PROBLEMS AND SOLUTIONS

Throughout the development of the project I found several difficulties to achieve the objectives set at the beginning.

As for example the pressure sensor, said sensor needed to be calibrated to be able to use it in the project, for this it was necessary to read from the datasheet.

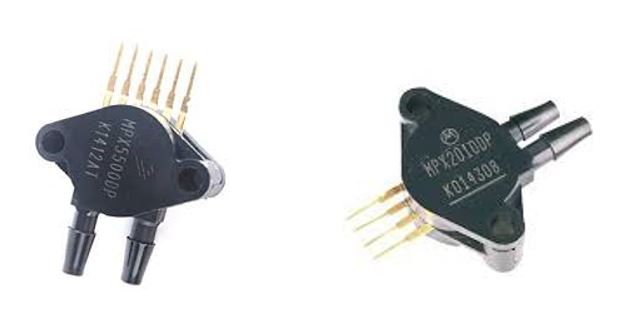

In the market there is the mp2100dp sensor and the mp5100dp. At first glance both are very identical

But reading the datasheet I was surprised that the first one only accepts up to 2BAR, while the second one reaches 7BAR. In the first test use 3 BAR as reference and it broke, this happens not to read the datasheet.

But reading the datasheet I was surprised that the first one only accepts up to 2BAR, while the second one reaches 7BAR. In the first test use 3 BAR as reference and it broke, this happens not to read the datasheet.

At the time of welding the tank, I did not check all the welding points.

There was a small hole where there was a water leak, as I had planned with the tank, this element became a bottleneck, so I must be more cautious.

In the same way, before welding the covers I have to make sure that there is no contact between the cable and the tank or the resistance, but it will produce continuity and I will not be able to measure the water level.

There was a small hole where there was a water leak, as I had planned with the tank, this element became a bottleneck, so I must be more cautious.

In the same way, before welding the covers I have to make sure that there is no contact between the cable and the tank or the resistance, but it will produce continuity and I will not be able to measure the water level.

When the water heating tests began, the steam began to escape through some holes where wires pass to the tank

In this case I had to use an industrial glue to cover these holes.

In this case I had to use an industrial glue to cover these holes.

After several tests, I could only start with the final experiments.

This stage was not planned, but like all projects, there will always be difficulties that we must solve during the journey and control the times to avoid not reaching the deadline.

Return to final project