Machine Design

Group Assignment

This is the second week of the machine building assignment, the work has been devided into two groups, one group for each motor construstion. The full documention of this machine design is shown in this group webpage.

http://fab.academany.org/2019/labs/barcelona/machine.mp4Producing a Turntable of a Full-Body Scanner

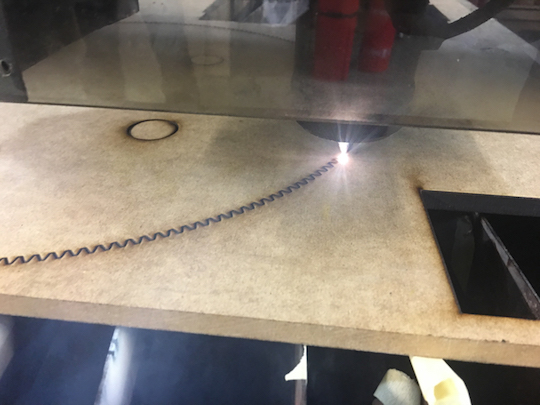

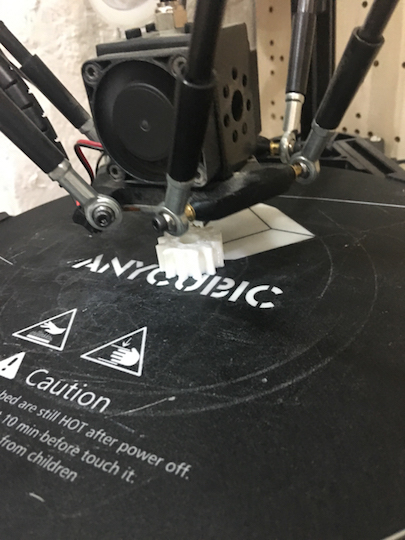

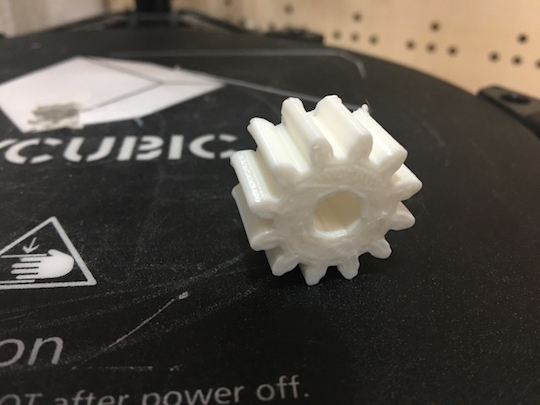

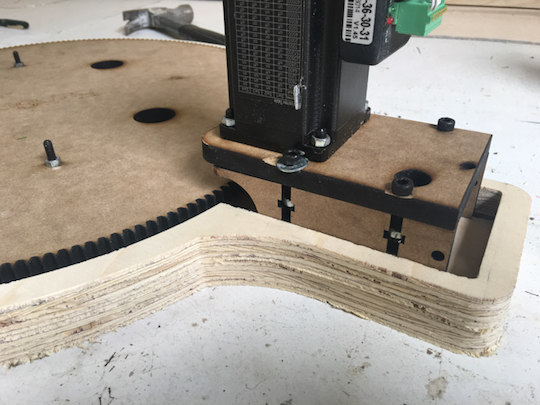

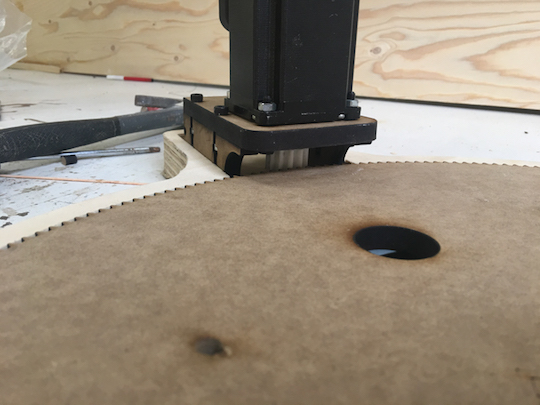

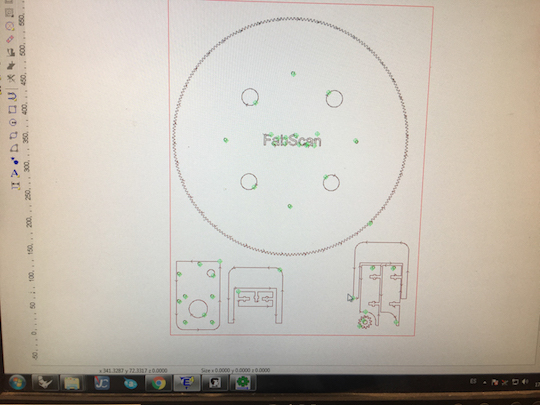

My part of this assignment was to produce the base structure and the gears of the turn table. The base structure actually was made by different machines: Laser Cutter, CNC Machine and 3D Printer. The material I used was mainly Plywood and MDF (medium density fibreboard), only the Pinion was produced with the 3D printer and PLA filament. We decided to use only two gears to make support surface rotate.

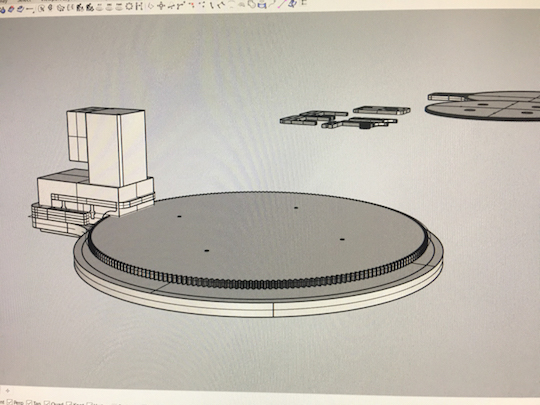

So there was on one side the big gear, which on the same time was the support surface, where the person stands to be scanned. On the other side was a small gear, aka the Pinion, which was going to be mounted directly to the motor shaft.

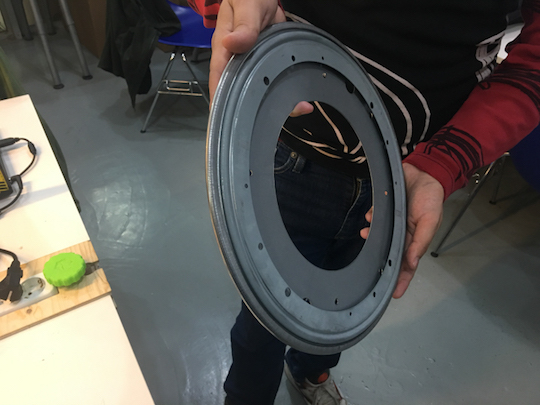

To provide the rotary motion of the support gear we used a Square Lazy Susan, which is a ball bearing turntable, and which was the starting point of my construction.

The size of the Lazy Susan, it's dimensions and position of the screws were decisive for the design.

3D Design

The complete turntable construction was designed in Rhinoceros. The parts were kept apart respective to the the specific machine job.

straight-cut gears are excellent at moderate speeds

The laser cut settings needed to be adjusted after some test cuts. The cut had to be precise to make the gears fit well, but the hardboard was 10 mm thick. We used