Week 03 assignments:

- Characterize your lasercutter, making test part(s) that vary cutting settings and dimensions

- Design, lasercut, and document a parametric press-fit construction kit, accounting for the lasercutter kerf

- Cut something on the vinylcutter

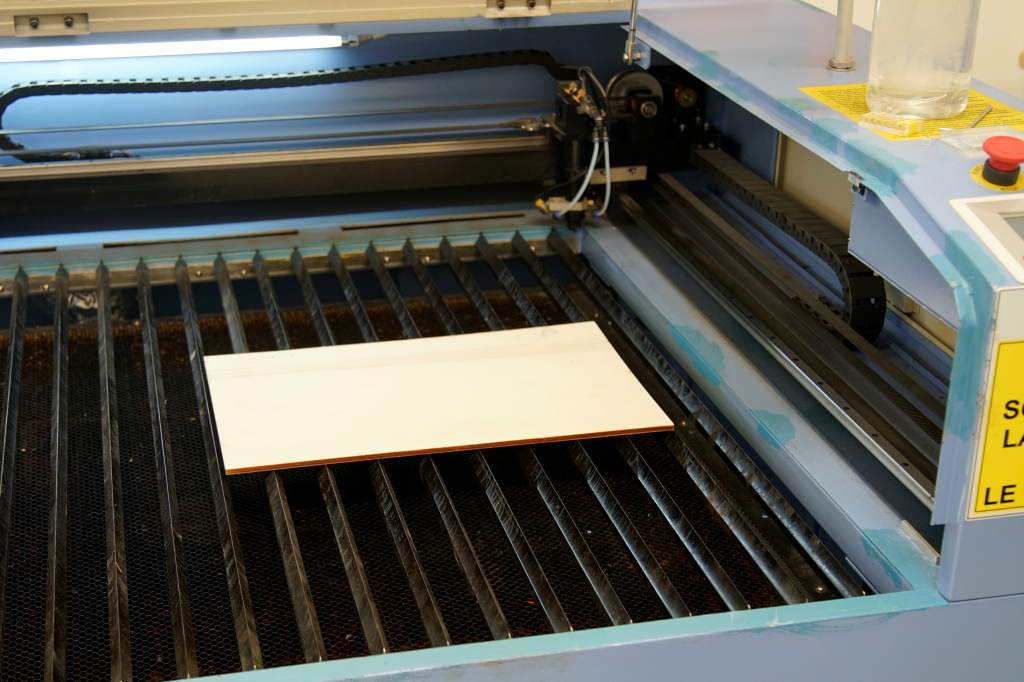

Characterizing our lasercutter

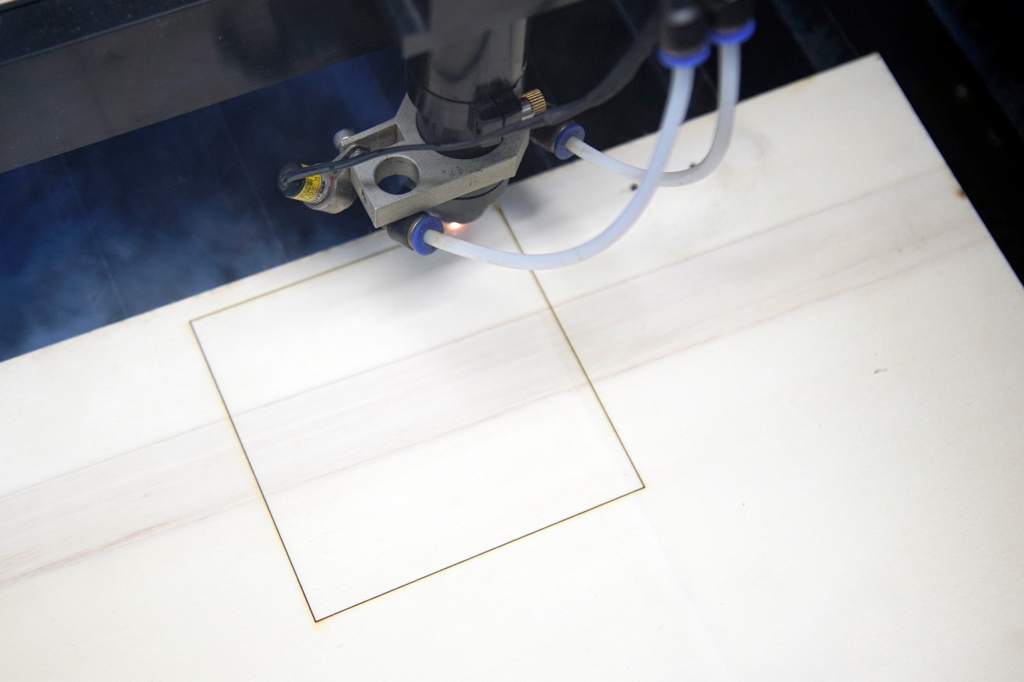

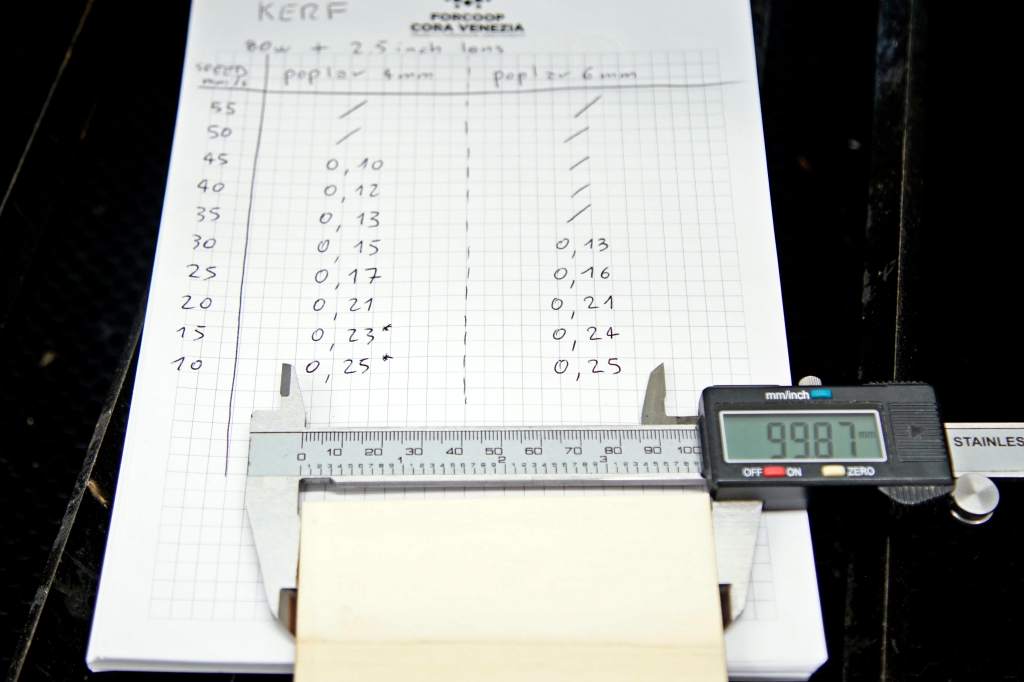

To calculate the kerf of Crunchlab's lasercutter at various settings i designed a 100mm * 100mm square and cutted it on 4mm and 6mm poplar plywood.

I measured the squares with a caliper and writed down the difference from the original 100mm

For the next assignment i will use 6mm poplar plywood so i need to offset the joints cut path by 0.065mm (0.13mm * 0.5).

Press-fit kit

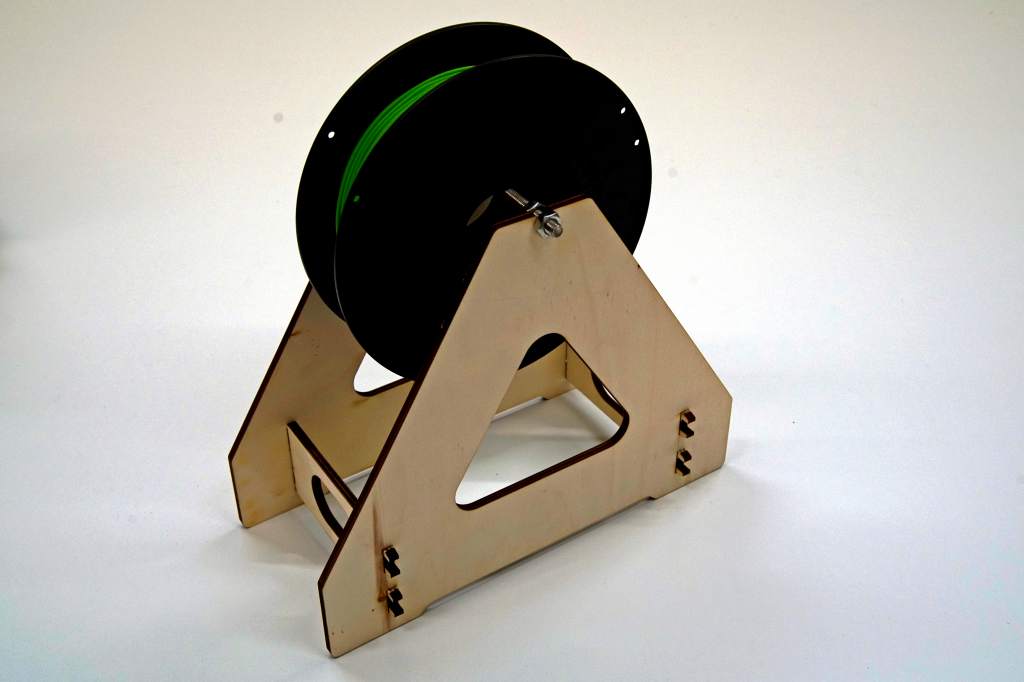

Few days ago the spool holder (made of acrylic) of one of our 3d printed fell on

the ground and shattered in tiny pieces :(

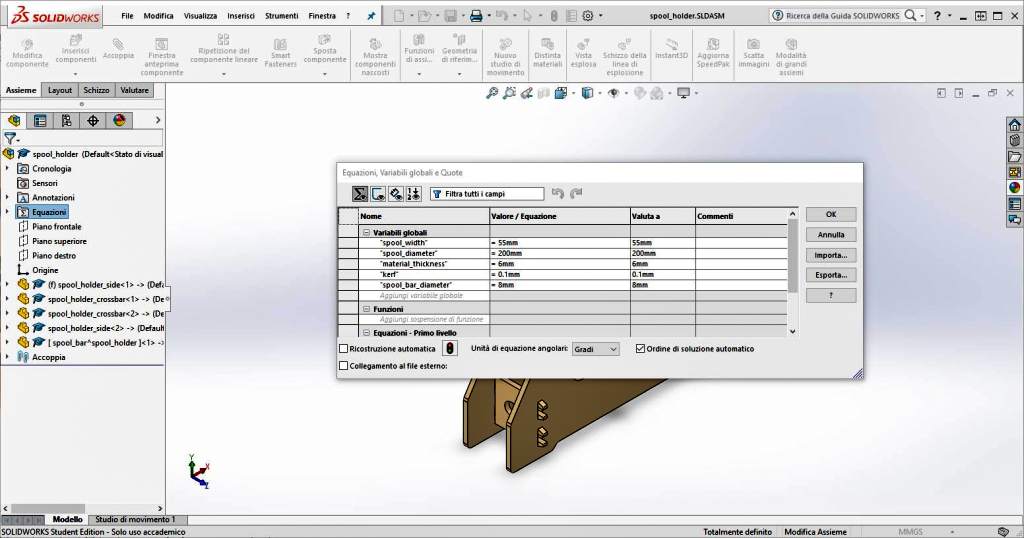

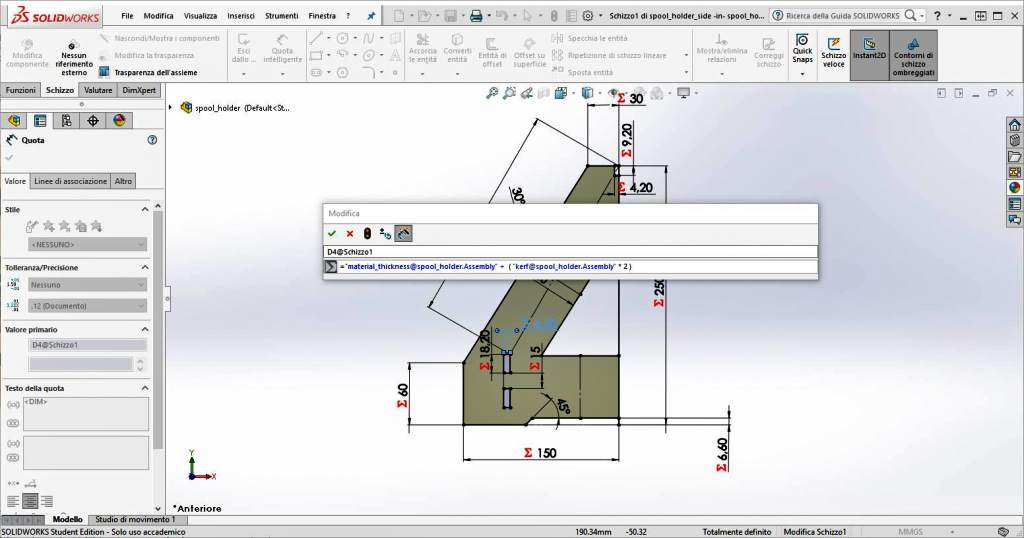

So i designed a parametric one with Solidworks.

Table of parameters.

Sketches (and 3d operations) dimensions refer to the parameter taking account of the kerf.

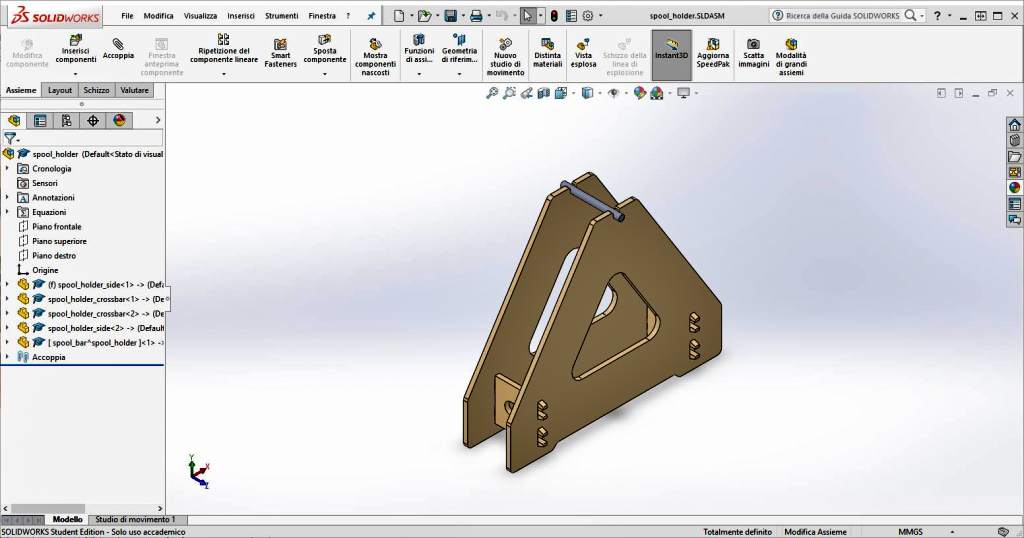

3D model completed.

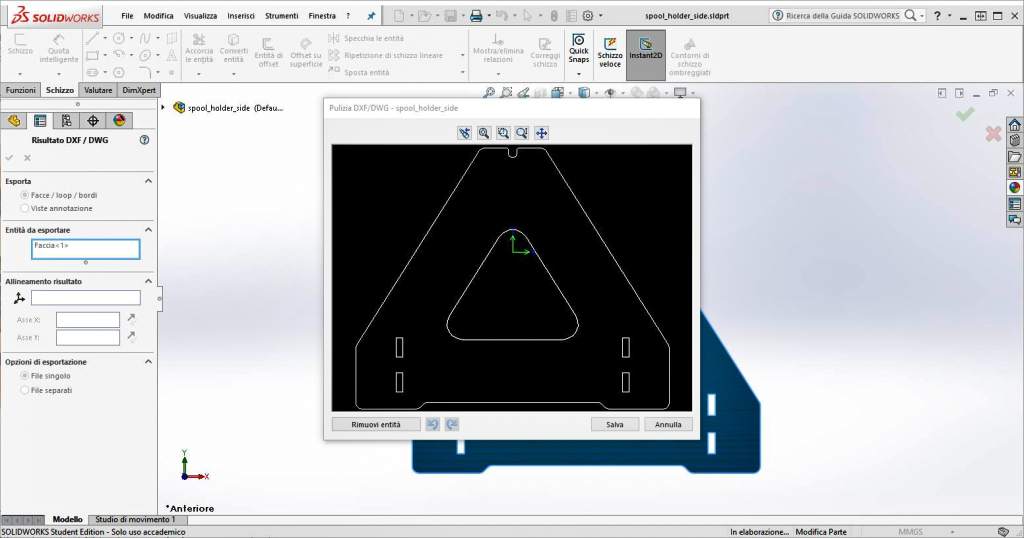

Exporting the dxf for lasercutting.

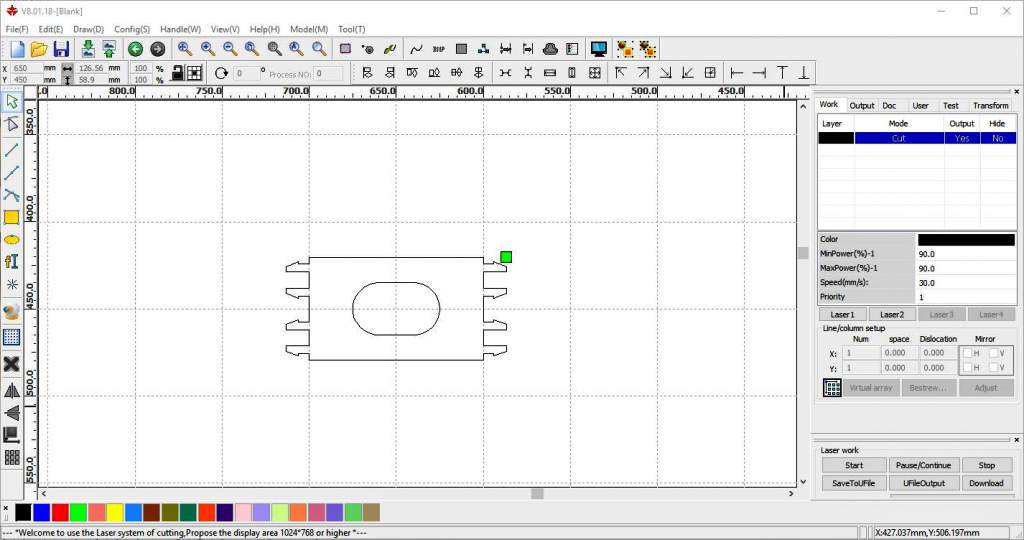

Setting the cut parameters in our lasercutter's CAM software.

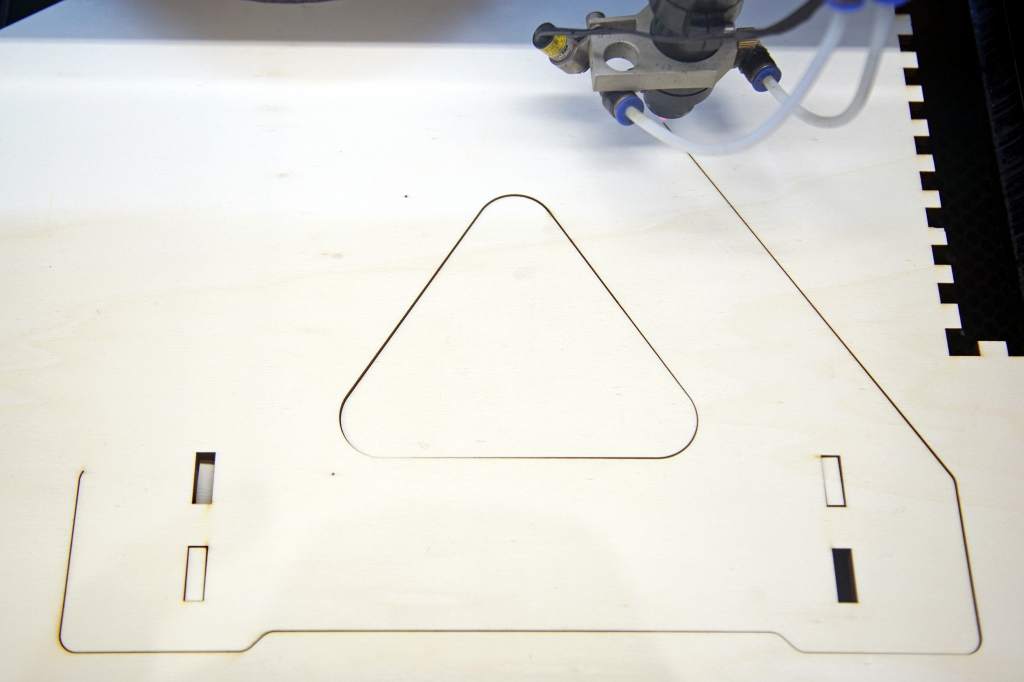

Lasercutting... :)

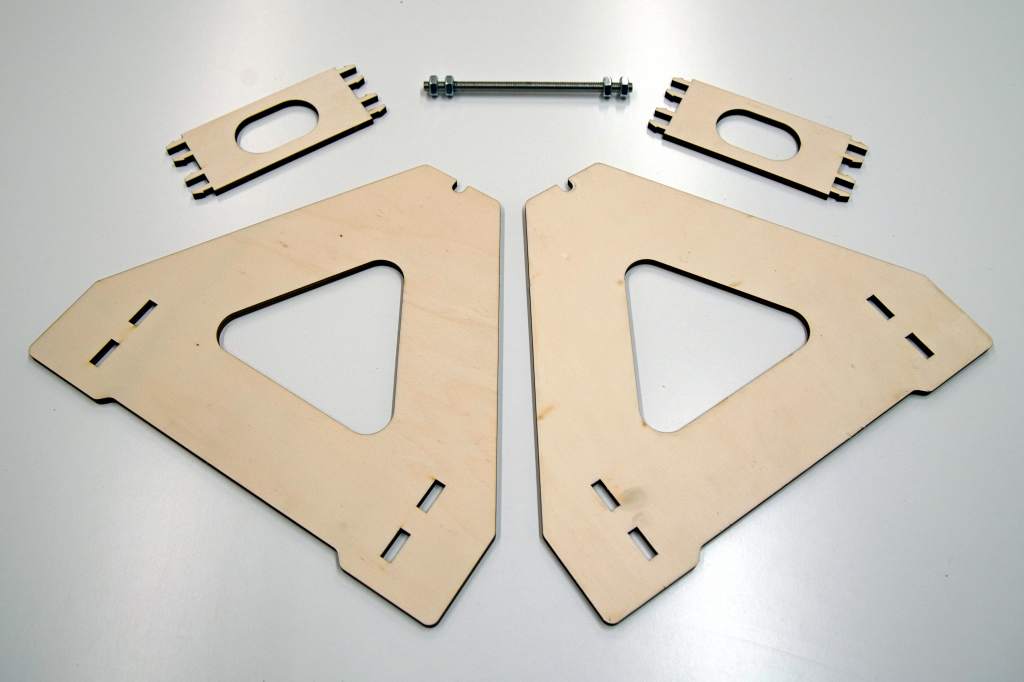

The complete kit.

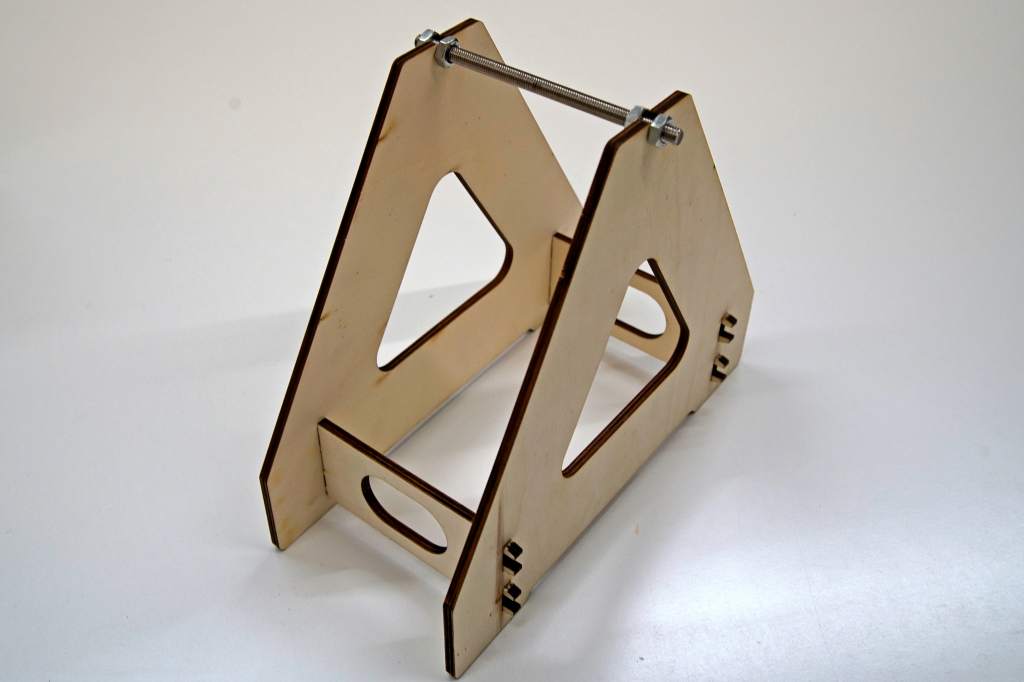

Final shot with the kit assembled.

Solidworks assembly

Side panel (Solidworks)

Side connector (Solidworks)

Side panel (DXF)

Side connector (DXF)

Vinylcutting

Unfortunately artistic creativity is not my forte and this is a disadvantage if

you want a new cool sticker for your PC.

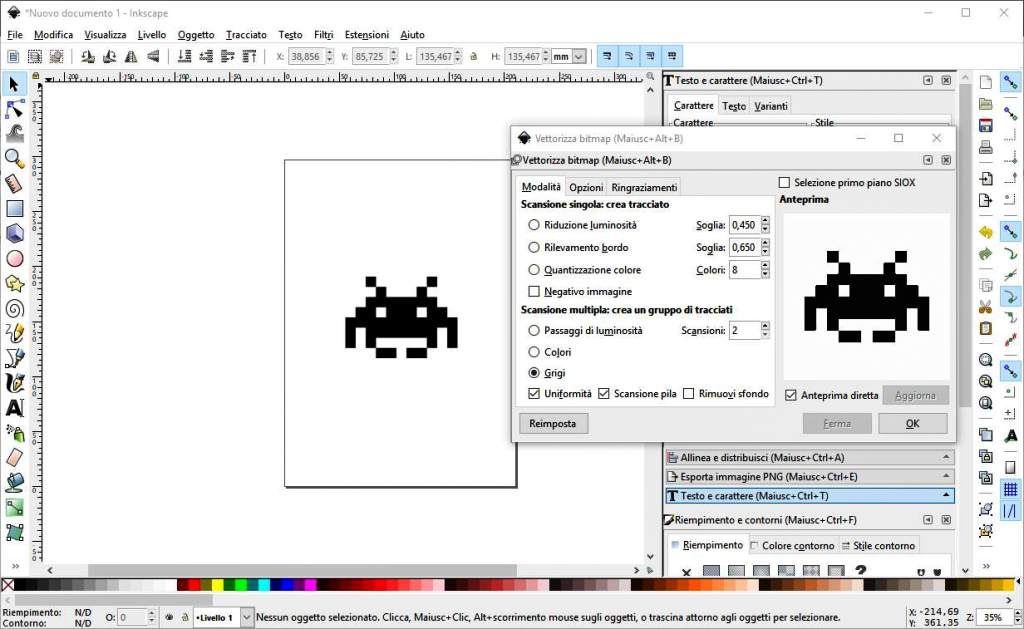

Nevertheless i like 8-bit/retro-computing style and finding the image of an alien

from Space Invaders it's easy.

Importing the alien bitmap in inkscape and converting it.

This was an easy image to vectorialize, easy peasy task for inkscape.

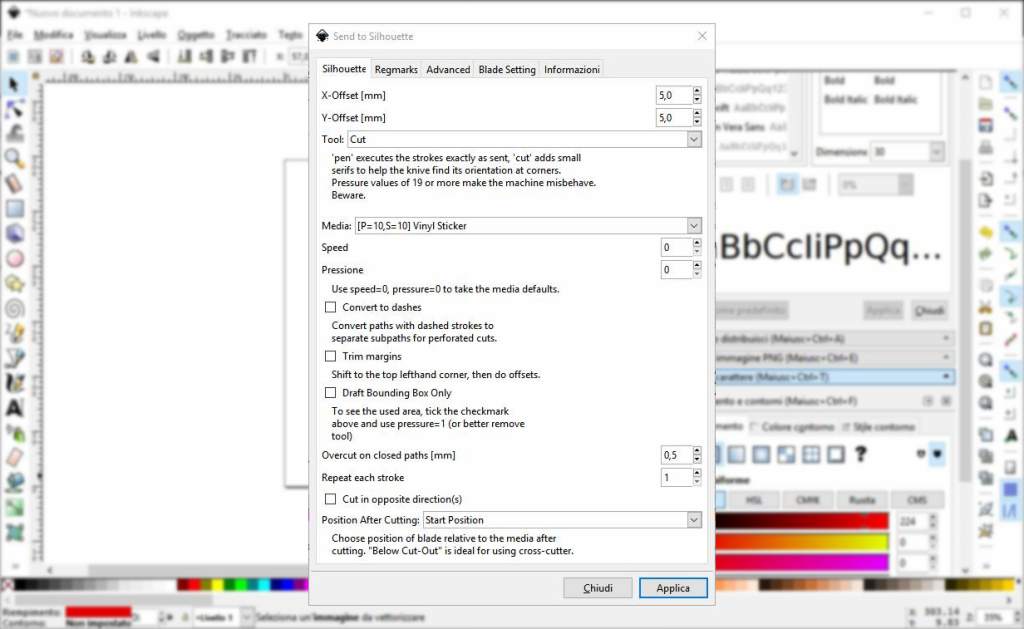

Setting up cut parameters with the inkscape-silhoutte plugin!

Where is my laser... knife cannon???

The green vinyl in here at Crunchlab was not bright enough to resemble an old green monochrome monitor but this orange remembers me the amber ones!

Space Invaders SVG