3. Computer aided design¶

Assignment

Model (raster, vector, 2D, 3D, render, animate, simulate, …) a possible final project, and post it on your class page

| Documentation |

|---|

| 1. Autocad_File.dxf |

| 2. Finger_joint_Box.svg |

This week, I’m going to work on modeling my boat and try to think of everything it has to contain. I’ll try to challenge myself to be as clean as posible in my design.

3.1 CAD Modeling¶

I have already a background in 2D and 3D CAD modeling but I’ve learnt from the class few ways to do 3d modeling :

- Constructive Solid Geometry (use constraints to make 3d models)

- Generative Design (Automated ways to do to 3D modeling using functions)

- Functional Representation modeling (CAD using graph to relate objects)

Also, I’ve understood that a functionality that I have to work with is parametric design.

Before going deepeer into making the boat, I’ve decided to experiment diferent softwares to understand the different possibilities each one can afford.

2D CAD modeling¶

There are two ways to make 2D CAD modeling :

- Raster (good to explain a concept)

- Vector (better to actually use the file for digital fabrication)

I’ll mostly focus on vector softwares as it’s going to be the most useful for me.

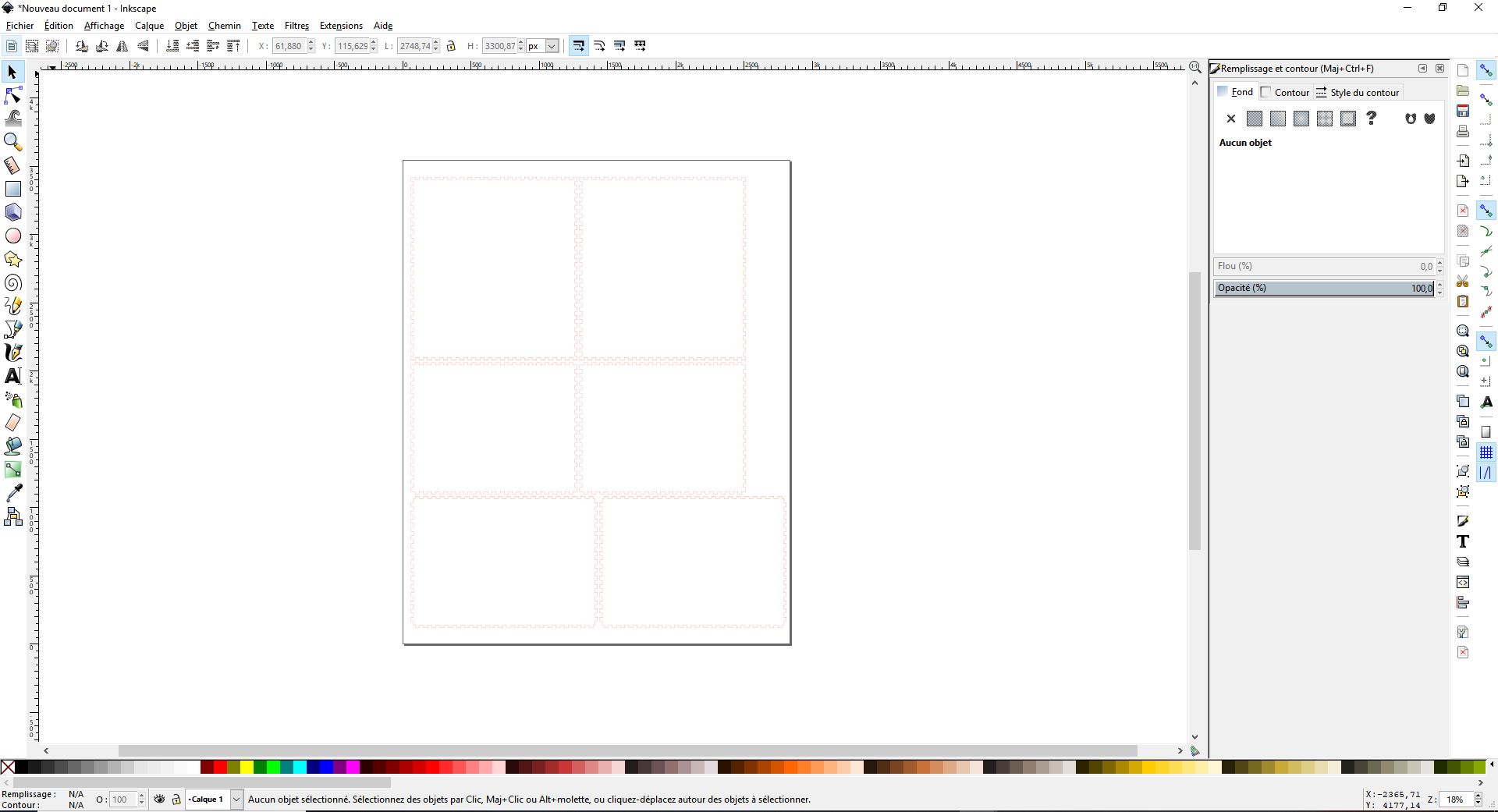

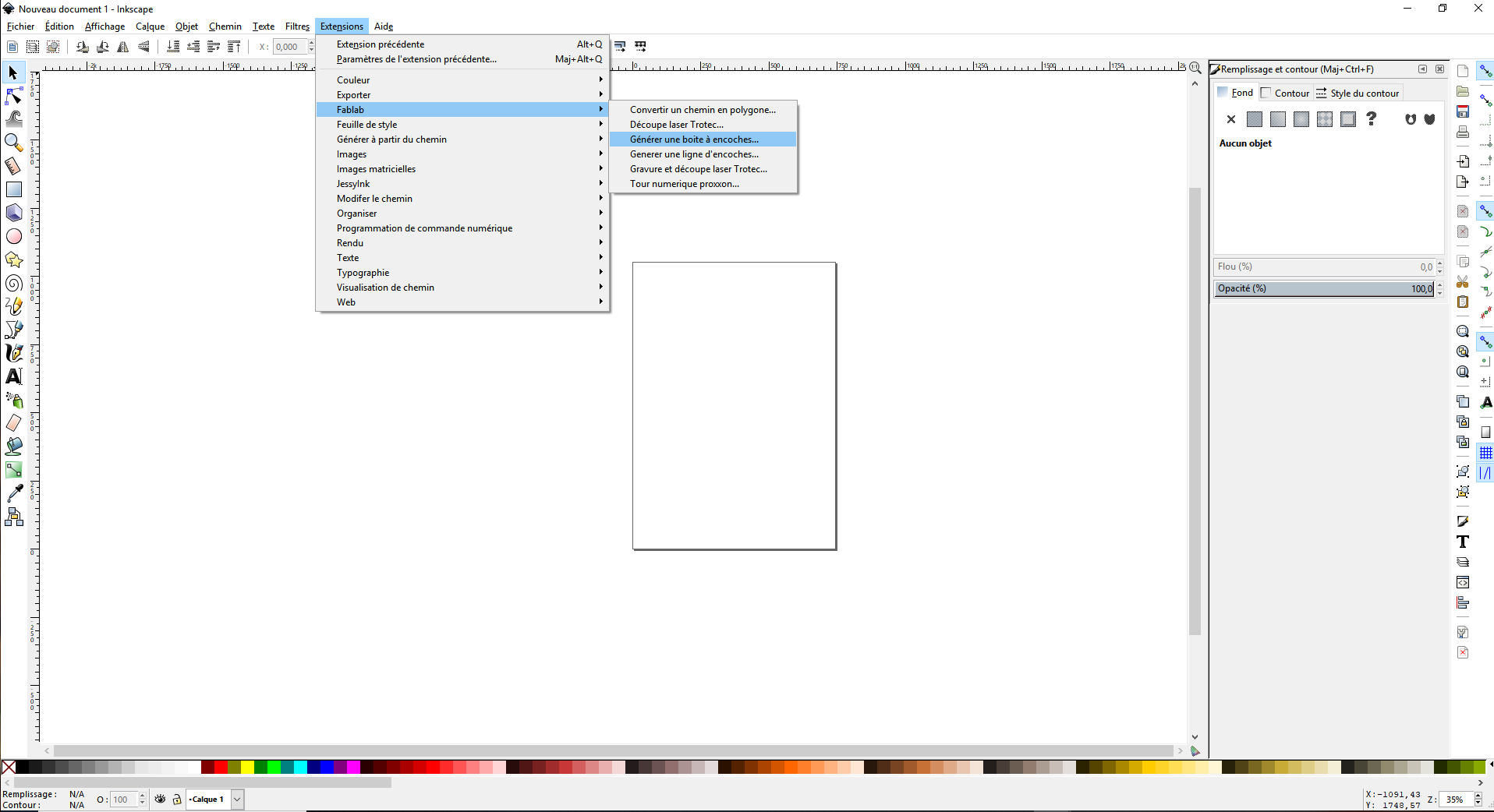

Inkscape¶

Inkscape is a free software where you can create vector 2D models. It’s a very powerful tool to make files for the laser cutter.

It’s relatively easy to use it as the interface is similar to many drawing softwares :

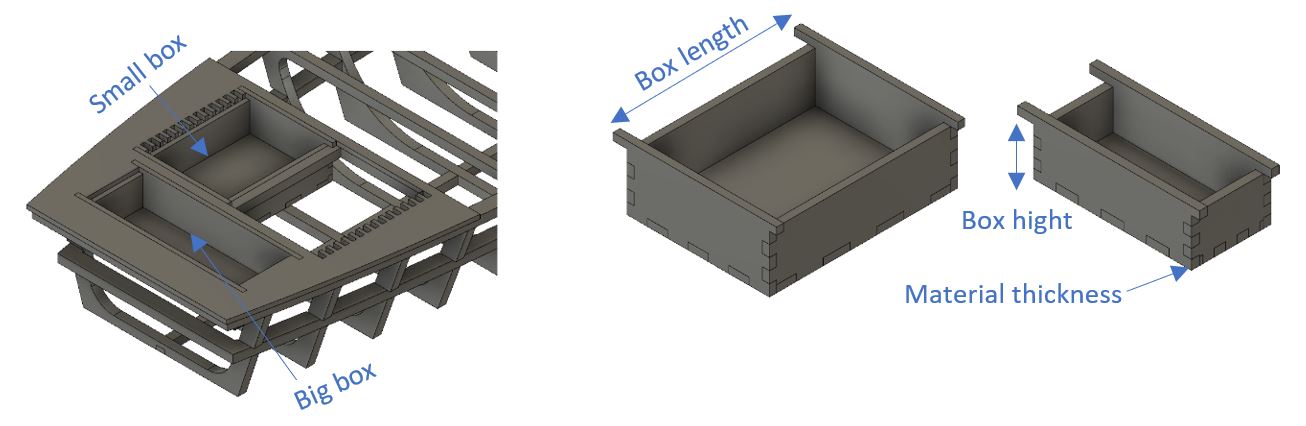

The cool thing about this software is that you can add plugins. A cool one is the fablab extension where you can for example generate parametric finger joints boxes.

On Inkscape website we can find well done tutorials to get to know more about how to use the software.

My idea of this tool :

| Easilly accessible | to put an exact dimension can be tricky |

| Support parametric design |

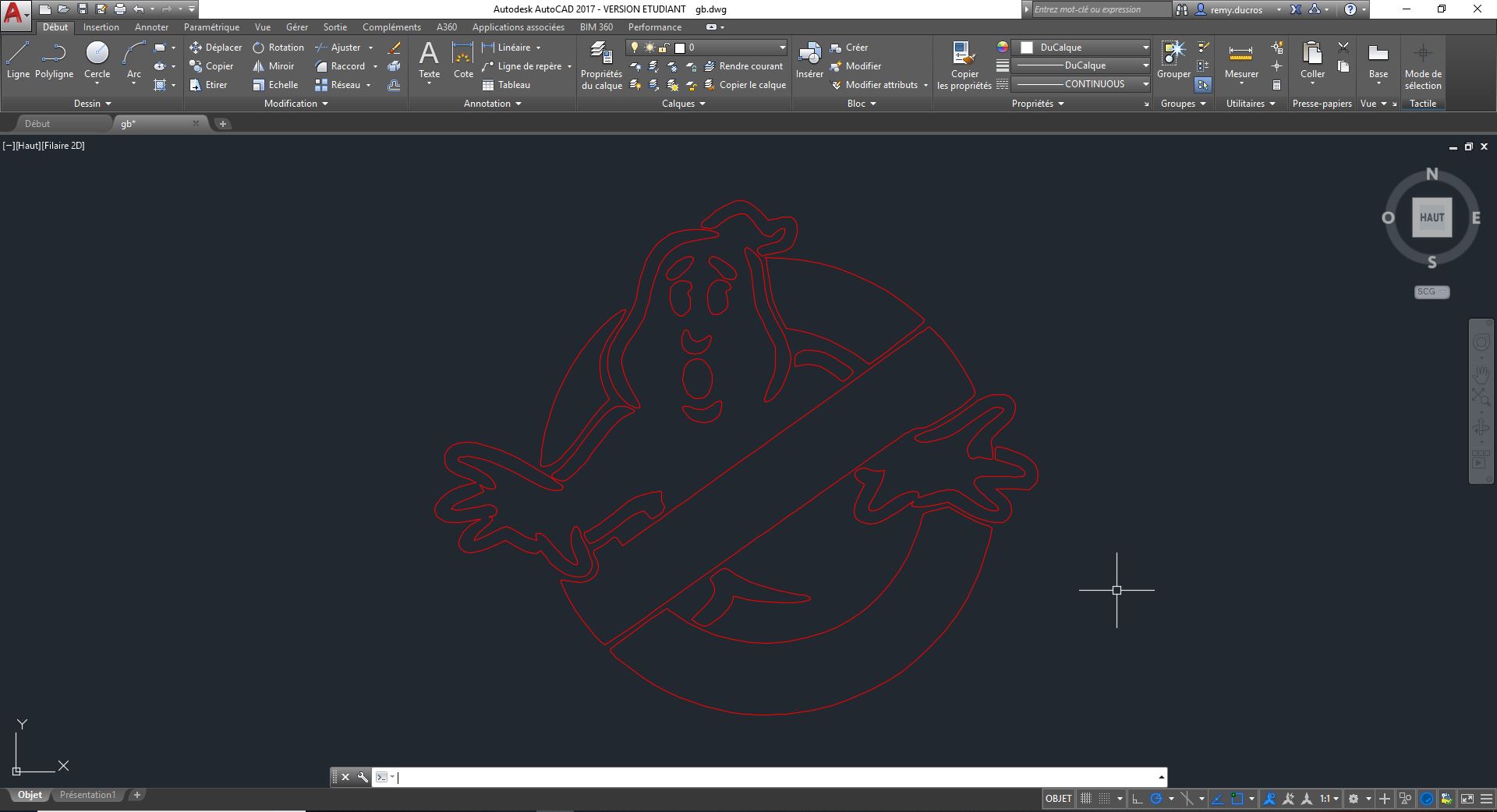

Autocad¶

Autocad is a software you can use to create 2D models (3D models as well but I don’t use it). It’s a very powerful tool to make files for the laser cutter.

It’s a software used a lot in the architecture field to make drawing of houses.

The cool thing about this software is that you can work with layers (like in photoshop) where you can asset some parameters. It’s useful for the laser cutter to make a difference between a line to cut or to engrave.

To draw using autocad we need to use the drawing elements of the software.

The particularity of this software is that you have to put dimensions as you draw (unlike solidworks for example where you can draw a circle then use a cotation tool to put the correct dimensions).

Few other tools I often use are :

- The Layer tool to give assets to the line I draw (we can change colors and thickness of each line to asset a job to the lasercutter like raster or vector).

- The Decompose tool to decompose dxf files we import from other softwares (like inkscape for example).

- The Delete all doubles tools to remove all the lines stacked on top of eachother. This tool is useful to avoid the laser cutter to cut multiple times on a line.

To get to know more about how to use this software there are great tutorials online.

My idea of this tool :

| Easily accessible | format issues |

3D CAD modeling¶

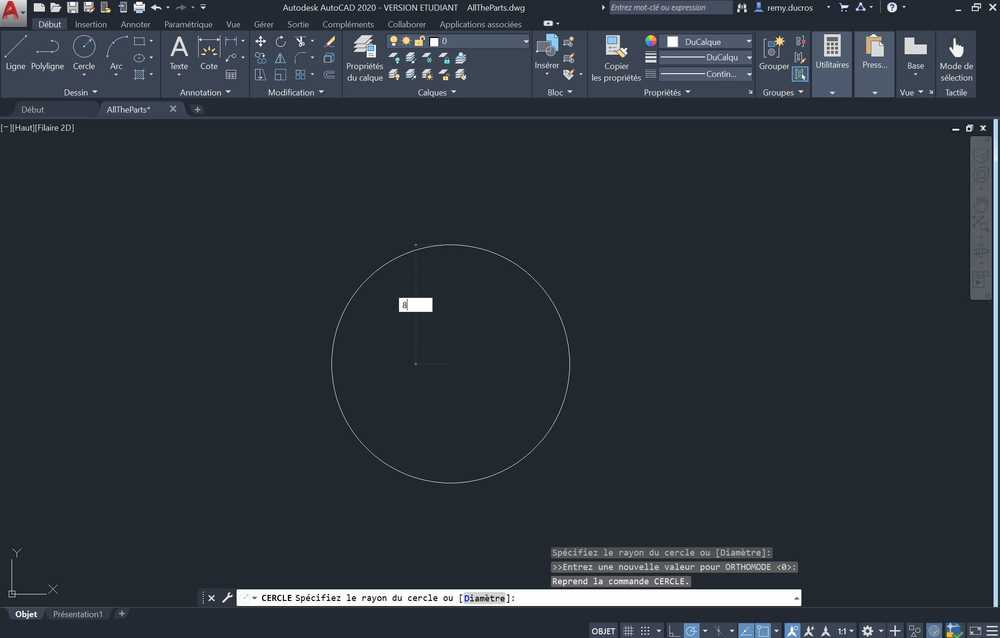

OpenScad¶

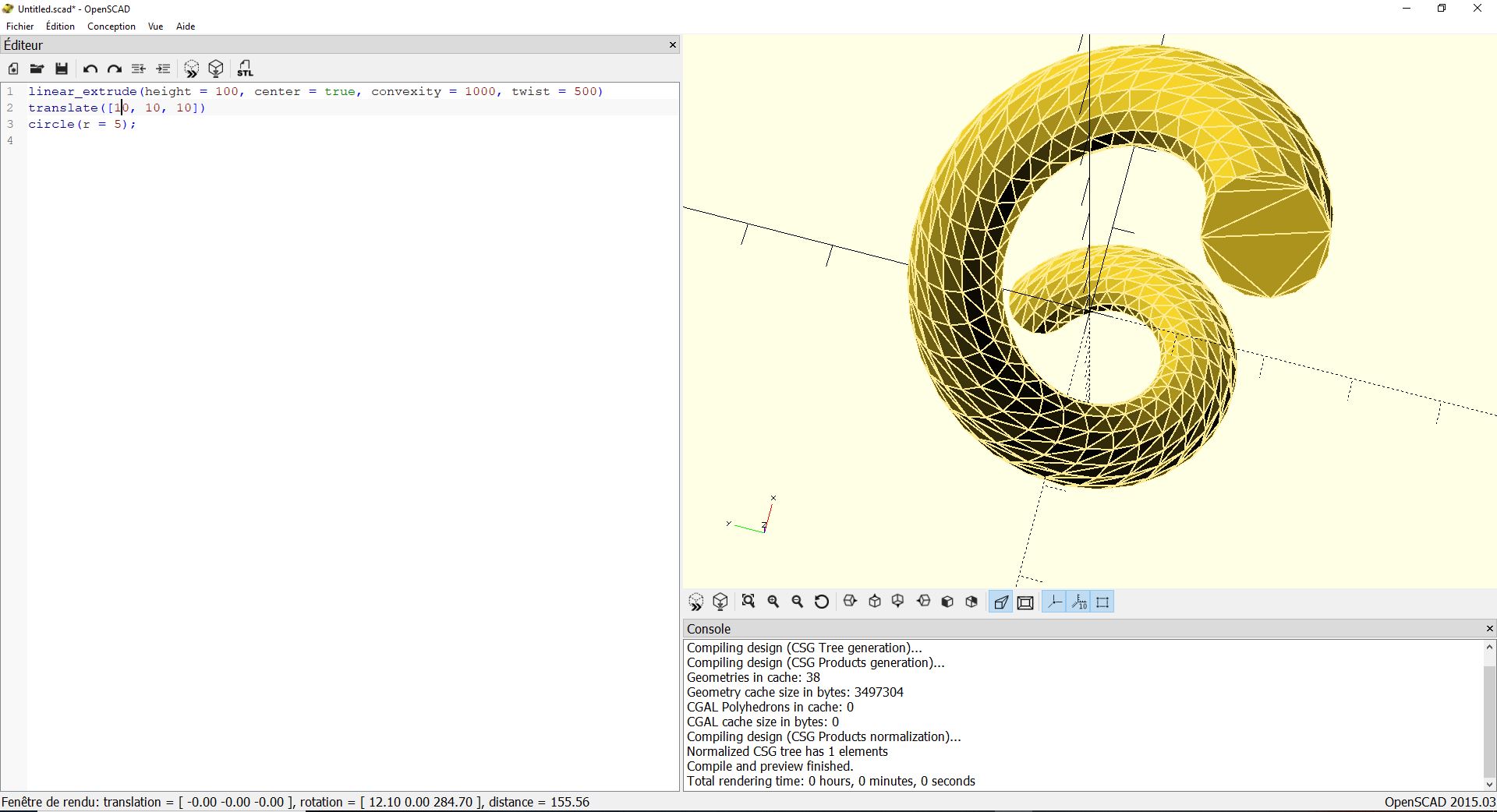

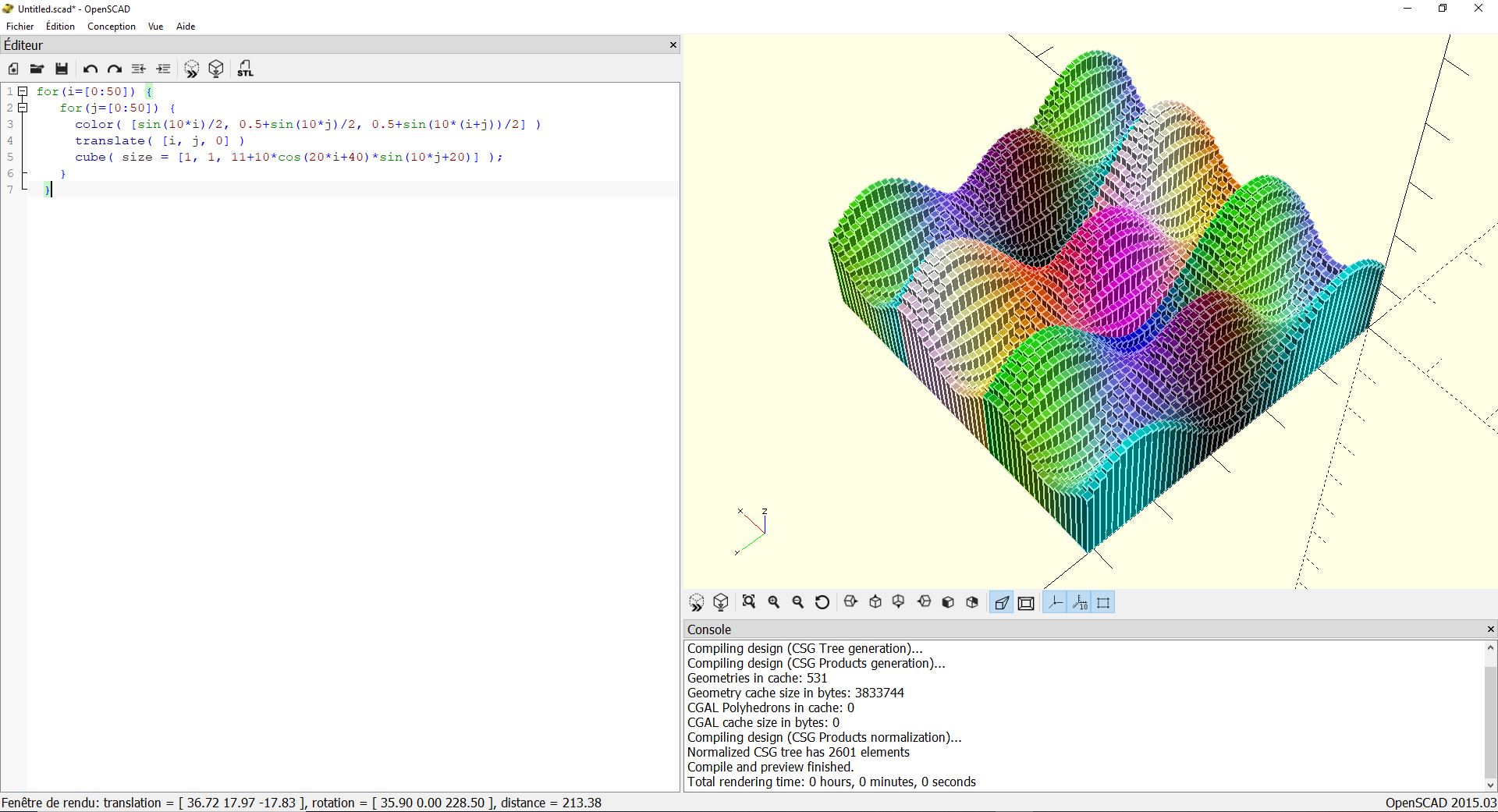

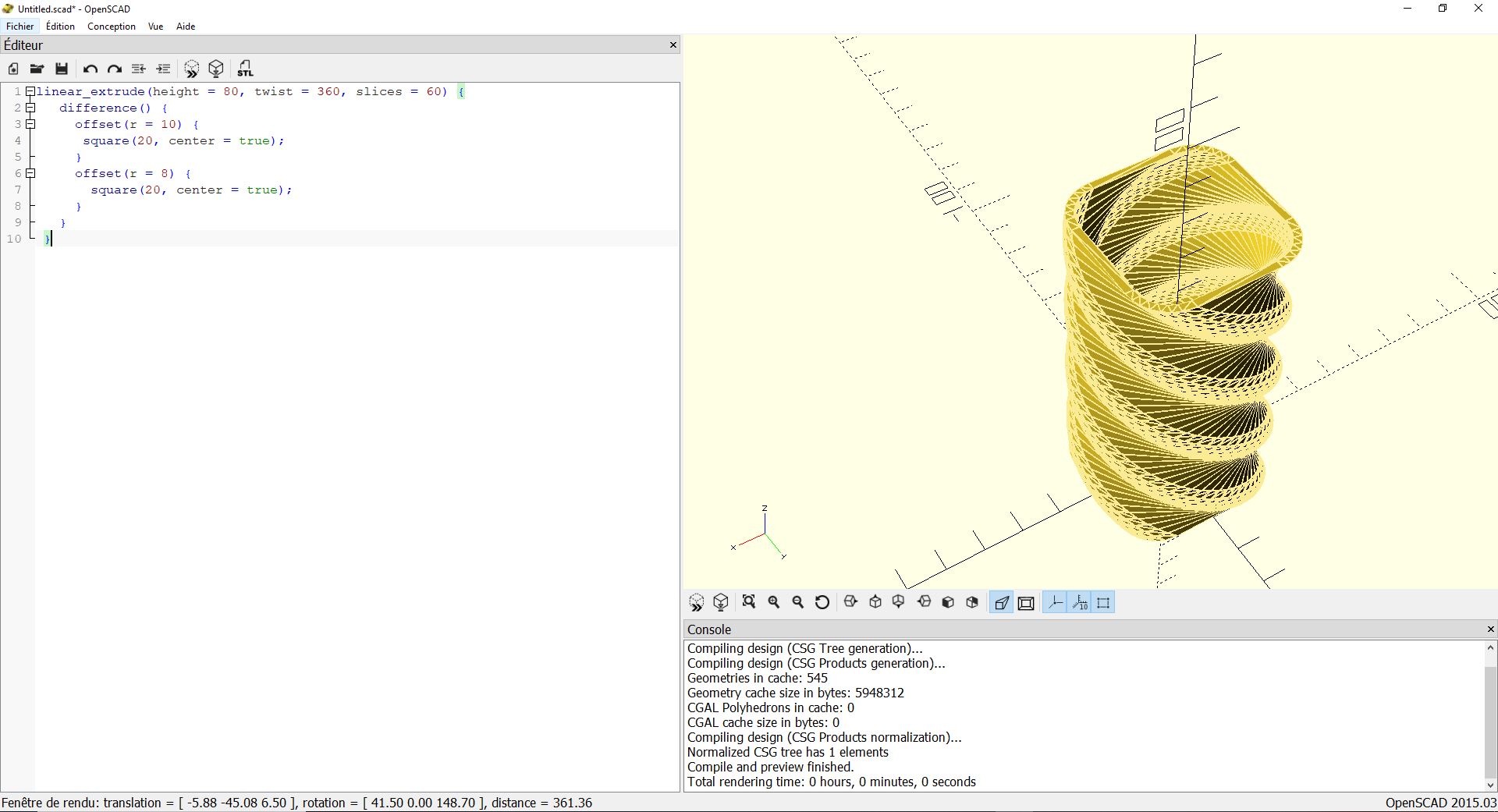

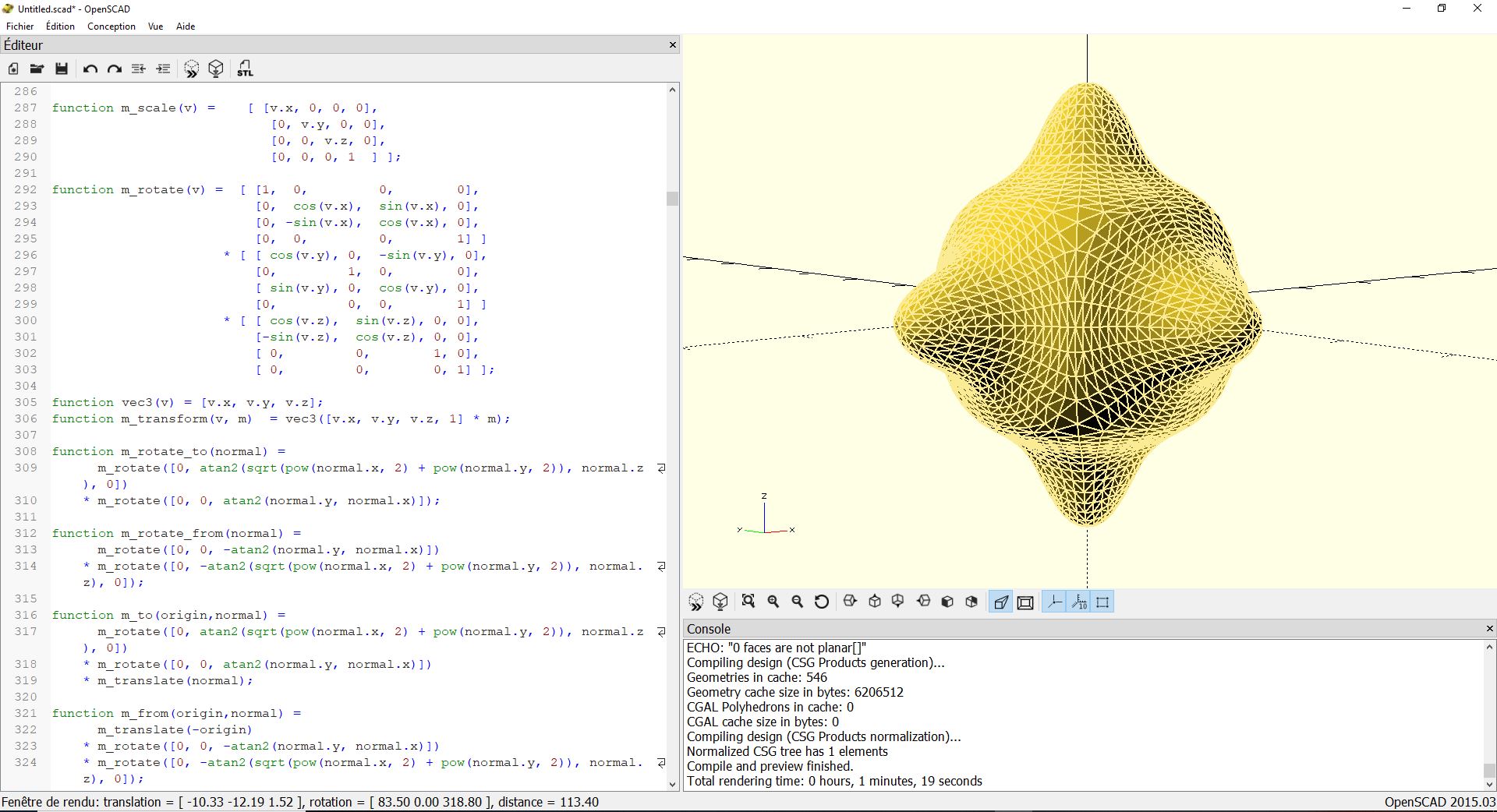

Openscad is an open source software where you can create 3D models by making line codes.

I’ve been through the OpenScad user manuel and also through the OpenScad cheat sheet to make some interesting shapes. This shapes are more or less complex.

|

|

|

|

The last one is a quite complex one (more than 1000 lines) based on Conway mathematical experiments. It took few minutes to compile.

NOTE : There is an online version of OpenScad called OpenJScad

My idea of this tool :

| You can make complex design | The interface is not very user friendly |

| You can make parametric design | The coding part is yet another thing to learn |

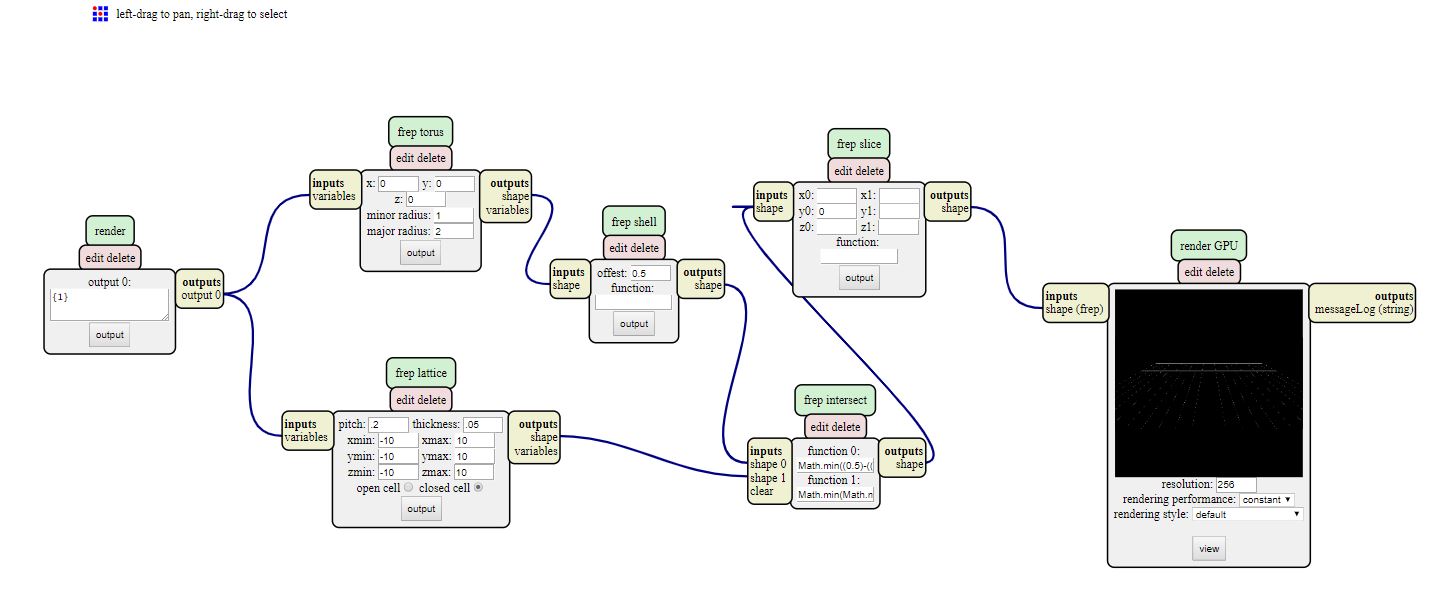

Mods¶

Mods is a web interface developped by MIT-CBA where you can create 3D models using linked graphs.

I was very impressed by Neil’s presentation but I didn’t managed to make it work properly. I think I was missing some key inputs to really get into it.

It’s a really cool tool but I don’t think, I’ll be using it for my project. I’ll go deeper into the online documentation to learn how to use it.

Fusion 360¶

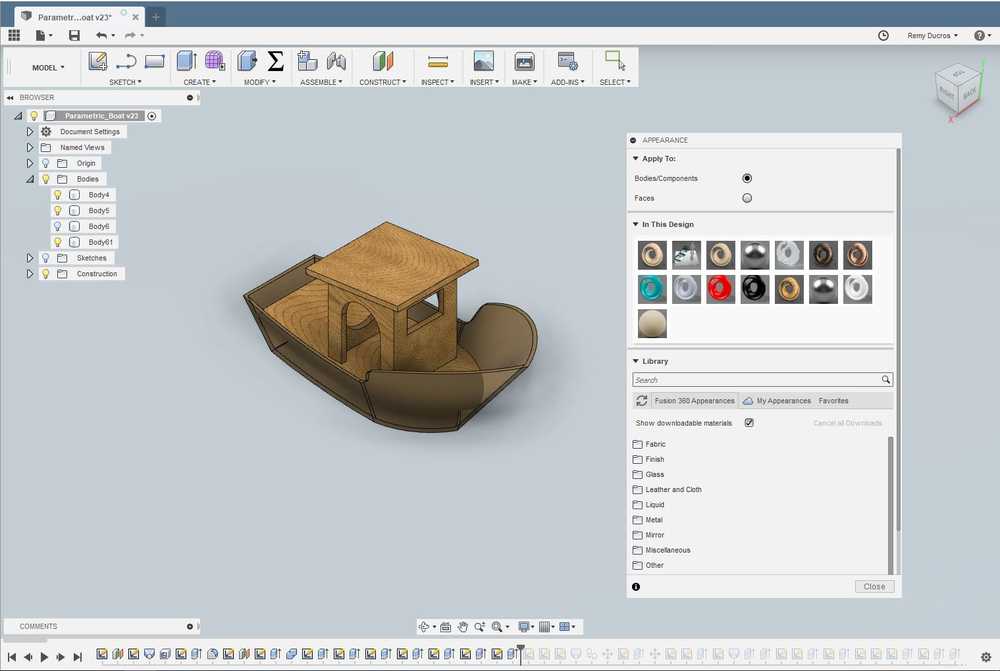

Fusion 360 is a CAD software developped by Autodesk.

I have a bit of experience with CAD modeling using Solidworks and Catia. I wanted to go for a software to keep doing my projects and I found Fusion 360 very handy.

I’ve already done some projects using Fusion 360 so I’m familiar with the environnement

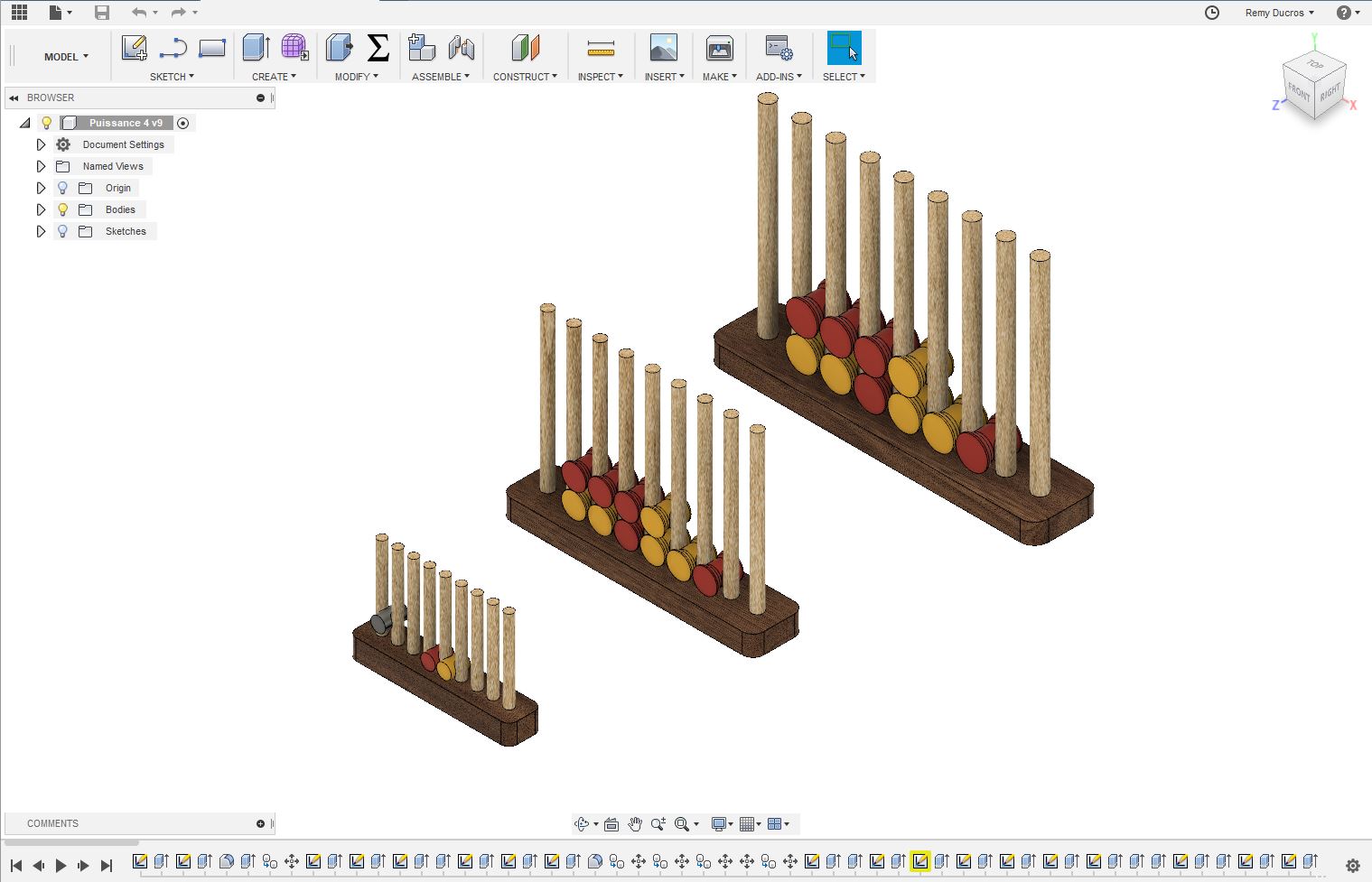

Here is a design of a bordorless connect four, I’ve made.

My idea of this tool :

| Easily accessible | Not open source |

| Cloud friendly | Need an internet connection to work properly |

| Complete | |

| Well integrated |

For my Fabacademy final project, I’ll work mostly with Fusion 360

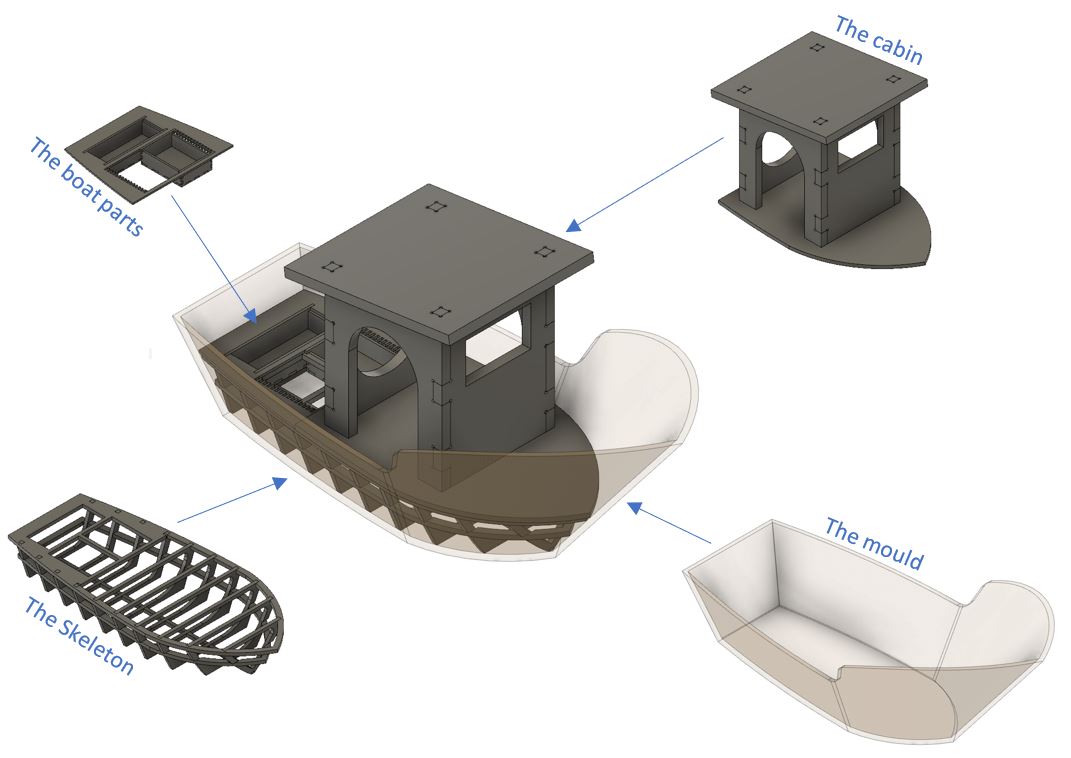

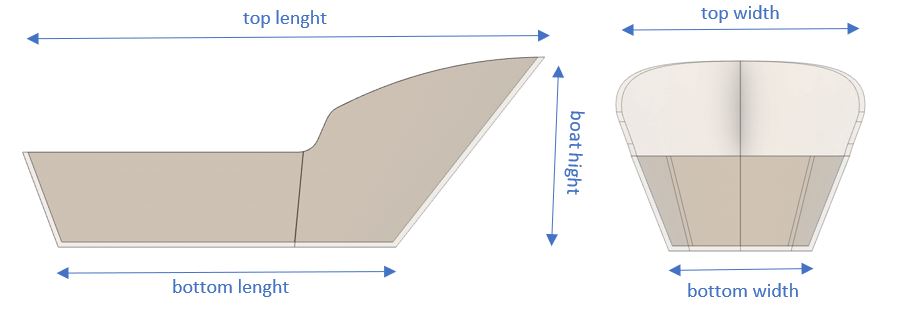

3.2 The design of the boat¶

I’m not a naval engineer and the shape of the boat is free, so I first went through images to see the different types of boats that exist.

I’ve seen a lot of different possibilities online.

However I didn’t find a shape not to simple yet not to complex to do the CAD model of.

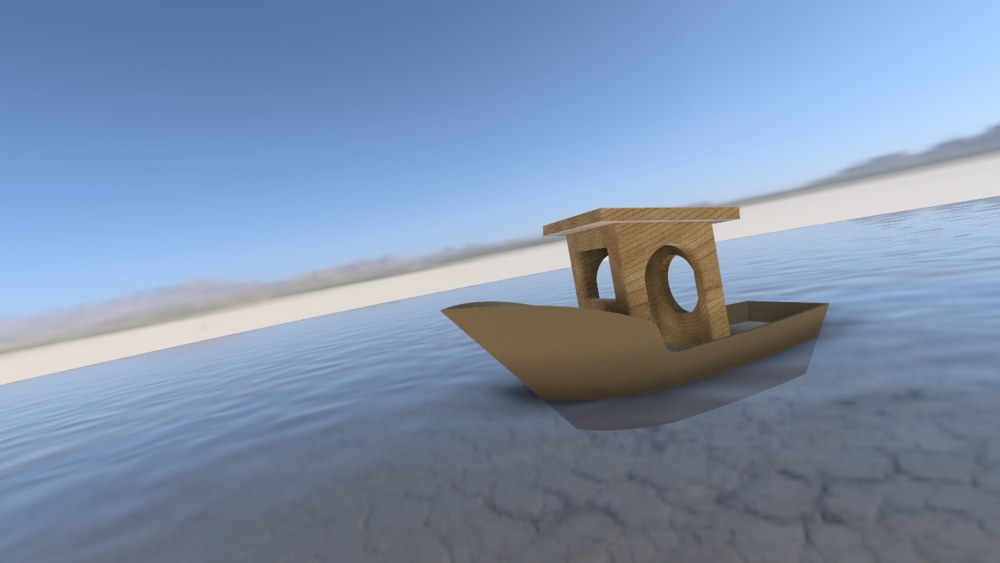

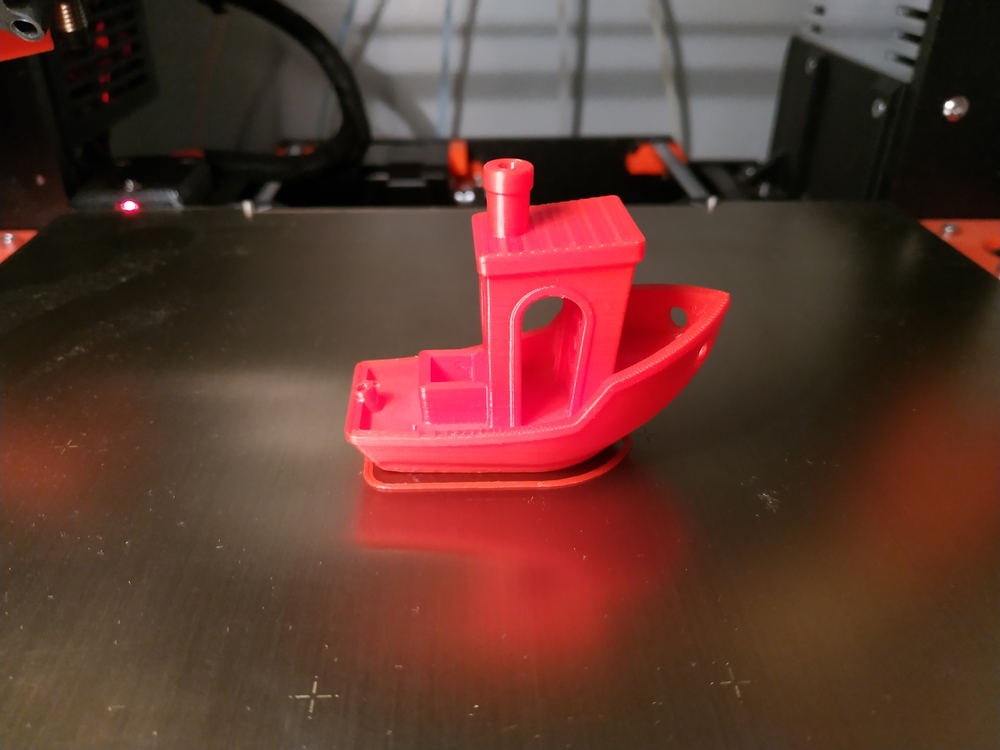

Finally I saw on a table in the fablab a 3D_Benchy. I 3D print a lot this model when I want to test a 3D printer.

I thought it would be a good idea to get my inspiration from this well known model, so I’ve printed one to have it in my hand to better understand the design of it.

I’ve decided to go for this design as well because I’ve seen many videos of it floating, even someone did a sRC model of it.

So let’s make my own version of the 3D benchy (but much bigger).

Parametric design in Fusion 360¶

For this projet I wanted to challenge myself and do something I’ve never done before : Parametric Design in Fusion 360.

Thanks to the Autodesk knowledge page and this page about best practices, I was able to identify some guidelines:

- All my sketchs must be fully constraint

- It’s sometimes better to use some constraints between sketchs elements rather than dimensions

- I can make a parameter linked with another one

- …MORE TO COME

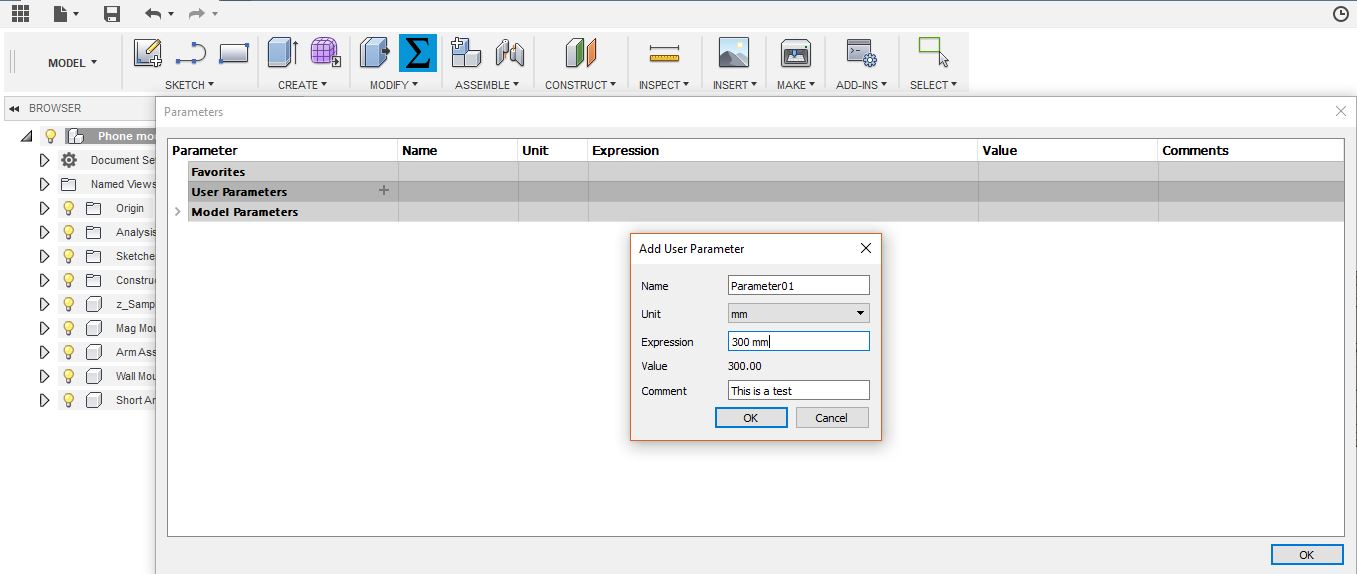

To use Parameters in my design in Fusion 360, I have to

- go to Model workspace

- then go down to Modify

- and finally Change parameters.

Then I have to add a User Parameter, give it a name, a value (you can change later), a comment. Later when I’ll put dimensions in my sketch, instead of putting a value, I’ll just put the parameter name and it will take the value you’ve pre-set.

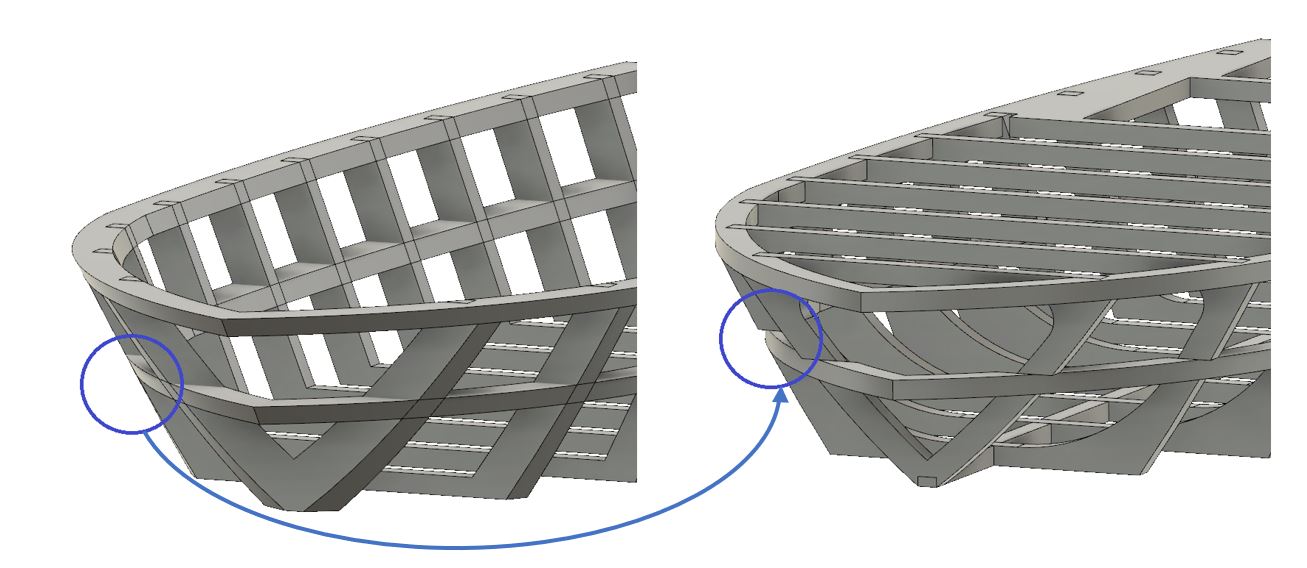

Overall, I’ve tried to use parameters and constraints as much as possible, to make this boat easy to modify if needed.

Yet I have to test the limits of each parameter and modify some sketchs if needed.

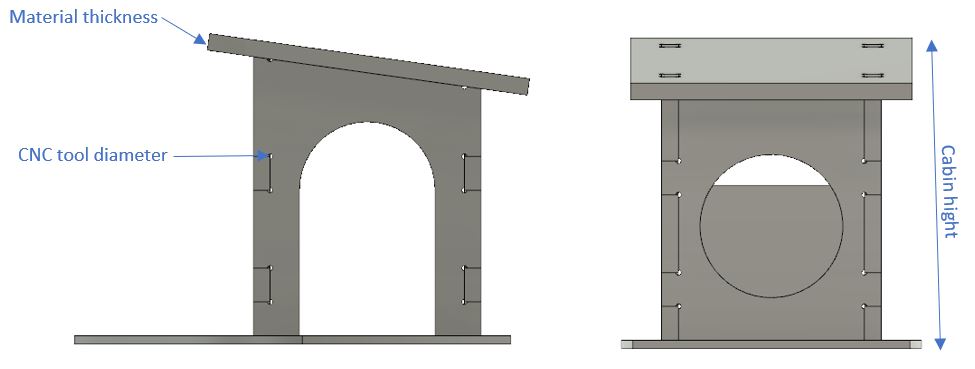

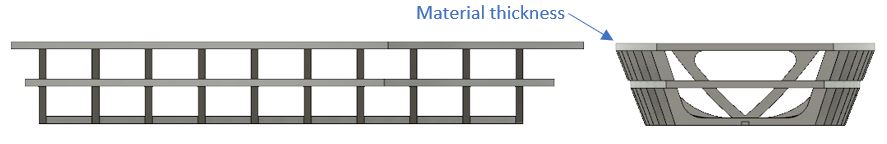

The main design¶

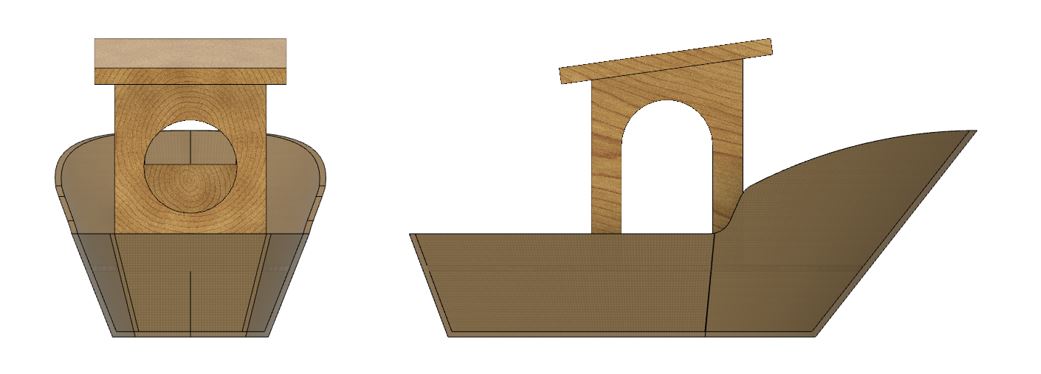

Here is a photo of the main design of my boat :

Here is a video showing the making process of the basic shape :

Here’s a 3D model of my basic design :