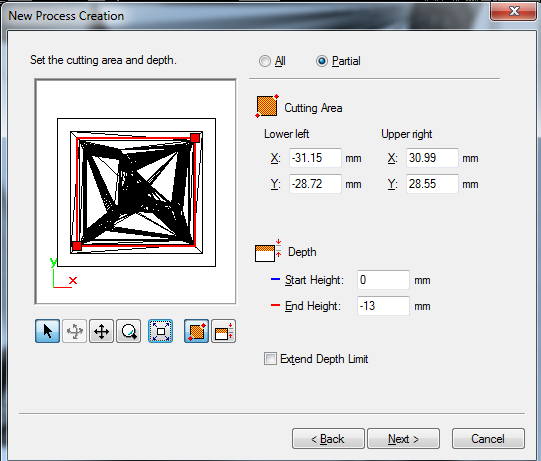

- Select the cutting area.

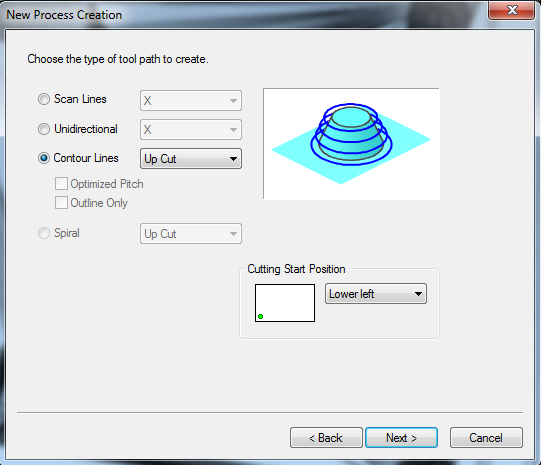

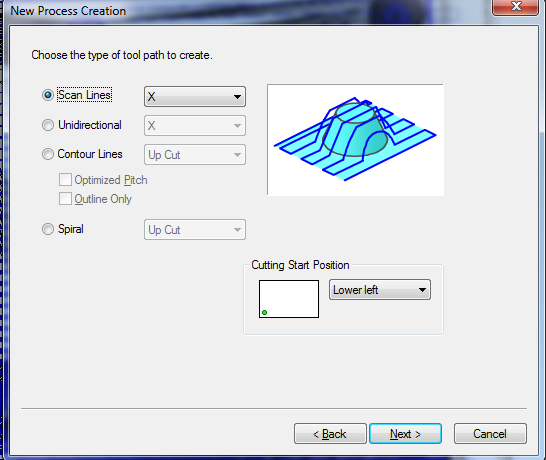

- Choose the type of tool path.

- Set the cutting parameters.

- Enter the name of the process and finish the roughing process.

- Now create the finishing process and repeat the above steps for finishing.

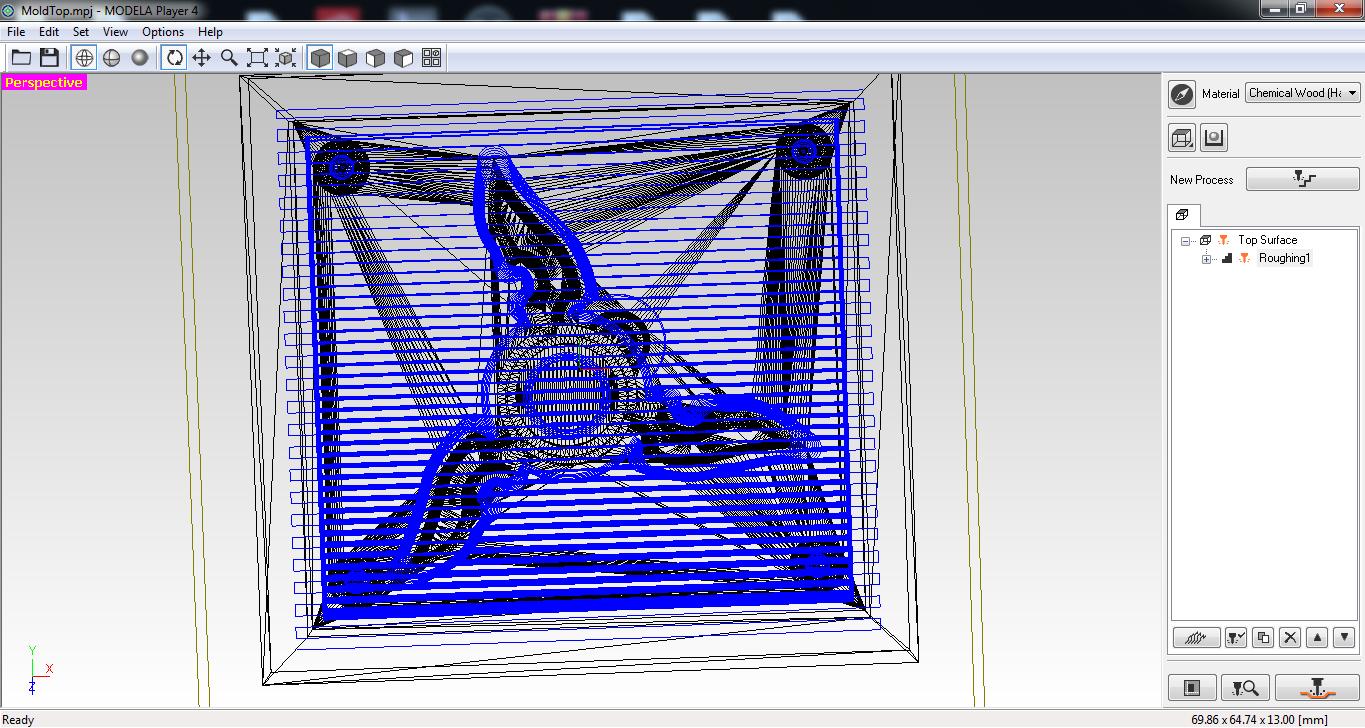

Milling the mold¶

- Now set the origin in Vpanel software

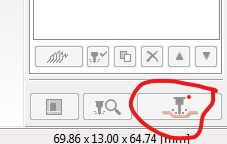

- Click on the toolbar in the Modela(shown in the below pic) to start the process.

Roughing

Finishing

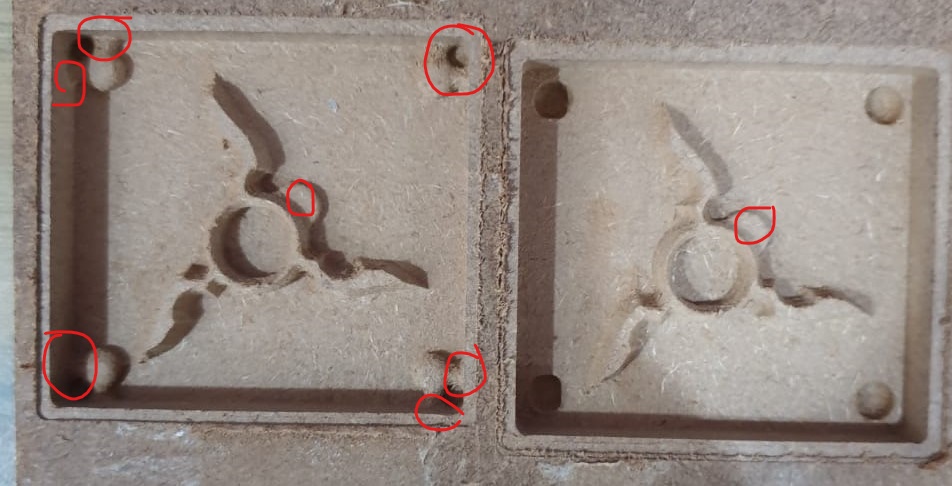

- Here, you can see some areas were not milled because there was not enough room for the tool to mill. Like I created 2.5 mm hole but the tool diameter was 3mm so It couldn’t drill and left that space. Then, I drill the holes using the drill machine.

Click here to download the second version of the design.

Pouring the silicon rubber into the mold¶

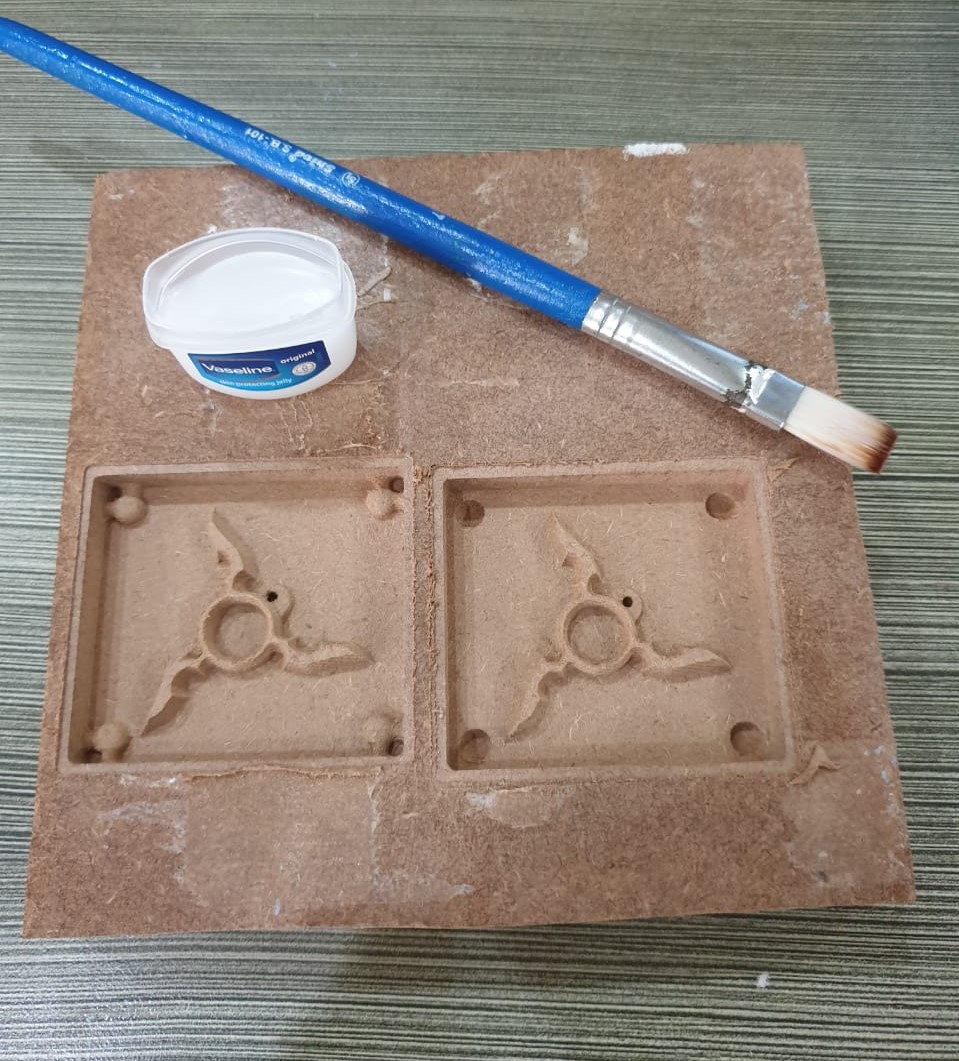

- First, apply some vaseline on the surface so that it would be easy to remove the silicon mold later.

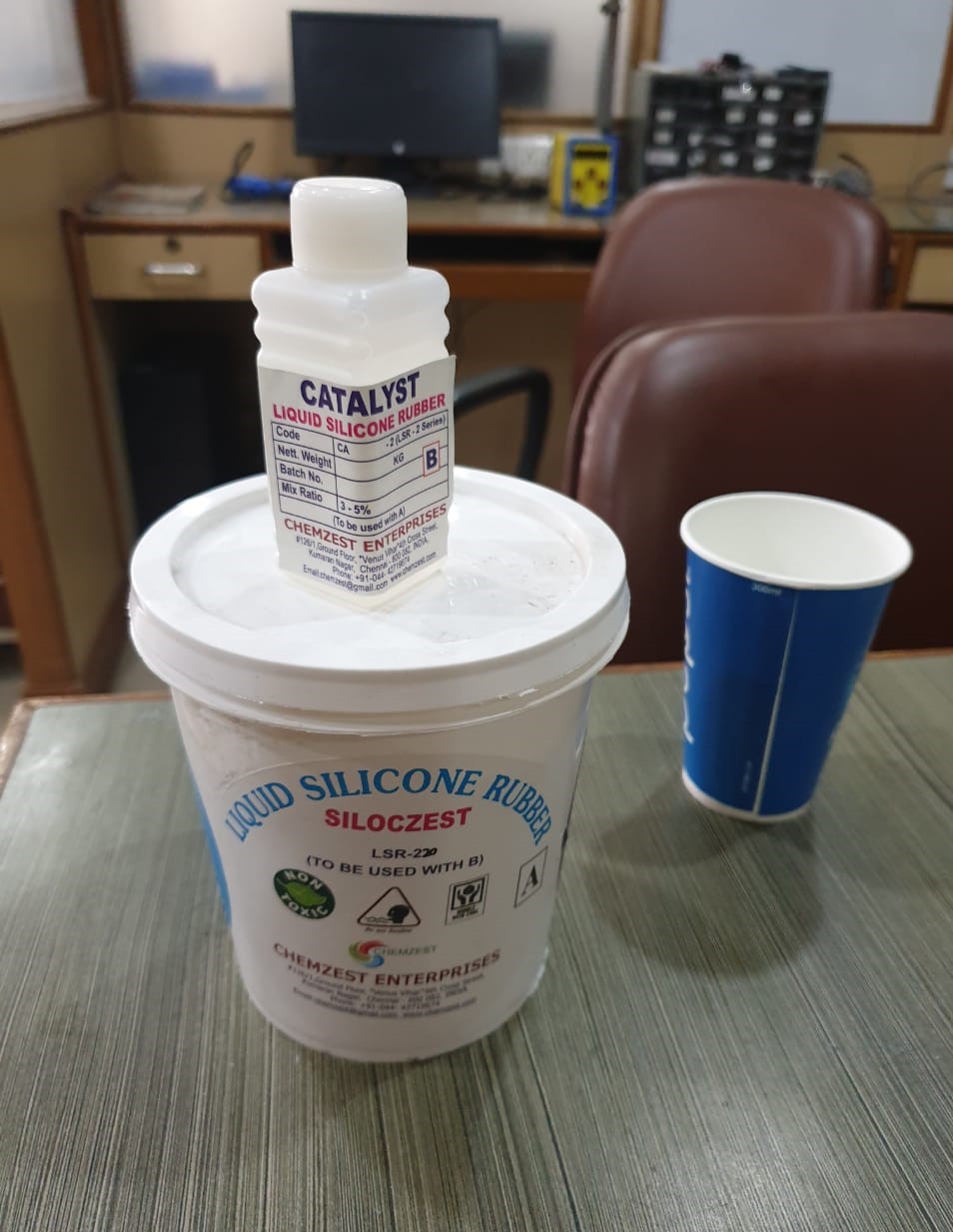

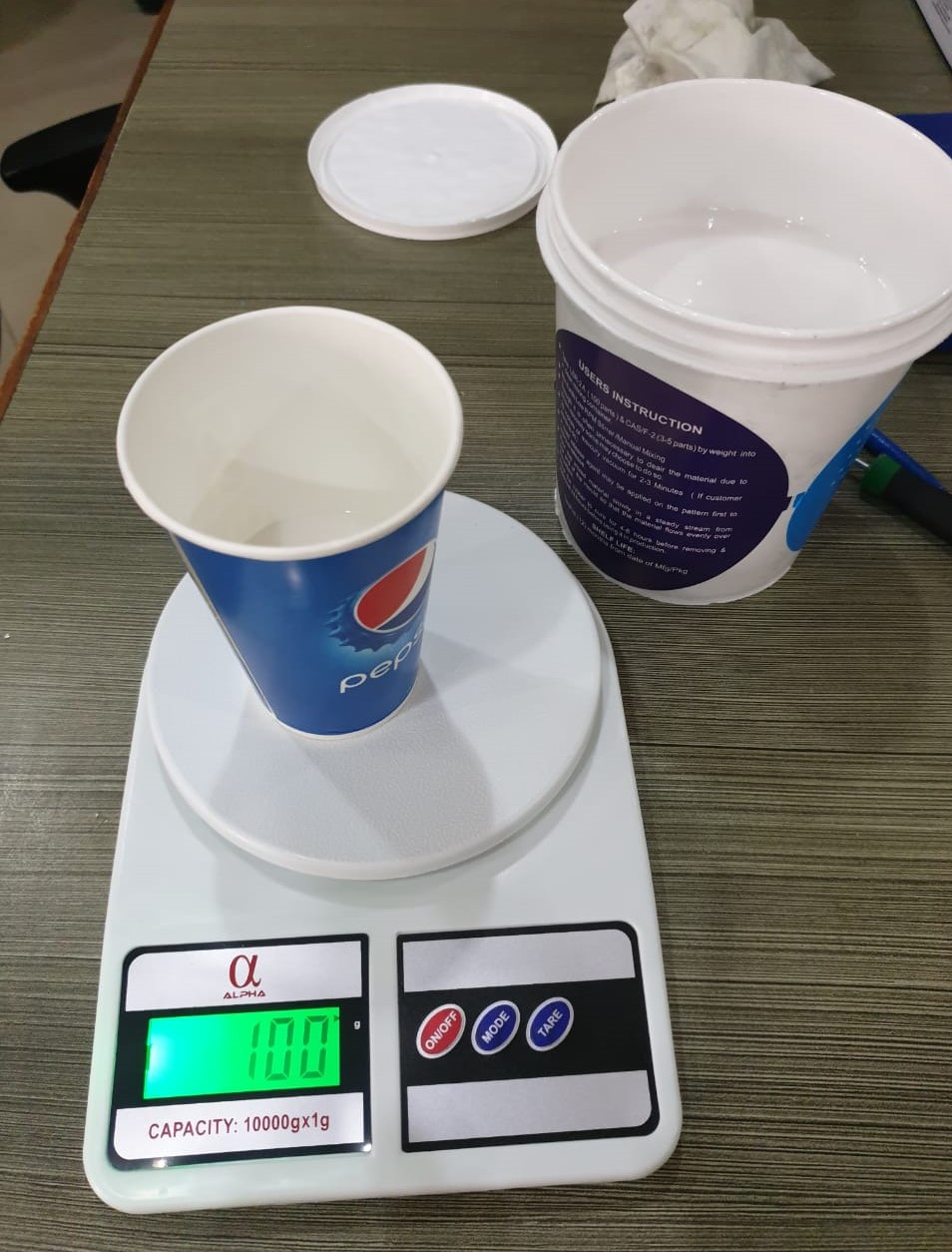

- Weigh 100 gm silicon on a weighing scale and mix 3gm of curing agent. Mix thoroughly using a stick and pour the mixture in the mold.

Silicon molds¶

Casting¶

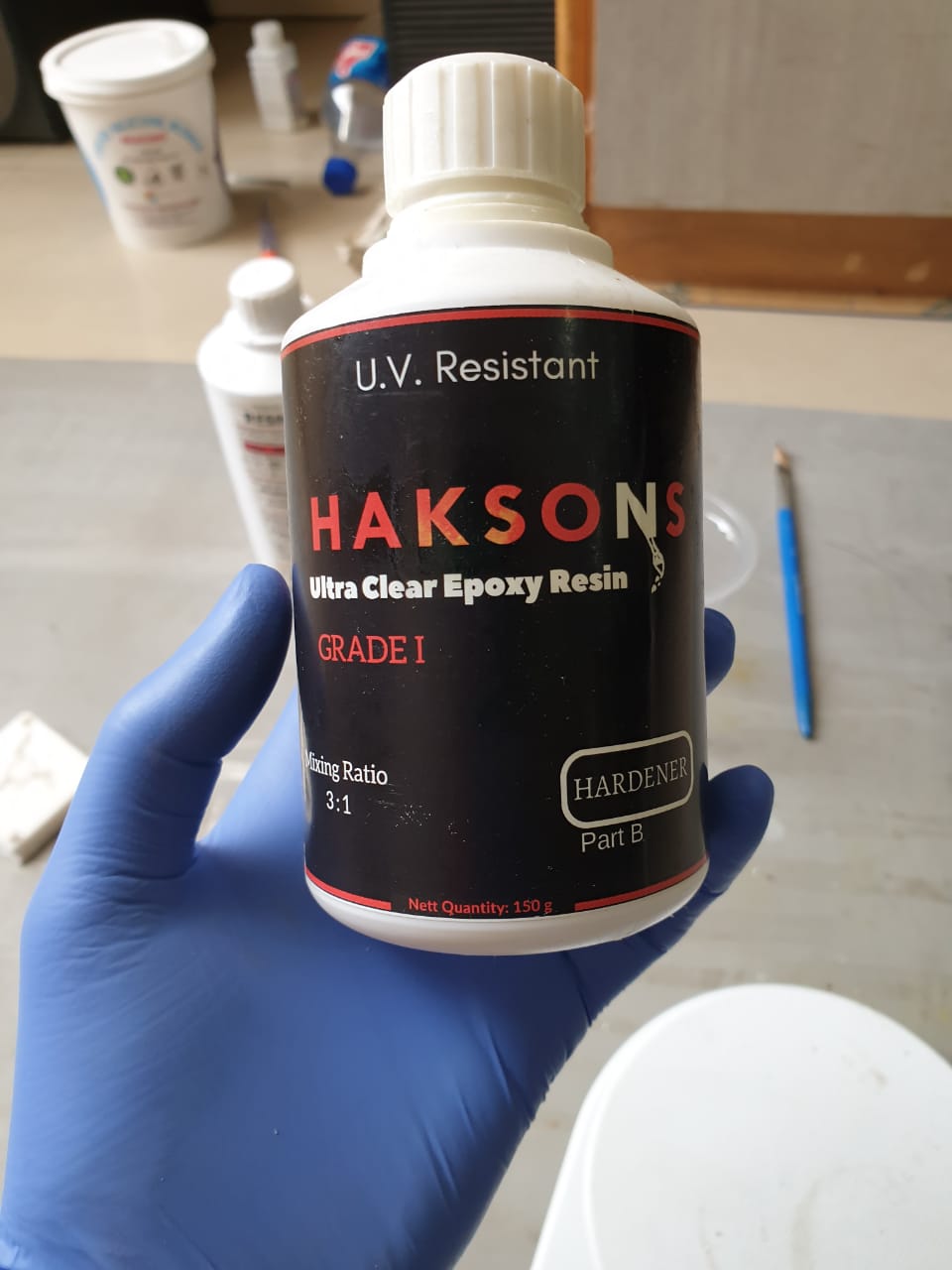

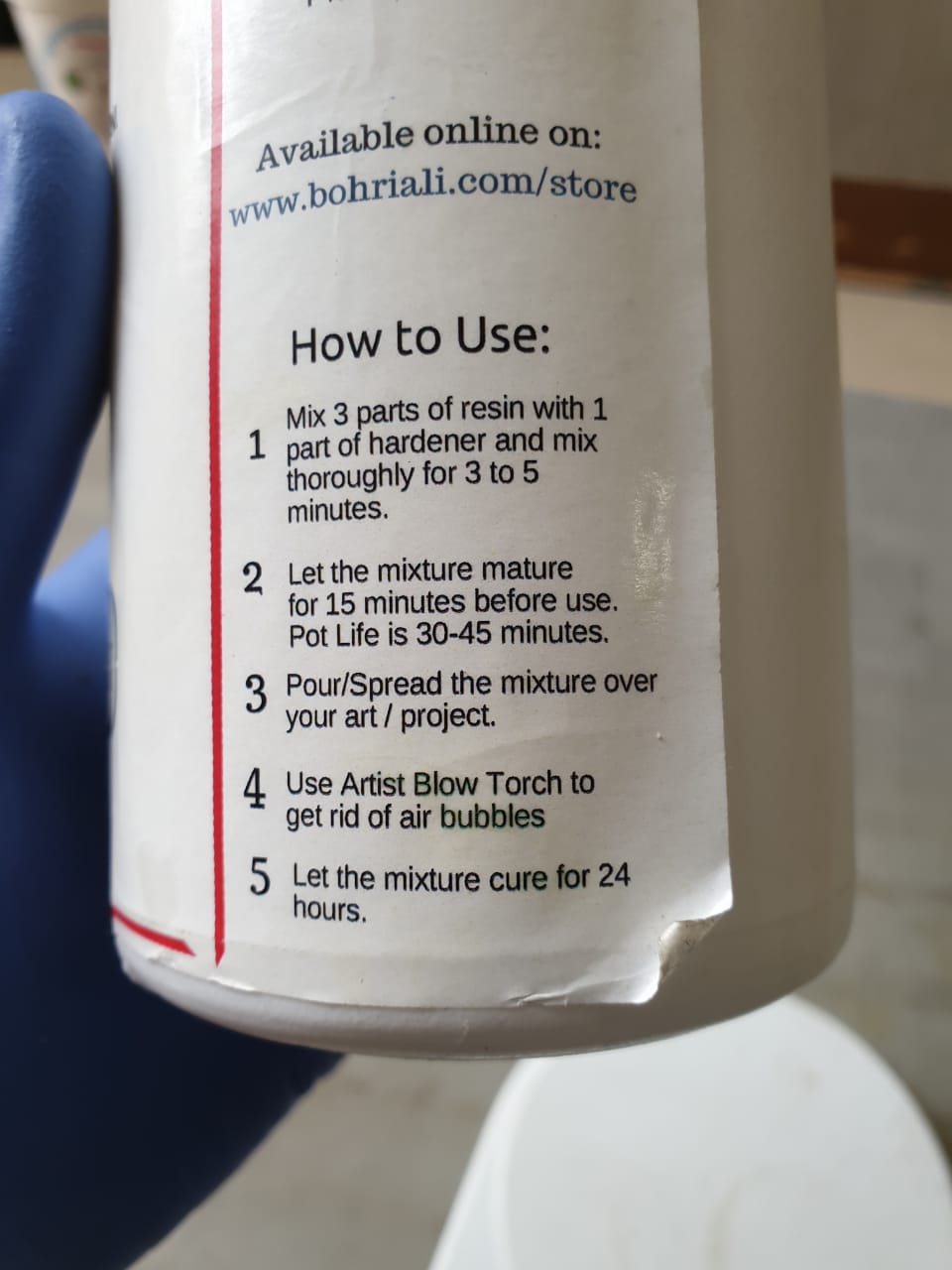

We had clear epoxy resin in the lab as casting material. It comes with two parts- Resin and hardener.

- Usage instructions were written on the bottle.

Final outcome¶

Learning outcome¶

- I learned how to design molds in fusion 360.

- I got to learn about various molding and casting techniques.

This work is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License.