Principles and Practices

Introduction

In the upcoming week assignments this Web Site will be my contribution to the documentation commitment, corresponding to the principles of the Fab Academy.

Sharing my learning experience and project development within an open community, and at the same time learing from it's knowledge resource, is a quite new, as also an inspiring experience for me. And not least this documentation will be crucial for my learning process and will serve as a memorandum of this course.

So I am looking forward to benefit from this open Fab Lab Community and to take advantage from it's guided accsess to the tools for digital fabrication. Also, I am aware of the responsibility that I am going to assume, in respecte of safety precaution and tasks as cleaning, maintaining, and improving the laboratory.

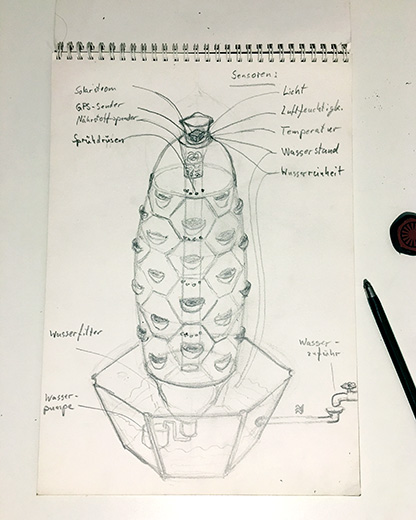

Final Project Sketch

For my final project I planed to design and build a module of an Aeroponic System, which can be controlled electronically by different sensors, measuring for example the temperature, humidity, light or the fill height of the water tank.

I made up a first sketch of my final project and presented it in this week 0 assignment:

The Aeroponic System provides the appropriate conditions for the plants to let them grow without soil. But it also needs a permanent power supply for the water pump, as well as it has to be controlled regulary. When an Aeroponic Systems fails, the plants degenerate faster than in other cultivation forms.

For this I will integrate electronic sensors into my Aeropoonic System to get concrete measurements about the actual growing conditions. The incoming data from the sensors can be processed and used to control the plant growth. At the same time these processed data may serve for research purposes to investigate the conditions that are provided by the Aeroponic System.

Why creating an other Aeroponic System?

Initially I was inspired by the latest achievments in Urban Gardening, its vesitile methods and techniques ranging from homemade devices to industrial food production.

Aeroponic Systems, same as Hydroponics and Aquaponics, can reduce the water consumption up to 70-90% less than in ordinary plant methods. No soil is needed, the plant's roots are hanging in the air. The water is going to be pumped up to the top and then drops down on the roots and at least back into the water tank. Other examples use high pressure pumps as spray mister to nutriate more efficiant.

In my case it will be a low pressure supply, because high pressure water pumps are still to expensive. It also says, that they require close monitoring and must be maintained frequently, e.g. to remove clogged spray heads due to salt incrustation.

The advantages of Aeroponics becomes more relevant in the future, especially in regions like for example here in Spain. In the agriculture sector there is a notable climate change, that has already influenced the agriculture harvest. Water will becomes less accessable and the rain periods have changed. The farmers are constrained to look out for alternatives to reduce the water consumption.

An Aeroponic System not only saves water, there are even more advantages like:

Material and Construction

Instead of just rebuilding an already existing grow tower, which are built with plastic or other similar material, I wanted to use clay. This requieres significant changesthe design, construction and production. I was inspired by the works, that were made in the IAAC and FabLab Barcelona. There are work experimenting with different types of clay and built special shapes, using the KUKA robot with an air pressure extruder (see also: Open Thesis Fabrication).

Building this Aeroponic Module led me into a lot of questions, that requires some decisions to be made, which I am going to resume here briefly:

Water Supply

Plants and Nutrition

Integrated Electronic Sensors

Nice to Have

Next Steps

I am looking forward to learn more about the different ways of digital production. In the upcoming 20 weeks I will work with different interesting machines and programs, and learn as much as possible about the divers fabrication techniques. And also, there is to manage the challanging task to coordinate the development of my final project within the assignment schedule. And last, but not least, the task of documenting the work in process.

Regarding to the question about who will use it (see assignment week 0), I will have to decide wether to create a device, that can be used for research purposes, or developing a prototyp, that might fit well into my household. These are two different kinds of devices, that require different designs and fabrication techniques.