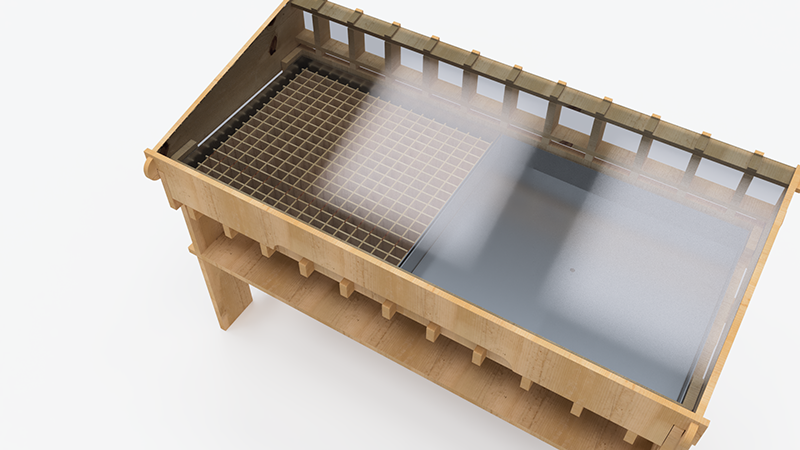

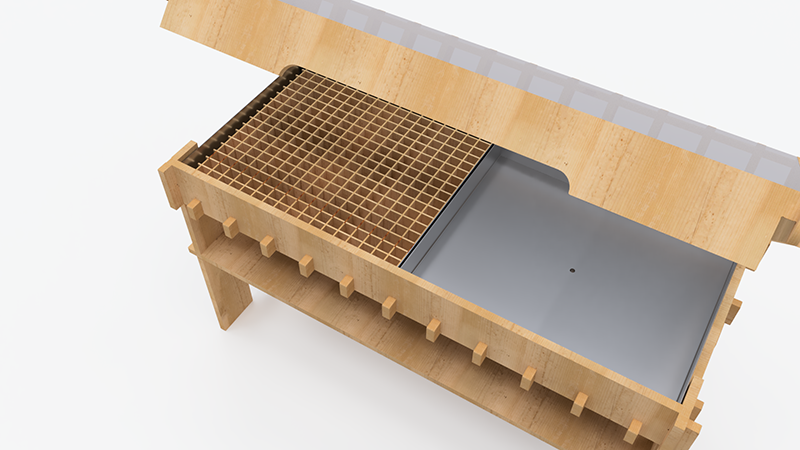

The GROUU nursery is an automated “bench greenhouse” aimed at efficiently and automatically sprouting seeds.

It takes GROUU name because it follows the same basic principles and goals as GROUU. Which is to be Modular and Open and contribute to an Open Agriculture Ecossistem

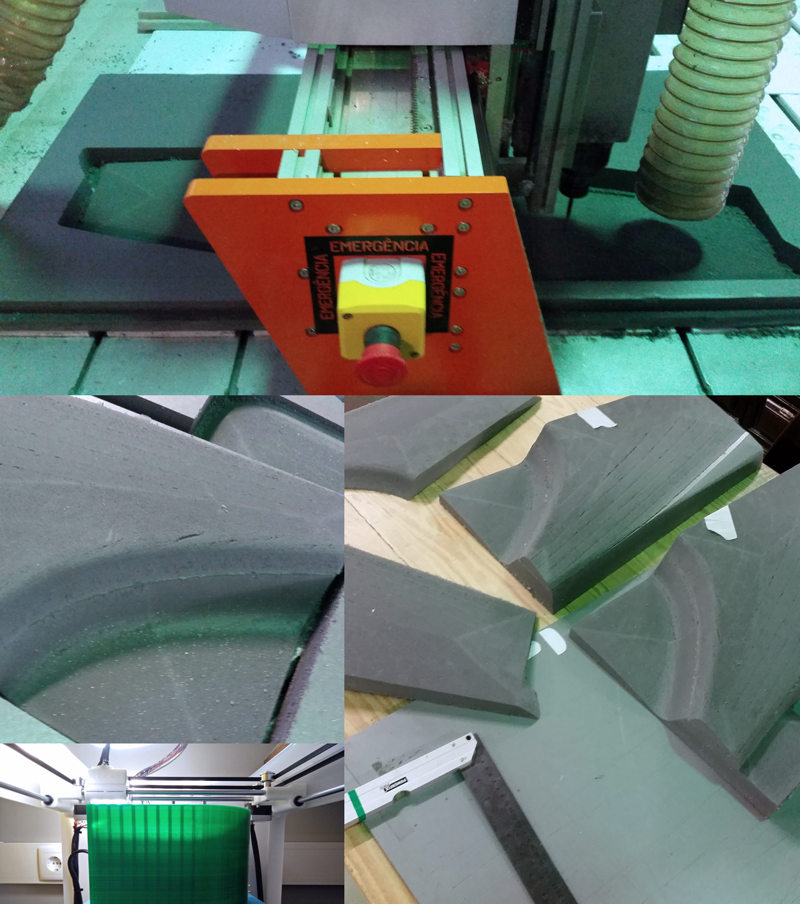

This first version was designed to be Fabricated for an workshop bettwen Ionannina and Tsoumerka, north of Greece

The CAD model (V1 - for Tsoumakers Workshop)

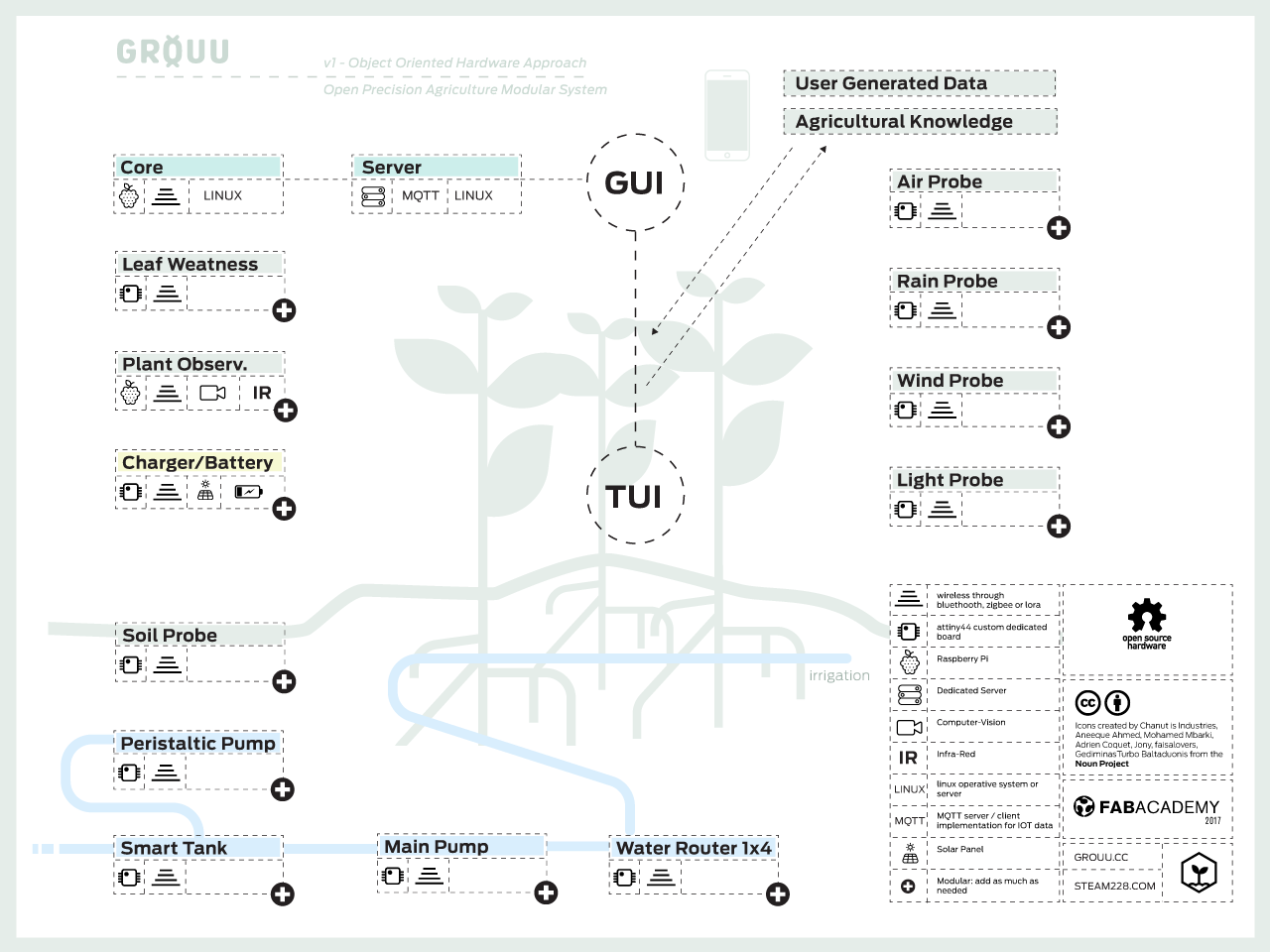

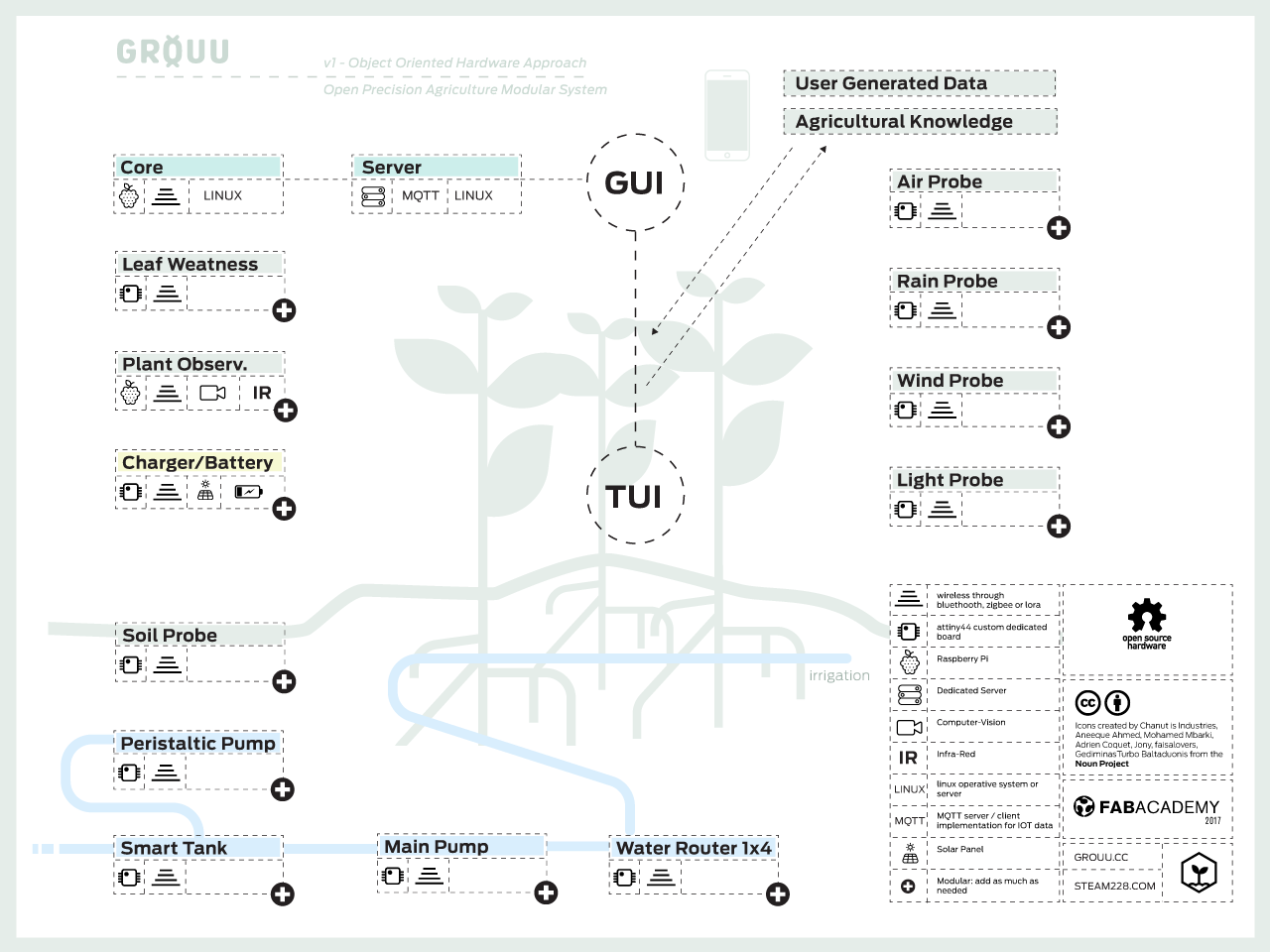

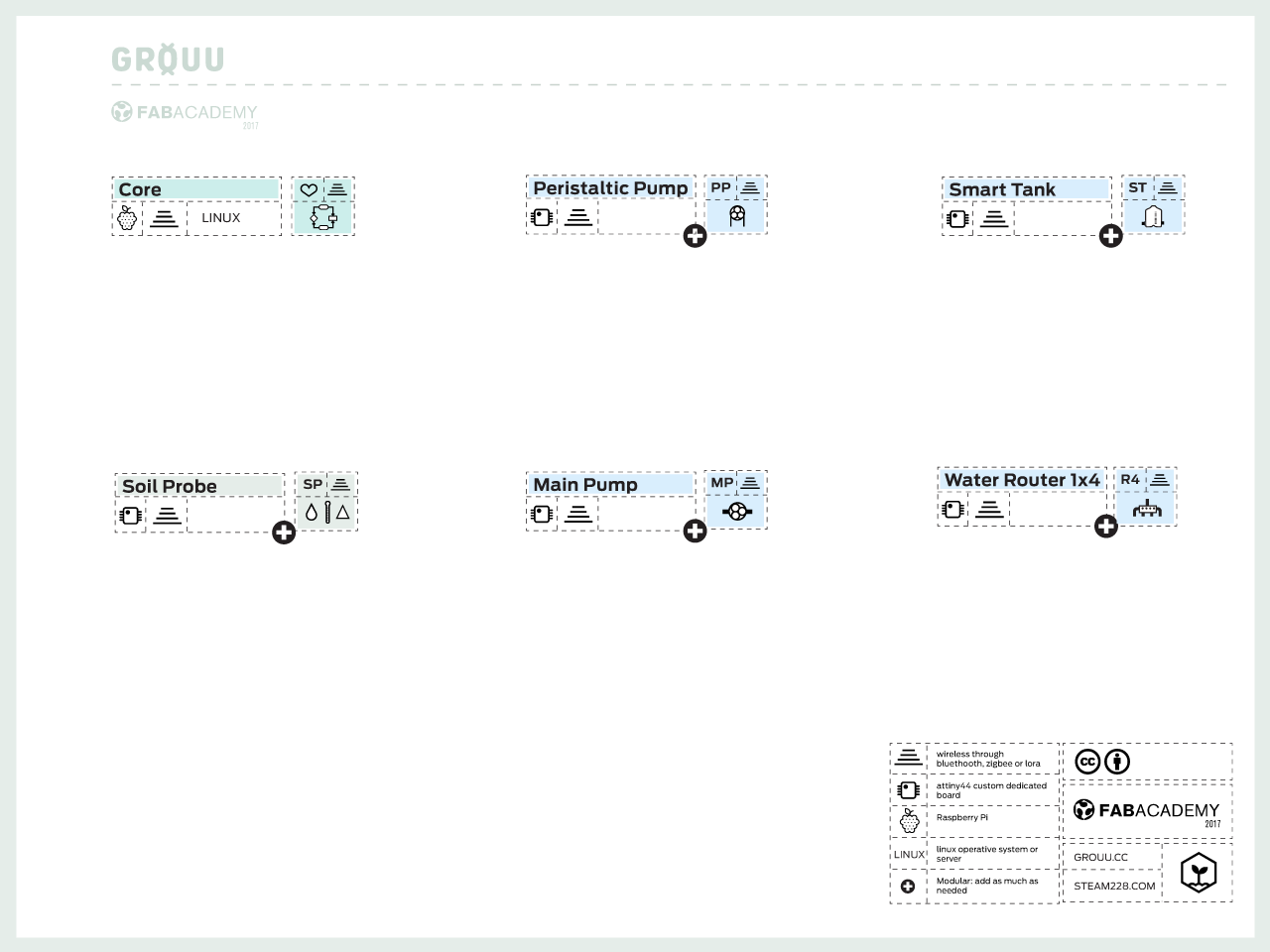

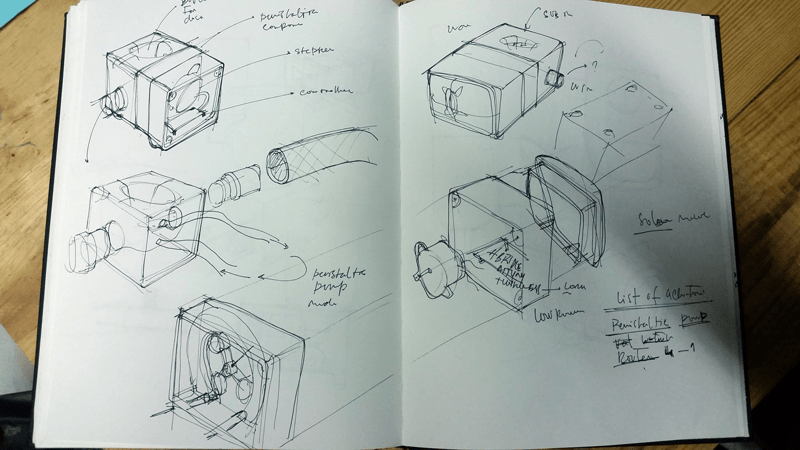

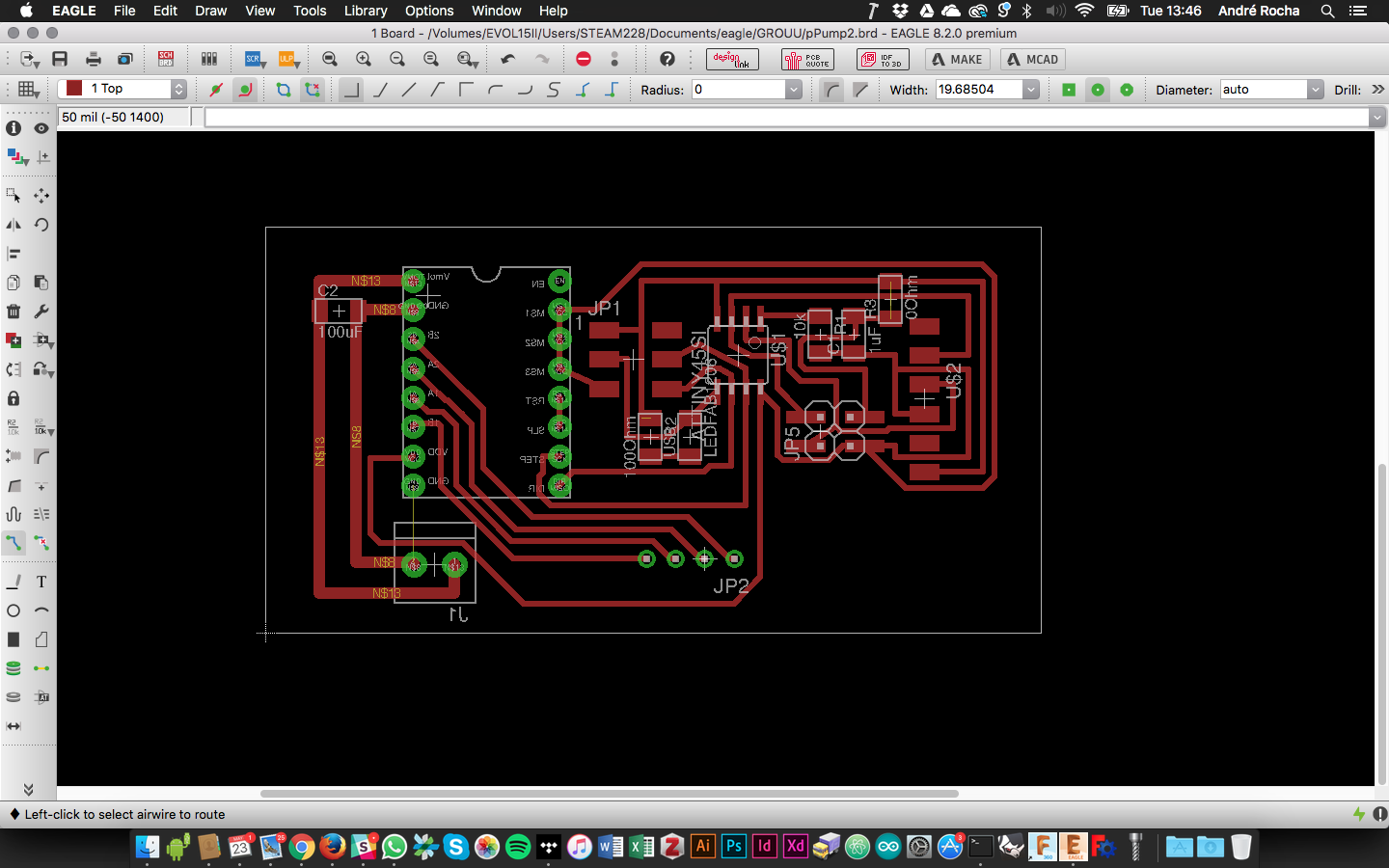

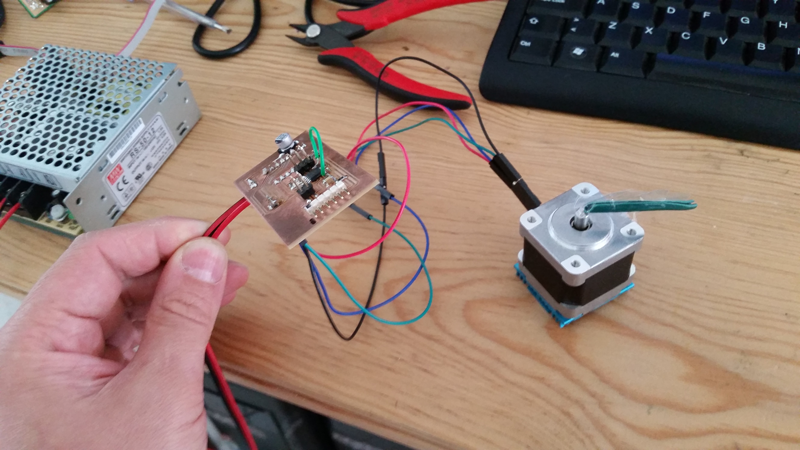

GROUU is about designing and prototyping a medium for Open Agriculture. It is a Precision Agriculture sensor network and an Irrigation and fertilization system but also a knowledge transfer platform, connecting both systems and humans. It follows a modular Object Oriented Hardware approach where “(...) software objects and hardware objects are peers that have procedures, methods, ports, and presentations. Machine building modules are available as software libraries are to programmers.” (Peek 2016).

The goal is to be able to adapt the same modules to different agricultural contexts and scales of production, by allowing configurations that go from the automation of a very simple balcony irrigation setup to installing a network of sensors and actuators throughout a large crop field. At the same time, data is processed and shared between explorations contributing for an Open Data and Knowledge ecosystem for agriculture, i.e., for a “distributed farming system based on new methods of communication, sensing, data collection, and automation that will enable network-effect advantages in the next generation of food production.” (Harper and Siller 2015)

Fab Academy presents as a great opportunity to prototype a second iteration.

GROUU started as a fully automated greenhouse, where we designed and built everything, This exploratory process allowed to gather knowledge and other resources about the applications, implications and feasibility of DiY Precision Agriculture as a part of a larger Open Agriculture Ecosystem.

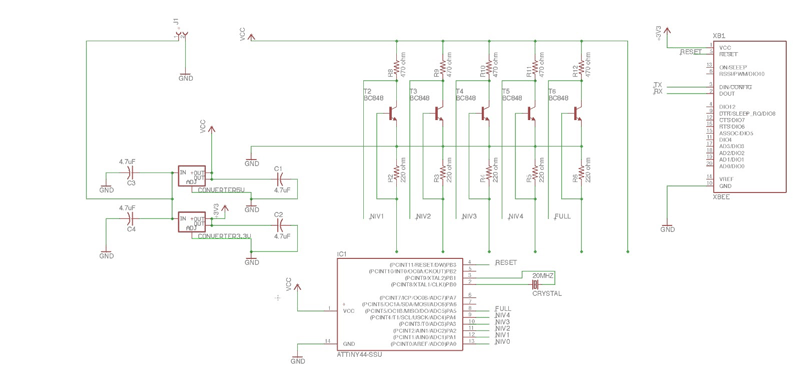

The first greenhouse wanted to act as laboratory for food production. (grouu.cc). Very similar to the the MIT food computer (Build a Personal Food Computer – MIT ...) yet not working on a closed environment and much more focused on automating traditional agriculture. It was composed by a main arduino and linux central hub to which the actuation units where connected to. The sensor modules were also arduino based and gathered data from a set of sensors (temperature and relative humidity, leaf wetness, soil moisture and soil temperature) sending it through a wired I2C connection to the main hub. The main hub published the data on a Google Sheet and kept it visually available on real time through a web dashboard.

This modules will follow an Object Oriented Hardware structure, allowing the users to install it in different contexts and agricultural scales.

This prototype implementation will be a precious tool for field studies through its implementation on different Agriculture scales and contexts.

Build a Personal Food Computer – MIT Media Lab. (n.d.). Retrieved March 28, 2018, from https://www.media.mit.edu/posts/build-a-food-computer/

Harper, C., & Siller, M. (2015). OpenAG: A Globally Distributed Network of Food Computing. IEEE Pervasive Computing / IEEE Computer Society [and] IEEE Communications Society, 14(4), 24–27.

Peek, N. (nadya M. (2016). Making machines that make : object-oriented hardware meets object-oriented software. Massachusetts Institute of Technology. Retrieved from https://dspace.mit.edu/handle/1721.1/107578?show=full